Home

>

Reprappers

>

Topic

Advice needed on improving print quality

Posted by canam

|

Advice needed on improving print quality February 08, 2012 02:39AM |

Registered: 14 years ago Posts: 12 |

Finally got past my extruder problems it seems. So attempted some first prints tonight. Would really appreciate some advice from experts at this point.

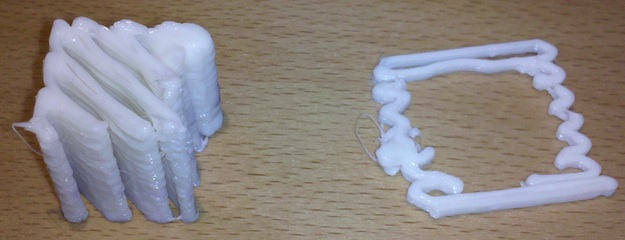

If you look at my picture, the item on the right was meant to be a nickel calibration test template (see [www.thingiverse.com]). The item on the left is meant to be a solid 20mmx20mmx20mm cube.

I used PLA plastic, 3mm filament. Reprap Host software and FiveD Gcode interpreter. Most of the parameters I used for the Reprap Host java program were the defaults. (I changed some benign things like the ending position of the bed after a print was done).

Anyway, I'm sure some of you have had this type of print occur rather than getting solid objects. How did you resolve the problem(s)? I would have expected the cube, in particular, to use cross-hatching, but it only laid down the print in one direction. The parameters used for crosshatching were: Extruder0_EvenHatchDirection(degrees)=45 & Extruder0_OddHatchDirection(degrees)=-45 (Note: That's MINUS 45 for the OddHatchDirection)

Any suggestions?

Edited 1 time(s). Last edit at 02/08/2012 02:41AM by canam.

If you look at my picture, the item on the right was meant to be a nickel calibration test template (see [www.thingiverse.com]). The item on the left is meant to be a solid 20mmx20mmx20mm cube.

I used PLA plastic, 3mm filament. Reprap Host software and FiveD Gcode interpreter. Most of the parameters I used for the Reprap Host java program were the defaults. (I changed some benign things like the ending position of the bed after a print was done).

Anyway, I'm sure some of you have had this type of print occur rather than getting solid objects. How did you resolve the problem(s)? I would have expected the cube, in particular, to use cross-hatching, but it only laid down the print in one direction. The parameters used for crosshatching were: Extruder0_EvenHatchDirection(degrees)=45 & Extruder0_OddHatchDirection(degrees)=-45 (Note: That's MINUS 45 for the OddHatchDirection)

Any suggestions?

Edited 1 time(s). Last edit at 02/08/2012 02:41AM by canam.

|

Re: Advice needed on improving print quality February 08, 2012 10:57AM |

Registered: 13 years ago Posts: 643 |

Move to a proper slicer and only use the host software for manual control and sending Gcode to the printer. Skeinforge, SFACT, Slic3r, and theres at least one more I can't remember - all of them will do a better job than the reprap software although Skeinforge in particular is tricky to set up. (To get you past the first stumbling block, reprap firmware needs the Dimension module to be turned on, and E steps per MM has to be calibrated in terms of filament fed rather than plastic extruded.)

|

Re: Advice needed on improving print quality February 08, 2012 06:09PM |

Registered: 12 years ago Posts: 229 |

Skeinforge + Pronterface Works best for me. I'll do a listing of my settings because things have changed and I don't think anyone has shared in a while.

Profile type: Extrusion

Profile Selection: PLA

Craft tab

Alteration Activate: yes

end.gcode You have to change the name of the alteration files in the skeinforge alterations folder for

start.gcode this to work.

Remove redundant mcode: yes

Replace variable with setting: yes

Bottom activate: yes

0.0

0.0

webbrowser

Carve

Add layer temp...: yes

1.8

2.0

1.0

0.4

0

912345678

Correct mesh

webbrowser

Chamber : only if you have a heated bed and you want it controlled through gcode

temps depend on the material used.

