Which Kit? Railcore? SecKit? Other?

Posted by Doppler9000

|

Which Kit? Railcore? SecKit? Other? March 06, 2020 04:46PM |

Registered: 4 years ago Posts: 17 |

Because I am not now in a position to build from scratch, I posed a question about a commercial corexy that could be improved. I was thinking along the lines of the Ender 3, where for not a lot of money, but a fair amount of time, people get a pretty good machine. I hadn't appreciated that there was such room for poor implementation of the corexy concept.

I wonder about a kit as the better high-value approach.

The SecKit seems pretty good, as does the Railcore, but I have not yet developed the intuition to critique different designs, so I am asking the experts here.

I wonder, too, what tends to become the binding constraint on higher print speeds.

Presumably, at the limit, the properties of the melted filament become the constraint?

Below that, does a smaller machine have a practical speed (mass) advantage over a larger, otherwise identical machine?

What would the speed profile curve look like as you scale up in 3 dimensions?

TIA

I wonder about a kit as the better high-value approach.

The SecKit seems pretty good, as does the Railcore, but I have not yet developed the intuition to critique different designs, so I am asking the experts here.

I wonder, too, what tends to become the binding constraint on higher print speeds.

Presumably, at the limit, the properties of the melted filament become the constraint?

Below that, does a smaller machine have a practical speed (mass) advantage over a larger, otherwise identical machine?

What would the speed profile curve look like as you scale up in 3 dimensions?

TIA

|

Re: Which Kit? Railcore? SecKit? Other? March 06, 2020 05:55PM |

Registered: 11 years ago Posts: 5,780 |

As near as I can tell, the SecKit is primarily a copy of my UMMD printer, so it should be pretty good if the guy paid attention to detail and used quality linear guides.

A lot of people go nutz trying to minimize moving mass so they can print as fast as possible, but in the end, moving the extruder around, even if it isn't super light, isn't the biggest problem. You have correctly surmised that the primary speed limitation in FDM printing is the extrusion. It isn't that you can't extrude quickly- that's the easy part. Extruding in a controlled way, as speed and direction change, is the problem. The Duet controller board running RepRapFirmware has some nice features for tuning nonlinearities in the extrusion.

One of the ways people try to minimize moving mass is to use a Bowden tube extruder so only the hot-end is mounted on the carriage. You can't print flexible material with a Bowden tube extruder. I find flexible material very useful, so I couldn't live with a Bowden tube set up. You may have other ideas.

Here's mine running at 200 mm/sec with acceleration set to 10k (yes, 10k), back when it still had a smoothieboard controller and a completely different extruder/carriage. The X axis+extruder carriage weighs about 1.5 kg. : [vimeo.com]

I don't run it that way normally. I typically have acceleration set to 2k, and print at 80 mm/sec or so to ensure high quality prints.

I'm generally not in a big hurry when I print, so I start the printer up at night before I go to bed. It doesn't really matter if the print takes 2 hours or 6 hours (or 20 hours or 60 hours). It's all the same to me.

I'm not a big fan of the Railcore design. Too many printed parts that extend beyond the frame, making it hard to enclose. The motor mounts look flexible, the pulley mounts don't look very good either. Standing a post with two pulleys up in a piece of printed plastic and putting tension on the belts is likely to cause the plastic to flex and tilt the post. I'm also not a fan of using multiple Z axis motors. They get out of sync when you cycle power and that tilts the bed so you have to have some sort of scheme to relevel the bed frequently. It looks like the design could easily be modified to use a single Z axis motor. It's hard to be sure from the CAD model that doesn't show the belts, but it looks like the A and G belt segments will not be parallel to the Y axis guide rails.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

A lot of people go nutz trying to minimize moving mass so they can print as fast as possible, but in the end, moving the extruder around, even if it isn't super light, isn't the biggest problem. You have correctly surmised that the primary speed limitation in FDM printing is the extrusion. It isn't that you can't extrude quickly- that's the easy part. Extruding in a controlled way, as speed and direction change, is the problem. The Duet controller board running RepRapFirmware has some nice features for tuning nonlinearities in the extrusion.

One of the ways people try to minimize moving mass is to use a Bowden tube extruder so only the hot-end is mounted on the carriage. You can't print flexible material with a Bowden tube extruder. I find flexible material very useful, so I couldn't live with a Bowden tube set up. You may have other ideas.

