Home

>

Reprappers

>

Topic

First print pics

Posted by steveo290

|

First print pics July 29, 2010 11:10PM |

Registered: 13 years ago Posts: 85 |

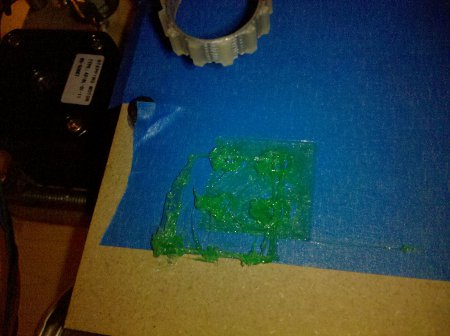

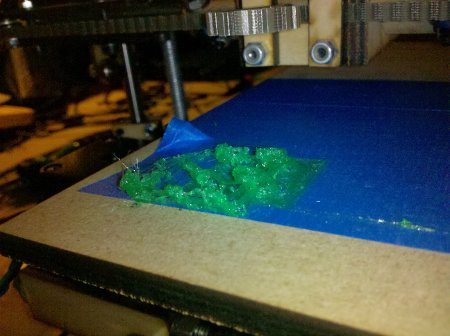

So I finally got all the pieces of my reprap working (aligned all the planets and moons in the milky way). I printed a few things out and I attached some pics of my best one. It is supposed to be a y bar clamp. The first layer looked to be going pretty well. The outline is good, the holes are circular and look to be placed correctly, and the infill (zipzag pattern? right?) is there. But it seems that every layer after that is offset slightly and does not include the infill. I am going to go through and properly config my extruder next. I just really needed to print something to make myself stay interested and motivated.

When I assembled my pinchwheel extruder I had to drill out the pinch wheel bracket and do some milling machine magic to get the gear to fit inside and grab the filament. So I am thinking that since I have a bigger gear on the shaft that it takes more steps to achieve the proper extruding speed. The offset though does not make sense. Did I screw up on the gcode creation? I used the stl from the stable branch I believe. Has anyone seen this thing before?

When I assembled my pinchwheel extruder I had to drill out the pinch wheel bracket and do some milling machine magic to get the gear to fit inside and grab the filament. So I am thinking that since I have a bigger gear on the shaft that it takes more steps to achieve the proper extruding speed. The offset though does not make sense. Did I screw up on the gcode creation? I used the stl from the stable branch I believe. Has anyone seen this thing before?

|

Re: First print pics July 30, 2010 10:06AM |

Registered: 16 years ago Posts: 536 |

Hard to say exactly from that photo, but my first guess would be not enough plastic - you should see nice exact filaments everywhere, not a loose mess. Check to see if your extruder is slipping, and check your X axis for slipping or missed steps as well. Make sure the E value in the is appropriate for your stepper, gear ratio, and filament size too.

Wade

Wade

|

Re: First print pics August 01, 2010 09:43PM |

Registered: 13 years ago Posts: 85 |

Ok so I have never been super at math. Can anyone give me a hand with the math on the commissioning page? I have all the numbers that I need I think.

Filament Diameter = 3mm

Nozzle Diameter = 0.4mm

Pinch Wheel Diameter = 10mm [sdp-si.com]

Steps of stepper = 1.8 degree, so 200 steps? (is that what is needed?)

Commissioning page [reprap.org]

Filament Diameter = 3mm

Nozzle Diameter = 0.4mm

Pinch Wheel Diameter = 10mm [sdp-si.com]

Steps of stepper = 1.8 degree, so 200 steps? (is that what is needed?)

Commissioning page [reprap.org]

|

Re: First print pics August 02, 2010 02:29AM |

Registered: 14 years ago Posts: 458 |

|

Re: First print pics August 02, 2010 02:44AM |

Registered: 14 years ago Posts: 323 |

|

Re: First print pics August 02, 2010 08:27AM |

Registered: 13 years ago Posts: 85 |

Thanks Grogyan, currently the default is 2.0 steps per mm which the comments in the code say is for a 8mm drive gear. Since I had a gear that was 2mm larger I thought that I would need to make the steps per mm higher, or am I supposed to add the result you got to the default 2.0? I will prolly try both lol.

|

Re: First print pics August 02, 2010 06:41PM |

Registered: 14 years ago Posts: 458 |

|

Re: First print pics August 02, 2010 06:56PM |

Registered: 14 years ago Posts: 458 |

For any gearbox, or geared extruder, the mere presence of gears increases the resolution of the extruder, thus you need to multiplay the ratio to the resolution you are driving the extruder at, usually 200 or 400 steps.

