|

bad print please advice May 24, 2015 05:30AM |

Registered: 9 years ago Posts: 50 |

Hi guys,

Its been a while since I've printed anything since my last jam (tried to print PLA than ABS than PLA => that coused the JAM)

Finally I had time to fix my printer.

My printer: kossel-mini (delta).

I've re-calibrated it to about 0.3-2 mm diff in 3 axes, I know its not perfect but for small parts it should be OK.

Re-calibrated the extrueder using richrap manual so 10 [cm] was exactly 10 [cm].

I've printed a box calibration test in cura (14.09, yes new version is available yet I wanted to use the old tools which worked for me in the past),

print configuration:

Print Speed 50[mm/sec]

Fill Density 100%

Printing temp 185[C]

Bed temp 60[C]

Diameter 1.75[mm]

Flow 100.0%

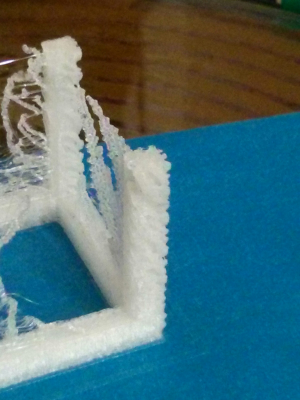

which came out terrible:

Please advice what could cause this issue??

The bottom part should be filled not with holes & jumps...

Its been a while since I've printed anything since my last jam (tried to print PLA than ABS than PLA => that coused the JAM)

Finally I had time to fix my printer.

My printer: kossel-mini (delta).

I've re-calibrated it to about 0.3-2 mm diff in 3 axes, I know its not perfect but for small parts it should be OK.

Re-calibrated the extrueder using richrap manual so 10 [cm] was exactly 10 [cm].

I've printed a box calibration test in cura (14.09, yes new version is available yet I wanted to use the old tools which worked for me in the past),

print configuration:

Print Speed 50[mm/sec]

Fill Density 100%

Printing temp 185[C]

Bed temp 60[C]

Diameter 1.75[mm]

Flow 100.0%

which came out terrible:

Please advice what could cause this issue??

The bottom part should be filled not with holes & jumps...

|

Re: bad print please advice May 24, 2015 06:40AM |

Registered: 9 years ago Posts: 50 |

Update:

I made another print in lower speed, only lower the

Print Speed 50[mm/sec] to 20[mm/sec]

I produced an improvement in the area close to printed bed as can be viewed in the pic.

Any ideas will be welcomed

I made another print in lower speed, only lower the

Print Speed 50[mm/sec] to 20[mm/sec]

I produced an improvement in the area close to printed bed as can be viewed in the pic.

Any ideas will be welcomed

|

Re: bad print please advice May 24, 2015 07:32AM |

Registered: 10 years ago Posts: 14,672 |

Looks like insufficient retraction to me, or retraction too slow. What settings are you using? Also, you shouldn't use 100% infill density.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: bad print please advice May 24, 2015 09:45AM |

Registered: 9 years ago Posts: 50 |

Thank you for the info.

Could you kindly explain the "you shouldn't use 100% infill density."

My settings -

under Basic:

Quality

Layer height (mm) 0.1

Shell thickness(mm) 1.0

Enable retraction [marked]

Fill

Bottom/Top thickness(mm) 0.6

Fill Density (%) 100

Speed and Temperature

Print speed (mm/s) 30

Print temperature (C) 185

Bed temperature (C) 60

Support

Support type [none]

Platform adhesion type [none]

Filament

Diameter (mm) 1.75

Flow (%) 100.0

under Advanced:

Machine

Nozzle size (mm) 0.35

Retraction

Speed (mm/s) 60.0

Distance (mm) 5.1

Quality

Initial layer thickness (mm) 0.2

Initial layer line width (%) 80

Cut off object bottom (mm) 0.0

Dual extursion overlap (mm) 0.15 <-- I don't have dual extrusion..

Speed

Travel speed (mm/s) 20

Bottom layer speed (mm/s) 20

Infill speed (mm/s) 0.0

Outer sheel speed (mm/s) 0.0

Inner shell speed ( mm/s) 0.0

Cool

Minimal layer time (sec) 5

Enable cooling fan [marked]

Could you kindly explain the "you shouldn't use 100% infill density."

