E3D's tool changing CoreXY design

Posted by dc42

|

E3D's tool changing CoreXY design March 21, 2018 02:34PM |

Registered: 10 years ago Posts: 14,672 |

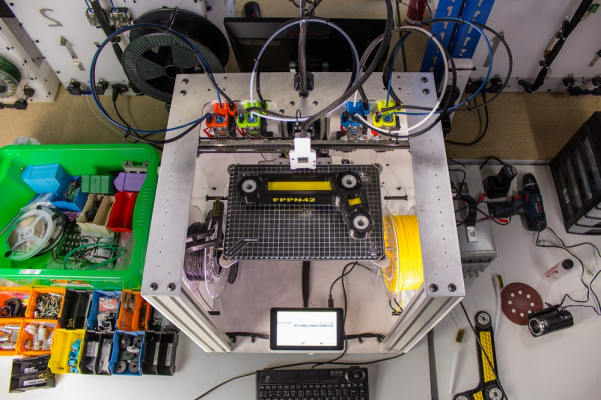

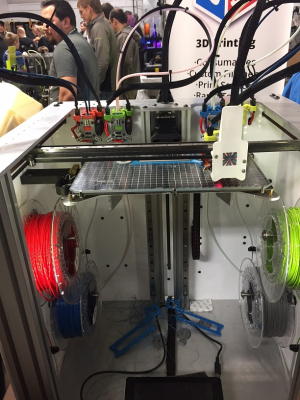

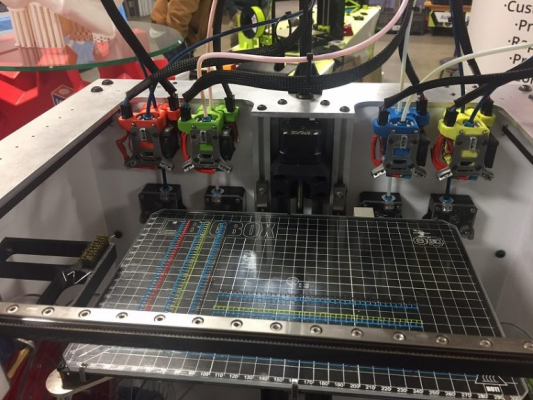

E3D has released some information about their CoreXY motion system with a 4-head tool changer at [e3d-online.com]. They are asking for expressions of interest + deposits from anyone interested in buying the kit of parts.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3D's tool changing CoreXY design March 21, 2018 07:24PM |

Registered: 12 years ago Posts: 19 |

|

Re: E3D's tool changing CoreXY design March 21, 2018 10:56PM |

Registered: 7 years ago Posts: 249 |

Looks pretty sweet!

Makes me sad to have spent so much time on CoreXYU

No reference to the final price, so making a deposit is questionable.

Perhaps the firmware will be open source so I can convert my CoreXYU to a tool changer?

Sounds like maybe the tidbits will be offered seperately instead of a complete kit...

Yea, I'd have to ditch the RADDS/Due for a Duet, but hey, be worth it.

Makes me sad to have spent so much time on CoreXYU

No reference to the final price, so making a deposit is questionable.

Perhaps the firmware will be open source so I can convert my CoreXYU to a tool changer?

Sounds like maybe the tidbits will be offered seperately instead of a complete kit...

Yea, I'd have to ditch the RADDS/Due for a Duet, but hey, be worth it.

|

Re: E3D's tool changing CoreXY design March 21, 2018 11:47PM |

Registered: 6 years ago Posts: 207 |

|

Re: E3D's tool changing CoreXY design March 22, 2018 03:22AM |

Registered: 10 years ago Posts: 14,672 |

Quote

prot0typ1cal

Looks pretty sweet!

Makes me sad to have spent so much time on CoreXYU

No reference to the final price, so making a deposit is questionable.

Perhaps the firmware will be open source so I can convert my CoreXYU to a tool changer?

Sounds like maybe the tidbits will be offered seperately instead of a complete kit...