I leave this deactivated and control bedtemp manually through pronterface

Clip: no, it's a useful plugin but causes errors when building some parts

Comb: no

Cool: yes, my settings don't produce good bridges (yet) but do well with tall objects.

2.0

slow down

2.0

30.0

13.0 (irrelevant with slow down)

cool_end.gcode (Again need to rename the alteration files)

cool_start.gcode

10.0

yes

yes

Dimension: Yes, If your extruder doesn't move you haven't activated this.

absolute distance

retraction speed: 13.0 (this works well for me)

filament diameter: 2.72mm (measure yours with a caliper)

Packing density: 0.97 (default is 1 for PLA)

91234.0

2.0

retract within island: no

retraction distance: 4.0mm (start with 1mm and go up by 1mm until you no longer get strings)

restart extra distance: 0.15 (start at 0.0 and go up by 0.05 until you see the perimeter start where the extruder starts)

Export activate: yes

no

yes

no

no

yes

delete all comments

Gcode Small

gcode

replace.csv

save penultimate: no

Fill activate: yes

100

0

2

1

1

0.2

0.1

10

0.0

0.0

45.0

1

90.0

Line (your preference) (lines do better at bridging)

0.15

Infill Solidity (ratio): 0.5 (I use 0.5 as standard and 1.0 for parts that need to be strong)

1.8 (this needs to be calibrated but i got good results with the default)

3

Nearest

60.0

Perimeter > Loops > Infill

Fillet: no

Home: no (you can use homing if your endstops are setup)

(alteration files need to be renamed)

Hop: no

Inset

no

yes

1.8

Ascending Area

0.6

yes

Jitter: yes

2.0

Lash: no

Limit: no

Multiply: no (I use this frequently for making many of the same thing. Just set the columns and rows you want and enable. Just remember to turn it off again right after you slice)

0.0

0.0

1

1

no

15.0

oozebane: no

Preface

meta: (blank?)

yes

yes

no

yes

yes

Raft activate: yes

yes

1.0 (Change these 2 variables to ~0.6 if your first layer is not sticking properly)

1.0 (They should always be the same)

0.5

1.5

0

0.375

no

1.0

1.0

1.0

1.0

1.0

0

0.45

support_end.gcode

support start.gcode

1.0

1.0

3.0

no

0.8

3.0

none

60.0

Scale: no

Skin: no

Skirt: yes

yes

4.0

1

Smooth: no

Speed: yes

yes

1.0 (increase by 0.1 until bridges don't sag)

1.0

1.0

0.0

15.0 (this is as fast as my heater can heat the filament, bigger heater faster speeds)

15.0 (these 2 variables should be the same)

1.0

1.0

1.0

1.0

0.5

1.0

1.0

1.0

50.0 (start with 30.0 and increase by 5 until you miss steps) (I keep mine at 50 so i don't stress the machine)

Splodge: no

Stretch: yes

5.0

0.35

0.0

0.35

0.1

2.0

Temperature: no (I control temp manually through pronterface)

Tower, unpause, widen, wipe: no

Also put this into your start.gcode so the extruder doesn't reverse at the beginning of a print:

G92 X0 Y0 Z0 E0

Hope that helps!

Profile type: Extrusion

Profile Selection: PLA

Craft tab

Alteration Activate: yes

end.gcode You have to change the name of the alteration files in the skeinforge alterations folder for

start.gcode this to work.

Remove redundant mcode: yes

Replace variable with setting: yes

Bottom activate: yes

0.0

0.0

webbrowser

Carve

Add layer temp...: yes

1.8

2.0

1.0

0.4

0

912345678

Correct mesh

webbrowser

Chamber : only if you have a heated bed and you want it controlled through gcode

temps depend on the material used.

I leave this deactivated and control bedtemp manually through pronterface

Clip: no, it's a useful plugin but causes errors when building some parts

Comb: no

Cool: yes, my settings don't produce good bridges (yet) but do well with tall objects.