Here's mine running at 200 mm/sec with acceleration set to 10k (yes, 10k), back when it still had a smoothieboard controller and a completely different extruder/carriage. The X axis+extruder carriage weighs about 1.5 kg. : [vimeo.com]

I don't run it that way normally. I typically have acceleration set to 2k, and print at 80 mm/sec or so to ensure high quality prints.

I'm generally not in a big hurry when I print, so I start the printer up at night before I go to bed. It doesn't really matter if the print takes 2 hours or 6 hours (or 20 hours or 60 hours). It's all the same to me.

I'm not a big fan of the Railcore design. Too many printed parts that extend beyond the frame, making it hard to enclose. The motor mounts look flexible, the pulley mounts don't look very good either. Standing a post with two pulleys up in a piece of printed plastic and putting tension on the belts is likely to cause the plastic to flex and tilt the post. I'm also not a fan of using multiple Z axis motors. They get out of sync when you cycle power and that tilts the bed so you have to have some sort of scheme to relevel the bed frequently. It looks like the design could easily be modified to use a single Z axis motor. It's hard to be sure from the CAD model that doesn't show the belts, but it looks like the A and G belt segments will not be parallel to the Y axis guide rails.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Which Kit? Railcore? SecKit? Other? March 06, 2020 09:34PM |

Registered: 4 years ago Posts: 17 |

Thanks, Mark.

Plagiarism Is the sincerest form of flattery...

I have been looking at the Zesty Nimble direct extruder with remote motor, at 27 grams.

At “overnight” speeds, does a corexy have inherent advantages over an equal cost cartesian with non-slung bed?

I have more to read, but that is the impression I have, thus far.

Edited 1 time(s). Last edit at 03/06/2020 10:30PM by Doppler9000.

Plagiarism Is the sincerest form of flattery...

I have been looking at the Zesty Nimble direct extruder with remote motor, at 27 grams.

At “overnight” speeds, does a corexy have inherent advantages over an equal cost cartesian with non-slung bed?

I have more to read, but that is the impression I have, thus far.

Edited 1 time(s). Last edit at 03/06/2020 10:30PM by Doppler9000.

|

Re: Which Kit? Railcore? SecKit? Other? March 07, 2020 12:30AM |

Registered: 11 years ago Posts: 5,780 |

I posted a CAD model of UMMD and a lot of information about problems and fixes for them. That's what open source is about. I'm surprised anyone tried to commercialize it because it isn't the cheapest way to build a printer, and cheapness seems to be the main driver of printer sales.

Most of the non corexy cartesian mechanisms move the X axis motor along the Y axis. A lot of people worry about the mass that motor adds, but I'm more concerned about having to run a cable to it. It's bad enough you have to run one to the extruder, but running two multiconductor cables to two moving motors is asking for trouble. I'm sure it can be done reliably if you apply enough effort, but it isn't my preference. My older printer, SoM, uses a flex ribbon cable to take all the signals and power to the extruder carriage. It has been working with 100% reliability for about 6 years now. If I could find a cheap source of that type cable and tools to terminate it I'd probably go into business selling it to 3D printer builders. I hate running cables to moving stuff and finally took the X axis endstop switch off the extruder carriage in SoM.

Back to your question. The short answer is no, I don't think there's any special advantage of corexy over any other cartesian (except maybe H-bot) when it comes to print quality when you're printing at "normal" speeds. Just about any mechanism will work fine. Corexy is pretty easy to build well, once you understand how it works.

I don't think much of the mechanical complication that something like a remote-motor extruder adds. The whole point of moving the motor off the extruder is to reduce moving mass so you can theoretically print faster, but in order to make it work they have to gear it down 20:1 and that may limit extrusion speed which will limit print speed anyway. What is the benefit that justifies the added cost and complication?

The Duet people are working on a design that runs power and a serial wire to the extruder and that's it. It'll have a board on the extruder carriage that drives the motor and controls the heater and fans. That will be a real advance over the multipin cabling and connectors that are needed now.

