Looking for some help some, tips

Posted by djinn5150

|

Re: Looking for some help some, tips June 08, 2014 01:10AM |

Registered: 10 years ago Posts: 229 |

Cura shouldn't have anything to do with your Z offset, that's in your firmware unless the start Gcode is overriding it. Did you put something in there? I don't use Cura - "the program", but my CAD has a CuraEngine Workbench plugin that I use almost exclusively. About the only downside I have with Cura is it won't do hexagon infill.

If your having to reset your Z offset al the time, there is something mechanical wrong, like an imprecise microswitch, or some unpredictable flexing somewhere.

Mark

If your having to reset your Z offset al the time, there is something mechanical wrong, like an imprecise microswitch, or some unpredictable flexing somewhere.

Mark

|

Re: Looking for some help some, tips June 08, 2014 01:12AM |

Registered: 11 years ago Posts: 791 |

Quote

djinn5150

I tried Cura and got 1 good print out of it, I really like the simplicity of the interface but for some reason It seems I need to calibrate the z-offset almost every print, and since the 1st print with cura I cannot get it to actually lay anything down on the bed, its always just a smidge too high for some reason and nothing sticks. I'll figure it out someday. On another note I did get my little 16x2 LCD up and running today so there's thatAlways improving

What have you got in the Cura start code?

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Looking for some help some, tips June 08, 2014 10:35AM |

Registered: 9 years ago Posts: 178 |

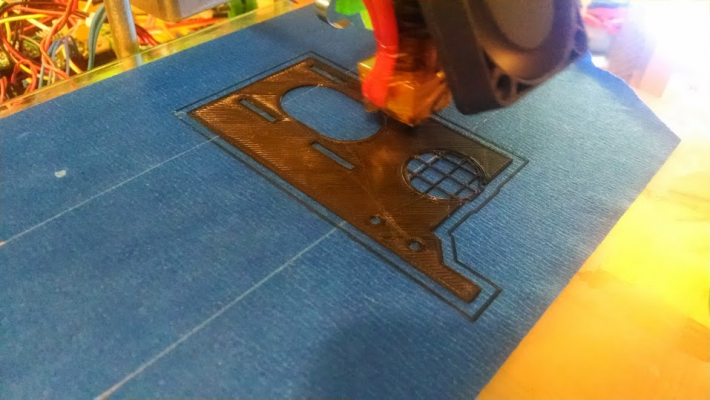

I think I found the sweet spot for the z offset, I'll give Cura another shot, I don't remember adding any offset in the Gcode but as frustrated as I was getting who knows. Maybee I'll give it another shot in the next few days. Definitely headed in the right direction though, did these last night.

|

Re: Looking for some help some, tips June 08, 2014 11:38AM |

Registered: 10 years ago Posts: 229 |

That's looking better.  Looks like the feed slowed a bit in spots, but is definitely an improvement.

Looks like the feed slowed a bit in spots, but is definitely an improvement.

Here are a couple of prints I did last night, Jack Blocks (step blocks) and Hold Downs for my CNC router. I was at the very limit for my text size on this one. Click the url just below the pic for high rez. Sliced with CuraEngine 14.3 and printed on my Smartrap using the J Head Light V2.

Mark

Ready for action

Almost able to read the small "mm" under the numbers.

Measuring the actual height of the 20 mm step.

Looks like the feed slowed a bit in spots, but is definitely an improvement.

Looks like the feed slowed a bit in spots, but is definitely an improvement. Here are a couple of prints I did last night, Jack Blocks (step blocks) and Hold Downs for my CNC router. I was at the very limit for my text size on this one. Click the url just below the pic for high rez. Sliced with CuraEngine 14.3 and printed on my Smartrap using the J Head Light V2.

Mark

Ready for action

Almost able to read the small "mm" under the numbers.

