CoreXY vs Quadrap mechanism

Posted by the_digital_dentist

|

CoreXY vs Quadrap mechanism November 26, 2015 06:35PM |

Registered: 11 years ago Posts: 5,780 |

Any insights on CoreXY vs Quadrap mechanisms for precision? Any gotchas I should know about with either?

I'm starting to think about building another printer and I like the CoreXY mechanism, but I think I want to go tall- 300mm square bed and 1m tall print capability. I have done some searches but have been unable to find anything on a tall CoreXY machines. Has anyone seen/done that sort of thing?

Edited 1 time(s). Last edit at 11/26/2015 06:44PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I'm starting to think about building another printer and I like the CoreXY mechanism, but I think I want to go tall- 300mm square bed and 1m tall print capability. I have done some searches but have been unable to find anything on a tall CoreXY machines. Has anyone seen/done that sort of thing?

Edited 1 time(s). Last edit at 11/26/2015 06:44PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CoreXY vs Quadrap mechanism November 26, 2015 07:04PM |

Registered: 10 years ago Posts: 179 |

Thats good news. I am looking forward to fallowing your new build.

Can you give a link to good information of what quadrap actually is?

It seems that corexy and quadrap only defines the motion of X and Y axis. Z axis motion solution is actually not defined by names such as corexy and quadrap and can be easily mixed on both of the mentioned designs. Or am I wrong?

This thread might be of your interest: [forums.reprap.org]

Can you give a link to good information of what quadrap actually is?

It seems that corexy and quadrap only defines the motion of X and Y axis. Z axis motion solution is actually not defined by names such as corexy and quadrap and can be easily mixed on both of the mentioned designs. Or am I wrong?

This thread might be of your interest: [forums.reprap.org]

|

Re: CoreXY vs Quadrap mechanism November 26, 2015 07:24PM |

Registered: 9 years ago Posts: 346 |

|

Re: CoreXY vs Quadrap mechanism November 26, 2015 08:35PM |

Registered: 11 years ago Posts: 5,780 |

I considered a delta, but they have to be quite a bit taller than the print capacity, and I'm not sure I trust the cartesian to spherical conversion to produce prints that are free of artifacts. They are pretty simple mechanically, aside from the specialized hardware for the effector rods. I'm not a huge fan of Bowden tube extruders. I haven't entirely ruled out a delta, so we'll see.

Here's a video of someone's quadrap running at 320 mm/sec. [www.youtube.com]

Print quality looks like what you'd expect at that speed, but I find the use of fishing line instead of belts interesting. As usual, I'm more interested in producing quality prints and don't care so much about speed. Here's another:

[www.youtube.com]

Here's a drawing showing a belt driven Quadrap mechanism: [www.3dcontentcentral.com]

The crossed members at the extruder carriage allow low moving masses because none of the motors (X,Y or E) are moving with the extruder carriage. It's actually pretty simple mechanically and the belts seem like they might be shorter than those in a coreXY. I don't know if I would use 2 X and 2 Y motors or use single motors with shafts running across the frame. I'm not a fan of dual motor set-ups. I would use linear guides for the main X and Y bearings, and as usual, minimize 3D printed part content in favor of metal parts.

I have an XY mechanism from a stratasys machine sitting unused right now, but I think that will end up in a chocolate printer eventually. That machine will have to print slow and the stratasys mechanism is very massive, so it's well suited to slow printing.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Here's a video of someone's quadrap running at 320 mm/sec. [www.youtube.com]

Print quality looks like what you'd expect at that speed, but I find the use of fishing line instead of belts interesting. As usual, I'm more interested in producing quality prints and don't care so much about speed. Here's another:

[www.youtube.com]

Here's a drawing showing a belt driven Quadrap mechanism: [www.3dcontentcentral.com]

The crossed members at the extruder carriage allow low moving masses because none of the motors (X,Y or E) are moving with the extruder carriage. It's actually pretty simple mechanically and the belts seem like they might be shorter than those in a coreXY. I don't know if I would use 2 X and 2 Y motors or use single motors with shafts running across the frame. I'm not a fan of dual motor set-ups. I would use linear guides for the main X and Y bearings, and as usual, minimize 3D printed part content in favor of metal parts.

I have an XY mechanism from a stratasys machine sitting unused right now, but I think that will end up in a chocolate printer eventually. That machine will have to print slow and the stratasys mechanism is very massive, so it's well suited to slow printing.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CoreXY vs Quadrap mechanism November 26, 2015 09:23PM |

Registered: 9 years ago Posts: 83 |

Quote

LarsK

Hey,

How come you are not looking at a Delta? It seems to me that it is the perfect solution for the geometry you want (300x300 x1000)

Delta's scale poorly, even more so when you're talking 1m Z axis-- My delta is 720mm tall, and has a build height of 280mm.

dc42's delta is 300mm diameter, 480-540mm print height, and is 1m tall. Best case, you're looking at 1.5-2.0 meter tall printer, and you're going to have to make the frame out of 2060 or something similar to get it to work. Even then, the bowden length would be pretty crazy (800-1000mm?).

Ordinarily, I'd suggest something like the triple C-bot-- 300x300 is pretty easy for the C-Bot design, but for that kind of Z height, you'd need leadscrews over 1m in length.

