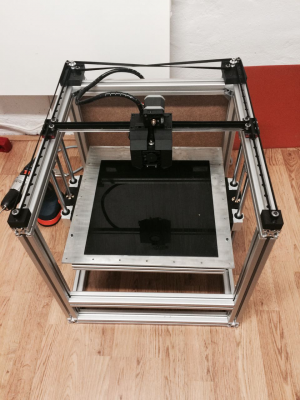

New printer build! My CoreXY.

Posted by robkar

|

Re: New printer build! My CoreXY. May 21, 2016 08:33PM |

Registered: 8 years ago Posts: 776 |

Quote

robkar

Wow lkcl, what a response! Where to start?

Quote

These are good points, I understand that my bed is levered around my X-axis. I have been considering a three point Z-axis before, I have this hidden in my CAD assembly:

oh cool.

Quote

This exact belt path will not work though, one of the screws will rotate the wrong direction

ehn? how the heck did you manage to do that?!

Quote

But it can be solved by putting an idler or two close to the motor / back screw, so that it rotates in the same direction as the others.

i just wrapped a single closed loop belt around a GT2-16t on the motor and those GT2-50s i printed up, offset the motor a bit so the GT2-16 had at least 90 degrees of belt on it, and it's working fine. racked it up quite tight though. oh, and i had to make the z-motor swivel on a 625 bearing about one of the lead screws.... don't ask...

Quote

The orange rods are 8mm lead screws, the grey ones are 12mm smooth rods. The belt here is actually 1750 mm long.. Will the elasticity (assuming standard China-made GT2 belt) cause any problems? Like in syncing the screws?

neeeh not at all. it's called "timing belt" for a reason.

Quote

Based on my initial tests of my current setup the bearings make it pretty solid anyhow, so I will probably do some test prints before modifying it (I only have two lead screws at hands atm, need to order and wait for one more to arrive to test the three point concept.. ) One should also remember, many printers do just fine with completely cantilevered beds, bearings exist for a reason

mmmm rumble, grumble mumble - look up what the_digital_dentist did. and see the discussion arouuund... mmm... page 6 to 7 of the Fusebox forum. yeahh it _can_ be done, there are printers that have done it... then you do the "digital_dentist" test which is to try to pull a part off a heated printbed hard, whilst it's still cooling down, and you can *see* how much the bed goes "bend, bend, flex"... and you go... "ah. damn"

Quote

Quote

lkcl

the original design that you had was much much better for structural integrity.

This is also mostly true. But I will not remove the front top bar completely, just move it down in order for the bed to be very accessible. I did also write that if it is not rigid enough, it is SUPER easy to move back to the top position.

if you want to make the bed accessible, what you should do is move it say.... 70 to 100mm up, and put corresponding bits all the way round so you have 2 stacks of 4 horizontal extrusions. ehh arse you can't do that - instead you'd need to increase the height by that 70 to 100mm instead because all the z stuff is in the way, you'd need to do all that just underneath what's currently the base. then by putting in a full set of corner-brackets in *both* (stacked) sets of 4 horizontal extrusions the uprights will become absolutely rock-solid. you'll still get a lever-effect (height is 500mm say, 100mm down is the 2nd set of horizontal extrusion, you'd get a 5:1 lever effect on all the corner-brackets... generally that's bad!)

buuut of course now you need uprights that are 100mm longer than what you've got in place now... bleh.

no, take those top two left and right corners, one in each hand, and go "waggle, waggle" - you'll soon see why that front bit (and associated corner brackets) are all needed...

iknowiknow it's really nice to have accessibiltiy. i really like the mendel90 because the printbed is at the bottom, but dang having the z wind all the way down.... you _could_ just put that into the firmware at the end, "please wind all the way down" instead...