Measuring the actual height of the 20 mm step.

|

Re: Looking for some help some, tips June 08, 2014 12:41PM |

Registered: 10 years ago Posts: 814 |

Sorry, kinda off subject. Mark what kind of router are you using. I have a Shapeoko built. I mounted a pen and had it write the Shapeoko test file. Currently my "Workspace" is filled with house building Supplies and TBucket parts, so it'll be a bit before I can make cnc sawdust. I am interested in any tips though...

|

Re: Looking for some help some, tips June 08, 2014 02:05PM |

Registered: 10 years ago Posts: 229 |

I've got a sorta Shapeoko like home built DIY kind of deal. Here is a video of it's first run. I'll drop you a PM when I have the refit/upgrades done and new videos up.  In the mean time, feel free to drop me a PM with any questions you have, so we don't corrupt djinn5150 thread . I'll do my best to answer.

In the mean time, feel free to drop me a PM with any questions you have, so we don't corrupt djinn5150 thread . I'll do my best to answer.

In the mean time, feel free to drop me a PM with any questions you have, so we don't corrupt djinn5150 thread . I'll do my best to answer.

In the mean time, feel free to drop me a PM with any questions you have, so we don't corrupt djinn5150 thread . I'll do my best to answer.

|

Re: Looking for some help some, tips June 08, 2014 02:45PM |

Registered: 9 years ago Posts: 178 |

Quote

regpye

What have you got in the Cura start code?

Sorry Regpye don't know how I missed your post but here goes..

;Sliced at: {day} {date} {time}

;Basic settings: Layer height: {layer_height} Walls: {wall_thickness} Fill: {fill_density}

;Print time: {print_time}

;Filament used: {filament_amount}m {filament_weight}g

;Filament cost: {filament_cost}

;M190 S{print_bed_temperature} ;Uncomment to add your own bed temperature line

;M109 S{print_temperature} ;Uncomment to add your own temperature line

G21 ;metric values

G90 ;absolute positioning

M82 ;set extruder to absolute mode

M107 ;start with the fan off

G1 Z10.0 F[travel_speed};

G28 X0 Y0 Z0 ;move X/Y to min endstops

G29 ;autolevel bed

G92 E0 ;zero the extruded length

G1 F200 E3 ;extrude 3mm of feed stock

G92 E0 ;zero the extruded length again

G1 F{travel_speed}

;Put printing message on LCD screen

M117 Printing...

|

Re: Looking for some help some, tips June 08, 2014 02:57PM |

Registered: 9 years ago Posts: 178 |

Quote

markstephen

That's looking better.Looks like the feed slowed a bit in spots, but is definitely an improvement.

Here are a couple of prints I did last night, Jack Blocks (step blocks) and Hold Downs for my CNC router. I was at the very limit for my text size on this one. Click the url just below the pic for high rez. Sliced with CuraEngine 14.3 and printed on my Smartrap using the J Head Light V2.

Mark

Ready for action

Almost able to read the small "mm" under the numbers.

Measuring the actual height of the 20 mm step.

Those are pretty nice there!! I'll get there, adjusted down my stepper currents and its almost silent now, trying to fine tune the calibration now. Did the 5 mm cube pryamid and came short about 1 mm. My strings are almost non existent now. Small items seem to print really well but when I move up to larger stuff like the Y plate it gets all wonky. Maybe its slicer, guess I'll play with cura and see if I cant get that sorted

|

Re: Looking for some help some, tips June 11, 2014 12:35PM |

Registered: 9 years ago Posts: 178 |

I think my Ramps board or stepper drivers are going bad/gone bad something, or could be PSU. Its acting really weird now, sometimes an axis(happens on all) will not respond to command, or if it does...say I send x + 10 from pronterface x will move in + then I send again it moves in - At first I thought It was maybe firmware so I tried loading sprinter and almost same thing happens not sure where to look where to start. I also tried starting fresh with marlin and get similar results. Oddly the extruder works just fine. If I swap x y z around they all act in a similar fashion.

Anyone have any thoughts or run across a similar problem?

Thanks again

If it helps my Marlin can be found here

Anyone have any thoughts or run across a similar problem?

Thanks again

If it helps my Marlin can be found here

|

Re: Looking for some help some, tips June 11, 2014 07:07PM |

Registered: 11 years ago Posts: 791 |

Quote

djinn5150

I think my Ramps board or stepper drivers are going bad/gone bad something, or could be PSU. Its acting really weird now, sometimes an axis(happens on all) will not respond to command, or if it does...say I send x + 10 from pronterface x will move in + then I send again it moves in - At first I thought It was maybe firmware so I tried loading sprinter and almost same thing happens not sure where to look where to start. I also tried starting fresh with marlin and get similar results. Oddly the extruder works just fine. If I swap x y z around they all act in a similar fashion.