Edited 1 time(s). Last edit at 03/07/2020 12:33AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Most of the non corexy cartesian mechanisms move the X axis motor along the Y axis. A lot of people worry about the mass that motor adds, but I'm more concerned about having to run a cable to it. It's bad enough you have to run one to the extruder, but running two multiconductor cables to two moving motors is asking for trouble. I'm sure it can be done reliably if you apply enough effort, but it isn't my preference. My older printer, SoM, uses a flex ribbon cable to take all the signals and power to the extruder carriage. It has been working with 100% reliability for about 6 years now. If I could find a cheap source of that type cable and tools to terminate it I'd probably go into business selling it to 3D printer builders. I hate running cables to moving stuff and finally took the X axis endstop switch off the extruder carriage in SoM.

Back to your question. The short answer is no, I don't think there's any special advantage of corexy over any other cartesian (except maybe H-bot) when it comes to print quality when you're printing at "normal" speeds. Just about any mechanism will work fine. Corexy is pretty easy to build well, once you understand how it works.

I don't think much of the mechanical complication that something like a remote-motor extruder adds. The whole point of moving the motor off the extruder is to reduce moving mass so you can theoretically print faster, but in order to make it work they have to gear it down 20:1 and that may limit extrusion speed which will limit print speed anyway. What is the benefit that justifies the added cost and complication?

The Duet people are working on a design that runs power and a serial wire to the extruder and that's it. It'll have a board on the extruder carriage that drives the motor and controls the heater and fans. That will be a real advance over the multipin cabling and connectors that are needed now.

Edited 1 time(s). Last edit at 03/07/2020 12:33AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Which Kit? Railcore? SecKit? Other? March 07, 2020 02:10AM |

Registered: 4 years ago Posts: 17 |

Quote

the_digital_dentist

I posted a CAD model of UMMD and a lot of information about problems and fixes for them. That's what open source is about. I'm surprised anyone tried to commercialize it because it isn't the cheapest way to build a printer, and cheapness seems to be the main driver of printer sales.

Most of the non corexy cartesian mechanisms move the X axis motor along the Y axis. A lot of people worry about the mass that motor adds, but I'm more concerned about having to run a cable to it. It's bad enough you have to run one to the extruder, but running two multiconductor cables to two moving motors is asking for trouble. I'm sure it can be done reliably if you apply enough effort, but it isn't my preference. My older printer, SoM, uses a flex ribbon cable to take all the signals and power to the extruder carriage. It has been working with 100% reliability for about 6 years now. If I could find a cheap source of that type cable and tools to terminate it I'd probably go into business selling it to 3D printer builders. I hate running cables to moving stuff and finally took the X axis endstop switch off the extruder carriage in SoM.

Back to your question. The short answer is no, I don't think there's any special advantage of corexy over any other cartesian (except maybe H-bot) when it comes to print quality when you're printing at "normal" speeds. Just about any mechanism will work fine. Corexy is pretty easy to build well, once you understand how it works.

I don't think much of the mechanical complication that something like a remote-motor extruder adds. The whole point of moving the motor off the extruder is to reduce moving mass so you can theoretically print faster, but in order to make it work they have to gear it down 20:1 and that may limit extrusion speed which will limit print speed anyway. What is the benefit that justifies the added cost and complication?

The Duet people are working on a design that runs power and a serial wire to the extruder and that's it. It'll have a board on the extruder carriage that drives the motor and controls the heater and fans. That will be a real advance over the multipin cabling and connectors that are needed now.

Very interesting about the moving wires, makes a lot of sense.

Good point, too, about the gear ratio on the remote extruder - just moves the problem, literally.

The Duet product sounds very interesting.

|

Re: Which Kit? Railcore? SecKit? Other? June 06, 2020 01:44PM |

Registered: 5 years ago Posts: 9 |

A lot of misinfo on the Railcore from the Dentist.

It is enclosable. You can purchase kits or do it yourself. The motors, except for the extruder motor, are kept outside of the hot build area.

These and many other Railcore parts are available in aluminum. Highly recommended for some parts. I believe you can purchase every part except the fan manifold in aluminum now. Not necessary for some parts, of course, but people like bling. Mandala Rose Works and 713 Maker have specialized in making railcore parts.

This re-tramming of the bed happens automatically, doesn't take more than a few seconds and levels the bed better than most can do with manual screws. It also accounts for different thickness springsteel build plates automatically.

They are parallel.

Quote

I'm not a big fan of the Railcore design. Too many printed parts that extend beyond the frame, making it hard to enclose.