2.0

slow down

2.0

30.0

13.0 (irrelevant with slow down)

cool_end.gcode (Again need to rename the alteration files)

cool_start.gcode

10.0

yes

yes

Dimension: Yes, If your extruder doesn't move you haven't activated this.

absolute distance

retraction speed: 13.0 (this works well for me)

filament diameter: 2.72mm (measure yours with a caliper)

Packing density: 0.97 (default is 1 for PLA)

91234.0

2.0

retract within island: no

retraction distance: 4.0mm (start with 1mm and go up by 1mm until you no longer get strings)

restart extra distance: 0.15 (start at 0.0 and go up by 0.05 until you see the perimeter start where the extruder starts)

Export activate: yes

no

yes

no

no

yes

delete all comments

Gcode Small

gcode

replace.csv

save penultimate: no

Fill activate: yes

100

0

2

1

1

0.2

0.1

10

0.0

0.0

45.0

1

90.0

Line (your preference) (lines do better at bridging)

0.15

Infill Solidity (ratio): 0.5 (I use 0.5 as standard and 1.0 for parts that need to be strong)

1.8 (this needs to be calibrated but i got good results with the default)

3

Nearest

60.0

Perimeter > Loops > Infill

Fillet: no

Home: no (you can use homing if your endstops are setup)

(alteration files need to be renamed)

Hop: no

Inset

no

yes

1.8

Ascending Area

0.6

yes

Jitter: yes

2.0

Lash: no

Limit: no

Multiply: no (I use this frequently for making many of the same thing. Just set the columns and rows you want and enable. Just remember to turn it off again right after you slice)

0.0

0.0

1

1

no

15.0

oozebane: no

Preface

meta: (blank?)

yes

yes

no

yes

yes

Raft activate: yes

yes

1.0 (Change these 2 variables to ~0.6 if your first layer is not sticking properly)

1.0 (They should always be the same)

0.5

1.5

0

0.375

no

1.0

1.0

1.0

1.0

1.0

0

0.45

support_end.gcode

support start.gcode

1.0

1.0

3.0

no

0.8

3.0

none

60.0

Scale: no

Skin: no

Skirt: yes

yes

4.0

1

Smooth: no

Speed: yes

yes

1.0 (increase by 0.1 until bridges don't sag)

1.0

1.0

0.0

15.0 (this is as fast as my heater can heat the filament, bigger heater faster speeds)

15.0 (these 2 variables should be the same)

1.0

1.0

1.0

1.0

0.5

1.0

1.0

1.0

50.0 (start with 30.0 and increase by 5 until you miss steps) (I keep mine at 50 so i don't stress the machine)

Splodge: no

Stretch: yes

5.0

0.35

0.0

0.35

0.1

2.0

Temperature: no (I control temp manually through pronterface)

Tower, unpause, widen, wipe: no

Also put this into your start.gcode so the extruder doesn't reverse at the beginning of a print:

G92 X0 Y0 Z0 E0

Hope that helps!

|

Re: Advice needed on improving print quality February 08, 2012 06:44PM |

Registered: 14 years ago Posts: 12 |

|

Re: Advice needed on improving print quality February 08, 2012 07:01PM |

Registered: 12 years ago Posts: 229 |

|

Re: Advice needed on improving print quality February 09, 2012 04:17AM |

Registered: 12 years ago Posts: 120 |

A good starter for very little default tweaking needed is the Repetier suite - Repetier host, and Repetier firmware.

The host auto installs slic3r (which again has minimal setup required) - but can be set to use skeinforge if you decide to go for the more comprehensive functionality after getting basic printing working.

Repetier Host

Firmware

The host auto installs slic3r (which again has minimal setup required) - but can be set to use skeinforge if you decide to go for the more comprehensive functionality after getting basic printing working.

Repetier Host

Firmware

Sorry, only registered users may post in this forum.