There's a pretty lengthy discussion on the original C-Bot at openbuilds, as well as a shorter, but still useful, discussion on the triple C-Bot (C-Bot with three leadscrew z-platform).

|

Re: CoreXY vs Quadrap mechanism November 26, 2015 11:43PM |

Registered: 10 years ago Posts: 15 |

You can try this concept.

[3dprintingindustry.com]

What you need to do is just building a XY drawing platform which can draw 300mm X 300mm and make the whole platform which can lift up and down. Both CoreXY or Quadrap system can achieve this purpose too.

Edited 1 time(s). Last edit at 11/26/2015 11:46PM by bunbun.

[3dprintingindustry.com]

What you need to do is just building a XY drawing platform which can draw 300mm X 300mm and make the whole platform which can lift up and down. Both CoreXY or Quadrap system can achieve this purpose too.

Edited 1 time(s). Last edit at 11/26/2015 11:46PM by bunbun.

|

Re: CoreXY vs Quadrap mechanism November 27, 2015 06:11AM |

Registered: 9 years ago Posts: 346 |

Quote

grat

Delta's scale poorly, even more so when you're talking 1m Z axis-- My delta is 720mm tall, and has a build height of 280mm.

dc42's delta is 300mm diameter, 480-540mm print height, and is 1m tall. Best case, you're looking at 1.5-2.0 meter tall printer, and you're going to have to make the frame out of 2060 or something similar to get it to work. Even then, the bowden length would be pretty crazy (800-1000mm?).

This is not correct. If DC42's does 500mm at 1m tall then to do another 500mm he just makes it 1.5m tall. In height it scales 1:1. You are thinking about the bed diameter which scales different. You are correct that normal bowden would not be optimal but there are many work arounds for this. See this also

I wanted to mention that there is / was a printer on kickstarter not so long ago that came at least close to the specs (470x435x690) - This one maybe it can serve as an inspiration in parts.

Edited 2 time(s). Last edit at 11/27/2015 06:15AM by LarsK.

|

Re: CoreXY vs Quadrap mechanism November 27, 2015 06:38AM |

Registered: 10 years ago Posts: 14,672 |

Quote

LarsK

Quote

grat

Delta's scale poorly, even more so when you're talking 1m Z axis-- My delta is 720mm tall, and has a build height of 280mm.

dc42's delta is 300mm diameter, 480-540mm print height, and is 1m tall. Best case, you're looking at 1.5-2.0 meter tall printer, and you're going to have to make the frame out of 2060 or something similar to get it to work. Even then, the bowden length would be pretty crazy (800-1000mm?).

This is not correct. If DC42's does 500mm at 1m tall then to do another 500mm he just makes it 1.5m tall. In height it scales 1:1. You are thinking about the bed diameter which scales different. You are correct that normal bowden would not be optimal but there are many work arounds for this. See this also

I wanted to mention that there is / was a printer on kickstarter not so long ago that came at least close to the specs (470x435x690) - This one maybe it can serve as an inspiration in parts.

To expand on this:

My delta has a round bed with a printable diameter of 300mm. If that is large enough for you, then to achieve about 1m print height you would need to increase the height by 0.5m as LarsK says. 2040 extrusion should be adequate if you use metal corners. The Bowden tube would have to be lengthened, but by somewhat less than 250mm because the head needs to go another 250mm up and another 250mm down relative to the extruder drive.

However, if you really do want a 300mm square print area, that imples a printable diameter of 424mm, so the diagonal rods would have to be lengthened by about 140mm and the printer would need to be about 1.64m high. This would be more of a challenge to get working well.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: CoreXY vs Quadrap mechanism November 27, 2015 09:39AM |

Registered: 9 years ago Posts: 722 |

Hi guys,

Your project will be probably one of the most interesting of the coming year.

I'm very excited to see how you will apply or change your previous building principles for this one.

The lenght of the Z axis on a Core XY is not a factor.

It's just a question of guide lenght and orverall strucrue IMHO.

I see no advantages to use a Quadrap system.

4 motors for 2 axis is 2 motors waisted, and an risk of getting out of synchronisation.

You can replace 2 motors by some dual shaft motors or rod transmission. To me it's a wrong good idea.

I feel the same about the ultimaker alike printhead which seems a waste of two more guides.

To me CoreXY is simply more pragmatic, it uses a reduced amount of components.

I believe it overtakes a delta by footprint and building area, with comparable performance and cost.

I know you have your own ideas about machine construction and strucrures.

But instead of using 2040 and metal corners, may I suggest you replace metal corners by just using 2080 for the stiles ?

To me, the rails should be 40x40mm for that height.

The use of a heavy material as pannels is probably a good idea to deal with vibrations on a tall machine.

I say that but maybe you do not want to print fast too. so vibrations should be limited.

May I suggest you consider HTD GT3 belts ?

I will follow your build with interest.

++JM

Edited 1 time(s). Last edit at 11/27/2015 09:42AM by J-Max.

Your project will be probably one of the most interesting of the coming year.

I'm very excited to see how you will apply or change your previous building principles for this one.

The lenght of the Z axis on a Core XY is not a factor.

It's just a question of guide lenght and orverall strucrue IMHO.

I see no advantages to use a Quadrap system.

4 motors for 2 axis is 2 motors waisted, and an risk of getting out of synchronisation.

You can replace 2 motors by some dual shaft motors or rod transmission. To me it's a wrong good idea.