Quote

Since you built a foldable printer I am pretty sure you can understand that there are reasons for not building the optimal machine from a structural mechanics point of view. My reason is that I want something that looks cool, is easy to work with and a little bit different. Yours was that you wanted it to be foldable!

i didn't compromise on the frame design *at all*! i did make a hilarious mistake at one point by ignoring my own design analysis though. the first video on the reprap wiki page (see sig) shows the mockup i did in cardboard. it's actually incredibly rigid, one of the reasons is because it's a smaller frame (312 x 358 x 440 when assembled) and extrusion bends based on a square law. so whilst most people say "don't use 15x15 extrusion because at 450mm long it bends like hell" i have a whopping 2.25x less flex, possibly even more, in the 15x15 extrusion, thanks to using monster 50mm corner-brackets as well as a much smaller length than most people would use.

even some of the plastic which is stupidly flexible, because there is another part next to it that locks in place, i was worried then amazed at how it stiffened up. unassembled the box halves are as floppy as a stiff cardboard box (no really!) assemble it, lock everything together, and it's as good as any cross-braced cube. and this is with 3mm hardboard and 15% of the extrusion taken out from various strategic edges. it's a bizarre paradox that at first glance shouldn't work, but it does, which is cool.

Edited 3 time(s). Last edit at 05/21/2016 08:41PM by lkcl.

-- sandwich200: compact portable folding corexy printer [reprap.org]

|

Re: New printer build! My CoreXY. May 21, 2016 08:38PM |

Registered: 8 years ago Posts: 776 |

Quote

robkar

Hehe yes. To be honest, most of the stuff I print is actually new parts for my 3D printer! This is the fun part, testing new stuff etc.

haha this has been a maaajor distraction from the libre laptop i'm doing - that took i think... a year to design? luckily i do have that project to distract me from the time-vortex-energy-sucking-allure-called-3d-printer-design....

|

Re: New printer build! My CoreXY. May 22, 2016 06:00AM |

Registered: 8 years ago Posts: 776 |

ah - something like this robkar, which is the "unobtanium" by nosmo.

see the double-level of extrusion all the way round? like that, only both layers level, and with corner-brackets on the inside on both levels, too. that would do the trick. i did see one where someone filled both levels with plywood - even hardboard would do the trick, you want to stop the rhombussing-effect of both bottom levels. hardboard's a low-cost way to do it.

see the double-level of extrusion all the way round? like that, only both layers level, and with corner-brackets on the inside on both levels, too. that would do the trick. i did see one where someone filled both levels with plywood - even hardboard would do the trick, you want to stop the rhombussing-effect of both bottom levels. hardboard's a low-cost way to do it.

|

Re: New printer build! My CoreXY. May 22, 2016 11:42AM |

Registered: 8 years ago Posts: 93 |

|

Re: New printer build! My CoreXY. May 22, 2016 01:03PM |

Registered: 8 years ago Posts: 776 |

|

Re: New printer build! My CoreXY. May 22, 2016 03:21PM |

Registered: 8 years ago Posts: 24 |

Quote

lkcl

Quote

robkar

Quote

This exact belt path will not work though, one of the screws will rotate the wrong direction

Quote

ehn? how the heck did you manage to do that?!

Look at the CAD screenshot of the (pretty stupid) Z-axis concept. Imagine the motor rotates clockwise, follow the belt and look at how the three screws will rotate.

Quote

Based on my initial tests of my current setup the bearings make it pretty solid anyhow, so I will probably do some test prints before modifying it (I only have two lead screws at hands atm, need to order and wait for one more to arrive to test the three point concept.. ) One should also remember, many printers do just fine with completely cantilevered beds, bearings exist for a reason

mmmm rumble, grumble mumble - look up what the_digital_dentist did. and see the discussion arouuund... mmm... page 6 to 7 of the Fusebox forum. yeahh it _can_ be done, there are printers that have done it... then you do the "digital_dentist" test which is to try to pull a part off a heated printbed hard, whilst it's still cooling down, and you can *see* how much the bed goes "bend, bend, flex"... and you go... "ah. damn"

Of course a cantilevered bed will flex if you pull/hit/bend it. The thing is, you will not do that while printing. Sure, some dynamic effects can be transferred from moving the printhead, but for smaller beds it sure works.

