Home

>

Reprappers

>

Topic

Hallow inside

Posted by Yamster

|

Hallow inside August 24, 2013 06:51PM |

Registered: 10 years ago Posts: 194 |

I just printed a small gear part for Greg's Wade extruder.

The overall print quality is alright, however I can see there's some void between the center hole and the gear teeth.

I don't think it's print quality/calibration issue; I've also printed the big gear and extruder main body, they all look very solid.

At this point I suspect this has something to do with the extrusion width. If it is, would there be a smart way of figuring out the correct extrusion width based on the size/shape of the object, instead of doing it by trail and error?

If it's not because of the extrusion width setting.. what could this be?

Edited 1 time(s). Last edit at 08/24/2013 06:51PM by Yamster.

The overall print quality is alright, however I can see there's some void between the center hole and the gear teeth.

I don't think it's print quality/calibration issue; I've also printed the big gear and extruder main body, they all look very solid.

At this point I suspect this has something to do with the extrusion width. If it is, would there be a smart way of figuring out the correct extrusion width based on the size/shape of the object, instead of doing it by trail and error?

If it's not because of the extrusion width setting.. what could this be?

Edited 1 time(s). Last edit at 08/24/2013 06:51PM by Yamster.

|

Re: Hallow inside August 24, 2013 07:01PM |

Registered: 10 years ago Posts: 194 |

Oh I forgot to add the extrusion setting head comments from the gcode file (generated by Slic3r) :

; layer_height = .3

; perimeters = 3

; top_solid_layers = 3

; bottom_solid_layers = 3

; fill_density = 0.6

; perimeter_speed = 40

; infill_speed = 70

; travel_speed = 140

; nozzle_diameter = 0.5

; filament_diameter = 2.83

; extrusion_multiplier = 1

; perimeters extrusion width = 0.66mm

; infill extrusion width = 0.66mm

; solid infill extrusion width = 0.66mm

; top infill extrusion width = 0.66mm

; layer_height = .3

; perimeters = 3

; top_solid_layers = 3

; bottom_solid_layers = 3

; fill_density = 0.6

; perimeter_speed = 40

; infill_speed = 70

; travel_speed = 140

; nozzle_diameter = 0.5

; filament_diameter = 2.83

; extrusion_multiplier = 1

; perimeters extrusion width = 0.66mm

; infill extrusion width = 0.66mm

; solid infill extrusion width = 0.66mm

; top infill extrusion width = 0.66mm

|

Re: Hallow inside August 24, 2013 07:05PM |

Registered: 10 years ago Posts: 194 |

And for comparison.. here's another print of the same small gear, which I have printed some time ago (I forgot what the exact settings were) using 0.35 mm nozzle head. For the small gear with void inside, I used 0.5 mm nozzle.

As you can see, there's a little bit of space in the same area, but it's a lot smaller. The void was small enough that I didn't consider that as an issue or abnormality back then.

Edited 1 time(s). Last edit at 08/24/2013 07:05PM by Yamster.

As you can see, there's a little bit of space in the same area, but it's a lot smaller. The void was small enough that I didn't consider that as an issue or abnormality back then.

Edited 1 time(s). Last edit at 08/24/2013 07:05PM by Yamster.

|

Re: Hallow inside August 24, 2013 07:45PM |

Registered: 12 years ago Posts: 198 |

three things you could try.

1. Set the extrusion width to your nozzle width in the advanced section in Slic3r.

2. Use only 1 parimiter for this print. This gives the slicer more space to actially fill in.

3. Make sure extra paramaters is switched off. Enforces 2.

Komb'

Glankonian Protoforms

1. Set the extrusion width to your nozzle width in the advanced section in Slic3r.

2. Use only 1 parimiter for this print. This gives the slicer more space to actially fill in.

3. Make sure extra paramaters is switched off. Enforces 2.

Komb'

Glankonian Protoforms

|

Re: Hallow inside August 24, 2013 08:33PM |

Registered: 17 years ago Posts: 392 |

That is odd. Technically, both small gears shown are flawed. They should have a patern of infill connecting the inner and outer surfaces, and they should be finished flat with a solid "cap". It should not be possible to see into them at all, unless the print was aborted before the top surface was filled in fully.