I feel the same about the ultimaker alike printhead which seems a waste of two more guides.

To me CoreXY is simply more pragmatic, it uses a reduced amount of components.

I believe it overtakes a delta by footprint and building area, with comparable performance and cost.

I know you have your own ideas about machine construction and strucrures.

But instead of using 2040 and metal corners, may I suggest you replace metal corners by just using 2080 for the stiles ?

To me, the rails should be 40x40mm for that height.

The use of a heavy material as pannels is probably a good idea to deal with vibrations on a tall machine.

I say that but maybe you do not want to print fast too. so vibrations should be limited.

May I suggest you consider HTD GT3 belts ?

I will follow your build with interest.

++JM

Edited 1 time(s). Last edit at 11/27/2015 09:42AM by J-Max.

|

Re: CoreXY vs Quadrap mechanism November 27, 2015 10:33AM |

Registered: 9 years ago Posts: 83 |

Quote

LarsK

This is not correct. If DC42's does 500mm at 1m tall then to do another 500mm he just makes it 1.5m tall.

Then it still falls within the range I specified of "1.5 to 2.0 meters".

Note that dc42 only claims 540mm build height in the middle-- for true wall-to-wall build height of 1000mm, more height is needed.

As he says, for true 300x300 square build area, again, more height is needed.

I like deltas-- up to a certain point, they're EASIER to get build height out of, and certainly you can build a delta that tall-- but for a full 300x300x1000, coreXY is probably going to be an easier solution to build.

|

Re: CoreXY vs Quadrap mechanism November 27, 2015 11:24AM |

Registered: 9 years ago Posts: 346 |

|

Re: CoreXY vs Quadrap mechanism November 27, 2015 03:10PM |

Registered: 9 years ago Posts: 722 |

Hi guys,

Sure stretch is very low, but more important, the resistance is very high,

the manufacturer says 6 times better than standard HTD.

That means you can use smaller belts that runs faster and weight less.

On my CNC I replaced HTD5M 15mm buy HTD3M GT3 5mm which can hold more torque !

Through, it's the best quality of belts I've ever seen, and it is incredibly quiet.

++JM

Sure stretch is very low, but more important, the resistance is very high,

the manufacturer says 6 times better than standard HTD.

That means you can use smaller belts that runs faster and weight less.

On my CNC I replaced HTD5M 15mm buy HTD3M GT3 5mm which can hold more torque !

Through, it's the best quality of belts I've ever seen, and it is incredibly quiet.

++JM

|

Re: CoreXY vs Quadrap mechanism November 29, 2015 04:24PM |

Registered: 11 years ago Posts: 5,780 |

I like the CoreXY mechanism because it can be built on a flat panel, helping ensure that the X and Y axes are in the same plane, and reducing the ways that things can get out of alignment. But then, there's the loooong belts.

With a delta, it seems the only tricky/critical alignment is setting the guide rails parallel. The bed can be adjusted so that it is orthogonal to the rails. The effector rods can be made identical lengths pretty easily. But then there's the loooong belts...

Hmmmm.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

With a delta, it seems the only tricky/critical alignment is setting the guide rails parallel. The bed can be adjusted so that it is orthogonal to the rails. The effector rods can be made identical lengths pretty easily. But then there's the loooong belts...

Hmmmm.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CoreXY vs Quadrap mechanism November 29, 2015 05:07PM |

Registered: 10 years ago Posts: 14,672 |

Quote

the_digital_dentist

With a delta, it seems the only tricky/critical alignment is setting the guide rails parallel.

Metal corners help a lot to avoid leaning towers in my experience. I don't use guide rails, I use wheeled carriages running on the outside of the extrusions. So I just need to get the extrusions perpendicular to the base - and of course the extrusions need to be straight.

Quote

the_digital_dentist

...But then there's the loooong belts...

The belts in my delta are nearly 2m long each, but I can jog the head vertically in steps of 0.025mm (four 1/16 microsteps) without difficulty. That's good enough IMO.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: CoreXY vs Quadrap mechanism November 30, 2015 03:31AM |

Registered: 9 years ago Posts: 722 |

Hi guys,

I guess the_digital_dentist is affraid about belts stretching, not belt resolution (if it's the proper word).

This fear comes for the technical chart of the belt showin "max stretch xx%".

So people think about belts as a bungee thing, what obviously it is not.

Belt stretching appears mostly when the tensioning is close to the rupture.

And it's relatively even as the load/tensioning is stable.

On my CNC mill I drive a 120kg (260lbs) gantry with belts and I reach a repeatability within 0.03mm.

Not bad for 3500mm belts, what do you think ?

You need a very expensive ballscrew to reach the same precision.

There's no secret, you just have to select the right belt for the application.

++JM

I guess the_digital_dentist is affraid about belts stretching, not belt resolution (if it's the proper word).

This fear comes for the technical chart of the belt showin "max stretch xx%".

So people think about belts as a bungee thing, what obviously it is not.

Belt stretching appears mostly when the tensioning is close to the rupture.

And it's relatively even as the load/tensioning is stable.

On my CNC mill I drive a 120kg (260lbs) gantry with belts and I reach a repeatability within 0.03mm.

Not bad for 3500mm belts, what do you think ?

You need a very expensive ballscrew to reach the same precision.