Anyone have any thoughts or run across a similar problem?

Thanks again

If it helps my Marlin can be found here

Check the wiring on your stop switches, maybe one or two have a bad connection and causing that problem. I have had that happen to me a couple of times in the past and it was simply a wire that had broken and was making and breaking while the wire was moving.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Looking for some help some, tips June 12, 2014 06:52PM |

Registered: 9 years ago Posts: 178 |

Yeah I was thinking that too but Have triple checked everything, now I have another strange behaviour, while im still having some issues with x/y randomly my Z seems to work as it should until I send a g30 command, it will go down about 1-2 mm then up then back down then stops, if I send say + 10 it will start to go up then sound like a jet engine reving up (stopped) then it will go up a bit again or it will work perfectly fine...its all random. Think I am going to walk away for a few days and come back to it with a clear mind. Right now its got me so frustrated that I am not thinking straight.

|

Re: Looking for some help some, tips June 19, 2014 05:50PM |

Registered: 9 years ago Posts: 178 |

So how much failure should a noob expect? I am getting very frustrated with this, and while my ego will not let it beat me I am getting very frustrated and doubting everything at this point.

I just don't get how I can have a beautiful print one second then try something else and it just fails miserably. I know I am having extrusion/feed issues that I can't seem to wrap my head around, my PLA(from JustPLA) seems to be pretty consistant at 1.75 +- .01. All my lines are very tight, almost to the point I felt like the ends were going to snap as I tighned things down. All the axis have a smooth movement to them. Its not as if the prints are out of shape or anything its mostly in extrusion slow downs, and at times the offset seems to be way off or the z position is. After a g29 probe it will warm up then start to print and be like .3mm above where it should be. I am thinking one of the "add-on" extruders from thingiverse or regpye's from the github files will help but I can't even get those to print of course.

Its not like I am totally inexperienced in computers, arduino's, electronics etc etc so its not like I can't comprehend this stuff. I know I cheaped out on some stuff could it be my electronics? Mostly my hotend, It is a china MK-V knockoff, precisely its this one.. Is there anything I can do improve on this thing?

I just don't know where to try and figure this out....but I feel like I am loosing my mind here.

I just don't get how I can have a beautiful print one second then try something else and it just fails miserably. I know I am having extrusion/feed issues that I can't seem to wrap my head around, my PLA(from JustPLA) seems to be pretty consistant at 1.75 +- .01. All my lines are very tight, almost to the point I felt like the ends were going to snap as I tighned things down. All the axis have a smooth movement to them. Its not as if the prints are out of shape or anything its mostly in extrusion slow downs, and at times the offset seems to be way off or the z position is. After a g29 probe it will warm up then start to print and be like .3mm above where it should be. I am thinking one of the "add-on" extruders from thingiverse or regpye's from the github files will help but I can't even get those to print of course.

Its not like I am totally inexperienced in computers, arduino's, electronics etc etc so its not like I can't comprehend this stuff. I know I cheaped out on some stuff could it be my electronics? Mostly my hotend, It is a china MK-V knockoff, precisely its this one.. Is there anything I can do improve on this thing?

I just don't know where to try and figure this out....but I feel like I am loosing my mind here.

|

Re: Looking for some help some, tips June 19, 2014 07:23PM |

Registered: 11 years ago Posts: 791 |

Quote

djinn5150

So how much failure should a noob expect? I am getting very frustrated with this, and while my ego will not let it beat me I am getting very frustrated and doubting everything at this point.

I just don't get how I can have a beautiful print one second then try something else and it just fails miserably. I know I am having extrusion/feed issues that I can't seem to wrap my head around, my PLA(from javascript:editor_tools_handle_help()JustPLA) seems to be pretty consistant at 1.75 +- .01. All my lines are very tight, almost to the point I felt like the ends were going to snap as I tighned things down. All the axis have a smooth movement to them. Its not as if the prints are out of shape or anything its mostly in extrusion slow downs, and at times the offset seems to be way off or the z position is. After a g29 probe it will warm up then start to print and be like .3mm above where it should be. I am thinking one of the "add-on" extruders from thingiverse or regpye's from the github files will help but I can't even get those to print of course.

