Home

>

Reprappers

>

Topic

Repetitive patterns in my prints and uneven wall thickness

Posted by FalloutBe

|

Repetitive patterns in my prints and uneven wall thickness January 11, 2015 09:54AM |

Registered: 9 years ago Posts: 63 |

Hello,

This is my first 3D printer (a prusa I3) and I'm printing test parts (ABS) to see how well it performs.

I have already calibrated my extruder; when asking for 100mm of material, the wire moves exactly 100mm, while the extruder does not skip any steps.

It does skip steps at the first layer of the print, likely because the head was too close to my printbed.

Printing bed was at 100°C, head temperature was increased every few layers, from 220°C to 260°C.

Bed is coated with hairspray.

These are my problems:

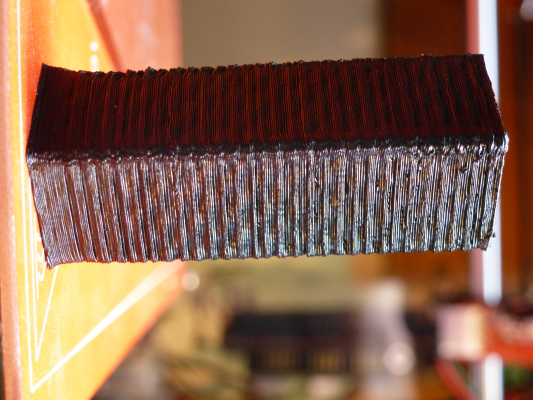

1) Not all layers have the same wall thickness; Looks like every 10 layers there is not enough material?

click to enlarge

I have looked up some guides to find out what this fenomenon is called,

but none of those things seem to look like the problem I'm having here.

The layer preview of Slic3r does not show these layers which have thinner walls. In Slic3r, everything looks perfectly straight.

The bottom ~25 layers actually look much better, apart from the fact that they are too wide.

(this problem I did find in the troubleshooting guide; apparently called "Elephant's foot"; I do not request any help for this problem)

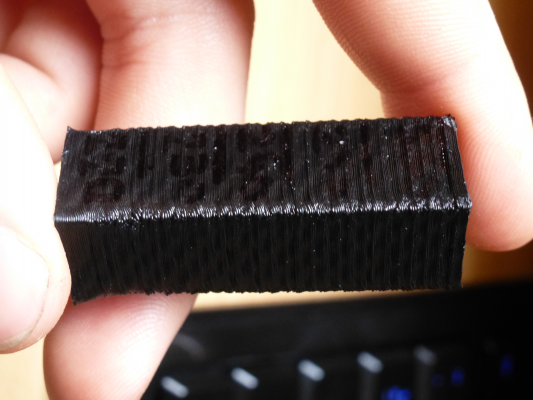

2) Print head temperatures marked:

This image does not illustrate any specific problem, I just wanted to show you at what temperature the different zones of the part were printed.

3) Strange diagonal pattern:

Is this caused by the mechanical construction of my axis? The belt does roll over 3d printed wheels, which are likely not round.

However, if this was the case, shouldn't that create a vertical pattern instead of a diagonal one?

4) Also, in the above picture you can see that the 2 corners on the back side of the piece (the side which pointed towards the negative Y direction) are bent upwards.

This problem occures over the whole temperature range

Kind regards

EDIT:

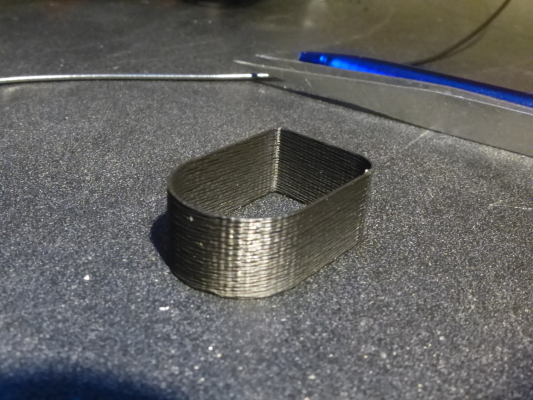

I printed another test part, which looks a thousand times better, but it is printed with roughly the same settings.

This part is only one layer thick and was printed at a constant nozzle temperature of 240°C; bed at 110°C

So, how come this part looks good, and the other part does not? is it simply because of the geometry of that part?

Edited 5 time(s). Last edit at 01/11/2015 11:12AM by FalloutBe.

This is my first 3D printer (a prusa I3) and I'm printing test parts (ABS) to see how well it performs.

I have already calibrated my extruder; when asking for 100mm of material, the wire moves exactly 100mm, while the extruder does not skip any steps.

It does skip steps at the first layer of the print, likely because the head was too close to my printbed.

Printing bed was at 100°C, head temperature was increased every few layers, from 220°C to 260°C.

Bed is coated with hairspray.

These are my problems:

1) Not all layers have the same wall thickness; Looks like every 10 layers there is not enough material?

click to enlarge

I have looked up some guides to find out what this fenomenon is called,

but none of those things seem to look like the problem I'm having here.