It is enclosable. You can purchase kits or do it yourself. The motors, except for the extruder motor, are kept outside of the hot build area.

Quote

The motor mounts look flexible, the pulley mounts don't look very good either. Standing a post with two pulleys up in a piece of printed plastic and putting tension on the belts is likely to cause the plastic to flex and tilt the post.

These and many other Railcore parts are available in aluminum. Highly recommended for some parts. I believe you can purchase every part except the fan manifold in aluminum now. Not necessary for some parts, of course, but people like bling. Mandala Rose Works and 713 Maker have specialized in making railcore parts.

Quote

I'm also not a fan of using multiple Z axis motors. They get out of sync when you cycle power and that tilts the bed so you have to have some sort of scheme to relevel the bed frequently. It looks like the design could easily be modified to use a single Z axis motor.

This re-tramming of the bed happens automatically, doesn't take more than a few seconds and levels the bed better than most can do with manual screws. It also accounts for different thickness springsteel build plates automatically.

Quote

It's hard to be sure from the CAD model that doesn't show the belts, but it looks like the A and G belt segments will not be parallel to the Y axis guide rails.

They are parallel.

|

Re: Which Kit? Railcore? SecKit? Other? June 06, 2020 04:57PM |

Registered: 8 years ago Posts: 123 |

Quote

the_digital_dentist

I'm not a big fan of the Railcore design. Too many printed parts that extend beyond the frame, making it hard to enclose. The motor mounts look flexible, the pulley mounts don't look very good either. Standing a post with two pulleys up in a piece of printed plastic and putting tension on the belts is likely to cause the plastic to flex and tilt the post. I'm also not a fan of using multiple Z axis motors. They get out of sync when you cycle power and that tilts the bed so you have to have some sort of scheme to relevel the bed frequently. It looks like the design could easily be modified to use a single Z axis motor. It's hard to be sure from the CAD model that doesn't show the belts, but it looks like the A and G belt segments will not be parallel to the Y axis guide rails.

That's interested to hear you say that. I don't pretend to be knowledgeabe, but I devoured your blog in 2018 (and so many thanks for logging your exploits) and I looked for a printer with :-

- minimal printed parts (you can replace all the internal parts with aluminium by purchasing and there are, or will be soon, open source versions of all aluminium parts)

- enclosable/enclosed

- 3 point bed levelling instead of 4 point bed bending (automatic too!)

- a Duet (as I was familiar with this board from the Ormerod 2 I'd had previously, you were on Smoothieware at the time, but moved to Duet later)

and so I chose the RailCore II, and have been very happy with it.

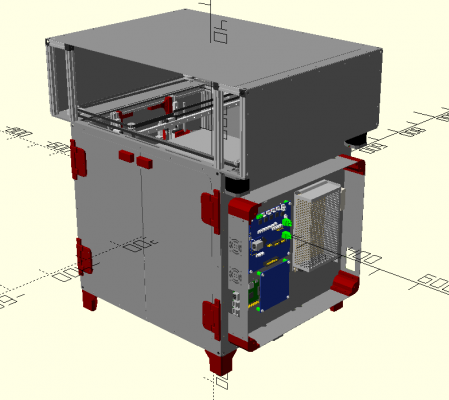

(I don't think it's too hard to enclose either - P.S. . this was a handy image with the front door of the top enclosure off, naturally that is closed off too.)

I would say, as a big fan of your blog (and a big fan of the RailCore admittedly) to at least give it another look - if you haven't recently.

Feel free to pop by the Discord if you are so inclined!

|

Re: Which Kit? Railcore? SecKit? Other? June 06, 2020 05:41PM |

Registered: 5 years ago Posts: 9 |

The enclosure can also keep the steppers outside, belts entering thru a slot in the panels. A cleaner look than the rendering above imo.

See enclosure here: [www.mandalaroseworks.com]

Edited 1 time(s). Last edit at 06/06/2020 05:41PM by Wescherry.

See enclosure here: [www.mandalaroseworks.com]

Edited 1 time(s). Last edit at 06/06/2020 05:41PM by Wescherry.

|

Re: Which Kit? Railcore? SecKit? Other? June 07, 2020 10:12AM |

Registered: 6 years ago Posts: 1,007 |

Quote

Wescherry

A lot of misinfo on the Railcore from the Dentist.

...