Quote

see the double-level of extrusion all the way round? like that, only both layers level, and with corner-brackets on the inside on both levels, too. that would do the trick. i did see one where someone filled both levels with plywood - even hardboard would do the trick, you want to stop the rhombussing-effect of both bottom levels. hardboard's a low-cost way to do it.

I understand what you mean, I know my latest design will be less structurally rigid. However, I will test if it really affects print quality.. I have now put it together (tapping all holes and aligning everything once again was freakin boring!!) and it really is not very flexible when I am pulling the front cornes apart. I will also put panels on its sides and the lower front part. Would it be more rigid if I put the front bar at the top? Of course. Do I like the open design of it as is now? Yes.

The new belt path seems to work fine!

|

Re: New printer build! My CoreXY. May 22, 2016 06:44PM |

Registered: 8 years ago Posts: 776 |

Quote

robkar

Look at the CAD screenshot of the (pretty stupid) Z-axis concept. Imagine the motor rotates clockwise, follow the belt and look at how the three screws will rotate.

i got it. you went over to the 2 front ones using the inner side of the belt then used the back side of the belt (turning it through 180) which yeah, as they say on mythbusters, "there's yer praaablummm"

yeah try just a single loop round all 3 and put the z-motor offset byy... mmm.... 50mm to the side of and 20mm behind the single lead screw. or so. whatever it is, you want large GT2-50t gears that will "grip" the belt fine even though you end up with only something like 40 degrees of contact on it at the single centre lead screw.

yeah try just a single loop round all 3 and put the z-motor offset byy... mmm.... 50mm to the side of and 20mm behind the single lead screw. or so. whatever it is, you want large GT2-50t gears that will "grip" the belt fine even though you end up with only something like 40 degrees of contact on it at the single centre lead screw.i'm kinda jealous of how well-presented your printer is..

|

Re: New printer build! My CoreXY. May 23, 2016 01:13PM |

Registered: 10 years ago Posts: 651 |

Perfect, what you've built is exactly what I have in the drawings for my machine, as far as the CoreXY part goes (mostly), I actually had a question about the linear rail for the X, as the carriage gets towards the middle, does the weight flex it down at all? Looks like you've got a supporting piece of metal that the X rail connects to, and that connects to the Y linear blocks. In the scenario that say one of the linear blocks moved slightly while one remained stationary, would you expect that metal and rail assembly to flex at all?

Edited 1 time(s). Last edit at 05/23/2016 01:14PM by FA-MAS.

|

Re: New printer build! My CoreXY. May 23, 2016 01:48PM |

Registered: 11 years ago Posts: 5,780 |

You've given up a lot of rigidity in the frame by eliminating the top front frame member. I would put it back in there and add a Zmax switch, then use the custom gcode in slic3r to send the bed to Zmax when a print is finished. It will leave the bed at the bottom of the machine where you can easily remove the print and will leave the extruder wide open for cleaning, etc. The frame member at top front will also make the printer easier to enclose, should the urge strike you. It is also a convenient place to mount lamps to illuminate the print.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: New printer build! My CoreXY. May 23, 2016 04:39PM |

Registered: 8 years ago Posts: 24 |

Quote

FA-MAS

Perfect, what you've built is exactly what I have in the drawings for my machine, as far as the CoreXY part goes (mostly), I actually had a question about the linear rail for the X, as the carriage gets towards the middle, does the weight flex it down at all?

I haven't really done proper measurements of deflection yet, but I really do not believe it will be a problem. I have used a 400 mm MGN12 rail for the X, it should be stiff enough. I believe the dynamic forces (from acceleration and deceleration) in Y are bigger than the by gravity imposed static force in Z. This is also why I put my X rail as I did (widest side in Y direction), opposed to having the carriage facing forward. Had serious problems deciding this, but I am happy with how it turned out.

Quote

Looks like you've got a supporting piece of metal that the X rail connects to, and that connects to the Y linear blocks. In the scenario that say one of the linear blocks moved slightly while one remained stationary, would you expect that metal and rail assembly to flex at all?

Nah, the rail or metal part will not flex in that direction. If anything, possible slop in the linear bearings themselves will let the X-carriage rotate around Z. But, this is maybe the main reason we are using coreXY kinematics, the forces act very beneficially on the carriage, there will be almost no twisting force.