Yvan

Singularity Machine

Yvan

Singularity Machine

|

Re: Hallow inside August 24, 2013 10:55PM |

Registered: 10 years ago Posts: 194 |

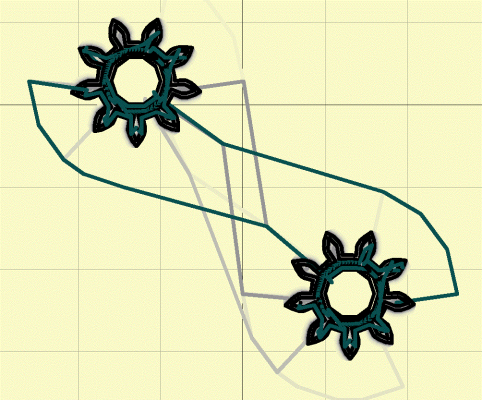

Yes.. this is weird indeed. After loading the g code into Pronterface, I checked the upper layers, where the gear teethe are. And, they are actually hallow! I don't see any infill lines between the center hole and the gear teeth (by the way, you will see two small gears - I wanted to slow down the print to prevent excessive curling, and instead of halving the feed rate, I thought I could just print two):

I could try some other extrusion width settings, but I'm also wondering if there's something wrong with the STL I used? I have attached the STL file ("smallgearmod_fixed_1.stl"); can someone slice it and check if the gear teeth have infills?

Edited 1 time(s). Last edit at 08/24/2013 10:56PM by Yamster.

I could try some other extrusion width settings, but I'm also wondering if there's something wrong with the STL I used? I have attached the STL file ("smallgearmod_fixed_1.stl"); can someone slice it and check if the gear teeth have infills?

Edited 1 time(s). Last edit at 08/24/2013 10:56PM by Yamster.

|

Re: Hallow inside August 25, 2013 01:09AM |

Registered: 11 years ago Posts: 342 |

Here is one I did a couple months ago with 30% in fill. This is pretty much what the pronterface preview shows. Even when I turn the infill up to 100% it still doesn't get much better than this.

[www.flickr.com]

[www.flickr.com]

[www.flickr.com]

[www.flickr.com]

|

Re: Hallow inside August 25, 2013 02:05AM |

Registered: 17 years ago Posts: 392 |

I've printed maybe 10 of those smaller gears by now, from the wades to the herringbone, to the eckstruder style, and none showed that hollowness.

About half were printed with a Windows Vista machine and RepSnapper. Now I'm using Slic3r on OS X, and some Scottish software called Macpronterface....so who knows... ??

I'm just trying to get my prints to look clean like appdev's!

Yvan

Singularity Machine

About half were printed with a Windows Vista machine and RepSnapper. Now I'm using Slic3r on OS X, and some Scottish software called Macpronterface....so who knows... ??

I'm just trying to get my prints to look clean like appdev's!

Yvan

Singularity Machine

|

Re: Hallow inside August 25, 2013 03:04AM |

Registered: 11 years ago Posts: 198 |

It's a question of finding the right slicing parameters, or choosing another slicer.

I downloaded thing 97377, and could quite easily replicate the issue, finally after playing around for quite some time i got it to slice nicely with these parameters:

; layer_height = 0.3

; perimeters = 2

; top_solid_layers = 3

; bottom_solid_layers = 3

; fill_density = 0.6

; perimeter_speed = 60

; infill_speed = 60

; travel_speed = 120

; nozzle_diameter = 0.5

; filament_diameter = 1.28379

; extrusion_multiplier = 1

; perimeters extrusion width = 0.62mm

; infill extrusion width = 0.62mm

; solid infill extrusion width = 0.62mm

; top infill extrusion width = 0.62mm

0.62mm extrusion with may be a bit on the low side for a 0.5mm nozzle, but it is worth a try.

Anything wider thou, Slic3r seeems to want to make a hollow part, regardless of the layer height.

I downloaded thing 97377, and could quite easily replicate the issue, finally after playing around for quite some time i got it to slice nicely with these parameters:

; layer_height = 0.3

; perimeters = 2

; top_solid_layers = 3

; bottom_solid_layers = 3

; fill_density = 0.6

; perimeter_speed = 60

; infill_speed = 60

; travel_speed = 120

; nozzle_diameter = 0.5

; filament_diameter = 1.28379

; extrusion_multiplier = 1

; perimeters extrusion width = 0.62mm

; infill extrusion width = 0.62mm

; solid infill extrusion width = 0.62mm

; top infill extrusion width = 0.62mm

0.62mm extrusion with may be a bit on the low side for a 0.5mm nozzle, but it is worth a try.

Anything wider thou, Slic3r seeems to want to make a hollow part, regardless of the layer height.

|

Re: Hallow inside August 25, 2013 08:35PM |

Registered: 17 years ago Posts: 392 |

What I don't understand is what the top three layers are up to. They should be solid, that has nothing to do with infill for example. It looks like it could be a bug affecting smaller thinner detail...?