The layer preview of Slic3r does not show these layers which have thinner walls. In Slic3r, everything looks perfectly straight.

The bottom ~25 layers actually look much better, apart from the fact that they are too wide.

(this problem I did find in the troubleshooting guide; apparently called "Elephant's foot"; I do not request any help for this problem)

2) Print head temperatures marked:

This image does not illustrate any specific problem, I just wanted to show you at what temperature the different zones of the part were printed.

3) Strange diagonal pattern:

Is this caused by the mechanical construction of my axis? The belt does roll over 3d printed wheels, which are likely not round.

However, if this was the case, shouldn't that create a vertical pattern instead of a diagonal one?

4) Also, in the above picture you can see that the 2 corners on the back side of the piece (the side which pointed towards the negative Y direction) are bent upwards.

This problem occures over the whole temperature range

Kind regards

EDIT:

I printed another test part, which looks a thousand times better, but it is printed with roughly the same settings.

This part is only one layer thick and was printed at a constant nozzle temperature of 240°C; bed at 110°C

So, how come this part looks good, and the other part does not? is it simply because of the geometry of that part?

Edited 5 time(s). Last edit at 01/11/2015 11:12AM by FalloutBe.

|

Re: Repetitive patterns in my prints and uneven wall thickness January 11, 2015 07:18PM |

Registered: 10 years ago Posts: 167 |

|

Re: Repetitive patterns in my prints and uneven wall thickness January 11, 2015 08:55PM |

Registered: 11 years ago Posts: 1,171 |

First problem you have is too much heat on the bed, it's know known that 85-90c is more than hot enough and higher can effect the print. Go to this page [reprap.org] and scroll down to "Part too hot" that black square is mine.

The zig zag looking pattern looks a lot like Z wobble to me, just do a search for it. Try printing that first item with the bed at 85c and slow the speed down say 25% and see if that helps (slower speed can help a little with Z wobble).

The zig zag looking pattern looks a lot like Z wobble to me, just do a search for it. Try printing that first item with the bed at 85c and slow the speed down say 25% and see if that helps (slower speed can help a little with Z wobble).

|

Re: Repetitive patterns in my prints and uneven wall thickness January 12, 2015 05:57PM |

Registered: 9 years ago Posts: 63 |

No, the hotend is really sturdy.Quote

Zerker

watching your print, does your hotend move at all?

Alright, I will not print with the heatbed hotter than 90°C anymoreQuote

tmorris9

First problem you have is too much heat on the bed, it's know known that 85-90c is more than hot enough and higher can effect the print. Go to this page [reprap.org] and scroll down to "Part too hot" that black square is mine.

The zig zag looking pattern looks a lot like Z wobble to me, just do a search for it. Try printing that first item with the bed at 85c and slow the speed down say 25% and see if that helps (slower speed can help a little with Z wobble).

This indeed seems to help a lot!

This indeed seems to help a lot!However this causes more warping but I'll have to fix that in other ways.

I'll check for the Z wobble tomorrow

thanks for your help!

thanks for your help!

|

Re: Repetitive patterns in my prints and uneven wall thickness January 14, 2015 07:58AM |

Admin Registered: 11 years ago Posts: 3,096 |

The best question in this case would be, to ask if you could post an image of your hotend and printer.

The warping could be caused by a poorly-aimed hotend cooler. And the wobble could be caused by not-straight Z-axis rods or by loose belts.

Another thing to check for would be if your extruder hobbed bolt is straight.

And last, are both your belt pulleys and pulleys themselves from the same standard? (GT2 or T2 or T2.5 etc). It can occur that when the pulley and belt are not using the same standards, that the printing becomes inaccurate.

http://www.marinusdebeer.nl/

The warping could be caused by a poorly-aimed hotend cooler. And the wobble could be caused by not-straight Z-axis rods or by loose belts.

Another thing to check for would be if your extruder hobbed bolt is straight.

And last, are both your belt pulleys and pulleys themselves from the same standard? (GT2 or T2 or T2.5 etc). It can occur that when the pulley and belt are not using the same standards, that the printing becomes inaccurate.

http://www.marinusdebeer.nl/

|

Re: Repetitive patterns in my prints and uneven wall thickness January 14, 2015 08:33AM |

Registered: 10 years ago Posts: 903 |

|

Re: Repetitive patterns in my prints and uneven wall thickness January 14, 2015 09:29AM |

Registered: 9 years ago Posts: 351 |

|

Re: Repetitive patterns in my prints and uneven wall thickness January 14, 2015 10:27AM |

Registered: 9 years ago Posts: 1,011 |

The glass point of ABS is 105°C. It's interesting to print the first layer at 110°C, a bit over the glass point temperature for ABS. That will help first layer to stick with the bed. Then reduce to 90°C for the next layers. A brim (at last 10mm) and 10mm walls can be very helpful to prevent wrapping on large and difficult parts.