The aluminum bar I put there for two reasons:

1) Ease of assembly. It is just a convenient way of mounting the x-rail in between the Y carriages.

2) It keeps the Y carriages on a fixed distance apart. The bar is very stiff it its horizontal direction (cannot be "compressed"). One have to be sure to mount the Y rails parallell though.

It is possible to not use the metal bar in between and just connect the X-rail and Y-carriages with plastic parts, but it might not be as rigid as this. I plan to design such a part later on, so that if anyone want to build this printer, there are no custom machined parts in it.

Good luck with your build!

|

Re: New printer build! My CoreXY. May 23, 2016 04:58PM |

Registered: 8 years ago Posts: 24 |

Quote

the_digital_dentist

You've given up a lot of rigidity in the frame by eliminating the top front frame member. I would put it back in there and add a Zmax switch, then use the custom gcode in slic3r to send the bed to Zmax when a print is finished. It will leave the bed at the bottom of the machine where you can easily remove the print and will leave the extruder wide open for cleaning, etc. The frame member at top front will also make the printer easier to enclose, should the urge strike you. It is also a convenient place to mount lamps to illuminate the print.

As I said before, I am aware of that. Both the rigidity part, and the enclosure aspect. As I also wrote before, it is extremely easy to mount the bar there IF I later on would like to, I have one spare that is already tapped and prepared. Just to prove my point I made a video for you guys:

link to video

Did some tests yesterday where I moved the printhead to max Y (close to the "open" edge of the frame), then went back and forth in full X range while increasing speed. I also repeated this test with different acceleration settings. Very pleased with how it looked, I couldn't FEEL any worrying wobble in the frame. But then I also think it is pretty difficult to draw any conclusions when there is no printing going on, no print artifacts to look at.

I will repeat (and make a video of) this test when I am ready to print (some work left on the build plate). For me this is so much more relevant than pulling the frame apart. I deadlift 200+kg, I am sure I could flex the frame if that would give me anything

It is though a good idea to cross the limits in terms of testing printing/travelling speed, e.g. by running it up until around 2x or 1.5x the wanted traveling speeds and accelerations in order to see what it can take.

Edited 2 time(s). Last edit at 05/23/2016 05:22PM by robkar.

|

Re: New printer build! My CoreXY. May 23, 2016 05:38PM |

Registered: 8 years ago Posts: 776 |

Quote

Looks like you've got a supporting piece of metal that the X rail connects to, and that connects to the Y linear blocks. In the scenario that say one of the linear blocks moved slightly while one remained stationary, would you expect that metal and rail assembly to flex at all?

Nah, the rail or metal part will not flex in that direction. If anything, possible slop in the linear bearings themselves will let the X-carriage rotate around Z. But, this is maybe the main reason we are using coreXY kinematics, the forces act very beneficially on the carriage, there will be almost no twisting force.

[/quote]

rrright, that's not actually true - it's true under "perfect" mechanical conditions.. it's true for the belts and for the x-assembly *if* they are perfectly stiff, perfectly perpendicular, and *if* the tension on both belts is *exactly* the same.

however, unless you get each belt lined up perfectly on each side (i.e. inline), then what happens is that you end up with twisting force. if you look for example at the Fusebox from above, the belts are alternately-offset, so there are two lines, where belt 1 LEFT is offset to the front and matches with belt 2 on the RIGHT side at the front, and belt 2 on the LEFT is offset to the BACK matches (lines up) with belt 1 on the RIGHT again at the back.

what _that_ means is that when the acceleration on belt1 is different from the acceleration on belt 2, you *WILL* get a rotational force of the carriage, which results in a torsional load on the linear bearings.

looking at the belt arrangement that you have, you also have the same arrangement: belt1 comes in on the front left, and goes all the way round to go to BACK right, and belt2 goes front right and comes in BACK left.

the worst case scenario for this situation is then where you get maximum acceleration on one belt alone, which iis.... thinking about iit... a 45 degree move.

now, the way to fix this is to make sure of two things:

- that the places where the belt is fixed are all - and i mean all four places - directly lined up on the same X line

- that the location where they are fixed is on the centre of gravity of the carriage

unfortunately that means adding a counterweight or perhaps having two rails and leaving the space free between them to put the hotend, or have the hotend slung underneath a single rail.