My settings -

under Basic:

Quality

Layer height (mm) 0.1

Shell thickness(mm) 1.0

Enable retraction [marked]

Fill

Bottom/Top thickness(mm) 0.6

Fill Density (%) 100

Speed and Temperature

Print speed (mm/s) 30

Print temperature (C) 185

Bed temperature (C) 60

Support

Support type [none]

Platform adhesion type [none]

Filament

Diameter (mm) 1.75

Flow (%) 100.0

under Advanced:

Machine

Nozzle size (mm) 0.35

Retraction

Speed (mm/s) 60.0

Distance (mm) 5.1

Quality

Initial layer thickness (mm) 0.2

Initial layer line width (%) 80

Cut off object bottom (mm) 0.0

Dual extursion overlap (mm) 0.15 <-- I don't have dual extrusion..

Speed

Travel speed (mm/s) 20

Bottom layer speed (mm/s) 20

Infill speed (mm/s) 0.0

Outer sheel speed (mm/s) 0.0

Inner shell speed ( mm/s) 0.0

Cool

Minimal layer time (sec) 5

Enable cooling fan [marked]

|

Re: bad print please advice May 24, 2015 11:52AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: bad print please advice May 24, 2015 01:05PM |

Registered: 9 years ago Posts: 50 |

Thank you for the replay.

Wow I didn't think about it & stored it in a not that good conditions... so I guess this is a very good direction that I should test.

Before running & buying new filament could advice on how to dry my current filament? or should I just buy new one?

Edited 1 time(s). Last edit at 05/24/2015 01:10PM by polkary.

Wow I didn't think about it & stored it in a not that good conditions... so I guess this is a very good direction that I should test.

Before running & buying new filament could advice on how to dry my current filament? or should I just buy new one?

Edited 1 time(s). Last edit at 05/24/2015 01:10PM by polkary.

|

Re: bad print please advice May 24, 2015 10:48PM |

Registered: 9 years ago Posts: 52 |

Drying filament isn't too hard. A gently warmed oven, a heating vent from a forced air furnace, or a warm sunny spot on a hot summer day will do the trick. Heating the filament relative to the surrounding environment drops the plastic's ability to hold water.

Most people don't like wet filament cause it can mess with some filaments adhesion and ascetic.

That said, PLA and nylon actually benefit from some water content. It helps align the polymer chains through hydrogen bonding after extrusion, but it's easy to have too much water.

Most people don't like wet filament cause it can mess with some filaments adhesion and ascetic.

That said, PLA and nylon actually benefit from some water content. It helps align the polymer chains through hydrogen bonding after extrusion, but it's easy to have too much water.

|

Re: bad print please advice May 25, 2015 03:07AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: bad print please advice May 27, 2015 03:01AM |

Registered: 9 years ago Posts: 50 |

Thank you all for the replays

I've validated the issue & I do have a wet filament, bubbles can be seen from the nuzzle head.

According to your experience when cooking the filament in toaster oven (not one I'll be using for food):

Edited 1 time(s). Last edit at 05/27/2015 03:02AM by polkary.

I've validated the issue & I do have a wet filament, bubbles can be seen from the nuzzle head.

According to your experience when cooking the filament in toaster oven (not one I'll be using for food):

- 60 degree (C) is OK for PLA? higher/lower?

- How many hours should I keep the filament in the toaster oven?

Edited 1 time(s). Last edit at 05/27/2015 03:02AM by polkary.

|

Re: bad print please advice May 27, 2015 03:43AM |

Registered: 8 years ago Posts: 5,232 |

I have no experience with drying PLA, but I wouldn´t want to risk deformation or baking from too high temperatures.

Depending on the reliability of your oven, I´d start with 50°C and leave it there for a few hours.

A bigger spool takes longer to dry inside.

I have all my spools in ziplock plastic bags together with a handful of rice. That helps to keep humidity down. ( Well my oldes spool is 4 weeks old, I´m a newbie.. )

)

-Olaf

Depending on the reliability of your oven, I´d start with 50°C and leave it there for a few hours.

A bigger spool takes longer to dry inside.

I have all my spools in ziplock plastic bags together with a handful of rice. That helps to keep humidity down. ( Well my oldes spool is 4 weeks old, I´m a newbie..

)

)-Olaf

|

Re: bad print please advice May 27, 2015 08:37AM |

Registered: 9 years ago Posts: 50 |

Thank you for the replay.