Yea, I'd have to ditch the RADDS/Due for a Duet, but hey, be worth it.

They blog entry mentions a likely final price of £1000-£2000, also that if it turns out to be too much for you then they will give you back your deposit.

The firmware is RepRapFirmware so it is definitely open source. AFAIK they are using the standard build of RRF, with commands in the tool change macro files to load and unload the tools.

Edited 1 time(s). Last edit at 03/22/2018 03:23AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3D's tool changing CoreXY design March 22, 2018 05:49AM |

Registered: 6 years ago Posts: 68 |

Who can remember the name of the 3d printer what was build very similar way? There was even enclosure and it was all black. Front profiles was rounded from outside corner and it was very neat looking...

Shamefully people did not buy enough of those and it was never on production... It was open source... I´m sure that E3D have enough name to get that thing going, hopefully learned from bigbox case...

Bed structure seems a little bit weak, but could be enough for small bed like that, and I´dont like cantilevered idlers neither. But I haven´t build any corexy things so cant say for sure...(I´m about to build)

Shamefully people did not buy enough of those and it was never on production... It was open source... I´m sure that E3D have enough name to get that thing going, hopefully learned from bigbox case...

Bed structure seems a little bit weak, but could be enough for small bed like that, and I´dont like cantilevered idlers neither. But I haven´t build any corexy things so cant say for sure...(I´m about to build)

|

Re: E3D's tool changing CoreXY design March 22, 2018 09:42AM |

Registered: 11 years ago Posts: 5,780 |

I can't understand why anyone is still designing printers that use 4 screws to level the bed.

Yeah, I know- autoleveling.

If no effort is made to make the bed flat and level, when the autoleveling fails you're not going to print. A bed that size can easily be made flat and level and you can still use autoleveling if you feel you must have it, but you'll still be able to print when the autoleveling fails.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Yeah, I know- autoleveling.

If no effort is made to make the bed flat and level, when the autoleveling fails you're not going to print. A bed that size can easily be made flat and level and you can still use autoleveling if you feel you must have it, but you'll still be able to print when the autoleveling fails.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: E3D's tool changing CoreXY design March 22, 2018 10:20AM |

Registered: 6 years ago Posts: 68 |

|

Re: E3D's tool changing CoreXY design March 23, 2018 12:44AM |

Registered: 10 years ago Posts: 18 |

I've seen the approach E3D have used before a few times. This one by #rolmie on YouTube looks very similar (appart from Maxwell Kinematic Coupling). But what I like about his work is his entry in this years Hackaday contest which uses a camera to auto align the multiple nozzles.

Let's hope E£D keep their version open source.

Edited 1 time(s). Last edit at 03/23/2018 01:06AM by Quazzer.

Let's hope E£D keep their version open source.

Edited 1 time(s). Last edit at 03/23/2018 01:06AM by Quazzer.

|

Re: E3D's tool changing CoreXY design March 23, 2018 06:53PM |

Registered: 8 years ago Posts: 601 |

Quote

the_digital_dentist

I can't understand why anyone is still designing printers that use 4 screws to level the bed.

Yeah, I know- autoleveling.

If no effort is made to make the bed flat and level, when the autoleveling fails you're not going to print. A bed that size can easily be made flat and level and you can still use autoleveling if you feel you must have it, but you'll still be able to print when the autoleveling fails.

I can't understand it either... I was one of the beta testers for E3Ds heated beds and they have put alot of thought into it to such as varied track sizes to remove hot spots, large connectors and wiring but still a pcb heater with 4 screws.. The one I tested also had no mounting holes for a 3 screw layout.

I gave quite a bit of feedback on this point but they don't seem to have implemented it.

|

Re: E3D's tool changing CoreXY design March 24, 2018 01:41AM |

Registered: 11 years ago Posts: 469 |

Interesting that they have stuck with BL touch despite the Duet controller. I've had nothing but great experiences with DC's IR probes..

