What is the cause of magical random ripples on the Core XY printer?

Posted by pasha4ur

|

What is the cause of magical random ripples on the Core XY printer? February 01, 2024 09:42AM |

Registered: 2 months ago Posts: 7 |

Hello

Help me please. I have voron trident like printer. My 1st custom assembly.

CONFIGURATION

• 4040 (v-slot) and 2040 (t-slot) frame with corners and corner outer plates;

• RDBB 500mm rails (12mm on X axis);

• powge pulleys and idlers, 6mm gates belts (tensioned at about115-120 Hz), fushi bearings;

• 8 mm aluminum print bed 355х355 + 4 mm glass mirror + 220 v heater;

• 8 mm lead screws with 4 lead and antiwobbling solution like wobbleX + couplers sit on thrust bearings;

• Bigtreetech Octopus Pro STM32F429 (CAN bridge mode) + tmc2209 (StealthChop is turned off) + Bigtreetech EBB36 printhead board;

• cloudray 17cs04a-170e motors with 0.73 A run current in Klipper config;

• Meanwell 350 24 V;

• Klicky probe;

• dragon burner printhead with sherpa mini extruder and LDO 36STH20 motor;

• Volcano aluminum hot end with short e3d v6 heatsink (dragon mount). Trianglelab;

• holder for cable [www.printables.com] ;

• Mobil grease Mobilux EP2 for rails and screws;

• 2 800 acceleration in klipper.

Video of the printer.: https://youtu.be/hUnr9MdLMdA

PROBLEM

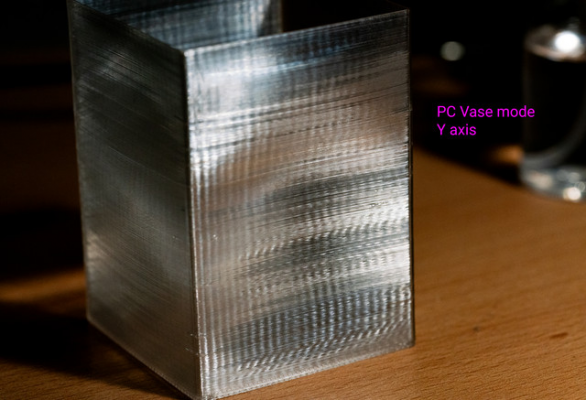

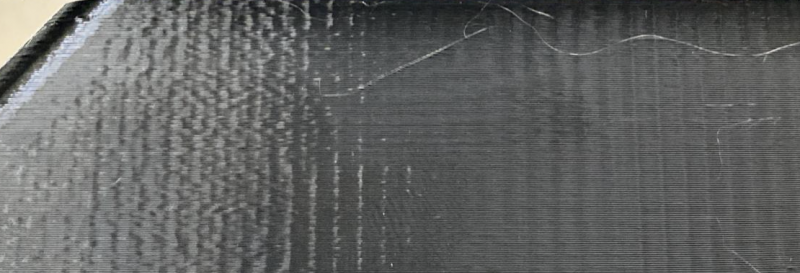

I have problem – random ripple on Y axis. In vase or regular print mode the ripple changes (size, angle, direction, depth) on different heights, sides and places of print bed. I printed 20 small objects (boxes) in serial mode and all objects had different ripple or some didn’t have it.

At speeds about 100 mm/s the Н axis often becomes smooth without ripples even from belts like on the X axis. But at this speed the corners and details are already slightly smoothed out.

I need to print some plastic at low speed, so you need to fix the problem.

On Orca Slicer VFA test from 30 to 140 mm/s (+5) the ripple changes even at the same speed segment.

The ripples seem to be more pronounced when the head moves backward on the Y axis.

At the moment, the printer has worked for about 400 hours. Over time, the defect became more noticeable.