There's no secret, you just have to select the right belt for the application.

++JM

|

Re: CoreXY vs Quadrap mechanism November 30, 2015 07:48AM |

Registered: 11 years ago Posts: 5,780 |

OK, so length of belts is not a concern... How about balancing the tension on the belts? It seems that if one belt is tighter than the other it will produce a torque that tries to shift one end of the X axis.

Edited 2 time(s). Last edit at 11/30/2015 07:52AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Edited 2 time(s). Last edit at 11/30/2015 07:52AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CoreXY vs Quadrap mechanism November 30, 2015 08:26AM |

Registered: 9 years ago Posts: 722 |

Hi guys,

How can one end be shifted ? In a CoreXY the belts are in Push-Pull motion.

What a belt gives from one side, It realeases from the other side. It's a balanced system.

Imagine what should happen if you did not put the B belt at all.

Just nothing, even there's full tensioning for one side and none for the other.

I believe as long as no belt is frankly loose you won't have any issue.

If a belt is overtight, as long as the steps per mm are adjusted it will be ok.

Actualy My CoreXY is dismantled for painting, but I will check with two belts at different tension.

However I'm not sure both belts were tighten excactly the same way someday on it.

I did not noticed any shift from one axis.

++JM

How can one end be shifted ? In a CoreXY the belts are in Push-Pull motion.

What a belt gives from one side, It realeases from the other side. It's a balanced system.

Imagine what should happen if you did not put the B belt at all.

Just nothing, even there's full tensioning for one side and none for the other.

I believe as long as no belt is frankly loose you won't have any issue.

If a belt is overtight, as long as the steps per mm are adjusted it will be ok.

Actualy My CoreXY is dismantled for painting, but I will check with two belts at different tension.

However I'm not sure both belts were tighten excactly the same way someday on it.

I did not noticed any shift from one axis.

++JM

|

Re: CoreXY vs Quadrap mechanism November 30, 2015 10:51AM |

Registered: 9 years ago Posts: 233 |

Hi D. Dentist.

I included a design feature in my printer that guaranteed equal belt tensions always. I used 1 continuous belt for both belt paths. you fix the belt ends on one side of the carriage first, and then, when you get the tension right, you just clamp the belt to the other side of the carriage to separate the single belt into 2 functional belts. This requires the belts to be on the same plane of course. BUT with a larger printer like you plan, a belt cross is even less of a problem than it was in my printer (which is to say, ZERO problem, with ZERO accuracy effects and no belt wear problems...). I guess, from reading your posts, that your sensibilities may encourage you toward separate levels for your belt paths.... However I think you will find that a correctly designed belt cross/twist will just work better for you.

I was also concerned with belt length and also bowden tube length. I therefore really concentrated on keeping my movements tight to the printbed, and the carriage small. Every mm you can shave from either X or Y axis length means 4mm less belts used. You could mount the bowden tube vertically above the printer bed center to shorten the bowden tube for a large printer.

When I was researching my printer, I talked to almost every major linear guide manufacturer (around 10 manufacturers). One very important feature in the CoreXY design when used with linear guides is to keep the Y axis guides perfectly parallel. And they really mean perfectly parallel!!! The most common failure for linear guides in all machinery is apparently not getting guides parallel. Hard linked linear guides (like what we do when clamping the X axis to the Y axis...) have no tolerance for variation in parallel at all. The best guides have an even LOWER tolerance for variation in parallel than the cheaper guides. Several of the manufacturers recommended that you machine perfectly parallel lips on the mounting plate at the inner edge of the two guides. Then you actually clamp the guides against the lips before screwing them into place. Apparently it is almost IMPOSSIBLE to drill holes in your plate accurately enough to keep parallel spec on the best guides. Since I did not use parallel lips, or even a mounting plate, I used cheap Chinese guides that have more forgiving tolerances and are more disposable. I suspect that YOU will be using sealed linear guides which have VERY tight tolerances and will probably require the lips.

Edited 1 time(s). Last edit at 11/30/2015 11:01AM by patrickrio.

I included a design feature in my printer that guaranteed equal belt tensions always. I used 1 continuous belt for both belt paths. you fix the belt ends on one side of the carriage first, and then, when you get the tension right, you just clamp the belt to the other side of the carriage to separate the single belt into 2 functional belts. This requires the belts to be on the same plane of course. BUT with a larger printer like you plan, a belt cross is even less of a problem than it was in my printer (which is to say, ZERO problem, with ZERO accuracy effects and no belt wear problems...). I guess, from reading your posts, that your sensibilities may encourage you toward separate levels for your belt paths.... However I think you will find that a correctly designed belt cross/twist will just work better for you.

I was also concerned with belt length and also bowden tube length. I therefore really concentrated on keeping my movements tight to the printbed, and the carriage small. Every mm you can shave from either X or Y axis length means 4mm less belts used. You could mount the bowden tube vertically above the printer bed center to shorten the bowden tube for a large printer.

