Djinn5150's SmartRap Core Build

Posted by djinn5150

|

Re: Djinn5150's SmartRap Core Build March 18, 2015 08:00PM |

Registered: 9 years ago Posts: 178 |

Well its printing, its messy, and way out of calibration. For some reason movements are nice and clean but slows way down when printing. I am thinking it is a artifact of 1/32 mcirostepping and the arduino. Can't seem to find much info on setting the Microstepping to 1/16 with theese drivers, some info says pull 2 jumpers which I tried stepping was way off. So if anyone has some insight to that I would love to hear it. I did manage to get the relay board wired up and configured to auto turn on the hotend fans when temp reaches 50c Believe I have also figured how to incorporate the Part cooling fan onto that board but I will only have on/off settings. I might just find a FET or two to fix that

That E3D knockoff has not impressed me yet but like I said...calibration. Still waiting on second hotend from china but the dual bracket seems to be doing well. I will need to make an additional bracket to go on the back of the "head" parts. Once belts are tightened it puts pressure on those peice and tweaks them a bit, a bracket on the back should solve that.

That E3D knockoff has not impressed me yet but like I said...calibration. Still waiting on second hotend from china but the dual bracket seems to be doing well. I will need to make an additional bracket to go on the back of the "head" parts. Once belts are tightened it puts pressure on those peice and tweaks them a bit, a bracket on the back should solve that.|

Re: Djinn5150's SmartRap Core Build March 18, 2015 08:14PM |

Registered: 10 years ago Posts: 814 |

|

Re: Djinn5150's SmartRap Core Build March 19, 2015 07:03PM |

Registered: 9 years ago Posts: 178 |

|

Re: Djinn5150's SmartRap Core Build March 20, 2015 10:21AM |

Registered: 10 years ago Posts: 814 |

|

Re: Djinn5150's SmartRap Core Build March 20, 2015 11:26AM |

Registered: 9 years ago Posts: 178 |

Actually compared to my last printer...a walk in the park.

Key points to watch for....

Now if I can get my calibration down I will be happy camper, it feels like temps are too high. This all metal might be throwing me for a loop....or I have the thermistor table off, but my bed and old hot end are reporting same temps at room temp so don't think so. Unless the tables get off at temp. But was printing a part last night and had to drop temp down to 173 to smooth things out a bit. But movement is pretty much spot on, I might ditch the PLA bushings on the X carriage there is just so much drag, we will see how things go in time they still need to break in.

Key points to watch for....

- Space Y rods evenly to each other not the box

- Make Sure Motor shafts/pulley combos are long enough to keep belts aligned

- If you can use something to decouple motors from the box itself, like some cork gasket material between the two( vibrations get quite loud)

- If you use a front crossmember on the box like I did...make it removable or better yet...acrylic Its rather annoying and in the way for wiring/viewing whats going on with initial layers of the print(won't really apply to your laser build Mike but for others)

- During belt installation start with the front side, insert belts right to end of clamp, no farther, install head mount, move around to back for tension too much will tweak on the bearing clamps.

Now if I can get my calibration down I will be happy camper, it feels like temps are too high. This all metal might be throwing me for a loop....or I have the thermistor table off, but my bed and old hot end are reporting same temps at room temp so don't think so. Unless the tables get off at temp. But was printing a part last night and had to drop temp down to 173 to smooth things out a bit. But movement is pretty much spot on, I might ditch the PLA bushings on the X carriage there is just so much drag, we will see how things go in time they still need to break in.

|

Re: Djinn5150's SmartRap Core Build March 20, 2015 11:59AM |

Registered: 10 years ago Posts: 814 |

|

Re: Djinn5150's SmartRap Core Build March 20, 2015 12:11PM |

Registered: 9 years ago Posts: 178 |

|

Re: Djinn5150's SmartRap Core Build March 20, 2015 12:45PM |

Registered: 10 years ago Posts: 814 |

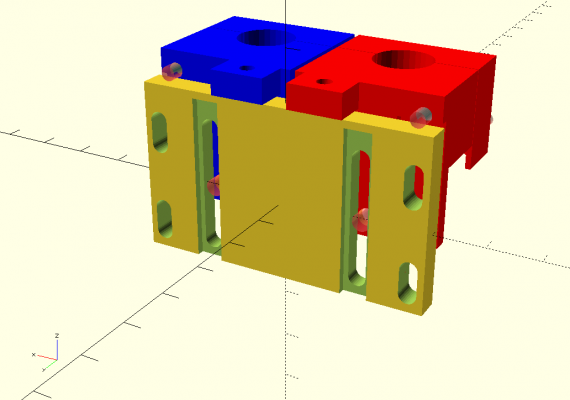

Not sure if I'm going to explain myself properly but....