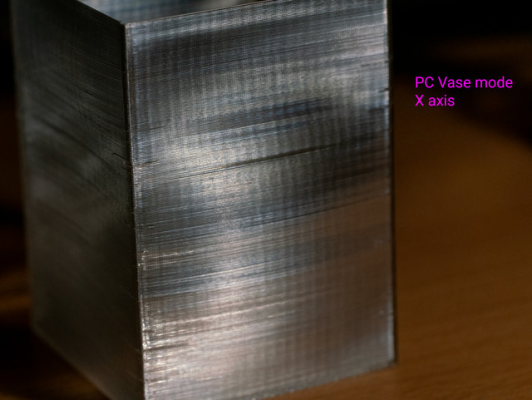

X axis

Y axis

But with every print and on every object the ripples are different. Ripples can only occur within a certain band in height or at intervals in height. Sometimes the ripples on 1 wall change to the opposite angle several times.

Video:

https://youtu.be/-ltobVDS04o

https://youtu.be/GEQGG2D71A8

I saw some amount of such ripple on some prints of users with other vorons with stock heavy print head.

I'VE ALREADY DONE

1. Changed printed Sherpa mini extruder to Fysetc CNC version with helical gears;

2. Changed hot end heatsink to Trianglelab. It has better heat break fixation;

3. Changed printhead fans to GDStime with ball bearings;

4. Changed tooth pulleys (they eat belts on Voron) to double flanged fushi bearings ;

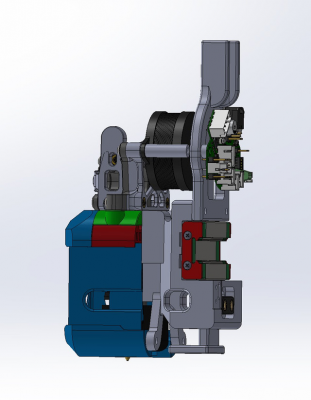

5. Changed printhead to more stable 8th version of Dragon Burner with custom very strong carriage. My custom desing;

6. Installed custom printhead board mount that is held by 4 screws to the carriage and extruder;

7. Installed 1mm M5 shims between all pulleys made from flanged fushi bearings. Voron eats belts in these places;

8. Changed M5x40 screws, M5 nuts and m3x8 screws (MGN12 mount) to titanium version;

9. Reduced the number of bolts and nuts for the X rails, using fastenings through 2 holes;

10. Changed cloudray 17cs04a-170e motors to 60 mm version (17CS07A-180E). And changed back;

11. Disassembled and cleaned X rails.

It did not help. Or I don't see any noticeable changes.

