Home

>

Reprappers

>

Topic

i need some advice

Posted by makovai

|

i need some advice December 30, 2013 09:56AM |

Registered: 10 years ago Posts: 41 |

I have been printing for a while now and all of a sudden I have a situation i just cant seem to figure out.

Curling, or massive strees in my parts.

I have two scenerio's of which neither are acceptable.

I get solid tight layers on the part, but cant get it to stick to the table, or I use ABS glue and it nice adheasion to the table but the stress breaks my layers apart.

I know this is a temperature issue. I have experimented with every combination of temperature, nozzle dia, and layer thickness i can think of. I print in a office room in my house. The temperature is a very comfortable 70° F.

Any suggestions would be appriciated.

Edited 1 time(s). Last edit at 12/30/2013 12:30PM by makovai.

Curling, or massive strees in my parts.

I have two scenerio's of which neither are acceptable.

I get solid tight layers on the part, but cant get it to stick to the table, or I use ABS glue and it nice adheasion to the table but the stress breaks my layers apart.

I know this is a temperature issue. I have experimented with every combination of temperature, nozzle dia, and layer thickness i can think of. I print in a office room in my house. The temperature is a very comfortable 70° F.

Any suggestions would be appriciated.

Edited 1 time(s). Last edit at 12/30/2013 12:30PM by makovai.

|

Re: i need some advice December 30, 2013 12:24PM |

Registered: 11 years ago Posts: 187 |

|

Re: i need some advice December 30, 2013 06:01PM |

Registered: 10 years ago Posts: 1,381 |

@makovai ,

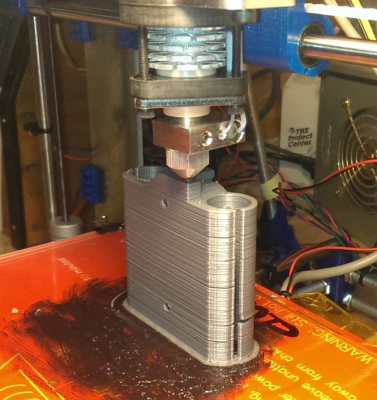

What kind of hot end are you using, looks like a custom thermal break, can you provide some details of it?

Notes:

ABS, (Acrylonitrile butadiene styrene, Type: extruded):

Drying Temperature:

Range: 70°C to 93.3°C, (158ºF to 200ºF)

Average: 80.9°C, (178ºF ).

Dry time:

Range: 2 to 4 hours.

Average: 3.2 hours.

Glass-transition temp:

Range: 108°C to 109°C.

Average: 108°C, (226.4ºF ).

Wikipedia: 105°C, (221ºF ).

Begin testing around this temp:

Substrate/bed temperature: <105°C, (221ºF ).

Enclosure temperature: <105°C, (221ºF ).

Material properties are generally stable between:

−20 and 80 °C (−4 and 176 °F).

Linear Mold Shrinkage (extruded):

0.002 – 0.008 cm/cm.

Average value: 0.00532 cm/cm.

Machine parameters:

Extrude temp (RepRap): 210 C ~ 240 C

Edited 1 time(s). Last edit at 12/30/2013 06:04PM by A2.

What kind of hot end are you using, looks like a custom thermal break, can you provide some details of it?

Notes:

ABS, (Acrylonitrile butadiene styrene, Type: extruded):

Drying Temperature:

Range: 70°C to 93.3°C, (158ºF to 200ºF)

Average: 80.9°C, (178ºF ).

Dry time:

Range: 2 to 4 hours.

Average: 3.2 hours.

Glass-transition temp:

Range: 108°C to 109°C.

Average: 108°C, (226.4ºF ).

Wikipedia: 105°C, (221ºF ).

Begin testing around this temp:

Substrate/bed temperature: <105°C, (221ºF ).

Enclosure temperature: <105°C, (221ºF ).

Material properties are generally stable between:

−20 and 80 °C (−4 and 176 °F).

Linear Mold Shrinkage (extruded):

0.002 – 0.008 cm/cm.

Average value: 0.00532 cm/cm.

Machine parameters:

Extrude temp (RepRap): 210 C ~ 240 C

Edited 1 time(s). Last edit at 12/30/2013 06:04PM by A2.

|

Re: i need some advice December 30, 2013 07:51PM |

Registered: 10 years ago Posts: 1,433 |

I sure thought I posted a reply to this already .....

Stick to the bed:

1) Bed is not level

2) Bed zero is wrong

3) Bed temp is wrong (if abs)

4) Printing speed on first layer is to fast

Upper layers:

1) Extruder temp is to low

2) Print speed is to low

3) Extrusion flow is to low

Either one:

1) Z axis is not calibrated

2) Extruder is not calibrated

Stick to the bed:

1) Bed is not level

2) Bed zero is wrong

3) Bed temp is wrong (if abs)

4) Printing speed on first layer is to fast

Upper layers:

1) Extruder temp is to low

2) Print speed is to low

3) Extrusion flow is to low

Either one:

1) Z axis is not calibrated

2) Extruder is not calibrated

|

Re: i need some advice December 30, 2013 08:13PM |

Registered: 13 years ago Posts: 567 |

If your print sticks well to the heated bed:

Every extruded layer shrinks during the difference in temp from being extruded to room temp.

If you always put a small (hot) layer on a big (cold) layer the model begins to warp.

So you have to lower the difference in temperature from extruding to room temp:

A too high extruder temp could cause that too. Higher the Bedtemp in upper layers could solve the problem too. (Avoid cold air around the bed - heatchamber)

vincent.

Edited 1 time(s). Last edit at 12/30/2013 08:14PM by vinmicgra.

########################

[the-sparklab.de]

OS, 3D Drucker, CNC,...

########################

Every extruded layer shrinks during the difference in temp from being extruded to room temp.

If you always put a small (hot) layer on a big (cold) layer the model begins to warp.

So you have to lower the difference in temperature from extruding to room temp:

A too high extruder temp could cause that too. Higher the Bedtemp in upper layers could solve the problem too. (Avoid cold air around the bed - heatchamber)

vincent.

Edited 1 time(s). Last edit at 12/30/2013 08:14PM by vinmicgra.

########################

[the-sparklab.de]

OS, 3D Drucker, CNC,...

########################

Sorry, only registered users may post in this forum.