... but there is a second corollary: to have the belts line up on the same X line, you need them to be offset, one above the other.

|

Re: New printer build! My CoreXY. May 23, 2016 05:40PM |

Registered: 8 years ago Posts: 776 |

Quote

robkar

As I said before, I am aware of that. Both the rigidity part, and the enclosure aspect. As I also wrote before, it is extremely easy to mount the bar there IF I later on would like to, I have one spare that is already tapped and prepared. Just to prove my point I made a video for you guys:

link to video

aw great, you did that "drill holes through the extrusion and use the centre tap hole" trick, _great_ - people who recommend it say that it's amazingly effective. i would say you don't need the corner brackets, but 2 one at each end like you have there would stop the bar from rotating. good job, robkar

|

Re: New printer build! My CoreXY. May 24, 2016 01:23PM |

Registered: 8 years ago Posts: 24 |

Quote

asbo

The stuff Mutley sells is called PrintBite and works better than PEI.Quote

lkcl

is that from mutley3d.com?

I had planned to buy a PEI sheet for the bed, but now I actually bought a piece of this Printbite instead. I hope it is good! Since I am using dc42s ir sensor it is also convienient that the Printbite is black and do not need any painting, unlike PEI. In terms of price the difference was not that big either, at least not for a rectangular sheet. PEI is probably cheaper, but I couldn't find any good prices for shipping it to Sweden..

|

Re: New printer build! My CoreXY. May 27, 2016 09:16AM |

Registered: 8 years ago Posts: 93 |

My PrintBite isn't black, it's a sort of yellow beige colour, not that it matters since dc42s IR sensor works perfectly on itQuote

robkar

Quote

asbo

The stuff Mutley sells is called PrintBite and works better than PEI.Quote

lkcl

is that from mutley3d.com?

I had planned to buy a PEI sheet for the bed, but now I actually bought a piece of this Printbite instead. I hope it is good! Since I am using dc42s ir sensor it is also convienient that the Printbite is black and do not need any painting, unlike PEI. In terms of price the difference was not that big either, at least not for a rectangular sheet. PEI is probably cheaper, but I couldn't find any good prices for shipping it to Sweden..

So far everything I've tried on the PrintBite just works, but I know Mutley gives really good customer support if you have any problems.

|

Re: New printer build! My CoreXY. May 27, 2016 05:14PM |

Registered: 8 years ago Posts: 24 |

Quote

asbo

My PrintBite isn't black, it's a sort of yellow beige colour, not that it matters since dc42s IR sensor works perfectly on itQuote

robkar

Quote

asbo

The stuff Mutley sells is called PrintBite and works better than PEI.Quote

lkcl

is that from mutley3d.com?

I had planned to buy a PEI sheet for the bed, but now I actually bought a piece of this Printbite instead. I hope it is good! Since I am using dc42s ir sensor it is also convienient that the Printbite is black and do not need any painting, unlike PEI. In terms of price the difference was not that big either, at least not for a rectangular sheet. PEI is probably cheaper, but I couldn't find any good prices for shipping it to Sweden..

So far everything I've tried on the PrintBite just works, but I know Mutley gives really good customer support if you have any problems.

I don't really know why I thought it would be black, all pictures clearly show this yellowish thing

Good to hear it works for you, looking forward to trying it out!

Good to hear it works for you, looking forward to trying it out!

|

Re: New printer build! My CoreXY. May 27, 2016 05:45PM |

Registered: 10 years ago Posts: 14,672 |

PrintBite is sufficiently opaque to IR to work well with my IR sensor as it comes. PEI is transparent to IR, which is why I recommend painting the reverse side black before sticking it down.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: New printer build! My CoreXY. July 19, 2017 10:45PM |

Registered: 7 years ago Posts: 34 |

Sorry, only registered users may post in this forum.