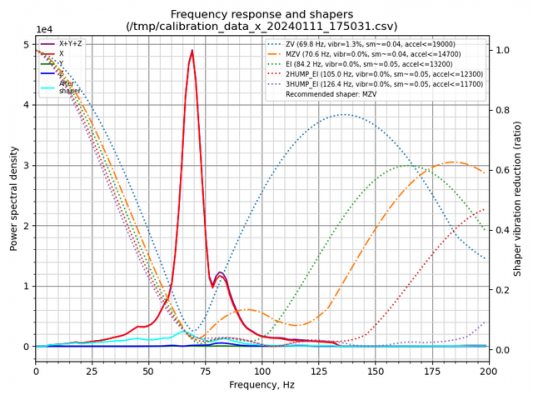

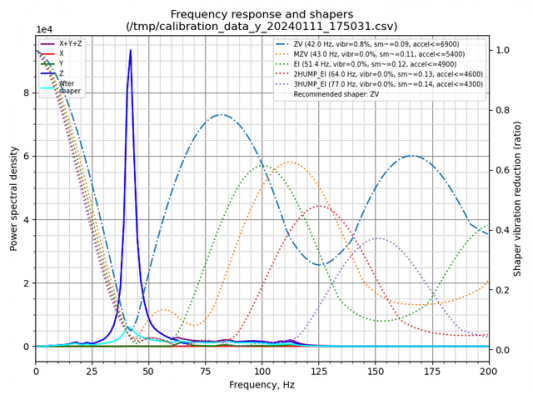

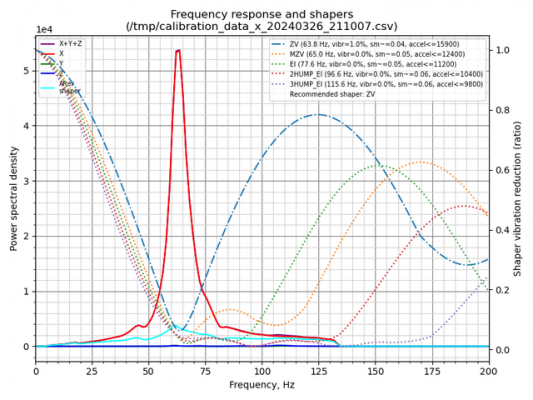

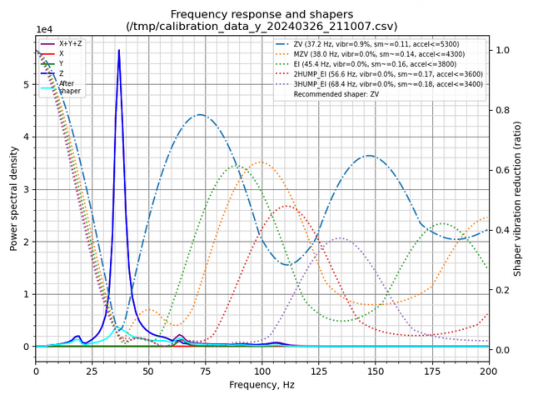

Input shaping results (only the hot end fan is on):

WHAT I'M GOING TO DO NEXT

I’ve already received parts

1. Change all printed parts in the XY gantry and printhead from ABS+ to ABS+ with 10% glass fiber;

2. Decoupler mod (without rubber motor mounts) https://www.printables.com/model/430168-voron-trident-stepper-decoupler

3. Active cooling and heatsinks for XY motors. They are only 50*;

4. Change XY motor drivers from tmc2209 to tmc2240;

5. Fix top parts of 2 M5 XY screws with pulleys which don’t use nuts;

6. Perhaps I'll replace the cable holder with a short flexible chain.

The carriage on the rail on the X-axis has a slight play if you apply force. It's very difficult for me to capture it on camera. I don't know if it should be like this. When removing and disassembling the rails by hand, no play is felt.

HIWIN rail cost a lot (like used ender 3 on ebay for 1 mgn12 500 mm). It’s hard times in Ukraine and I’m not sure that Ukrainian sellers sell original HIWIN. But I don't want to play the game of matching balls for Chinese rails.

In the future (to assemble the IDEX) I will buy expensive rails with 2 carriages (it is difficult to find 2 identical carriages for Chinese rails). But I wouldn't want to spend money on it now.

P.S. 1 man solved it by replacing rails https://www.facebook.com/groups/voroncorexy/permalink/1800631243698767/

After replacing the printed parts I will try to loosen the Y-axis rails, move the X-axis and fix the rails again.

Edited 4 time(s). Last edit at 02/01/2024 05:25PM by pasha4ur.

Help me please. I have voron trident like printer. My 1st custom assembly.

CONFIGURATION

• 4040 (v-slot) and 2040 (t-slot) frame with corners and corner outer plates;

• RDBB 500mm rails (12mm on X axis);

• powge pulleys and idlers, 6mm gates belts (tensioned at about115-120 Hz), fushi bearings;

• 8 mm aluminum print bed 355х355 + 4 mm glass mirror + 220 v heater;

• 8 mm lead screws with 4 lead and antiwobbling solution like wobbleX + couplers sit on thrust bearings;

• Bigtreetech Octopus Pro STM32F429 (CAN bridge mode) + tmc2209 (StealthChop is turned off) + Bigtreetech EBB36 printhead board;

• cloudray 17cs04a-170e motors with 0.73 A run current in Klipper config;

• Meanwell 350 24 V;

• Klicky probe;

• dragon burner printhead with sherpa mini extruder and LDO 36STH20 motor;

• Volcano aluminum hot end with short e3d v6 heatsink (dragon mount). Trianglelab;

• holder for cable [www.printables.com] ;

• Mobil grease Mobilux EP2 for rails and screws;

• 2 800 acceleration in klipper.