Yvan

Singularity Machine

Yvan

Singularity Machine

|

Re: Hallow inside August 26, 2013 01:44PM |

Registered: 10 years ago Posts: 194 |

So.. It is a slicing issue. There actually was a very similar issue in another forum: [forums.reprap.org] It's quite funny that it's almost identical issue I had, including the fact that the reporter had a problem only printing a small extruder gear! The only difference was that I was printing a gear with "tire track" teeth (not sure what its proper name is.. when the gear is in upright position, the teeth look like <<< rather than | | | from side) while the other one had straight teeth.

I tried the following setting with my Slic3r and got a considerably better result:

; layer_height = .3

; perimeters = 3

; top_solid_layers = 3

; bottom_solid_layers = 3

; fill_density = 0.6

; perimeter_speed = 40

; infill_speed = 60

; travel_speed = 140

; nozzle_diameter = 0.5

; filament_diameter = 2.80

; extrusion_multiplier = 1

; perimeters extrusion width = 0.50mm

; infill extrusion width = 0.50mm

; solid infill extrusion width = 0.50mm

; top infill extrusion width = 0.50mm

; first layer extrusion width = 0.50mm

I think 0.50mm extrusion width is a bit too narrow for my nozzle size (which is also 0.50mm) and the layer height (0.3mm, so the width is only 167% of the height), but oh well, it worked.

Two gears on the let are with 0.66mm extrusion width setup, and the other two on the right is with the above setup:

Yes, it's a bit of mystery why Slic3r would not fill the void. Maybe it's a bug, or maybe it just determined it won't be possible or practical even to try to infill for such a small space with the specified extrusion width. Or, can it be Pronterface which ignores certain g code instructions which it cannot fulfill, such as infilling a very small gap?

With a smaller extrusion width value, I can see the infill line in the Pronterface layer view.

Edited 1 time(s). Last edit at 08/26/2013 01:45PM by Yamster.

I tried the following setting with my Slic3r and got a considerably better result:

; layer_height = .3

; perimeters = 3

; top_solid_layers = 3

; bottom_solid_layers = 3

; fill_density = 0.6

; perimeter_speed = 40

; infill_speed = 60

; travel_speed = 140

; nozzle_diameter = 0.5

; filament_diameter = 2.80

; extrusion_multiplier = 1

; perimeters extrusion width = 0.50mm

; infill extrusion width = 0.50mm

; solid infill extrusion width = 0.50mm

; top infill extrusion width = 0.50mm

; first layer extrusion width = 0.50mm

I think 0.50mm extrusion width is a bit too narrow for my nozzle size (which is also 0.50mm) and the layer height (0.3mm, so the width is only 167% of the height), but oh well, it worked.

Two gears on the let are with 0.66mm extrusion width setup, and the other two on the right is with the above setup:

Yes, it's a bit of mystery why Slic3r would not fill the void. Maybe it's a bug, or maybe it just determined it won't be possible or practical even to try to infill for such a small space with the specified extrusion width. Or, can it be Pronterface which ignores certain g code instructions which it cannot fulfill, such as infilling a very small gap?

With a smaller extrusion width value, I can see the infill line in the Pronterface layer view.

Edited 1 time(s). Last edit at 08/26/2013 01:45PM by Yamster.

|

Re: Hallow inside August 26, 2013 02:05PM |

Registered: 11 years ago Posts: 198 |

Infill in small features seems to have haunted Slic3r for quite a while.

As for print width I would try to get it as wide as possible, until Slic3r starts to act up. It should give you stronger parts and less warping.

With 0.5mm nozzle I usually print at 0.75mm*0.25mm, and 0.5mm*0.2mm with 0.35mm nozzle. This seems to work great for me, but for some prints this obviously needs to be tweaked.

As for print width I would try to get it as wide as possible, until Slic3r starts to act up. It should give you stronger parts and less warping.

With 0.5mm nozzle I usually print at 0.75mm*0.25mm, and 0.5mm*0.2mm with 0.35mm nozzle. This seems to work great for me, but for some prints this obviously needs to be tweaked.

|

Re: Hallow inside August 26, 2013 03:17PM |

Registered: 17 years ago Posts: 392 |

The term for those gears is herringbone BTW.

The two new ones will certainly be stronger.

Yvan

Singularity Machine

The two new ones will certainly be stronger.

Yvan

Singularity Machine

Sorry, only registered users may post in this forum.