I plan to cut out of the spool about 2 [M] for test print to verify that this is the "only" issue for the terrible prints.

I just don't know what is "a few hours".

I know that the time depends on the heat & on the amount of filament & it's purity so..

Basically I would like receive feedback from people how did made this procedure, lets assume:

I plan to cut out of the spool about 2 [M] for test print to verify that this is the "only" issue for the terrible prints.

I just don't know what is "a few hours".

I know that the time depends on the heat & on the amount of filament & it's purity so..

Basically I would like receive feedback from people how did made this procedure, lets assume:

- My toster oven is OK, and 50[C] is exactly 50[C].

- The PLA is of very good production and from good source.

|

Re: bad print please advice May 27, 2015 11:01PM |

Registered: 9 years ago Posts: 52 |

Generally speaking, low temperatures for longer periods of time work better than a high temperature for a shorter time. There's a few reasons for this, but it might take some time and get technical.

You actually don't need high temperatures, but it's easier then vacuums, and silica beads/hygroscopic salts.

I'm not sure if a toaster oven is the best option for drying filament. Literally, you're just trying to make the filament a bit warmer than the surrounding area.

You actually don't need high temperatures, but it's easier then vacuums, and silica beads/hygroscopic salts.

I'm not sure if a toaster oven is the best option for drying filament. Literally, you're just trying to make the filament a bit warmer than the surrounding area.

|

Re: bad print please advice May 28, 2015 05:48PM |

Registered: 9 years ago Posts: 50 |

|

Re: bad print please advice May 29, 2015 04:33PM |

Registered: 9 years ago Posts: 569 |

Saw on a Google+ post that someone recently dried their ABS (?) in the oven at 50 C (120ish F) for 8 hours which did the trick, though I am not sure I would go that long.

PLA is corn-based, so I would assume you could safely dry it in your oven, the biggest issue would be deforming the spool the filament is on.

As for your infill density, 100% is a solid fill object. Depending on the part and its intended use, you can normally get away with 10-20% infill settings, which should use a lot less filament and print much faster. In most cases, 40-50% infill will be just as strong, if not stronger than, 100% infill. There will of course be times when you want a solid 80-100% infill on your printed parts, but those prints are few and far between for most users.

PLA is corn-based, so I would assume you could safely dry it in your oven, the biggest issue would be deforming the spool the filament is on.

As for your infill density, 100% is a solid fill object. Depending on the part and its intended use, you can normally get away with 10-20% infill settings, which should use a lot less filament and print much faster. In most cases, 40-50% infill will be just as strong, if not stronger than, 100% infill. There will of course be times when you want a solid 80-100% infill on your printed parts, but those prints are few and far between for most users.

|

Re: bad print please advice May 30, 2015 07:14AM |

Registered: 11 years ago Posts: 973 |

If it's pla then temperature is too low especially for speed your going at, different manufacturers of pla can extrude at different temps I would try 200 see if any difference

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

Check my rubbish blog for my prusa i3

up and running

[3dimetech.blogspot.co.uk]

|

Re: bad print please advice June 20, 2015 09:19AM |

Registered: 9 years ago Posts: 50 |

Hi all,

Thank you all for the support, I try to dry the PLA several times.

After a few attempts I bought new PLA filament,

I arrived in the good case with silca gel in it so I assume it is OK.

My print came out BAD as before :/

Before the hotend jam I was able to print rotating things like this .

But my last print was like this at start we can see the spikes :

The end product was full of none continuous print lines with huge hols in it:

Please advice, should I replace the hotend? (it started after I've tried to print ABS ->PLA ->ABS... )

any ideas will be welcomed..

What can cause this??

Thank you all for the support, I try to dry the PLA several times.

After a few attempts I bought new PLA filament,

I arrived in the good case with silca gel in it so I assume it is OK.

My print came out BAD as before :/

Before the hotend jam I was able to print rotating things like this .

But my last print was like this at start we can see the spikes :

The end product was full of none continuous print lines with huge hols in it:

Please advice, should I replace the hotend? (it started after I've tried to print ABS ->PLA ->ABS... )

any ideas will be welcomed..

What can cause this??

|

Re: bad print please advice June 20, 2015 09:25PM |

Registered: 9 years ago Posts: 59 |

I'm still learning what it takes to get good prints too, but a few observations I have made:

5mm retraction is a lot, I use 1mm

I print PLA at 195, I have printed at 185 and it seemed ok, but I seem to get more consistent prints at 195.

