Home

>

Reprappers

>

Topic

ExMrClean comes alive!

Posted by freds

|

ExMrClean comes alive! January 02, 2009 02:02AM |

Registered: 15 years ago Posts: 300 |

|

Re: ExMrClean comes alive! January 02, 2009 11:05AM |

Registered: 16 years ago Posts: 622 |

Very interesting reading...I like that you went the same way as Nophead. I kinda wish I had done the same now...that xy stage looks pretty sweet. After you ran it for 24 hours, did you notice any changes, settling, drift, or lost steps? I imagine not but you never know with these used parts/machines.

I'm working on an extruder design that does not require specialty components--just stuff you can get from an Ace Hardware store. You might consider taking a look at the Builder's blog post I did on it. At the very most, you will need a short section of PTFE for a thermal break. I am working on that problem too but I don't have as good of results on it. The extruder is, as I'm sure you know, the thing that gives us the most headache.

Anyway, great progress and keep up the good work!

[www.urbansurvivalists.com]

I'm working on an extruder design that does not require specialty components--just stuff you can get from an Ace Hardware store. You might consider taking a look at the Builder's blog post I did on it. At the very most, you will need a short section of PTFE for a thermal break. I am working on that problem too but I don't have as good of results on it. The extruder is, as I'm sure you know, the thing that gives us the most headache.

Anyway, great progress and keep up the good work!

[www.urbansurvivalists.com]

|

Re: ExMrClean comes alive! January 02, 2009 12:16PM |

Registered: 15 years ago Posts: 300 |

Hi Demented

You know I didn't really check after 24 hours, in the first four hours the X stage only came up with a delta of three steps. This is at 2000 steps per inch over a distance of around 10 inches. The Y stage was a delta of one for about eight inchs of travel.

However accuracy depends on the weakest link and that is definately my Z stage which with it's required arm to reach the center of travel is not as a stiff as I would wish.

So I am not sure how well it will mill which was part of the orginal goal. I will blog more about that soon.

The X & Y stages have 5 TPI ball screws and the Z stage has a 20 TPI ball screw. Though in calculating reported steps between stops it seems my driver is not half stepping on the Z stage.

In the process of cleaning things up so I can take more pictures and blog some more about my progress. Then I am going to write a checkout program to exercise it better and report more details. I will post the program and my results on here.

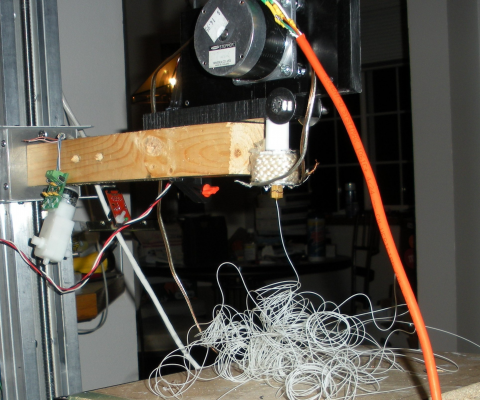

The wiring is kind of cluttered right now as I had used the Arduino wiring as a model when wiring up for my Sanguino and then found out the pin assigments were vastly different for the Sanguino (most wires on the other side of the breakout board).

I saw your blog entry on the extruder and will be very much interested in your results.

You know I didn't really check after 24 hours, in the first four hours the X stage only came up with a delta of three steps. This is at 2000 steps per inch over a distance of around 10 inches. The Y stage was a delta of one for about eight inchs of travel.

However accuracy depends on the weakest link and that is definately my Z stage which with it's required arm to reach the center of travel is not as a stiff as I would wish.

So I am not sure how well it will mill which was part of the orginal goal. I will blog more about that soon.

The X & Y stages have 5 TPI ball screws and the Z stage has a 20 TPI ball screw. Though in calculating reported steps between stops it seems my driver is not half stepping on the Z stage.

In the process of cleaning things up so I can take more pictures and blog some more about my progress. Then I am going to write a checkout program to exercise it better and report more details. I will post the program and my results on here.

The wiring is kind of cluttered right now as I had used the Arduino wiring as a model when wiring up for my Sanguino and then found out the pin assigments were vastly different for the Sanguino (most wires on the other side of the breakout board).

I saw your blog entry on the extruder and will be very much interested in your results.

|

Re: ExMrClean comes alive! January 06, 2009 01:34PM |

Registered: 16 years ago Posts: 622 |

I really like ball screws and recirculating ball nuts! We used those in our OIT RepStrap here

oitreprap.googlepages.com

They give flawless performance. Slowdown isn't too bad either since the tpi is pretty low. Only problem I have with them is their cost...damn things are expensive!