Maybe redesign the X blocks to have a M4 screw placed through them in the X axis direction. Add a block to the back of the hotend mount for the M4 screws to screw in from the X blocks. Slot the Hotend mounting holes to the X blocks.

You would loosen the Hotend mount to X blocks screws, and then use the M4 screws to pull the blocks towards each other to tension the belts, and provide support. then retighten the hotend mount.

That make sense?

Maybe redesign the X blocks to have a M4 screw placed through them in the X axis direction. Add a block to the back of the hotend mount for the M4 screws to screw in from the X blocks. Slot the Hotend mounting holes to the X blocks.

You would loosen the Hotend mount to X blocks screws, and then use the M4 screws to pull the blocks towards each other to tension the belts, and provide support. then retighten the hotend mount.

That make sense?

|

Re: Djinn5150's SmartRap Core Build March 20, 2015 01:37PM |

Registered: 9 years ago Posts: 178 |

|

Re: Djinn5150's SmartRap Core Build March 23, 2015 02:13PM |

Registered: 9 years ago Posts: 178 |

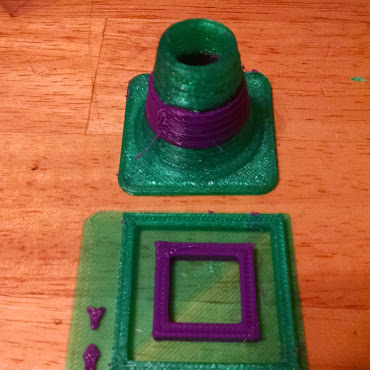

Calibration coming along, Yoda printed at 150micron layer.

|

Re: Djinn5150's SmartRap Core Build April 02, 2015 12:00PM |

Registered: 9 years ago Posts: 3 |

Looks awesome,

I am planning a SmartRap Core build using a milk crate. I am quite a noob and I have a question or two for you or anyone else here that would like to school me.

I would like to edit the parts needed from the youmagine file, I plan on using 8MM rods for all axis (local hardware store only has 8MM rod).

The Internal dimensions of the milk crate I plan on using: Width / Length (X&Y) 12 inches (304.8 mm), Height (Z) 10.5 inches (266.7 mm), Wall thickness 1cm (10 mm).

Question:

The OpenJSCAD parameters: build width, build height, build depth I assume (note assume) are the dimensions I gave above.. correct?

Once the parameters are good, I am gong to get the parts printed off today (my local library offers 3d printing service) and then start building.

Thank you

I am planning a SmartRap Core build using a milk crate. I am quite a noob and I have a question or two for you or anyone else here that would like to school me.

I would like to edit the parts needed from the youmagine file, I plan on using 8MM rods for all axis (local hardware store only has 8MM rod).

The Internal dimensions of the milk crate I plan on using: Width / Length (X&Y) 12 inches (304.8 mm), Height (Z) 10.5 inches (266.7 mm), Wall thickness 1cm (10 mm).

Question:

The OpenJSCAD parameters: build width, build height, build depth I assume (note assume) are the dimensions I gave above.. correct?

Once the parameters are good, I am gong to get the parts printed off today (my local library offers 3d printing service) and then start building.

Thank you

|

Re: Djinn5150's SmartRap Core Build April 02, 2015 12:23PM |

Registered: 10 years ago Posts: 814 |

Set the rod diameters to 8mm and wall thickness to 10mm, and print.

Once you fit the rod holders for the Y axis. Measure and cut your rods. Then install your X axis parts on the Y rods and measure and cut for your X axis rods.

Same for Z.

The jscad dimensions are the build area. not the box, but you can adjust the build area to get the box dimensions you need if you want. If you do that it will tell you what the rod length is for each axis and belt length.

Once you fit the rod holders for the Y axis. Measure and cut your rods. Then install your X axis parts on the Y rods and measure and cut for your X axis rods.