Video of the printer.: https://youtu.be/hUnr9MdLMdA

PROBLEM

I have problem – random ripple on Y axis. In vase or regular print mode the ripple changes (size, angle, direction, depth) on different heights, sides and places of print bed. I printed 20 small objects (boxes) in serial mode and all objects had different ripple or some didn’t have it.

At speeds about 100 mm/s the Н axis often becomes smooth without ripples even from belts like on the X axis. But at this speed the corners and details are already slightly smoothed out.

I need to print some plastic at low speed, so you need to fix the problem.

On Orca Slicer VFA test from 30 to 140 mm/s (+5) the ripple changes even at the same speed segment.

The ripples seem to be more pronounced when the head moves backward on the Y axis.

At the moment, the printer has worked for about 400 hours. Over time, the defect became more noticeable.

X axis

Y axis

But with every print and on every object the ripples are different. Ripples can only occur within a certain band in height or at intervals in height. Sometimes the ripples on 1 wall change to the opposite angle several times.

Video:

https://youtu.be/-ltobVDS04o

https://youtu.be/GEQGG2D71A8

I saw some amount of such ripple on some prints of users with other vorons with stock heavy print head.

I'VE ALREADY DONE

1. Changed printed Sherpa mini extruder to Fysetc CNC version with helical gears;

2. Changed hot end heatsink to Trianglelab. It has better heat break fixation;

3. Changed printhead fans to GDStime with ball bearings;

4. Changed tooth pulleys (they eat belts on Voron) to double flanged fushi bearings ;

5. Changed printhead to more stable 8th version of Dragon Burner with custom very strong carriage. My custom desing;

6. Installed custom printhead board mount that is held by 4 screws to the carriage and extruder;

7. Installed 1mm M5 shims between all pulleys made from flanged fushi bearings. Voron eats belts in these places;

8. Changed M5x40 screws, M5 nuts and m3x8 screws (MGN12 mount) to titanium version;

9. Reduced the number of bolts and nuts for the X rails, using fastenings through 2 holes;

10. Changed cloudray 17cs04a-170e motors to 60 mm version (17CS07A-180E). And changed back;

11. Disassembled and cleaned X rails.

It did not help. Or I don't see any noticeable changes.

Input shaping results (only the hot end fan is on):

WHAT I'M GOING TO DO NEXT

I’ve already received parts

1. Change all printed parts in the XY gantry and printhead from ABS+ to ABS+ with 10% glass fiber;

2. Decoupler mod (without rubber motor mounts) https://www.printables.com/model/430168-voron-trident-stepper-decoupler

3. Active cooling and heatsinks for XY motors. They are only 50*;

4. Change XY motor drivers from tmc2209 to tmc2240;

5. Fix top parts of 2 M5 XY screws with pulleys which don’t use nuts;

6. Perhaps I'll replace the cable holder with a short flexible chain.

The carriage on the rail on the X-axis has a slight play if you apply force. It's very difficult for me to capture it on camera. I don't know if it should be like this. When removing and disassembling the rails by hand, no play is felt.

HIWIN rail cost a lot (like used ender 3 on ebay for 1 mgn12 500 mm). It’s hard times in Ukraine and I’m not sure that Ukrainian sellers sell original HIWIN. But I don't want to play the game of matching balls for Chinese rails.

In the future (to assemble the IDEX) I will buy expensive rails with 2 carriages (it is difficult to find 2 identical carriages for Chinese rails). But I wouldn't want to spend money on it now.