When I was researching my printer, I talked to almost every major linear guide manufacturer (around 10 manufacturers). One very important feature in the CoreXY design when used with linear guides is to keep the Y axis guides perfectly parallel. And they really mean perfectly parallel!!! The most common failure for linear guides in all machinery is apparently not getting guides parallel. Hard linked linear guides (like what we do when clamping the X axis to the Y axis...) have no tolerance for variation in parallel at all. The best guides have an even LOWER tolerance for variation in parallel than the cheaper guides. Several of the manufacturers recommended that you machine perfectly parallel lips on the mounting plate at the inner edge of the two guides. Then you actually clamp the guides against the lips before screwing them into place. Apparently it is almost IMPOSSIBLE to drill holes in your plate accurately enough to keep parallel spec on the best guides. Since I did not use parallel lips, or even a mounting plate, I used cheap Chinese guides that have more forgiving tolerances and are more disposable. I suspect that YOU will be using sealed linear guides which have VERY tight tolerances and will probably require the lips.

Edited 1 time(s). Last edit at 11/30/2015 11:01AM by patrickrio.

|

Re: CoreXY vs Quadrap mechanism November 30, 2015 12:00PM |

Registered: 9 years ago Posts: 346 |

Quote

patrickrio

I was also concerned with belt length and also bowden tube length. I therefore really concentrated on keeping my movements tight to the printbed, and the carriage small. Every mm you can shave from either X or Y axis length means 4mm less belts used. You could mount the bowden tube vertically above the printer bed center to shorten the bowden tube for a large printer.

That is some good insight. Your comment about extruder in center just jerked my mind into a solution for a problem of heat enclosing my printer, that I have been boxing with for a week. Thank you.

About twisting belts; The center cord stays the same length so it should have zero impact. It is commonly used and also described in literature, such as here from Mechanical Components Handbook . I also use twisted belts.

|

Re: CoreXY vs Quadrap mechanism November 30, 2015 02:33PM |

Registered: 9 years ago Posts: 233 |

The key to good cross/twist design is to have the pulleys before and after the twist stationary. also, if you have 2 pulleys before and after stationary, you can actually vary the heights of the nearest 4 pulleys to make belt passes without touching easier....one belt can go high while one belt goes low without impact to belt tension or belt length. 6mm wide GT2 and MXL can do a 180 degree twist in 20CM distance and be completely within spec.

|

Re: CoreXY vs Quadrap mechanism December 01, 2015 12:15PM |

Registered: 11 years ago Posts: 5,780 |

Quote

patrickrio

When I was researching my printer, I talked to almost every major linear guide manufacturer (around 10 manufacturers). One very important feature in the CoreXY design when used with linear guides is to keep the Y axis guides perfectly parallel. And they really mean perfectly parallel!!! The most common failure for linear guides in all machinery is apparently not getting guides parallel. Hard linked linear guides (like what we do when clamping the X axis to the Y axis...) have no tolerance for variation in parallel at all. The best guides have an even LOWER tolerance for variation in parallel than the cheaper guides. Several of the manufacturers recommended that you machine perfectly parallel lips on the mounting plate at the inner edge of the two guides. Then you actually clamp the guides against the lips before screwing them into place. Apparently it is almost IMPOSSIBLE to drill holes in your plate accurately enough to keep parallel spec on the best guides. Since I did not use parallel lips, or even a mounting plate, I used cheap Chinese guides that have more forgiving tolerances and are more disposable. I suspect that YOU will be using sealed linear guides which have VERY tight tolerances and will probably require the lips.

I am using two parallel linear guides in the Y axis of my printer. I didn't have much trouble getting them parallel- the procedure for aligning them parallel is similar to aligning round guide rails- you move the carriage to one end of the rails, tighten it down, then move to the other end and tight it down. In the case of linear guides, instead of going to the opposite end, you move it down past the next hole and tighten those screws, and keep going until you reach the far end of the rails. The final adjustment is to loosen the screws in the bearing blocks and move the carriage back and forth a few times, then tighten those screws back down. Though not ideal, it seems to work fine in my printer's Y axis.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CoreXY vs Quadrap mechanism December 02, 2015 05:42PM |

Registered: 9 years ago Posts: 233 |

Yes, that is the procedure for getting parallel.... however, some of the manufacturers feel pretty strongly that this is not enough to meet spec. a few of the manufacturers, IKO for example, will not even honor the warranty on their smaller sealed guides if you do not have a mounting lip. I believe this is up to their 12mm rail miniature sealed guides.

I did not have a lip on my design either, and did exactly as you did to get them parallel.

I did not have a lip on my design either, and did exactly as you did to get them parallel.

|

Re: CoreXY vs Quadrap mechanism December 03, 2015 03:11AM |

Registered: 9 years ago Posts: 722 |

hi guys,

I agree with patrickrio. Maybe a lot of people here knows already that.

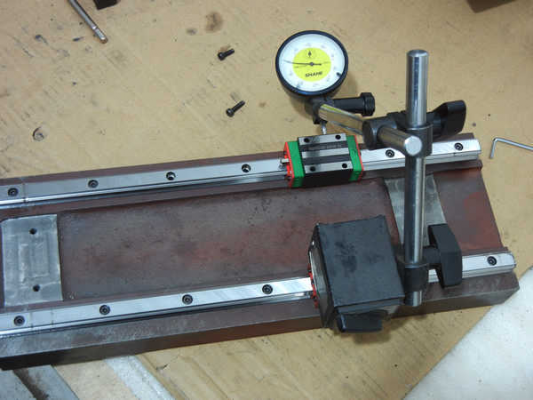

The proper way to set up the seccond rail ils to mount a dial indicator on the first one and measure distance on the full stroke.