This, assuming its relatively affordable, could be a game changer and get rid of those extremely time consuming and wasteful purge structures.... I'm in

This, assuming its relatively affordable, could be a game changer and get rid of those extremely time consuming and wasteful purge structures.... I'm in

|

Re: E3D's tool changing CoreXY design March 24, 2018 07:46AM |

Registered: 9 years ago Posts: 330 |

What happens to the other tools when you are not printing with them? I assume the heating mechanism is embedded in the tool heads, so they are going to be kept at the same temperature (or slightly cooler), so that when you pick up one tool, it is ready to print. However, this still doesn't solve the problem of oozing in the parked tool, so similar to IDEX machines, you'll need a way to block the nozzle when it is parked and still need a small tower to prime the nozzle when it is picked up.

|

Re: E3D's tool changing CoreXY design March 24, 2018 08:12AM |

Registered: 11 years ago Posts: 5,780 |

I would assume (and I may be wrong) that the plastic oozing out of the nozzle when it sits idle but hot is due to plastic just above the normal melt zone in the hot-end melting as heat creeps up the filament. As the plastic heats it expands and pushes molten filament out the nozzle. If you block the nozzle, the molten filament is going to have to go somewhere, so it's going to go up instead of down and out. I'm not sure that's a good thing to do. Maybe it's better to let it drool and wipe the drool off when the machine picks up the tool...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: E3D's tool changing CoreXY design March 24, 2018 09:24AM |

Registered: 10 years ago Posts: 14,672 |

Quote

the_digital_dentist

I would assume (and I may be wrong) that the plastic oozing out of the nozzle when it sits idle but hot is due to plastic just above the normal melt zone in the hot-end melting as heat creeps up the filament. As the plastic heats it expands and pushes molten filament out the nozzle. If you block the nozzle, the molten filament is going to have to go somewhere, so it's going to go up instead of down and out. I'm not sure that's a good thing to do. Maybe it's better to let it drool and wipe the drool off when the machine picks up the tool...

I think the main reason for oozing is residual pressure in the Bowden tube pushing the filament out. If I am right, the amount of oozing should be much less with direct drive extruders; but I don't have any of those to compare with.

It's normal to reduce the temperature of idle tools to somewhat below normal printing temperature, e.g. 150C for PLA. This will cause the already-molten filament to contract.

If you are right and the filament does expand significantly overall, then my expectation would be that the amount of expansion is going to be small and with the nozzle blocked it will push the filament a tiny amount up the heat break, not far enough or quickly enough to cause a filament jam. In Bowden systems (which they are mostly using), there is plenty of slack in the Bowden tube to handle the expansion. In direct drive extruders there will be less; but if necessary the extruder motor current could be reduced for idle tools in order to relax the pressure.

Like you I am surprised they went for 4 bed levelling screws. However, they are using a PCB bed heater, which isn't as rigid as cast aluminium. Maybe it is sufficiently flexible that 4 screws are better than 3 in this case. Personally I would choose cast aluminium and a silicone heater, with either 3 levelling screws or 3 independently-driven leadscrews instead of the single leadscrew cantilever design.

I have one on order, so I'll be able to see how well it works when it is delivered, assuming they have enough interest to go ahead with manufacture.

Edited 2 time(s). Last edit at 03/24/2018 09:27AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3D's tool changing CoreXY design March 24, 2018 12:54PM |

Registered: 7 years ago Posts: 128 |

Couldn't you just retract the filament beyond the heater and then after a tool change just pre-feed some material? doesn't seem like a big deal to me but maybe I'm over simplifying.

A tool change doesn't have to be fast it just has to be accurate.