P.S. 1 man solved it by replacing rails https://www.facebook.com/groups/voroncorexy/permalink/1800631243698767/

After replacing the printed parts I will try to loosen the Y-axis rails, move the X-axis and fix the rails again.

Edited 4 time(s). Last edit at 02/01/2024 05:25PM by pasha4ur.

|

Re: What is the cause of magical random ripples on the Core XY printer? February 01, 2024 01:17PM |

Registered: 11 years ago Posts: 5,780 |

Post some pictures of the prints.

Are the problems only on the Y axis and not on X axis?

Dual drive gear extruders such as the BMG and Sherpa Mini are known to cause uneven Z axis surfaces due to poor meshing of the gears.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Are the problems only on the Y axis and not on X axis?

Dual drive gear extruders such as the BMG and Sherpa Mini are known to cause uneven Z axis surfaces due to poor meshing of the gears.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: What is the cause of magical random ripples on the Core XY printer? February 01, 2024 02:33PM |

Registered: 2 months ago Posts: 7 |

Quote

the_digital_dentist

Post some pictures of the prints.

Are the problems only on the Y axis and not on X axis?

Dual drive gear extruders such as the BMG and Sherpa Mini are known to cause uneven Z axis surfaces due to poor meshing of the gears.

You can see problems in video. It's hard to show it on photo with transparent materials.

Only on Y.

I changed gears to such. 0 effects

Edited 1 time(s). Last edit at 02/01/2024 02:58PM by pasha4ur.

|

Re: What is the cause of magical random ripples on the Core XY printer? February 01, 2024 04:46PM |

Registered: 2 months ago Posts: 7 |

X axis

Y axis

But with every print and on every object the ripples are different. Ripples can only occur within a certain band in height or at intervals in height. Sometimes the ripples on 1 wall or change to the opposite angle several times.

Edited 1 time(s). Last edit at 02/01/2024 05:11PM by pasha4ur.

Y axis

But with every print and on every object the ripples are different. Ripples can only occur within a certain band in height or at intervals in height. Sometimes the ripples on 1 wall or change to the opposite angle several times.

Edited 1 time(s). Last edit at 02/01/2024 05:11PM by pasha4ur.

|

Re: What is the cause of magical random ripples on the Core XY printer? February 01, 2024 07:50PM |

Registered: 11 years ago Posts: 5,780 |

I don't know if helical gears are supposed to fix the problem associated with dual drive gear extrusion. If you have a single drive gear extruder available, give it a try and see if the problems persist.

What is different when the extruder moves in X and when it moves in Y? With Y axis movement the Y axis linear bearings move and the corner pulleys and pulleys at the motors turn. With X axis movement, the X axis linear bearings move and all the pulleys turn. It could be a problem with the Y axis linear guides.

I see stacked bearings at the ends of the X axis with the belt teeth touching the bearing surface. What size are those bearings? If those bearings are small, there will be few teeth touching them and they will cog as the belts move on them, possibly causing the vertical ripple. Does the spacing of the ripples match the belt pitch? One possible cure is to put a twist in each belt along the Y axis in the long, straight runs from the motors to the corner pulleys. That will put the smooth back side of the belt against the pulleys and should eliminate cogging. You may have to redesign the belt clamps at the extruder carriage to make that work. Another possible cure is to use larger bearings for the pulleys so that more teeth will contact the pulley surface. That will increase moving mass, but the bearings will last a loooong time.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

What is different when the extruder moves in X and when it moves in Y? With Y axis movement the Y axis linear bearings move and the corner pulleys and pulleys at the motors turn. With X axis movement, the X axis linear bearings move and all the pulleys turn. It could be a problem with the Y axis linear guides.

