Home

>

Reprappers

>

Topic

flow rate gone to the dogs...!!!

Posted by ekaggrat

|

flow rate gone to the dogs...!!! February 03, 2014 12:50PM |

Registered: 11 years ago Posts: 364 |

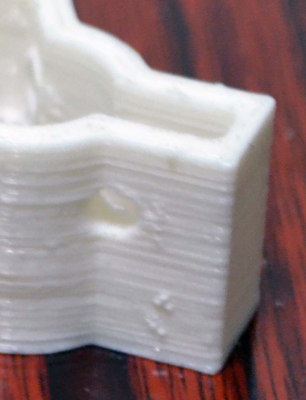

my z artifacts have gone from near perfect from the object on the left to the object on the right.. I know it is some kind of flow rate issue but cant seem to figure it out ... checked the extruder steps twice... checked the pid tuning of the hotend... but cant seem to get it ... The only thing i changed was the linear bearing on the z axis and the extruder main gear as it had snapped on the axis... the new gear is better than the old one..

any ideas???

the hot end is a j-head with a 0.4 mm nozzle and the print is done at 0.25mm layer height... the printer is a mendelmax 1.5... the z axis threaded rods are m6 rods... and the z axis is set to 1/16 microstepping...

any ideas???

the hot end is a j-head with a 0.4 mm nozzle and the print is done at 0.25mm layer height... the printer is a mendelmax 1.5... the z axis threaded rods are m6 rods... and the z axis is set to 1/16 microstepping...

|

Re: flow rate gone to the dogs...!!! February 03, 2014 01:17PM |

Registered: 10 years ago Posts: 466 |

|

Re: flow rate gone to the dogs...!!! February 03, 2014 01:31PM |

Registered: 11 years ago Posts: 364 |

my z axis has a z screw isolator like this one

thingiverse

so i doubt it is that .. also it is not so regular as z wobble

thingiverse

so i doubt it is that .. also it is not so regular as z wobble

|

Re: flow rate gone to the dogs...!!! February 04, 2014 02:16AM |

Registered: 11 years ago Posts: 349 |

|

Re: flow rate gone to the dogs...!!! February 04, 2014 03:07AM |

Registered: 11 years ago Posts: 364 |

okay after lot of breaking my head did a check on the extruder motor pushing the filament.. it turns out that there is a variation in the amount of filament pushed... i ran a test to push the filament 50mm and the actual length pushed varies randomly by 5-8 mm....

any ideas whats causing it...?? the motor driver is set to 1/8 steps and it is a generation 4 electronics motor driver... also checked if the filament is slipping and it is not...

any ideas whats causing it...?? the motor driver is set to 1/8 steps and it is a generation 4 electronics motor driver... also checked if the filament is slipping and it is not...

|

Re: flow rate gone to the dogs...!!! February 04, 2014 11:00AM |

Registered: 10 years ago Posts: 241 |

If the teeth in your gear are clogged, it can prevent good grip on the filament. Also short teeth.

If the center hole on the gear is not "centered" this will turn in an oval. Making varied extrusions.

Also, trying to push the filament too fast. If your extruder motor has high enough torque, it won't skip. Causing the gear to turn and cut a groove in the filament loosing friction. Either turn your heat up, or turn your speed down might help.

On the same note. If your motor doesn't have the torque, it may skip steps. Causing inconsistent extruded lengths.

If the center hole on the gear is not "centered" this will turn in an oval. Making varied extrusions.

Also, trying to push the filament too fast. If your extruder motor has high enough torque, it won't skip. Causing the gear to turn and cut a groove in the filament loosing friction. Either turn your heat up, or turn your speed down might help.

On the same note. If your motor doesn't have the torque, it may skip steps. Causing inconsistent extruded lengths.

Sorry, only registered users may post in this forum.