Its not like I am totally inexperienced in computers, arduino's, electronics etc etc so its not like I can't comprehend this stuff. I know I cheaped out on some stuff could it be my electronics? Mostly my hotend, It is a china MK-V knockoff, precisely its this one.. Is there anything I can do improve on this thing?

I just don't know where to try and figure this out....but I feel like I am loosing my mind here.

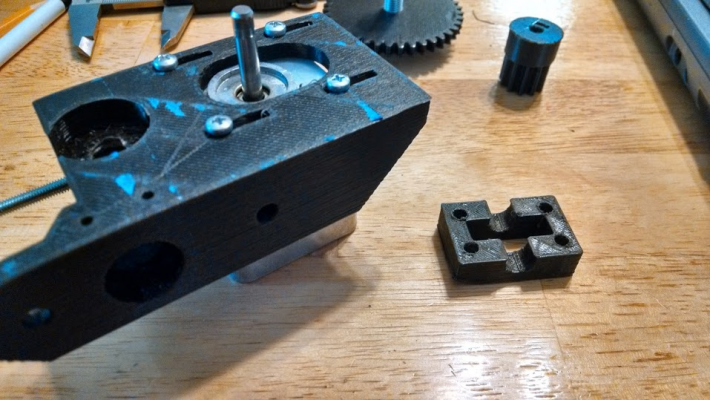

If you are able to get hold of a geared extruder (almost any one) you can convert it to be a Bowden quite easily.

See the photo of a Wades type I just happened to have on hand that I did a quick conversion so that I didn't need to use the direct drive extruder any more.

I later designed a geared extruder especially for the SmartRap as you may have already seen in my later builds.

I just added a metal plate to the extruder and screwed a pneumatic fitting in this case to the plate. The plate just bolts onto the extruder on the mounting holes.

The plate doesn't need to be metal, it could be plastic like acrylic. The foot was printed, but you can improvise with anything that will hold the extruder on a flat surface, an easy way would be to use the same plate and have it fold at 90 degrees so that it forms the foot and also the adapter plate.

If you don't have a pneumatic fitting, you can easily use a couple of nuts, one on either side of the plate and screw the nuts onto the PTFE tube. The nuts will make the tube fixed to the plate so you wont be able to do a quick release as the pneumatic fitting allows, but I never used that feature anyway. Nuts might be the better way, certainly cheaper anyway.

Edited 1 time(s). Last edit at 06/19/2014 07:29PM by regpye.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Looking for some help some, tips June 21, 2014 08:06PM |

Registered: 9 years ago Posts: 178 |

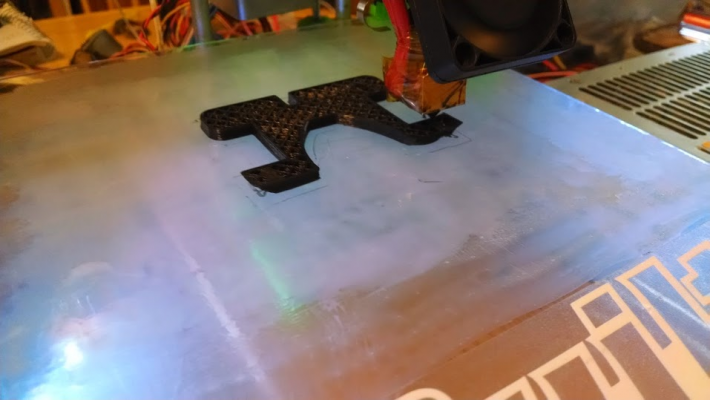

Well looks like I got most of my issues settled out, at least for now. I have had several successful prints at this point and will be changing to a Wades extruder not to far into the future. But for now it seems to be working quite well. Once I get a few brackets printed I will get my "build" finalized and start a new thread with some photos.

|

Re: Looking for some help some, tips June 21, 2014 08:12PM |

Registered: 11 years ago Posts: 791 |

Quote

djinn5150

Well looks like I got most of my issues settled out, at least for now. I have had several successful prints at this point and will be changing to a Wades extruder not to far into the future. But for now it seems to be working quite well. Once I get a few brackets printed I will get my "build" finalized and start a new thread with some photos.

