Home

>

Reprappers

>

Topic

Temperature control of melted filament is the key of quality printing.

Posted by janpenguin

|

Temperature control of melted filament is the key of quality printing. June 25, 2015 07:34AM |

Registered: 9 years ago Posts: 189 |

Layer fan I added lately made printing impossible models I gave up.

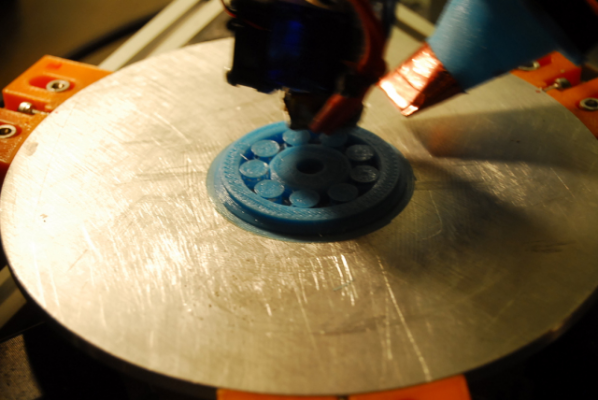

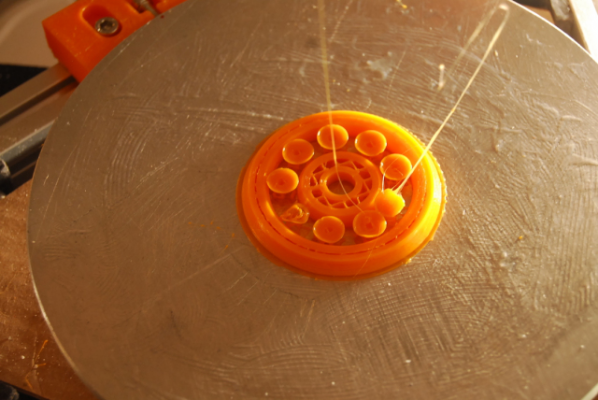

A ball bearing

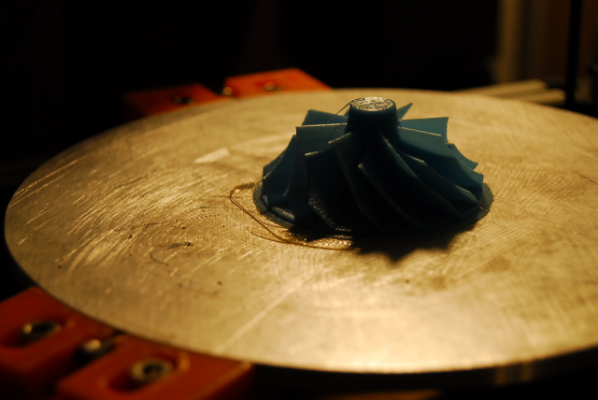

Impeller of a blower

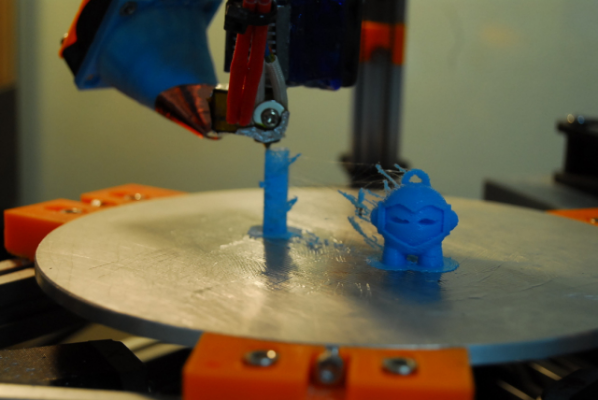

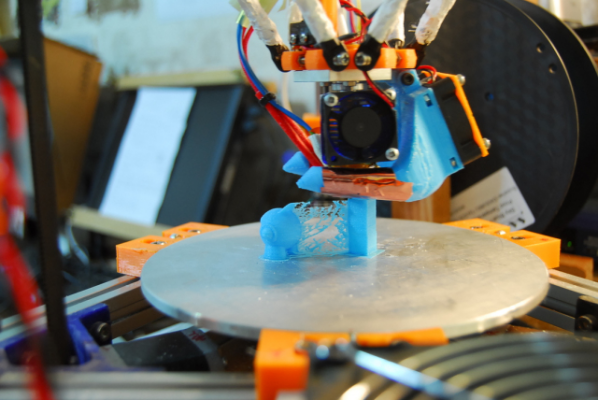

I was pumped up and suddenly the Marvin hit me hard. I think I spent 16 hours to print one decent Marvin.