Same for Z.

The jscad dimensions are the build area. not the box, but you can adjust the build area to get the box dimensions you need if you want. If you do that it will tell you what the rod length is for each axis and belt length.

|

Re: Djinn5150's SmartRap Core Build April 02, 2015 12:29PM |

Registered: 9 years ago Posts: 3 |

|

Re: Djinn5150's SmartRap Core Build April 02, 2015 01:09PM |

Registered: 9 years ago Posts: 178 |

The other option you have is play with the build volume in the "wall and rod size" section to get an idea of the "over Build" size, I know we discussed it earlier in this thread but I am thinking x is like 55 over and y is 30, I might have that wrong but I think you get the idea. The threaded Z is broken on youmagine I have uploaded a heavy duty z to youmagine that I am using now, works pretty well. Added some nutcatches to the support beams to allow you to tighten build platform very well without fear of stripping out plastic. Love the idea of the milk crate, keep us posted.

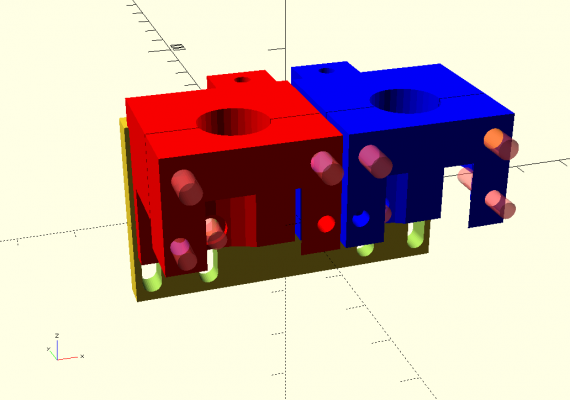

Since I am here i might as well drop a quick update....

My dual head design when to trash when I recieved the second hotend, total derp moment in ordering from 2 different suppliers, Now I have 2 all metal hotends that are about 7mm difference in height. So to the openscad drawing board I have gone, currently printing an independently height adjustable mount. I'll update more once I get further testing completed.

I also have developed a skew in printing square objects, Belts are "musically" tight so I don't think its belts, something must have gotten out of square somewhere.

Since I am here i might as well drop a quick update....

My dual head design when to trash when I recieved the second hotend, total derp moment in ordering from 2 different suppliers, Now I have 2 all metal hotends that are about 7mm difference in height. So to the openscad drawing board I have gone, currently printing an independently height adjustable mount. I'll update more once I get further testing completed.

I also have developed a skew in printing square objects, Belts are "musically" tight so I don't think its belts, something must have gotten out of square somewhere.

|

Re: Djinn5150's SmartRap Core Build April 02, 2015 02:18PM |

Registered: 9 years ago Posts: 3 |

Thank you very much djunn5150! grabbed the heavy duty z.

Once I begin my Milk crate build I will start a new thread and hopefully post my build progress from concept to working device.

For sh!ts and giggles I am going to build 2 milk crate printers the same time, 1 using gt2 belts / pulleys the other utilizing fishing-line. See if I can get both working.

As for electronics I have bottom of the barrel crap that I acquired a year a go for a song and dance (v1 geeetech melzi kit). It will be decent enough to get things moving any how. I have pretty mush everything besides an extruder ... I am in progress of ordering one.

Any way, thanks again! I hope to see more of your build(s)

Thank you

Gilbot

Once I begin my Milk crate build I will start a new thread and hopefully post my build progress from concept to working device.

For sh!ts and giggles I am going to build 2 milk crate printers the same time, 1 using gt2 belts / pulleys the other utilizing fishing-line. See if I can get both working.

As for electronics I have bottom of the barrel crap that I acquired a year a go for a song and dance (v1 geeetech melzi kit). It will be decent enough to get things moving any how. I have pretty mush everything besides an extruder ... I am in progress of ordering one.