Quote

I'm also not a fan of using multiple Z axis motors. They get out of sync when you cycle power and that tilts the bed so you have to have some sort of scheme to relevel the bed frequently. It looks like the design could easily be modified to use a single Z axis motor.

This re-tramming of the bed happens automatically, doesn't take more than a few seconds and levels the bed better than most can do with manual screws. It also accounts for different thickness springsteel build plates automatically.

.....

And you NEED this re-tramming due to the motors getting out of sync !

And you NEED to have the bed mounted on flexible joint to the three Z carriage, here they use rubber washers and screws. Not very neat and not a very good kinematic mount either !

A properly designed, built machine DOESN't NEED that.

Edited 1 time(s). Last edit at 06/07/2020 10:13AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Which Kit? Railcore? SecKit? Other? June 07, 2020 02:57PM |

Registered: 5 years ago Posts: 9 |

|

Re: Which Kit? Railcore? SecKit? Other? June 07, 2020 03:08PM |

Registered: 10 years ago Posts: 14,672 |

It's a question of whether you prefer mechanical complexity or electrical complexity. If you are more comfortable with mechanics, you will prefer a single Z motor driving all 3 leadscrews with a closed loop belt, and bed levelling screws to get the bed level. If the frame is sturdy and rigid enough, once levelled it should stay levelled. OTOH if you are more comfortable with electrical complexity, you may prefer three separate motors driven by independent drivers, and no bed levelling screws.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Which Kit? Railcore? SecKit? Other? September 03, 2023 11:57PM |

Registered: 8 years ago Posts: 72 |

Hi All,

This may be an older thread but still applies to my questions. I have a Cartesian printer (clone prusa p3 steel). I want to build a CoreXY with a 350x350x400 give or take. My city recently opened a nice maker space, and I was going to build something like the UMMD. But I don’t know if I’ll have the time to put into it. There is some appeal for me to learn how to use shop tools like the lathe.

Assuming time is going to be a constraint, I’ve looked at options like the newer SecKit or Railcore ii 300zlt. I’m not a fan of the screws and 3 motors driving the z axis, but it would still be better than my shitty 3mm aluminum build plate. I’ve also looked at the Bambi x1c and creality k1 max. I don’t carefor their heat beds and proprietary nature.

I have a few of questions. Are there other CoreXY builds I should look at? How much time would something like a UMMD take to build assuming parts were easy to source (excluding the training the maker space would need to provide for equipment use)? If I had to do a 3 motor z axis with current electronics, tramming should’ve be an issue right?

This may be an older thread but still applies to my questions. I have a Cartesian printer (clone prusa p3 steel). I want to build a CoreXY with a 350x350x400 give or take. My city recently opened a nice maker space, and I was going to build something like the UMMD. But I don’t know if I’ll have the time to put into it. There is some appeal for me to learn how to use shop tools like the lathe.

Assuming time is going to be a constraint, I’ve looked at options like the newer SecKit or Railcore ii 300zlt. I’m not a fan of the screws and 3 motors driving the z axis, but it would still be better than my shitty 3mm aluminum build plate. I’ve also looked at the Bambi x1c and creality k1 max. I don’t carefor their heat beds and proprietary nature.

I have a few of questions. Are there other CoreXY builds I should look at? How much time would something like a UMMD take to build assuming parts were easy to source (excluding the training the maker space would need to provide for equipment use)? If I had to do a 3 motor z axis with current electronics, tramming should’ve be an issue right?

|

Re: Which Kit? Railcore? SecKit? Other? September 04, 2023 11:25AM |

Registered: 11 years ago Posts: 5,780 |

You won't need training on a lathe to build a UMMD copy. It's not entirely necessary to use a milling machine, either, though it can be very useful. Simple cuts and accurate, square drilling are the main uses for the mill- square up the ends and matching lengths of the frame pieces so that they bolt together squarely, and milling the perimeter of bed plate. You will want to drill holes squarely in the tubes for mounting pulleys, and drilling the holes to mount the Y axis linear guides and milling the t-slot flat where the Z axis guides will mount. Access to a fly cutter can be handy for cutting the large holes in the motor mounts, but a hole saw can be used instead. If you buy frame pieces from Misumi, they'll be cut squarely and accurately, so you might be able to get away with just a drill press instead of a mill. The mill can be useful for making cuts in the bed plate for the kinematic mount, though it's not entirely necessary. I invested in a 3 flute tungsten carbide mill (about $30) that's 1/2" diameter and has 2" cutting length for quickly squaring ends of t-slot in a single pass. I use it on an old Bridgeport mill at the makerspace.