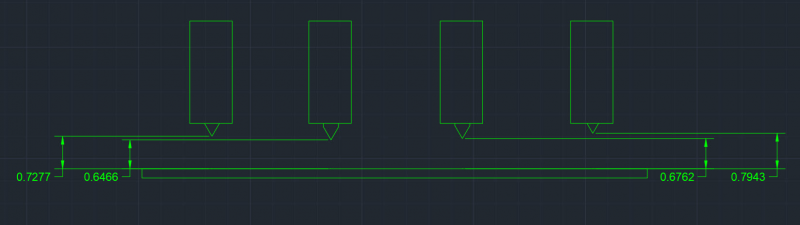

I was thinking about the tool change concept and the accuracy after a tool change, not necessarily about the mount itself but the tool tip to the bed. How are each of those tool heads going to be setup exactly the same... I don't think it can happen.

On my CNC when a tool change is needed it has to use a "touch off" to account for the difference in tool height.

I wonder how that is being accomplished? I might be answering my own question but possibly each unit has a BL Touch?

I'm currently re-designing my CoreXY and I really like the XY axis design on an aluminum plate, gonna borrow that design.

ampapa,

A tool change doesn't have to be fast it just has to be accurate.

I was thinking about the tool change concept and the accuracy after a tool change, not necessarily about the mount itself but the tool tip to the bed. How are each of those tool heads going to be setup exactly the same... I don't think it can happen.

On my CNC when a tool change is needed it has to use a "touch off" to account for the difference in tool height.

I wonder how that is being accomplished? I might be answering my own question but possibly each unit has a BL Touch?

I'm currently re-designing my CoreXY and I really like the XY axis design on an aluminum plate, gonna borrow that design.

ampapa,

|

Re: E3D's tool changing CoreXY design March 24, 2018 05:41PM |

Registered: 11 years ago Posts: 335 |

I'm not a huge fan of toolchanging because it is such a large and complex feature, which reduces the number of options you have in terms of heating the build chamber, layer cooling, wire management, etc... Its also expensive enough that IDX or actuated hot-ends look competitive for two nozzles, which is often enough (especially if you have a bowden splitter).

Direct drive extruders still ooze quite a bit, but you can build a wipe tower or purge into a bin. I've been under the impression that the plastic slowly off-gases or decomposes at >~160c because the extruder will continue to ooze even if you drop the temperature 10-20c.

Direct drive extruders still ooze quite a bit, but you can build a wipe tower or purge into a bin. I've been under the impression that the plastic slowly off-gases or decomposes at >~160c because the extruder will continue to ooze even if you drop the temperature 10-20c.

|

Re: E3D's tool changing CoreXY design March 24, 2018 10:25PM |

Registered: 11 years ago Posts: 469 |

The alu base plate sold me too !!Quote

ampapa

Couldn't you just retract the filament beyond the heater and then after a tool change just pre-feed some material? doesn't seem like a big deal to me but maybe I'm over simplifying.

A tool change doesn't have to be fast it just has to be accurate.

I was thinking about the tool change concept and the accuracy after a tool change, not necessarily about the mount itself but the tool tip to the bed. How are each of those tool heads going to be setup exactly the same... I don't think it can happen.

On my CNC when a tool change is needed it has to use a "touch off" to account for the difference in tool height.

I wonder how that is being accomplished? I might be answering my own question but possibly each unit has a BL Touch?

I'm currently re-designing my CoreXY and I really like the XY axis design on an aluminum plate, gonna borrow that design.

ampapa,

I doubt each unit will have a Z sensor . I'm guessing each will have its own "Z offset" predetermined in a calibration routine.

Inevitably there will have to be some form of purge / wipe routine Having that take place "in" the model as part of the infil might work but creating a slicer that can do that would be a headache.

Either way im looking forward to seeing this develop

Ive been looking for a project worthy of getting to grips with some Odrive servos and this might be it !

Edited 1 time(s). Last edit at 03/24/2018 11:35PM by bigfilsing.

|

Re: E3D's tool changing CoreXY design March 25, 2018 05:14AM |

Registered: 10 years ago Posts: 14,672 |

Quote

ampapa

Couldn't you just retract the filament beyond the heater and then after a tool change just pre-feed some material? doesn't seem like a big deal to me but maybe I'm over simplifying.