Through, the first rail must be mounted accurately too. It's wise to provide a screw adjusting system on at last one plane on each rail.

It's crucial on acurate linear rails, but it's still important on any guide system for the efficiency, accuracy and durability.

++JM

I agree with patrickrio. Maybe a lot of people here knows already that.

The proper way to set up the seccond rail ils to mount a dial indicator on the first one and measure distance on the full stroke.

Through, the first rail must be mounted accurately too. It's wise to provide a screw adjusting system on at last one plane on each rail.

It's crucial on acurate linear rails, but it's still important on any guide system for the efficiency, accuracy and durability.

++JM

|

Re: CoreXY vs Quadrap mechanism December 05, 2015 07:17AM |

Registered: 9 years ago Posts: 1,035 |

Very interesting topics around this post. Can you guys point to some images depicting the lip you are talking about or any video that you might know of dial indicator parallel guides installation etc? I know that big companies sometimes have videos that would show how some of their equipment is to be installed, maintained or serviced. When you come across such a subject I am sure many of you already know many things being discussed here but many of us have little clue so any visual aid is welcomed.

+patrickrio: Regarding the equal tension belts I endorse such tactics and I believe that they should be implemented in more designs that fragment the motion with several belts. Belts are cheap, spectra is even cheaper. I have actually designed such a single-wire Z-lift platform in my "rotary-only motion" experiments but at least on this forum it didn't have much success (maybe too complicated for ensuring accuracy). It has a single spectra line that goes around all the pulleys and is only tensioned in one spot then clamped on each pulley. It is easier with belt because of the teeth that make it so much more easier to clamp.

+DD: I am also building a corexy and am very interested in a good way to ensure parallelism between X and Y carriages. Thanks DD for pointing that out, I haven't come across the procedure so far.

Why does the Quadrap looks so much like the ultimaker's XY arrangement? What is so special about it that it is only now that this design starts to pop in forum posts and 3d printers? I get it that it uses spectra and replaces the linear rods Y with alu extrusions but you can do that with corexy and it looks cleaner and simpler.

Edited 1 time(s). Last edit at 12/05/2015 07:19AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

+patrickrio: Regarding the equal tension belts I endorse such tactics and I believe that they should be implemented in more designs that fragment the motion with several belts. Belts are cheap, spectra is even cheaper. I have actually designed such a single-wire Z-lift platform in my "rotary-only motion" experiments but at least on this forum it didn't have much success (maybe too complicated for ensuring accuracy). It has a single spectra line that goes around all the pulleys and is only tensioned in one spot then clamped on each pulley. It is easier with belt because of the teeth that make it so much more easier to clamp.

+DD: I am also building a corexy and am very interested in a good way to ensure parallelism between X and Y carriages. Thanks DD for pointing that out, I haven't come across the procedure so far.

Why does the Quadrap looks so much like the ultimaker's XY arrangement? What is so special about it that it is only now that this design starts to pop in forum posts and 3d printers? I get it that it uses spectra and replaces the linear rods Y with alu extrusions but you can do that with corexy and it looks cleaner and simpler.

Edited 1 time(s). Last edit at 12/05/2015 07:19AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: CoreXY vs Quadrap mechanism December 05, 2015 07:45AM |

Registered: 9 years ago Posts: 722 |

Hi,

And a good link about the 6 degrees of freedom and accuracy measurement : Ensuring Linear Motion Devices Meet the Needs of the Application

They uses a granite block as reference plate. I guess sadly none of us own one.

But reference can be one stile (or rail) of your structure. But you need to always reference to... that reference.

You should not reference from another element until that element is perfectly referenced with your initial reference.

(Uh... I wonder if I'm understandable...)

Here Spectra line is expensive. (about 16€/roll) I guess anywhere over the world you want Spectra line to save money.

First, even if you can get a cheap Specta spool, you're only saving fiew bucks.

Belts are accurate and pulleys are machined. Printed Spectra pulleys are probably not as accurate.

If quality comes first and price comes seccond, you want belts and pulleys or better.

++JM

And a good link about the 6 degrees of freedom and accuracy measurement : Ensuring Linear Motion Devices Meet the Needs of the Application

They uses a granite block as reference plate. I guess sadly none of us own one.

But reference can be one stile (or rail) of your structure. But you need to always reference to... that reference.

You should not reference from another element until that element is perfectly referenced with your initial reference.

(Uh... I wonder if I'm understandable...)

Here Spectra line is expensive. (about 16€/roll) I guess anywhere over the world you want Spectra line to save money.

First, even if you can get a cheap Specta spool, you're only saving fiew bucks.

Belts are accurate and pulleys are machined. Printed Spectra pulleys are probably not as accurate.

If quality comes first and price comes seccond, you want belts and pulleys or better.