Whatever you do, don't use 20 mm or 1" t-slot for the frame. It's cheaper and more rigid to use larger t-slot and just bolt it together than to use small t-slot and dozens of braces and corner plates and all the hardware that goes with them.

If you build it like UMMD- a single motor driving the Z axis- you won't really need auto tramming, but if you want it, use it. I wouldn't try to use a 3 mm plate for a bed that's 350 x350 mm. It's going to be too flexible. 6 mm or 8 mm cast tooling plate should work fine. Whatever you do, get a bed heater that's the same size as the bed plate. I see a lot of designs where the plate is a lot bigger than the heater- that's asking for it to warp when heated because the heated center of the plate will expand more than the unheated edges. Use ears for bed support screws like UMMD. If you use 3 screws or belts to lift the bed, put the reference and pitch support screws at corners of the plate and the roll screw at the middle of the edge opposite the the other two screws. Even if you use auto tramming, use the kinematic mount for the plate. That allows it to expand when heated without pushing laterally on anything.

I still use the original piece of 0.7 mm PEI (6+ years old) glued to the aluminum plate for the print surface. Everything sticks, though some materials stick a little better than I would like. I find that putting a few drops of IPA at the base of the print helps release prints from the PEI. PEI coated flexible steel sheets are OK, too, but thickness may vary so you may need auto tramming/zeroing to accommodate multiple steel sheets.

If you're mostly going to print with PLA (ugh!) or PETG you don't need to heat the enclosure (but enclosure is still a good idea) and you can put the motors inside the enclosure. If you ever intend to print with ABS, you'll need an enclosure and a heater for it. You need to get to 50C as a minimum to ensure reliable ABS printing, though even higher temperatures would be better, especially if you want to make large prints. Be sure the design you choose can be easily enclosed. You might want to move the motors outside the enclosure, depending on how hot you want it to get. The X and Y motors get about 10C above room temperature, so it would probably have been OK to put them inside the enclosure. The Z motor

Your printer is going to have a big footprint, maybe too big for most desks. If it will end up standing on the floor or on a cart, consider just making the machine taller, and then you can also expand the Z axis for taller prints. Make sure you can fit the printer through standard doorways (or your own doorways), and consider putting the electronics on top of the machine- that keeps everything accessible and cables short.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Whatever you do, don't use 20 mm or 1" t-slot for the frame. It's cheaper and more rigid to use larger t-slot and just bolt it together than to use small t-slot and dozens of braces and corner plates and all the hardware that goes with them.

If you build it like UMMD- a single motor driving the Z axis- you won't really need auto tramming, but if you want it, use it. I wouldn't try to use a 3 mm plate for a bed that's 350 x350 mm. It's going to be too flexible. 6 mm or 8 mm cast tooling plate should work fine. Whatever you do, get a bed heater that's the same size as the bed plate. I see a lot of designs where the plate is a lot bigger than the heater- that's asking for it to warp when heated because the heated center of the plate will expand more than the unheated edges. Use ears for bed support screws like UMMD. If you use 3 screws or belts to lift the bed, put the reference and pitch support screws at corners of the plate and the roll screw at the middle of the edge opposite the the other two screws. Even if you use auto tramming, use the kinematic mount for the plate. That allows it to expand when heated without pushing laterally on anything.

I still use the original piece of 0.7 mm PEI (6+ years old) glued to the aluminum plate for the print surface. Everything sticks, though some materials stick a little better than I would like. I find that putting a few drops of IPA at the base of the print helps release prints from the PEI. PEI coated flexible steel sheets are OK, too, but thickness may vary so you may need auto tramming/zeroing to accommodate multiple steel sheets.