I see stacked bearings at the ends of the X axis with the belt teeth touching the bearing surface. What size are those bearings? If those bearings are small, there will be few teeth touching them and they will cog as the belts move on them, possibly causing the vertical ripple. Does the spacing of the ripples match the belt pitch? One possible cure is to put a twist in each belt along the Y axis in the long, straight runs from the motors to the corner pulleys. That will put the smooth back side of the belt against the pulleys and should eliminate cogging. You may have to redesign the belt clamps at the extruder carriage to make that work. Another possible cure is to use larger bearings for the pulleys so that more teeth will contact the pulley surface. That will increase moving mass, but the bearings will last a loooong time.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: What is the cause of magical random ripples on the Core XY printer? February 01, 2024 07:58PM |

Registered: 2 months ago Posts: 7 |

Why are you talking about extruder if on X axis all is good?Quote

the_digital_dentist

I don't know if helical gears are supposed to fix the problem associated with dual drive gear extrusion. If you have a single drive gear extruder available, give it a try and see if the problems persist.

What is different when the extruder moves in X and when it moves in Y?

Did you read 1st message? I changed tooth pulleys to bearing and NOTHING CHANGED. NOTHING.Quote

I see stacked bearings at the ends of the X axis with the belt teeth touching the bearing surface. What size are those bearings?

Edited 1 time(s). Last edit at 02/01/2024 07:58PM by pasha4ur.

|

Re: What is the cause of magical random ripples on the Core XY printer? February 03, 2024 10:19AM |

Registered: 11 years ago Posts: 5,780 |

I see two problems in the prints you have posted. There are regularly spaced vertical ripples in both X and Y sides of the print, and there are semi random ripples in the Y axis side of the print.

If you print the same box multiple times, do the semi random looking ripples look identical in each print?

I asked about the diameter of the bearings you are using for pulleys (you gave no answer) because if they are small, they may be the cause of the regularly spaced vertical ripples seen in both X and Y sides of the prints. When you changed the pulleys to bearings at the ends of the X axis, did you also change the other pulleys to bearings? If the original pulleys were small, they could also cause those vertical ripples. I asked if the spacing of the ripples matches the belt pitch and again, no answer. Going from small toothed pulleys to small bearings might not have much effect on the print quality. That is why I suggested trying a twist in the belt so the smooth side of the belt rides on the bearings. It's probably easier to twist the belt than to redesign the blocks to hold larger diameter bearings.

Try changing the microstepping used in the extruder and reprint the same vase box and see if the ripples in the Y axis look identical to those in the prints you photographed.

What are the steps/mm values set for each axis? Are they the same (they should be...)?

Try printing the vase box oriented at 45 degrees on the bed plate. That way, when it prints only one motor will drive the motion for each side of the print. If the more random looking ripples persist on only two opposite sides of the print, that says maybe there's a problem with the mechanism that is driving the motion along that one direction. If the random ripples occur on all sides, then the problem isn't restricted to the mechanism along one side.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If you print the same box multiple times, do the semi random looking ripples look identical in each print?

I asked about the diameter of the bearings you are using for pulleys (you gave no answer) because if they are small, they may be the cause of the regularly spaced vertical ripples seen in both X and Y sides of the prints. When you changed the pulleys to bearings at the ends of the X axis, did you also change the other pulleys to bearings? If the original pulleys were small, they could also cause those vertical ripples. I asked if the spacing of the ripples matches the belt pitch and again, no answer. Going from small toothed pulleys to small bearings might not have much effect on the print quality. That is why I suggested trying a twist in the belt so the smooth side of the belt rides on the bearings. It's probably easier to twist the belt than to redesign the blocks to hold larger diameter bearings.

Try changing the microstepping used in the extruder and reprint the same vase box and see if the ripples in the Y axis look identical to those in the prints you photographed.

What are the steps/mm values set for each axis? Are they the same (they should be...)?