++JM

|

Re: CoreXY vs Quadrap mechanism December 05, 2015 07:59AM |

Registered: 9 years ago Posts: 233 |

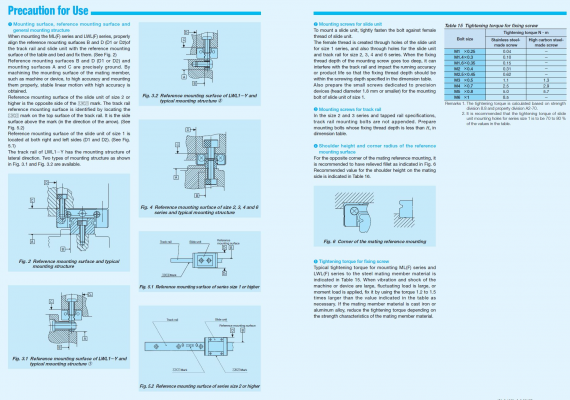

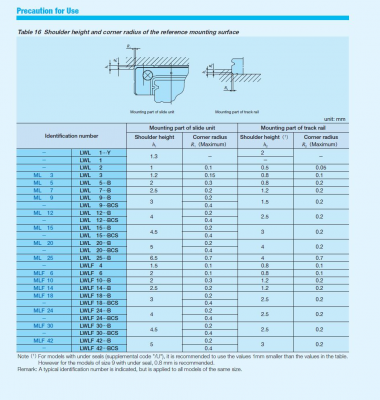

Here are the descriptions and drawings from the IKO manuals... similar stuff in other manufacturer manuals...

|

Re: CoreXY vs Quadrap mechanism December 05, 2015 08:05AM |

Registered: 9 years ago Posts: 233 |

I am actually working on my Delta design that uses these rails now. A big advantage of the Delta design for linear rails is that NONE of the rails are paired, so you do not have the same problems with being parallel. Sure you WANT them parallel, but you will not affect product life or warranty if they are not parallel.

|

Re: CoreXY vs Quadrap mechanism December 05, 2015 08:10AM |

Registered: 9 years ago Posts: 1,035 |

Quote

J-Max

And a good link about the 6 degrees of freedom and accuracy measurement : Ensuring Linear Motion Devices Meet the Needs of the Application

They uses a granite block as reference plate. I guess sadly none of us own one.

But reference can be one stile (or rail) of your structure. But you need to always reference to... that reference.

You should not reference from another element until that element is perfectly referenced with your initial reference.

(Uh... I wonder if I'm understandable...)

Yes, reference to initial reference seems like the best solution as you only need your machine to be parallel to your machine. Perfectly understandable. I wonder how much would such a contraption cost and if it makes sense for us who can't really build machines with the accuracy that such dial contraption would ensure.

Quote

J-Max

Here Spectra line is expensive. (about 16€/roll) I guess anywhere over the world you want Spectra line to save money.

First, even if you can get a cheap Specta spool, you're only saving fiew bucks.

Belts are accurate and pulleys are machined. Printed Spectra pulleys are probably not as accurate.

If quality comes first and price comes seccond, you want belts and pulleys or better.

Belts are difficult to use in non-linear devices like the one I linked to because it's difficult to engage a toothed pulley that sits in between to segments of straight line. One would have to insert two additional pulleys that would force the belt go around as many teeth as possible around the large pulley, something like this. Also having such a large pulley like in my design is quite difficult to have it machined. The closest I can think of is glue a belt around it so the other belt has something to engage to.

The only really bothersome thing with spectra is motor engagement (no teeth) and string walking. Very annoying indeed, loosing a lot of accuracy there

.

.RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: CoreXY vs Quadrap mechanism December 05, 2015 10:26AM |

Registered: 11 years ago Posts: 5,780 |

Quote

patrickrio

Yes, that is the procedure for getting parallel.... however, some of the manufacturers feel pretty strongly that this is not enough to meet spec. a few of the manufacturers, IKO for example, will not even honor the warranty on their smaller sealed guides if you do not have a mounting lip. I believe this is up to their 12mm rail miniature sealed guides.

I did not have a lip on my design either, and did exactly as you did to get them parallel.

Since I'm buying used linear guides, I don't care about a warranty. It's a simple mechanism. It isn't going to suddenly stop working- the block won't sieze up one day, the balls aren't going to fall out of the bearing block, and the rail isn't going to break in two. All that will happen is motion will get sloppier as the rail and balls wear. It will have to get a lot sloppier to be as bad as bearings on a round rail, so even when the linear guide is out of spec, it's still better than the next best thing. Look at the load specs for even a small linear guide. The loads they are subjected to in a 3D printer are a tiny fraction of their rated loads. They aren't going to wear out in your lifetime. If you don't have the alignment absolutely perfect it doesn't matter. If the thing moves easily (easily enough for a wimpy little NEMA-17 motor to move it) without binding, it's aligned as well as it needs to be. The procedure I used to align the parallel rails in my machine gave very even, smooth motion so I'm not going to worry about it, and I'm going to keep on using linear guides, probably in ways that would make the manufacturers cringe.

What does a linear guide warranty cover? How would you even make a warranty claim on a linear guide? Are you going to track the distance the thing has moved in your printer? How would you do that? Would you provide the design of the printer to the linear guide manufacturer to prove that there are no stresses that exceed the products specs? Do you know what the actual loads are in your printer? How would they be able to tell from your design what the loads are in your machine? Would they bother trying to analyze it?

Here's something to think about- the linear guide is made of steel and we typically mount them on aluminum. What happens as the temperature rises in the machine? The aluminum expands a lot more than the steel- are the rail mounting screws going to slide a little in their holes or is the whole thing going to warp? What happens to your extremely careful alignment even if you have the manufacturer recommended reference lip? What happens to your alignment after multiple heat/cool cycles?