If you're mostly going to print with PLA (ugh!) or PETG you don't need to heat the enclosure (but enclosure is still a good idea) and you can put the motors inside the enclosure. If you ever intend to print with ABS, you'll need an enclosure and a heater for it. You need to get to 50C as a minimum to ensure reliable ABS printing, though even higher temperatures would be better, especially if you want to make large prints. Be sure the design you choose can be easily enclosed. You might want to move the motors outside the enclosure, depending on how hot you want it to get. The X and Y motors get about 10C above room temperature, so it would probably have been OK to put them inside the enclosure. The Z motor

Your printer is going to have a big footprint, maybe too big for most desks. If it will end up standing on the floor or on a cart, consider just making the machine taller, and then you can also expand the Z axis for taller prints. Make sure you can fit the printer through standard doorways (or your own doorways), and consider putting the electronics on top of the machine- that keeps everything accessible and cables short.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Which Kit? Railcore? SecKit? Other? September 05, 2023 06:53PM |

Registered: 8 years ago Posts: 72 |

|

Re: Which Kit? Railcore? SecKit? Other? February 09, 2024 07:27PM |

Registered: 8 years ago Posts: 72 |

Quote

the_digital_dentist

You won't need training on a lathe to build a UMMD copy. It's not entirely necessary to use a milling machine, either, though it can be very useful. Simple cuts and accurate, square drilling are the main uses for the mill- square up the ends and matching lengths of the frame pieces so that they bolt together squarely, and milling the perimeter of bed plate. You will want to drill holes squarely in the tubes for mounting pulleys, and drilling the holes to mount the Y axis linear guides and milling the t-slot flat where the Z axis guides will mount. Access to a fly cutter can be handy for cutting the large holes in the motor mounts, but a hole saw can be used instead. If you buy frame pieces from Misumi, they'll be cut squarely and accurately, so you might be able to get away with just a drill press instead of a mill. The mill can be useful for making cuts in the bed plate for the kinematic mount, though it's not entirely necessary. I invested in a 3 flute tungsten carbide mill (about $30) that's 1/2" diameter and has 2" cutting length for quickly squaring ends of t-slot in a single pass. I use it on an old Bridgeport mill at the makerspace.

Whatever you do, don't use 20 mm or 1" t-slot for the frame. It's cheaper and more rigid to use larger t-slot and just bolt it together than to use small t-slot and dozens of braces and corner plates and all the hardware that goes with them.

If you build it like UMMD- a single motor driving the Z axis- you won't really need auto tramming, but if you want it, use it. I wouldn't try to use a 3 mm plate for a bed that's 350 x350 mm. It's going to be too flexible. 6 mm or 8 mm cast tooling plate should work fine. Whatever you do, get a bed heater that's the same size as the bed plate. I see a lot of designs where the plate is a lot bigger than the heater- that's asking for it to warp when heated because the heated center of the plate will expand more than the unheated edges. Use ears for bed support screws like UMMD. If you use 3 screws or belts to lift the bed, put the reference and pitch support screws at corners of the plate and the roll screw at the middle of the edge opposite the the other two screws. Even if you use auto tramming, use the kinematic mount for the plate. That allows it to expand when heated without pushing laterally on anything.

I still use the original piece of 0.7 mm PEI (6+ years old) glued to the aluminum plate for the print surface. Everything sticks, though some materials stick a little better than I would like. I find that putting a few drops of IPA at the base of the print helps release prints from the PEI. PEI coated flexible steel sheets are OK, too, but thickness may vary so you may need auto tramming/zeroing to accommodate multiple steel sheets.

If you're mostly going to print with PLA (ugh!) or PETG you don't need to heat the enclosure (but enclosure is still a good idea) and you can put the motors inside the enclosure. If you ever intend to print with ABS, you'll need an enclosure and a heater for it. You need to get to 50C as a minimum to ensure reliable ABS printing, though even higher temperatures would be better, especially if you want to make large prints. Be sure the design you choose can be easily enclosed. You might want to move the motors outside the enclosure, depending on how hot you want it to get. The X and Y motors get about 10C above room temperature, so it would probably have been OK to put them inside the enclosure. The Z motor

Your printer is going to have a big footprint, maybe too big for most desks. If it will end up standing on the floor or on a cart, consider just making the machine taller, and then you can also expand the Z axis for taller prints. Make sure you can fit the printer through standard doorways (or your own doorways), and consider putting the electronics on top of the machine- that keeps everything accessible and cables short.