I had to come up with a dummy object for controlling of cooling time.

The second best Marvin

Layer height: 0.05 mm

Printing speed: 60 mm/s

Temperature: 200 C

And I figured the layer fan installed wouldn't provide good air flow to the nozzle tip so

I replaced the corn duct with oval shape. And it indeed performed well. Layer height 0.1 mm of Marvin

turned out better than above one.

A ball bearing

Impeller of a blower

I was pumped up and suddenly the Marvin hit me hard. I think I spent 16 hours to print one decent Marvin.

I had to come up with a dummy object for controlling of cooling time.

The second best Marvin

Layer height: 0.05 mm

Printing speed: 60 mm/s

Temperature: 200 C

And I figured the layer fan installed wouldn't provide good air flow to the nozzle tip so

I replaced the corn duct with oval shape. And it indeed performed well. Layer height 0.1 mm of Marvin

turned out better than above one.

|

Re: Temperature control of melted filament is the key of quality printing. June 25, 2015 07:46AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Temperature control of melted filament is the key of quality printing. June 25, 2015 09:30AM |

Registered: 9 years ago Posts: 41 |

Axial fans don't like back pressure. They work great when the can push the air freely, but fan ducts that restrict the airflow tend to reduce the ability of the axial fan to push air through. I would try looking into using a radial fan. They can really push a lot of air. I was using this design and had a TON of cooling. It was just too big and bulky. Here is a picture of my marvin using the radial fan cooling duct.

|

Re: Temperature control of melted filament is the key of quality printing. June 25, 2015 02:24PM |

Registered: 9 years ago Posts: 977 |

Quote

dbrewski

Axial fans don't like back pressure. They work great when the can push the air freely, but fan ducts that restrict the airflow tend to reduce the ability of the axial fan to push air through.

...

That is 100% correct. However, since I am the designer of some of the fan ducts janpenguin has posted above, I would like to add a few remarks about how they were designed and the amount of air that they manage to push with a 40mm fan. BTW, you can find these fan duct designs on Thingiverse, and they include the OpenSCAD source so anybody can modify them and experiment with the shape, size of outlet, etc.

See here: [www.thingiverse.com]

My first remark is that these are layer fans, used for printing PLA and avoiding stringing, enabling the printing of overhangs and bridges, etc.

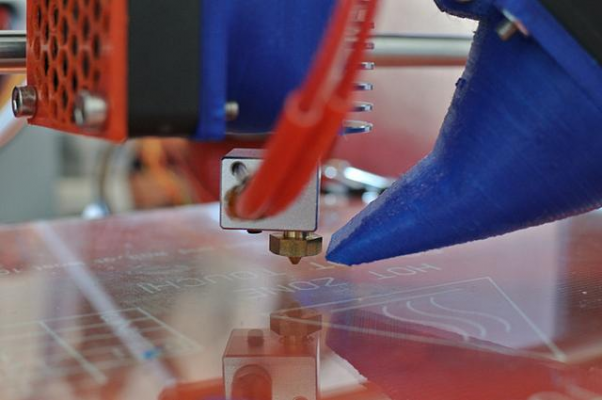

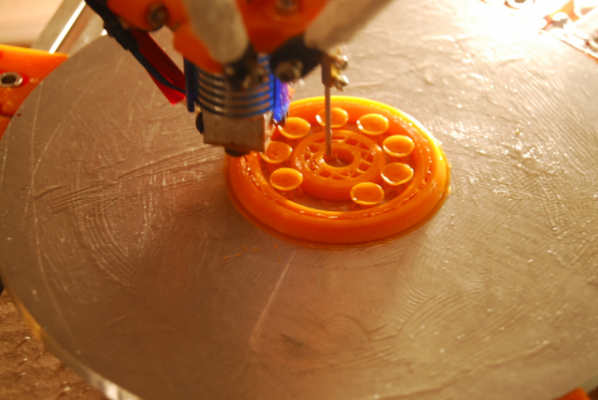

So what you really want is to cool the PLA as it comes out of the extruder and latest printed layer of the object itself, but in fact the area that you want to cool down is very small, so it does not take a lot of air to effectively get the desired result. However, what you really, really want is to come very close to the tip of the nozzle, as shown in this picture:

In my experience, a cheap ($1) 40mm axial fan with a properly designed fan duct that does not restrict air flow, correctly pointed to the tip of the nozzle, can be run at between 70% and 90% of its top speed (hence the PWM control and the options in the slicer software to control fan speed), and you can get perfect results.