You can worry about all this stuff or you can build your machine and get it working. Even with less than ideal installation, linear guides work better than the next best thing.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: CoreXY vs Quadrap mechanism December 05, 2015 11:10AM |

Registered: 9 years ago Posts: 233 |

Dentist, all good points.

And to your point, I am also using my rails in ways that would make the manufacturers cringe. I am not chastising you for doing the same thing, believe me. However, I do think that when I do my next CoreXY i will likely use a plate like you are. I also think that machining 2 parallel lips might not be very expensive on such a plate. If the cutout and holes of the plate are done by CNC, the parallel lips may only require another automated tool change and two tool passes. In addition to any warranty advantages, the lips make initial setup easier, and make replacing parts easier too. Rail installation only requires clamping rails against the lips and then putting screws in all at the same time as fast as you please, perfect parallel every time with dramatically smaller chance of error. For one off machines and prototypes it may be desired to "skip the lips" for simplicity and iterative advantages, but the more standardized and repetitive a machine design becomes, the more the lips make sense.

Obviously the warranty only matters if you are buying new guides. It seems that the mounting lip are more of an immediate warranty disqualification than anything. If they know you didn't use a mounting lip in a paired guide situation, your claim is immediately disqualified. They also inspect returned guides and parallel failure has an easily recognized wear pattern.

Of all the rail manufacturers I talked to IKO the most and in greatest detail.

The engineer at IKO I talked to said that failed rails due to lack of parallel was the biggest failure mode of installed rails and since it wasn't their fault they didn't want to bear the cost of warranty. He said that the main other disqualification was if the rails were obviously loaded out of tolerance. However, he said that loads out of tolerance were a bit less cut and dried, so disqualification in this case mainly happened in cases of gross overloading. Once again, the wear pattern on rails was a big clue to overloading. Other than this, he said they rarely had problems, and tended to honor warranty claims that DID happen pretty liberally.

I did not get into the warranty weeds in my discussions with other companies, but I assume some similarity.

As for the warping with heat, the lip would probably tend to help with that too..... the screws move slightly in the holes over the length of the rail, but the lip distance from the holes changes very little....

Edit: forgot the 3rd major failure mode IKO mentioned... dirty environment with hard abrasive dust and not installing approved rail sweeps. Once again, inspecting the guides gives teltale signs of this owner caused failure mode.

The whole point of the discussion is to bring attention to the "gotchas" of installation - and parallel is the biggest gotcha I see for CoreXY when using linear guides. Maybe it is not that big of a gotcha, but I think it may be the biggest one. Adding lips to a design may not cost much, and pretty much eliminates (or at least reduces substantially) all facets of the problem as it exists in the CoreXY mechanism.

Best,

Patrick

Edited 6 time(s). Last edit at 12/05/2015 12:13PM by patrickrio.

And to your point, I am also using my rails in ways that would make the manufacturers cringe. I am not chastising you for doing the same thing, believe me. However, I do think that when I do my next CoreXY i will likely use a plate like you are. I also think that machining 2 parallel lips might not be very expensive on such a plate. If the cutout and holes of the plate are done by CNC, the parallel lips may only require another automated tool change and two tool passes. In addition to any warranty advantages, the lips make initial setup easier, and make replacing parts easier too. Rail installation only requires clamping rails against the lips and then putting screws in all at the same time as fast as you please, perfect parallel every time with dramatically smaller chance of error. For one off machines and prototypes it may be desired to "skip the lips" for simplicity and iterative advantages, but the more standardized and repetitive a machine design becomes, the more the lips make sense.

Obviously the warranty only matters if you are buying new guides. It seems that the mounting lip are more of an immediate warranty disqualification than anything. If they know you didn't use a mounting lip in a paired guide situation, your claim is immediately disqualified. They also inspect returned guides and parallel failure has an easily recognized wear pattern.

Of all the rail manufacturers I talked to IKO the most and in greatest detail.

The engineer at IKO I talked to said that failed rails due to lack of parallel was the biggest failure mode of installed rails and since it wasn't their fault they didn't want to bear the cost of warranty. He said that the main other disqualification was if the rails were obviously loaded out of tolerance. However, he said that loads out of tolerance were a bit less cut and dried, so disqualification in this case mainly happened in cases of gross overloading. Once again, the wear pattern on rails was a big clue to overloading. Other than this, he said they rarely had problems, and tended to honor warranty claims that DID happen pretty liberally.

I did not get into the warranty weeds in my discussions with other companies, but I assume some similarity.

As for the warping with heat, the lip would probably tend to help with that too..... the screws move slightly in the holes over the length of the rail, but the lip distance from the holes changes very little....

Edit: forgot the 3rd major failure mode IKO mentioned... dirty environment with hard abrasive dust and not installing approved rail sweeps. Once again, inspecting the guides gives teltale signs of this owner caused failure mode.

The whole point of the discussion is to bring attention to the "gotchas" of installation - and parallel is the biggest gotcha I see for CoreXY when using linear guides. Maybe it is not that big of a gotcha, but I think it may be the biggest one. Adding lips to a design may not cost much, and pretty much eliminates (or at least reduces substantially) all facets of the problem as it exists in the CoreXY mechanism.

Best,

Patrick

Edited 6 time(s). Last edit at 12/05/2015 12:13PM by patrickrio.

Sorry, only registered users may post in this forum.