Hi DD,

I've went through your blog and the thread you hosted on this domain. I'm finally ready to start assembling this thing. I'm going to use our maker space. I have a couple of questions to get started. I want a 350x350x500 build volume. How do I go about sizing the 40x40 t slot? I'll use Misumi to save time. Besides the cuts, they tap the ends and make tool access holes. I see a total of 19 40t extrusions. They are as follows: 4 large outer corner extrusions, 4 for the xy plane connected inside the 4 corners, 2 z axis, 1 for z motor/gear, 2 connected to z motor/gear, 2 upper support and 2 lower support, 2 for the heatbed. I'm sure there will be questions outside of what you have noted. Perhaps we can talk over private message if easier. Thanks for your input.

|

Re: Which Kit? Railcore? SecKit? Other? February 10, 2024 10:10AM |

Registered: 11 years ago Posts: 5,780 |

I wouldn't cut the frame pieces yet! If you do you'll have to figure out how to stuff everything into the frame. It's better to design the stuff that goes in the frame first, then figure out the frame pieces needed to enclose it.

Since you have decided on the print volume, I'd start by designing the extruder carriage first, then the rest of the XY stage. It will have to be 400-450 mm square to allow a single extruder to cover the 350x350 bedplate, larger if you want multiple extruders. Once the XY stage is worked out, get to work on the Z axis. Finally the outer frame.

If you aren't currently using 3D CAD software, now is the time to learn! Model everything in CAD- it will prevent a lot of errors (and save a lot of remaking parts - and money- that don't fit together) and reveal a lot of problem areas you'll have to work around as you build. Fusion360 or DesignSpark Mechanical are both free (maybe OnShape, too?). DSM is the easiest to learn- it is similar to but much better then sketchup. Fusion360 requires a bit more effort to learn but is more capable than DSM and worth the effort. You don't have to model every nut and bolt that goes into the machine, but the holes they go in should be modeled so you can use the CAD file as a drilling guide.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Since you have decided on the print volume, I'd start by designing the extruder carriage first, then the rest of the XY stage. It will have to be 400-450 mm square to allow a single extruder to cover the 350x350 bedplate, larger if you want multiple extruders. Once the XY stage is worked out, get to work on the Z axis. Finally the outer frame.

If you aren't currently using 3D CAD software, now is the time to learn! Model everything in CAD- it will prevent a lot of errors (and save a lot of remaking parts - and money- that don't fit together) and reveal a lot of problem areas you'll have to work around as you build. Fusion360 or DesignSpark Mechanical are both free (maybe OnShape, too?). DSM is the easiest to learn- it is similar to but much better then sketchup. Fusion360 requires a bit more effort to learn but is more capable than DSM and worth the effort. You don't have to model every nut and bolt that goes into the machine, but the holes they go in should be modeled so you can use the CAD file as a drilling guide.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Which Kit? Railcore? SecKit? Other? February 10, 2024 02:24PM |

Registered: 8 years ago Posts: 72 |

Thanks for the planning instructions. I didn't plan on using dual extruders, but I'm wondering how difficult it would be to have an IDEX setup. I've read about alignment issues with the hotend. Since this would be mostly metal it would be easier. Duet can support it. What are your thoughts on that?

I know how to design parts in Fusion 360. I'll just need to learn how to add and assemble components.I agree this will be much easier overall.

I know how to design parts in Fusion 360. I'll just need to learn how to add and assemble components.I agree this will be much easier overall.

|

Re: Which Kit? Railcore? SecKit? Other? February 10, 2024 08:19PM |

Registered: 11 years ago Posts: 5,780 |

I'm not really familiar with the belt layouts people are using for IDEX, but the basic principle of keeping the working segments parallel to the guide rails will apply. If you think you might want to build with a single extruder and convert to IDEX at some point in the future, it would be best to design the XY stage to accommodate that now- trying to shoehorn an additional extruder and mounts for motors, pulleys, and belts into an existing design can be difficult.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Which Kit? Railcore? SecKit? Other? April 18, 2024 05:16PM |

Registered: 8 years ago Posts: 72 |

Iv'e been trying to work on this when I have pockets of time. Here is what I am thinking for the belt layout to get the IDEX setup. With a 350x350x500 build volume, I was thinking the frame would be 580x580 assuming the x bearing blocks are about 50mm. I'll have to play with that a bit factoring in end stop and probably having end stops on the extruders so they don't collide.

Any thoughts on this setup?

Any thoughts on this setup?

Sorry, only registered users may post in this forum.