Note that all the above only applies to PLA, not to ABS. And apart from PLA and ABS, I have not tested other types of filament yet.

I have even had people complaining that the air flow was excessive, and I had to explain to them that they had to connect the fan to the PWM D9 output of the RAMPS to get proper control of the airflow!

Edited 3 time(s). Last edit at 06/26/2015 03:45AM by AndrewBCN.

|

Re: Temperature control of melted filament is the key of quality printing. June 25, 2015 02:27PM |

Registered: 9 years ago Posts: 977 |

|

Re: Temperature control of melted filament is the key of quality printing. June 25, 2015 02:35PM |

Registered: 11 years ago Posts: 335 |

|

Re: Temperature control of melted filament is the key of quality printing. June 25, 2015 02:49PM |

Registered: 9 years ago Posts: 977 |

Quote

691175002

Do you find that designs which blow air from only one direction produce slightly different results depending on geometry of the part being printed or the direction in which the extruder is moving?

Yes indeed that is correct, the results are (slightly) different depending on how the part is oriented in relation to the airflow, and whether there are vertical walls, etc.

The truth is that airflow is only (sort of) laminar within a few millimeters after leaving the outlet of the fan duct, once it hits the printed object it is chaotic and we have zero control over what it cools down properly or not.

You can see all sorts of fan duct designs on Thingiverse, some people seem to believe that they can force airflow into a circular pattern around the nozzle, but that is pure wishful thinking, air does not behave like that at all.

You will find a "forked" fan duct among those that I have published, it is an attempt to blow air from two opposite directions, and it does work well enough. But to be honest the simple fan ducts I have posted also work more than well enough for me already, so I have not bothered with installing the heavier forked fan duct in my printers.

|

Re: Temperature control of melted filament is the key of quality printing. June 25, 2015 03:28PM |

Registered: 9 years ago Posts: 41 |

Quote

AndrewBCN

Quote

dbrewski

Axial fans don't like back pressure. They work great when the can push the air freely, but fan ducts that restrict the airflow tend to reduce the ability of the axial fan to push air through.

...

That is 100% correct. However, since I am the designer of some of the fan ducts janpenguin has posted above, I would like to add a few remarks about how they were designed and the amount of air that they manage to push with a 40mm fan. BTW, you can find these fan designs on Thingiverse, and they include the OpenSCAD source so anybody can modify them and experiment with the shape, size of outlet, etc.

See here: [www.thingiverse.com]

My first remark is that these are layer fans, used for printing PLA and avoiding stringing, enabling the printing of overhangs and bridges, etc.

So what you really want is to cool the PLA as it comes out of the extruder and latest printed layer of the object itself, but in fact the area that you want to cool down is very small, so it does not take a lot of air to effectively get the desired result. However, what you really, really want is to come very close to the tip of the nozzle, as shown in this picture:

In my experience, a cheap ($1) 40mm axial fan with a properly designed fan duct that does not restrict air flow, correctly pointed to the tip of the nozzle, can be run at between 70% and 90% of its top speed (hence the PWM control and the options in the slicer software to control fan speed), and you can get perfect results.

Note that all the above only applies to PLA, not to ABS. I have not tested other types of filament yet.

I have even had people complaining that the air flow was excessive, and I had to explain to them that they had to connect the fan to the PWM D9 output of the RAMPS to get proper control of the airflow!

Thank you for the detailed explanation. I'm hoping you can clear up my understanding on the exact purpose of cooling PLA. My understanding is that you want the current printed layer to be solid for the next layer to go on top. If the top layer is still soft, then the extruder doesn't have a solid surface to lay down plastic. I don't understand why cooling only at the tip is desired. Would it not be better to have air blowing across a greater area to remove more heat from the part?

Edited 1 time(s). Last edit at 06/25/2015 03:28PM by dbrewski.

|

Re: Temperature control of melted filament is the key of quality printing. June 25, 2015 08:45PM |

Registered: 9 years ago Posts: 977 |

Quote

dbrewski

...

Thank you for the detailed explanation. I'm hoping you can clear up my understanding on the exact purpose of cooling PLA. My understanding is that you want the current printed layer to be solid for the next layer to go on top. If the top layer is still soft, then the extruder doesn't have a solid surface to lay down plastic. I don't understand why cooling only at the tip is desired. Would it not be better to have air blowing across a greater area to remove more heat from the part?

Please note that my understanding of the layer fan use and how it affects print quality is strictly derived from my own relatively short experience in printing PLA parts. So take it all with a kg or two of salt.