0.1mm layer heights are tricky (though I haven't experimented much). Try printing at 0.2mm (I have 0.35mm nozzle as well, and I often print at around 0.2mm, sometimes a bit more, sometimes a bit less).

Small items are difficult to print at what might be your normal settings. I am thinking of your upright edges. The printer will print one perimeter, then the next perimeter outside (or inside) the first, but because the first perimeter was so short, it prints the second perimeter before the first has 'set', So the first perimeter is still soft and can be dragged by the nozzle as it lays the new perimeter. And when the nozzle moves to the next corner, it could drag some of the soft PLA with it. So I really slow down the print on things like that, I slow it WAY down. I even find myself sometimes blowing on it to help it set before the nozzle comes back and pushes everything around. I plan to install a print fan, hopefully it will help.

Have you tried a simpler print: just a standard cube?

Eric

5mm retraction is a lot, I use 1mm

I print PLA at 195, I have printed at 185 and it seemed ok, but I seem to get more consistent prints at 195.

0.1mm layer heights are tricky (though I haven't experimented much). Try printing at 0.2mm (I have 0.35mm nozzle as well, and I often print at around 0.2mm, sometimes a bit more, sometimes a bit less).

Small items are difficult to print at what might be your normal settings. I am thinking of your upright edges. The printer will print one perimeter, then the next perimeter outside (or inside) the first, but because the first perimeter was so short, it prints the second perimeter before the first has 'set', So the first perimeter is still soft and can be dragged by the nozzle as it lays the new perimeter. And when the nozzle moves to the next corner, it could drag some of the soft PLA with it. So I really slow down the print on things like that, I slow it WAY down. I even find myself sometimes blowing on it to help it set before the nozzle comes back and pushes everything around. I plan to install a print fan, hopefully it will help.

Have you tried a simpler print: just a standard cube?

Eric

|

Re: bad print please advice June 21, 2015 01:27AM |

Registered: 9 years ago Posts: 50 |

Eric thank you for the tips.

Yes every thing I print tern out bad (even when printing at 30 mm/sec speed in all movements not only print speed but from point to point as well).

It seems like in each layer the output isn't ok you can see in the first pic (link) in my previous post.

While all of what you wrote seems OK, I would prefer to stick to what worked for me in the past.

This will help me to isolate the problem.

What I don't get is why in the past I could print rotating parts like this:

It came out rotating smoothly since all was calibrated perfectly.

But now my print gets this holes...

Currently I'm suspecting the

Please help me to understand if I'm correct (tests to verify which is to blame) or add ideas about what might else go bad..

Thank you all

Edited 1 time(s). Last edit at 06/21/2015 01:35AM by polkary.

Yes every thing I print tern out bad (even when printing at 30 mm/sec speed in all movements not only print speed but from point to point as well).

It seems like in each layer the output isn't ok you can see in the first pic (link) in my previous post.

While all of what you wrote seems OK, I would prefer to stick to what worked for me in the past.

This will help me to isolate the problem.

What I don't get is why in the past I could print rotating parts like this:

It came out rotating smoothly since all was calibrated perfectly.

But now my print gets this holes...

Currently I'm suspecting the

- nuzzle head

- timing belt

Please help me to understand if I'm correct (tests to verify which is to blame) or add ideas about what might else go bad..

Thank you all

Edited 1 time(s). Last edit at 06/21/2015 01:35AM by polkary.

|

Re: bad print please advice June 21, 2015 04:04AM |

Registered: 8 years ago Posts: 5,232 |

185°C and 0.1mm layer are a bit extreme. Try 0.2mm and 195°C.

If nothing helps, get a new nozzle or some solvent to clean your nozzle ( acetone will help against ABS-remains )

-Olaf

PS: I´ve seen Emmets geared filament holder on thingiverse, but I didn´t know it was printed in one piece ( a new challenge YEAH )

( a new challenge YEAH )

Edited 1 time(s). Last edit at 06/21/2015 04:06AM by o_lampe.