The diagonal pattern sources certainly in transmission parts. There's maybe several problems in one, check all : pulleys (metal machined ones does not cost that much), threaded rods, nuts, bearings... For the layer thickness, the temperature or cooling is certainly to blame. What you call an elephant foot (I'm not sure it's the proper word, because it's usualy about the 2-3 first layers only) makes me think your hotend cooling system does not work properly. It looks like the temperature raise during the first 15 layers (or so) then the heatsink cannot manage to lower enough the temperature.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

The diagonal pattern sources certainly in transmission parts. There's maybe several problems in one, check all : pulleys (metal machined ones does not cost that much), threaded rods, nuts, bearings... For the layer thickness, the temperature or cooling is certainly to blame. What you call an elephant foot (I'm not sure it's the proper word, because it's usualy about the 2-3 first layers only) makes me think your hotend cooling system does not work properly. It looks like the temperature raise during the first 15 layers (or so) then the heatsink cannot manage to lower enough the temperature.

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Repetitive patterns in my prints and uneven wall thickness January 14, 2015 11:57AM |

Registered: 9 years ago Posts: 63 |

- Hotend cooling: This prusa I3 cools the metal block just above the hot end, but there is no fan present, which is aimed towards the hot tip or towards the object.

- Z wobble: The two belts are resting on a bearing, surrounded by a "round" 3d printed ring, which is not really as round as I thought it was. I can actually clearly see the outer end of the belt coming further and shorter as it rotates around the plastic pulley.

- Z rods: These are connected to the Z stepper motors with a connection piece, which has screws in it to fasten the rods. However, fastening them pushes the rods away from that screw, towards the outside, which results in a threaded rod which is off-center.

The above 3 problems are solved for me now I don't need any more help with these because I know what to do to fix them.

I don't need any more help with these because I know what to do to fix them.

About the heated bed temperature: I tried printing at about 80c which causes a lot more warping. Elephant; mouse ears don't really help a lot. I'm guessing my hairspray is just really crappy.

If I print on electrical tape it sticks a lot better. I'm going to buy some other tape though, because the electrical tape is a pain to remove ^^ it sticks way to well.

Actually I guess all my problems stated above, have been solved thank you all for the handy tips!

thank you all for the handy tips!

@Ohmarinus: I don't think taking a pictore of the hot end is of any more use because I do not have a hot end cooler; unless you still want to see a picture for another reason?

Edited 1 time(s). Last edit at 01/14/2015 11:59AM by FalloutBe.

- Z wobble: The two belts are resting on a bearing, surrounded by a "round" 3d printed ring, which is not really as round as I thought it was. I can actually clearly see the outer end of the belt coming further and shorter as it rotates around the plastic pulley.

- Z rods: These are connected to the Z stepper motors with a connection piece, which has screws in it to fasten the rods. However, fastening them pushes the rods away from that screw, towards the outside, which results in a threaded rod which is off-center.

The above 3 problems are solved for me now

I don't need any more help with these because I know what to do to fix them.

I don't need any more help with these because I know what to do to fix them.About the heated bed temperature: I tried printing at about 80c which causes a lot more warping. Elephant; mouse ears don't really help a lot. I'm guessing my hairspray is just really crappy.

If I print on electrical tape it sticks a lot better. I'm going to buy some other tape though, because the electrical tape is a pain to remove ^^ it sticks way to well.

Actually I guess all my problems stated above, have been solved

thank you all for the handy tips!

thank you all for the handy tips!@Ohmarinus: I don't think taking a pictore of the hot end is of any more use because I do not have a hot end cooler; unless you still want to see a picture for another reason?

Edited 1 time(s). Last edit at 01/14/2015 11:59AM by FalloutBe.

|

Re: Repetitive patterns in my prints and uneven wall thickness January 14, 2015 12:54PM |

Registered: 9 years ago Posts: 1,011 |

If you like painters tape, try 3M #3434

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

Collective intelligence emerges when a group of people work together effectively. Prusa i3 Folger (A lot of the parts are wrong, boring !)

|

Re: Repetitive patterns in my prints and uneven wall thickness January 14, 2015 01:35PM |

Registered: 9 years ago Posts: 465 |

The off-center of the threaded rods for the Z axis isn't much of a problem, as the angle that they form from the motor to where they hold the X carriage up doesn't really change, so changing the couplers won't make a significant difference, unless the point where the rods support the carriage is significantly off center from the axis of the motor, which is not the case in any of the designs that I've seen.

It does make a tiny difference in the lift, of the cosine of the angle that the rod is at. If you are a full 1 degree off, instead of 1mm, you'll get 0.9998477mm. chances are that you're much less than 1 degree off, and that the error is smaller than that. (Actually chances are that your threaded rod pitch is off by more than that.)

It does make a tiny difference in the lift, of the cosine of the angle that the rod is at. If you are a full 1 degree off, instead of 1mm, you'll get 0.9998477mm. chances are that you're much less than 1 degree off, and that the error is smaller than that. (Actually chances are that your threaded rod pitch is off by more than that.)

Sorry, only registered users may post in this forum.