Try printing the vase box oriented at 45 degrees on the bed plate. That way, when it prints only one motor will drive the motion for each side of the print. If the more random looking ripples persist on only two opposite sides of the print, that says maybe there's a problem with the mechanism that is driving the motion along that one direction. If the random ripples occur on all sides, then the problem isn't restricted to the mechanism along one side.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: What is the cause of magical random ripples on the Core XY printer? March 19, 2024 07:17AM |

Registered: 2 months ago Posts: 7 |

Hello

There are different artefacts on different prints even on same place

I rebulit all XY gantry, reprinted gantry and print head with ABS+ Glass Fiber, made decoupler mod for motors with bearings

Dissembled and cleaned XY rails, changed balls in X rails ещ +2 (removed the backlash but imput shaping became worse). I changed TMC 2209(UART) to TMC2240 (SPI)

Nothing helped.

Maybe need to make experiments with extruder motor. I used printed Shepra mini with 3 kits of gears before. Now I have several CNC Sherpa mini.

Other people made a lot of work but couldn't fins solution [forum.vorondesign.com]

And 1 was in the pressure advance [www.reddit.com]

Prusa i3 with marlin [forum.prusa3d.com]

Problem is only on Y. Changing from pulleys to bearings changed NOTHING in problem (

Edited 5 time(s). Last edit at 03/19/2024 08:01AM by pasha4ur.

There are different artefacts on different prints even on same place

I rebulit all XY gantry, reprinted gantry and print head with ABS+ Glass Fiber, made decoupler mod for motors with bearings

Dissembled and cleaned XY rails, changed balls in X rails ещ +2 (removed the backlash but imput shaping became worse). I changed TMC 2209(UART) to TMC2240 (SPI)

Nothing helped.

Maybe need to make experiments with extruder motor. I used printed Shepra mini with 3 kits of gears before. Now I have several CNC Sherpa mini.

Other people made a lot of work but couldn't fins solution [forum.vorondesign.com]

And 1 was in the pressure advance [www.reddit.com]

Prusa i3 with marlin [forum.prusa3d.com]

Quote

I asked about the diameter of the bearings you are using for pulleys (you gave no answer) because if they are small, they may be the cause of the regularly spaced vertical ripples seen in both X and Y sides of the prints.

Problem is only on Y. Changing from pulleys to bearings changed NOTHING in problem (

There is no opportunity for this in voron design.Quote

That is why I suggested trying a twist in the belt so the smooth side of the belt rides on the bearings

Quote

What are the steps/mm values set for each axis? Are they the same (they should be...)?

##################################################################### # X/Y Stepper Settings ##################################################################### ## B Stepper - Left ## Connected to MOTOR_0 ## Endstop connected to DIAG_0 [stepper_x] step_pin: PF13 dir_pin: PF12 enable_pin: !PF14 rotation_distance: 40 microsteps: 32 full_steps_per_rotation:200 #set to 400 for 0.9 degree stepper #endstop_pin: EBBCan: PB5 endstop_pin: tmc2240_stepper_x:virtual_endstop #tmc2209_stepper_x:virtual_endstop homing_retract_dist: 0 position_min: -45 ## UART 2209 # [tmc2209 stepper_x] # uart_pin: PC4 # interpolate: False # run_current: 0.72 # sense_resistor: 0.110 # stealthchop_threshold: 0 #999999 # diag_pin: ^PG6 # driver_SGTHRS: 130 # 255 is most sensitive value, 0 is least sensitive ## SPI 2240 [tmc2240 stepper_x] spi_software_sclk_pin: EXP2_2 spi_software_mosi_pin: EXP2_6 spi_software_miso_pin: EXP2_1 spi_speed: 2500000 cs_pin: PC4 run_current: 0.65 diag0_pin: ^!PG6 #^PG6 driver_SGT: 1 stealthchop_threshold: 0 ## A Stepper - Right ## Connected to MOTOR_1 ## Endstop connected to DIAG_1 [stepper_y] step_pin: PG0 dir_pin: PG1 enable_pin: !PF15 rotation_distance: 40 microsteps: 32 full_steps_per_rotation:200 #set to 400 for 0.9 degree stepper #endstop_pin: PG9 can printhead endstop_pin: tmc2240_stepper_y:virtual_endstop #tmc2209_stepper_y:virtual_endstop homing_retract_dist: 0 position_min: 0 ##-------------------------------------------------------------------- ## UART 2209 # [tmc2209 stepper_y] # uart_pin: PD11 # interpolate: False # run_current: 0.65 # sense_resistor: 0.110 # stealthchop_threshold: 0 #999999 # diag_pin: ^PG9 # use the same pin that was previously the endstop_pin! # driver_SGTHRS: 130 # 255 is most sensitive value, 0 is least sensitive ## SPI 2240 [tmc2240 stepper_y] spi_software_sclk_pin: EXP2_2 spi_software_mosi_pin: EXP2_6 spi_software_miso_pin: EXP2_1 spi_speed: 2500000 cs_pin: PD11 run_current: 0.65 diag0_pin: ^!PG9 #^PG9 driver_SGT: 1 stealthchop_threshold: 0 #999999