Actually the entire printed part is constantly losing heat by convection and radiation during the entire printing process, and you want to keep the entire part around 60C (this is one of the reasons why we use a heated bed), and then when the printing is done you want it to cool down slowly to room temperature to relieve internal stress (and most parts shrink slightly too as they cool down). So my understanding is that you don't want to force cool the entire part during the print, you only want to control the temperature of the zone that the printer is working on at any moment i.e. the latest, topmost layer and in that layer, just the area around the tip of the nozzle. I put control in bold here because that is exactly what we want, we don't want the temperature to be too high (which results in stringing, and failed bridges/overhangs, etc) or too low (bad adherence between layers, delamination, jammed hotends, etc).

Also my understanding is that you only can (and really want to) have control over three different parameters during any PLA print:

- The nozzle temperature.

- The extrusion speed (which is determined from the printing speed).

- The amount of airflow provided by the layer fan.

Edited 1 time(s). Last edit at 06/26/2015 03:49AM by AndrewBCN.

|

Re: Temperature control of melted filament is the key of quality printing. June 25, 2015 09:08PM |

Registered: 9 years ago Posts: 189 |

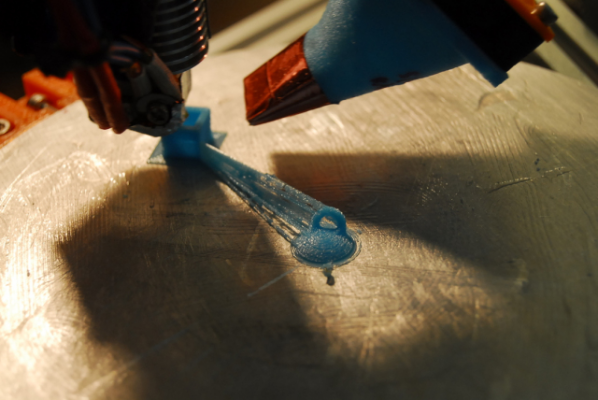

The oval shape duct in action.

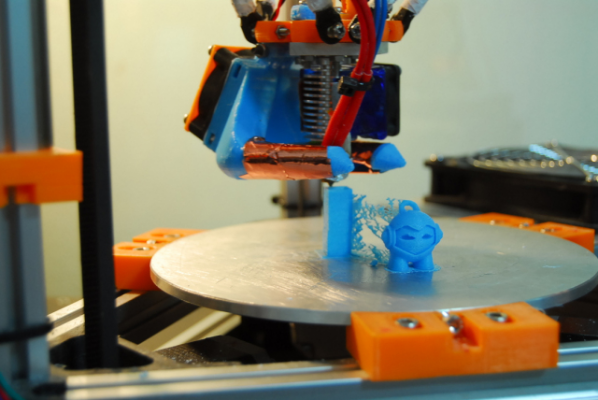

Best Marvin

1.75 mm PLA

Layer height: 0.1 mm

Printing speed: 60 mm/s

There are many fan duct designs for layer fan. The reason I chose Andrew's one is that it comes with various mounting parts and OpenSCAD files.

I think just breeze of air near the nozzle hardens melted filament quickly so that next layer will be formed properly.

When the nozzle moves too slow, heat from the nozzle itself soften adjacent layers cause deformation of object.

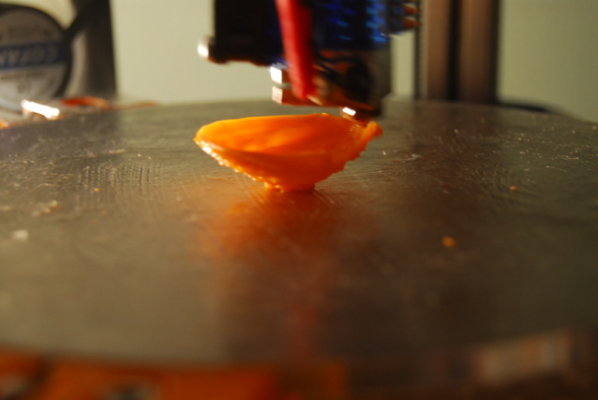

Smeared spheres

Failed attempts of ball bearing

Best Marvin

1.75 mm PLA

Layer height: 0.1 mm

Printing speed: 60 mm/s

There are many fan duct designs for layer fan. The reason I chose Andrew's one is that it comes with various mounting parts and OpenSCAD files.

I think just breeze of air near the nozzle hardens melted filament quickly so that next layer will be formed properly.

When the nozzle moves too slow, heat from the nozzle itself soften adjacent layers cause deformation of object.

Smeared spheres

Failed attempts of ball bearing

Sorry, only registered users may post in this forum.