Very interested in your blog progress!

Demented

[www.urbansurvivalists.com]

oitreprap.googlepages.com

They give flawless performance. Slowdown isn't too bad either since the tpi is pretty low. Only problem I have with them is their cost...damn things are expensive!

Very interested in your blog progress!

Demented

[www.urbansurvivalists.com]

|

Re: ExMrClean comes alive! January 07, 2009 08:03PM |

Registered: 15 years ago Posts: 300 |

Hi Demented

Thanks for the comments. I am fairly much caught up with my blogging now. Here's my lastests posts.

SMC mode for single cable end stop sensors [exmrclean.blogspot.com]

More on End Stops [exmrclean.blogspot.com]

Mounting the Z stage [exmrclean.blogspot.com]

Major construction is done! [exmrclean.blogspot.com]

Thanks for the comments. I am fairly much caught up with my blogging now. Here's my lastests posts.

SMC mode for single cable end stop sensors [exmrclean.blogspot.com]

More on End Stops [exmrclean.blogspot.com]

Mounting the Z stage [exmrclean.blogspot.com]

Major construction is done! [exmrclean.blogspot.com]

|

Re: ExMrClean comes alive! January 11, 2009 03:22AM |

Registered: 16 years ago Posts: 622 |

Looking good. Maybe I missed it in there somewhere but how much time do these recent blog posts account for? Are we talking months? Weeks? Days?

What is your next step?

Demented

[www.urbansurvivalists.com]

What is your next step?

Demented

[www.urbansurvivalists.com]

|

Re: ExMrClean comes alive! January 12, 2009 12:40AM |

Registered: 15 years ago Posts: 300 |

Fairly much everything has been done in the last six to eight weeks, kind of hard to keep track when I started. Sort of have been off work for the holidays, going back to tomorrow.

Got my order in the store for extruder related stuff and bought more parts on here, so experimenting with a little bit of milling, publishing a test tool that I am working on and building my extruder are my next goals. Been eyeing your extruder design to fiddle up the mechanics part.

Whats the part number for the shoulder bolt that you are using?

Got my order in the store for extruder related stuff and bought more parts on here, so experimenting with a little bit of milling, publishing a test tool that I am working on and building my extruder are my next goals. Been eyeing your extruder design to fiddle up the mechanics part.

Whats the part number for the shoulder bolt that you are using?

|

Re: ExMrClean comes alive! January 13, 2009 11:42AM |

Registered: 16 years ago Posts: 622 |

I believe this is the part number from Fastenal

31161517

But I'm never really sure about shoulder bolts. They have a bunch of dimensions that regular bolts don't. If I understand it right the first letter-number combo in the spec refers to the shoulder diameter--the part the bearing will sit on--and the second number-letter combo refers to the length of the shoulder from the cap to the beginning of the shoulder.

So, for that bolt you will need some M6-1.0 nuts. Like these:

31161727

That's what I would order--if I had to order these instead of having them sitting around! Don't take my word for it, ask around, go in to an actual Fastenal store or other store where they would know. Make sure cause these aren't the kinds of fasteners you can just use for something else very easily. Kinda specific.

Hope that helped.

Demented

[www.urbansurvivalists.com]

31161517

But I'm never really sure about shoulder bolts. They have a bunch of dimensions that regular bolts don't. If I understand it right the first letter-number combo in the spec refers to the shoulder diameter--the part the bearing will sit on--and the second number-letter combo refers to the length of the shoulder from the cap to the beginning of the shoulder.

So, for that bolt you will need some M6-1.0 nuts. Like these:

31161727

That's what I would order--if I had to order these instead of having them sitting around! Don't take my word for it, ask around, go in to an actual Fastenal store or other store where they would know. Make sure cause these aren't the kinds of fasteners you can just use for something else very easily. Kinda specific.

Hope that helped.

Demented

[www.urbansurvivalists.com]

|

Re: ExMrClean comes alive! March 23, 2009 11:38PM |

Registered: 15 years ago Posts: 300 |

Well after lots of trys and experimentation I finally have a working extruder!

I built this up using my drill press and Delrin plastic. As you can see it is a stepper motor pinch wheel design.

I will blog more about it when I have time, been drafted by a local high school to advise a bunch of boys on getting a reprap working in their enviroment.

I built this up using my drill press and Delrin plastic. As you can see it is a stepper motor pinch wheel design.

I will blog more about it when I have time, been drafted by a local high school to advise a bunch of boys on getting a reprap working in their enviroment.

Sorry, only registered users may post in this forum.