That's what I do on my dual nozzle Ormerod, which has a PTFE lined hot end. But the all metal E3Dv6 isn't tolerant of such large retractions.

Quote

ampapa

I was thinking about the tool change concept and the accuracy after a tool change, not necessarily about the mount itself but the tool tip to the bed. How are each of those tool heads going to be setup exactly the same... I don't think it can happen.

They don't need to be set up the same because you can configure the offets of each tool in firmware using G10.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3D's tool changing CoreXY design March 25, 2018 08:14AM |

Registered: 7 years ago Posts: 128 |

@bigfilsing @DC42, I get the offset settings but I'm still not sure that will solve the problem.

Maybe I'm misunderstanding how the tool change works but it looks like they each have a home on the back plate held in place magnetically and on homing rods. Each tool I assume has its own heater, hot end and fan. So, essentially they are identical in configuration but when you change from one tool to another it's not possible that they are all the same length and therefore the tip to bed measurement will be different, offset or not, at some point the offset has to be measured against the bed to be useable, isn't that correct?

ampapa,

Maybe I'm misunderstanding how the tool change works but it looks like they each have a home on the back plate held in place magnetically and on homing rods. Each tool I assume has its own heater, hot end and fan. So, essentially they are identical in configuration but when you change from one tool to another it's not possible that they are all the same length and therefore the tip to bed measurement will be different, offset or not, at some point the offset has to be measured against the bed to be useable, isn't that correct?

ampapa,

|

Re: E3D's tool changing CoreXY design March 25, 2018 08:29AM |

Registered: 8 years ago Posts: 312 |

The grabbing mechanism looks to me as very secure and positionally defined. It really does look tight. Also like the fact that once engaged, no more power is needed. But I think I would like to use something similar on the tool storage rack, to strip the tool off of the print head and not simply rely on magnets to pull it off and keep it stored.

I cannot help but wonder what they mean with the open standard, how much of it will be defined and how much it will be, use as you will.

For instance, I would like to use it upside down. And how much input from others they will accept and invite.

Also, I would love to know more about the actual size and how much space the servo takes up. Time to send an email I guess.

They did implement a little dump bucket and a cleaning brush for the nozzle, that is good. Also, they do talk about ram-purge, but have not found a lot of details on that. (didn't really look al that hard, seemed self-evident) So to me, it is clear they are thinking about ooze and how to handle hot ends that are not in use.

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

I cannot help but wonder what they mean with the open standard, how much of it will be defined and how much it will be, use as you will.

For instance, I would like to use it upside down. And how much input from others they will accept and invite.

Also, I would love to know more about the actual size and how much space the servo takes up. Time to send an email I guess.

They did implement a little dump bucket and a cleaning brush for the nozzle, that is good. Also, they do talk about ram-purge, but have not found a lot of details on that. (didn't really look al that hard, seemed self-evident) So to me, it is clear they are thinking about ooze and how to handle hot ends that are not in use.

Lykle

________________________________________________

Co-creator of the Zesty Nimble, worlds lightest Direct Drive extruder.

[zesty.tech]

|

Re: E3D's tool changing CoreXY design March 25, 2018 08:52AM |

Registered: 10 years ago Posts: 14,672 |

Quote

ampapa

@bigfilsing @DC42, I get the offset settings but I'm still not sure that will solve the problem.

Maybe I'm misunderstanding how the tool change works but it looks like they each have a home on the back plate held in place magnetically and on homing rods. Each tool I assume has its own heater, hot end and fan. So, essentially they are identical in configuration but when you change from one tool to another it's not possible that they are all the same length and therefore the tip to bed measurement will be different, offset or not, at some point the offset has to be measured against the bed to be useable, isn't that correct?

You can configure a Z offset for each tool as well as XY offsets.