If nothing helps, get a new nozzle or some solvent to clean your nozzle ( acetone will help against ABS-remains )

-Olaf

PS: I´ve seen Emmets geared filament holder on thingiverse, but I didn´t know it was printed in one piece

( a new challenge YEAH )

( a new challenge YEAH )Edited 1 time(s). Last edit at 06/21/2015 04:06AM by o_lampe.

|

Re: bad print please advice June 21, 2015 04:57AM |

Registered: 9 years ago Posts: 606 |

|

Re: bad print please advice June 21, 2015 05:57PM |

Registered: 9 years ago Posts: 50 |

|

Re: bad print please advice June 22, 2015 06:49AM |

Registered: 10 years ago Posts: 167 |

have you tried doing a cold pull?

chances are there is still some junk in your nozzle.

those holes look like under extrusion.

do a cold pull do a small print test if the pull comes out clean or if not clean try a harsher cleaning method likr acetone (will only work if the junk is ABS) or a blow torch (requires you disasemble your hot end as you dont ant to break any PEEK or teflon, or your heater/thermistor)

if thaat doesnt do it then i dont know, for your calibration to have worked you would have to have cheked for tension a slippage issues already

chances are there is still some junk in your nozzle.

those holes look like under extrusion.

do a cold pull do a small print test if the pull comes out clean or if not clean try a harsher cleaning method likr acetone (will only work if the junk is ABS) or a blow torch (requires you disasemble your hot end as you dont ant to break any PEEK or teflon, or your heater/thermistor)

if thaat doesnt do it then i dont know, for your calibration to have worked you would have to have cheked for tension a slippage issues already

|

Re: bad print please advice June 22, 2015 08:13AM |

Registered: 9 years ago Posts: 50 |

and we have a winner!

Zerker thank you!

Yesterday someone (whose opinion I respect VERY MUCH) saw my print and told me that it's look like under extrusion & asked if my nuzzle is 100% clean.

Yet I think that all thought I only printed ABS / PLA i might have some issues with the nuzzle not perfectly clean.

I hope to install a new all metal nuzzle (E3D) this weekend to test it...

Thank you for the input

Will report if this works..

Regards

Zerker thank you!

Yesterday someone (whose opinion I respect VERY MUCH) saw my print and told me that it's look like under extrusion & asked if my nuzzle is 100% clean.

Yet I think that all thought I only printed ABS / PLA i might have some issues with the nuzzle not perfectly clean.

I hope to install a new all metal nuzzle (E3D) this weekend to test it...

Thank you for the input

Will report if this works..

Regards

|

Re: bad print please advice August 14, 2015 12:01PM |

Registered: 9 years ago Posts: 50 |

Hi guys,

Hope you could help me again.

Finally my E3D has arrive & had time to install it.

Re-calibrated EVERYTHING and started printing a box.

Didn't need to finish till the end to see that the under extrusion I was expecting to be resolved when switching to E3D v6 didn't resolved.

So I guess this isn't the issue (new E3D v6 didn't use it before, printed only PLA in this test only)

Attached it the start of the print:

This is the exact issues that I had before.

Plz advice.

Hope you could help me again.

Finally my E3D has arrive & had time to install it.

Re-calibrated EVERYTHING and started printing a box.

Didn't need to finish till the end to see that the under extrusion I was expecting to be resolved when switching to E3D v6 didn't resolved.

So I guess this isn't the issue (new E3D v6 didn't use it before, printed only PLA in this test only)

Attached it the start of the print:

This is the exact issues that I had before.

Plz advice.

|

Re: bad print please advice August 14, 2015 09:43PM |

Registered: 8 years ago Posts: 14 |

so if youre under extruding then wouldn't you go into your firmware and recalculate your steps for the extruder? Are you sure they are correct? Check twice pour once type of thing!!! I had a similar issue and this resolved it!!! it also saved me some money cause I was leaning towards buying a new hot end too!!! What kind of printer do you have?

Edited 2 time(s). Last edit at 08/14/2015 09:44PM by Cbrowder22.

Edited 2 time(s). Last edit at 08/14/2015 09:44PM by Cbrowder22.

|

Re: bad print please advice August 15, 2015 03:26AM |

Registered: 9 years ago Posts: 50 |

Thank you for the replay.

My printer is kossel mini.

I have made the extruder test according to richrap link

I get 10 c"m exactly so I assume that the extruder is calibrated..

My printer is kossel mini.

I have made the extruder test according to richrap link

I get 10 c"m exactly so I assume that the extruder is calibrated..

Sorry, only registered users may post in this forum.