Any way, thanks again! I hope to see more of your build(s)

Thank you

Gilbot

|

Re: Djinn5150's SmartRap Core Build April 02, 2015 04:02PM |

Registered: 9 years ago Posts: 1 |

|

Re: Djinn5150's SmartRap Core Build April 02, 2015 07:24PM |

Registered: 10 years ago Posts: 814 |

|

Re: Djinn5150's SmartRap Core Build April 02, 2015 07:28PM |

Registered: 10 years ago Posts: 814 |

|

Re: Djinn5150's SmartRap Core Build April 02, 2015 07:40PM |

Registered: 11 years ago Posts: 791 |

Should be able to use the Genie MK1 hotends with this setup too.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Djinn5150's SmartRap Core Build April 02, 2015 07:47PM |

Registered: 9 years ago Posts: 178 |

Or I could just try this

|

Re: Djinn5150's SmartRap Core Build April 02, 2015 07:53PM |

Registered: 11 years ago Posts: 791 |

That's a pretty good idea for adjusting the height on each hotend, I like that.

[regpye.com.au]

"Experience is the mother of all knowledge." --Leonardo da Vinci

|

Re: Djinn5150's SmartRap Core Build April 02, 2015 08:41PM |

Registered: 9 years ago Posts: 178 |

Quote

regpye

That's a pretty good idea for adjusting the height on each hotend, I like that.

Thanks Regpye, been tossing around ideas in my head for a week on this, finally settled on this one, once I have it fully assembled i will post some pics, but seems pretty solid. Can't really tell in the images but there is a recess in the top of the bracket for adjustment screw to rest in to help keep things lined up and from wanting to lean forward.

Couple things I might change before "final" instead of having the slot go so far down I will shorten it and open up at the top for easy removal. I am also considering moving hotend fans to the side like the second link from MadMike8's post so I can include part cooling fans off the bottom front.

|

Re: Djinn5150's SmartRap Core Build April 04, 2015 11:26PM |

Registered: 9 years ago Posts: 178 |

So close.... So far..... Never again will I buy an all metal knock off, not even 3hrs on it and I've cleared more heat creep swollen pla jams then I ever had to with my cheap China j-head....ugg

|

Re: Djinn5150's SmartRap Core Build April 04, 2015 11:59PM |

Registered: 10 years ago Posts: 814 |

|

Re: Djinn5150's SmartRap Core Build April 05, 2015 12:16AM |

Registered: 9 years ago Posts: 178 |

the j-head does the new all metals do not, the are bored at about 2mm. I was thinking bout trying to bore them out to 4mm to allow the bowden to go down to the heatbreak. Funny thing is its the smaller of the 2 that is giving me the most problems, the larger(first one I got) has been working pretty well, only had a couple jams with it and they were only when I was trying to change out filament and slow retract. Of course its pla, might try some abs in them too see how that goes until I can get my chimera.

|

Re: Djinn5150's SmartRap Core Build April 05, 2015 12:19AM |

Registered: 9 years ago Posts: 178 |

|

Re: Djinn5150's SmartRap Core Build April 06, 2015 09:57AM |

Registered: 9 years ago Posts: 180 |

I got a cheap $10.00 all metal hot end, containing an an inner PTFE tube, from AliExpress. I made some minor changes to it following Bruno M.'s video on YouTube and it has worked beautifully so far. Here are the details if you are interested:

[smartrapbuild.files.wordpress.com]

[smartrapbuild.files.wordpress.com]

|

Re: Djinn5150's SmartRap Core Build April 06, 2015 10:11AM |

Registered: 9 years ago Posts: 180 |

I am thinking of converting my SmartRap into the CoreXY.

I see that there is a belt being utilized for the Z axis. Has this been reliable so far or would a threaded rod be better?

How is the printed bed being held down to the part on the Z axis that moves up and down? Are there any reinforcements, such as protruding rods that support the weight? I suspect that the front of the printed bed would need some type of support otherwise it would sag downward in the front due to the weight?

Thanks,

Jose

I see that there is a belt being utilized for the Z axis. Has this been reliable so far or would a threaded rod be better?

How is the printed bed being held down to the part on the Z axis that moves up and down? Are there any reinforcements, such as protruding rods that support the weight? I suspect that the front of the printed bed would need some type of support otherwise it would sag downward in the front due to the weight?

Thanks,

Jose

|

Re: Djinn5150's SmartRap Core Build April 06, 2015 11:08AM |

Registered: 10 years ago Posts: 814 |

|

Re: Djinn5150's SmartRap Core Build April 06, 2015 11:15AM |

Registered: 9 years ago Posts: 180 |

Sorry, only registered users may post in this forum.