Looking good now.

Pays to stay with it for a while, the problems are very good, it makes you learn something.

If you had just bought it ready to print out of the box you would not appreciate the machine as much.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Looking for some help some, tips June 21, 2014 08:27PM |

Registered: 9 years ago Posts: 178 |

Isn't that the truth, and honestly I think most of my problems were in my inexperience in setting up slicer and impatience, at least for my build 30mm/s is just to fast for decent prints, running at 20 and things are going well. I would love to pull a bit more speed out of if but I am not going to look a printed gift horse in the mouthQuote

regpye

Looking good now.

Pays to stay with it for a while, the problems are very good, it makes you learn something.

If you had just bought it ready to print out of the box you would not appreciate the machine as much.

|

Re: Looking for some help some, tips June 21, 2014 08:33PM |

Registered: 11 years ago Posts: 791 |

Quote

djinn5150

Isn't that the truth, and honestly I think most of my problems were in my inexperience in setting up slicer and impatience, at least for my build 30mm/s is just to fast for decent prints, running at 20 and things are going well. I would love to pull a bit more speed out of if but I am not going to look a printed gift horse in the mouthQuote

regpye

Looking good now.

Pays to stay with it for a while, the problems are very good, it makes you learn something.

If you had just bought it ready to print out of the box you would not appreciate the machine as much.

You will get there. I am printing at higher speeds with mine.

When I get this next printer finished we will see how fast I can push it, and make a video.

Need to have good flow of plastic for speed, so a good extruder is a must and so is a good hotend.

BTW: I have updated my website with the extruder files. Some changes and all files are now split from each other where needed.

Some extra parts such as mounting brackets and a new Guidler to replace the last one I had.

Photos of each part added to make it easier to see what you are downloading.

Enjoy!

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Looking for some help some, tips June 21, 2014 08:49PM |

Registered: 9 years ago Posts: 178 |

Awesome I will for sure have a look, maybe I'll just go that way instead of the this Wades I printed out, can't hurt to have extra parts laying around. I do like your's and its "add-on" style to the Smartrap, maybe I'll give it a go now things are running so smooth. Any tips on learning CAD on the side. I never have had any experience in it at all. I have been able to make a few things in sketch up but, trying to do some things in it is just leaving me lost. I am trying to make a set of mounting rings for a guidescope for my father and his telescope and just keep falling short with adding holes for the adjustment screws in the rings. Essentially trying to model something like this from scratch.

|

Re: Looking for some help some, tips June 21, 2014 09:37PM |

Registered: 11 years ago Posts: 791 |

Quote

djinn5150

Awesome I will for sure have a look, maybe I'll just go that way instead of the this Wades I printed out, can't hurt to have extra parts laying around. I do like your's and its "add-on" style to the Smartrap, maybe I'll give it a go now things are running so smooth. Any tips on learning CAD on the side. I never have had any experience in it at all. I have been able to make a few things in sketch up but, trying to do some things in it is just leaving me lost. I am trying to make a set of mounting rings for a guidescope for my father and his telescope and just keep falling short with adding holes for the adjustment screws in the rings. Essentially trying to model something like this from scratch.

If you send me the exact measurements of the object, I can design it for you and send you the STL files.

I use Alibre Design for my designing, I believe it has now changed it's name to GeoMagic.

It is not free software, but also not that expensive either, but it certainly is very good and easy to use.

I taught myself how to use it by just playing with it for a few days, but there are many videos online that show you how to do everything and with a bit of thinking you can work out how to do many things not listed.

Anyway, I just went and found the webpage for you that has the new info about it, my version is a few years old now, but I don't want to upgrade because it does all I want and I have learnt this version so much now.

GeoMagic

If you want some videos to learn how to use it, here are a few to start with.

Edited 1 time(s). Last edit at 06/21/2014 10:44PM by regpye.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

Sorry, only registered users may post in this forum.