Edited 1 time(s). Last edit at 03/25/2018 08:52AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: E3D's tool changing CoreXY design March 25, 2018 08:57AM |

Registered: 11 years ago Posts: 5,780 |

Quote

dc42

I think the main reason for oozing is residual pressure in the Bowden tube pushing the filament out. If I am right, the amount of oozing should be much less with direct drive extruders; but I don't have any of those to compare with.

It's normal to reduce the temperature of idle tools to somewhat below normal printing temperature, e.g. 150C for PLA. This will cause the already-molten filament to contract.

If you are right and the filament does expand significantly overall, then my expectation would be that the amount of expansion is going to be small and with the nozzle blocked it will push the filament a tiny amount up the heat break, not far enough or quickly enough to cause a filament jam. In Bowden systems (which they are mostly using), there is plenty of slack in the Bowden tube to handle the expansion. In direct drive extruders there will be less; but if necessary the extruder motor current could be reduced for idle tools in order to relax the pressure.

Like you I am surprised they went for 4 bed levelling screws. However, they are using a PCB bed heater, which isn't as rigid as cast aluminium. Maybe it is sufficiently flexible that 4 screws are better than 3 in this case. Personally I would choose cast aluminium and a silicone heater, with either 3 levelling screws or 3 independently-driven leadscrews instead of the single leadscrew cantilever design.

I've seen a lot of oozing/drooling in direct drive extruders. Interestingly, there seems to be less with large nozzle diameters than small ones, and I'm not just talking length. The 0.8 mm nozzle I was using on a volcano heater block didn't drool at all, and in fact seemed to do the opposite- as if the surface tension of the molten filament was pulling the filament back up into the nozzle instead of pushing or letting it drip out. I was having problems with gaps at the start of lines/layers that I haven't gone back to sort out yet.

Someone on another forum suggested they may have just used a bed assembly from an older machine to get up and running with the new tool changer as quickly as possible.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: E3D's tool changing CoreXY design March 25, 2018 09:02AM |

Registered: 8 years ago Posts: 622 |

Quote

motley

It looks amazing - not just the tool changing but the motion system as well.

I'm in the queue...

Yes the motion system got me all excited to start with, but on further reading and as far as I can tell, it's just CoreXY with stacked belts (unless I missed something).

[somei3deas.wordpress.com]

[www.youtube.com]

|

Re: E3D's tool changing CoreXY design March 25, 2018 09:15AM |

Registered: 8 years ago Posts: 622 |

Quote

the_digital_dentist

I can't understand why anyone is still designing printers that use 4 screws to level the bed.

Yeah, I know- autoleveling.

If no effort is made to make the bed flat and level, when the autoleveling fails you're not going to print. A bed that size can easily be made flat and level and you can still use autoleveling if you feel you must have it, but you'll still be able to print when the autoleveling fails.

Totally agree. It really isn't difficult or costly to build a printer with an inherently flat bed that can be levelled once during commissioning and thereafter stays level. An aluminium tooling plate with a single motor driving 3 screws via a continuous belt. How complicated is that?

[somei3deas.wordpress.com]

[www.youtube.com]

|

Re: E3D's tool changing CoreXY design March 27, 2018 01:35PM |

Registered: 7 years ago Posts: 18 |

|

Re: E3D's tool changing CoreXY design April 02, 2018 09:01PM |

Registered: 9 years ago Posts: 31 |

I've been pondering ways to make the kinematic coupling more DIY-able. Perhaps three parallel pairs of drill rod embedded in a printed part could take the place of the v-grooves, with a similar setup for 3 ball bearings on the mating surface. It seems like alignment isn't as important as repeatability and consistency in this application.

The locking mechanism is another problem unto itself...

The locking mechanism is another problem unto itself...

|

Re: E3D's tool changing CoreXY design April 06, 2018 01:48AM |

Registered: 6 years ago Posts: 134 |

|

Re: E3D's tool changing CoreXY design April 07, 2018 08:30AM |

Registered: 7 years ago Posts: 128 |

Sorry, only registered users may post in this forum.