Edited 5 time(s). Last edit at 03/19/2024 08:01AM by pasha4ur.

|

Re: What is the cause of magical random ripples on the Core XY printer? March 19, 2024 10:33AM |

Registered: 2 months ago Posts: 7 |

|

Re: What is the cause of magical random ripples on the Core XY printer? March 27, 2024 08:40AM |

Registered: 2 months ago Posts: 7 |

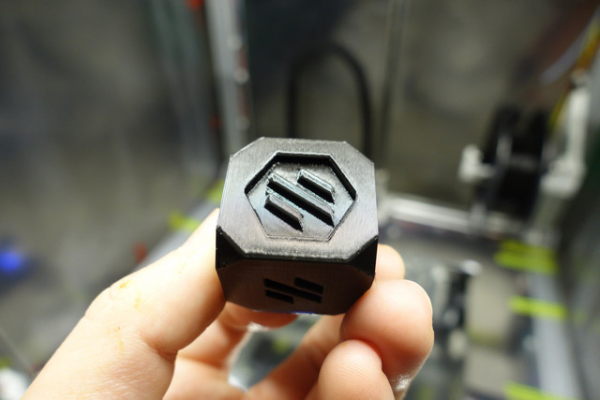

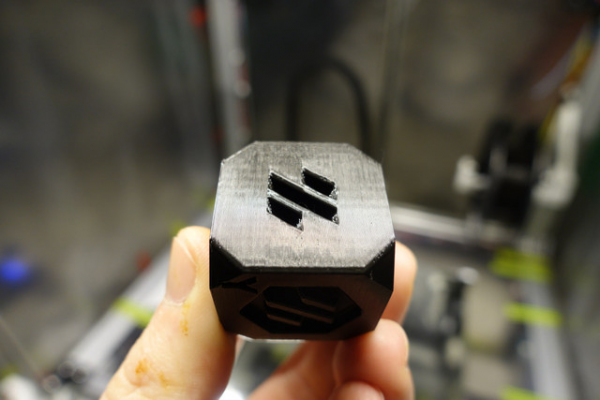

Hello

I printed 1st time the voron cube. Raised an acceleration to 3 000 mm/s2. Speed is 100 mm/s.

It's interesting that random ripples moved from Y axis to back side on X. Front X also has 2mm ripples from belts. Y doesn't have 2 mm ripples.

I also changed belts and X rail but this doesn't change problem with random ripples on Y on slow speeds.

I printed 1st time the voron cube. Raised an acceleration to 3 000 mm/s2. Speed is 100 mm/s.

It's interesting that random ripples moved from Y axis to back side on X. Front X also has 2mm ripples from belts. Y doesn't have 2 mm ripples.

I also changed belts and X rail but this doesn't change problem with random ripples on Y on slow speeds.

Sorry, only registered users may post in this forum.