For Adrian's geared extruder the resolution increases for each 1mm of extrusion.

The gear ratio on Adrian's gearbox is 11:59 or 5.3636, multiplied with the resolution you are driving at

ie full step is 200

quater step is 800

Adrian initially used half step or 400 steps per 360

The Gear ratio of Wade's extruder is 14:33 or 2.3571

I don't know how he got a value of 2.0 as the result should be

2.3712

Edited 1 time(s). Last edit at 08/03/2010 12:54AM by Grogyan.

For Adrian's geared extruder the resolution increases for each 1mm of extrusion.

The gear ratio on Adrian's gearbox is 11:59 or 5.3636, multiplied with the resolution you are driving at

ie full step is 200

quater step is 800

Adrian initially used half step or 400 steps per 360

The Gear ratio of Wade's extruder is 14:33 or 2.3571

I don't know how he got a value of 2.0 as the result should be

2.3712

Edited 1 time(s). Last edit at 08/03/2010 12:54AM by Grogyan.

|

Re: First print pics August 03, 2010 03:32AM |

Registered: 14 years ago Posts: 3,742 |

Use Wade's spreadsheet to help calculate the proper feedrates: feedrates.ods or feedrates.xls.

And yes, for Adrian's geared extruder the E_STEPS_PER_MM should be 2.37.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

And yes, for Adrian's geared extruder the E_STEPS_PER_MM should be 2.37.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: First print pics August 03, 2010 08:56AM |

Registered: 13 years ago Posts: 85 |

If I am only using one gear as in the pinch wheel, what number do I use for the gear ratio? My gear info is a few posts above. I have been trying to work through other solutions and other math to try to determine what I need to do but I can't. Grog, I know you posted "0.8488", is that for a geared extruder like wades or adrians? If not then how can reducing the current number of steps per mm I am using (2.0 default, and not enough extrusion) result in better flow?

|

Re: First print pics August 03, 2010 09:01AM |

Registered: 14 years ago Posts: 3,742 |

Gear ratio = 1/1 = 1 when only using one gear.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: First print pics August 03, 2010 09:58AM |

Registered: 13 years ago Posts: 85 |

|

Re: First print pics August 03, 2010 11:14AM |

Registered: 14 years ago Posts: 323 |

|

Re: First print pics August 03, 2010 02:50PM |

Registered: 14 years ago Posts: 458 |

Gear ratio will always be 1 if you are using a pinch wheel only hence for your parameters the gear ratio of 1 was used.

Yet for Adrian's geared extruder the ratio is 5, but he also uses an 8mm pinch wheel and 400 steps (half step).

I looked at the posed spreadsheet before, and that I found unnecessarily complicated, so the eqution I used is at the bottom of the commisiong page, its so simple I can use any basic calculator, ie I used the basic one in windows to produce that result for you of 0.8488

Yet for Adrian's geared extruder the ratio is 5, but he also uses an 8mm pinch wheel and 400 steps (half step).

I looked at the posed spreadsheet before, and that I found unnecessarily complicated, so the eqution I used is at the bottom of the commisiong page, its so simple I can use any basic calculator, ie I used the basic one in windows to produce that result for you of 0.8488

|

Re: First print pics August 03, 2010 03:11PM |

Registered: 13 years ago Posts: 85 |

Ok well perhaps you can show me where my math is wrong. I was plugging values into the formula that you have on the commissioning page and came up with 0.1131. It seems simple enough, I don't know why I can't get my fat head wrapped around it. Thank you for the assistance so far though.

((200 x 1)/(3.14159 x 10)) x ((.4/3)squared)

Edit: Another excel sheet calc I found said 0.1131 as well, I couldn't get your feedrate one to work with just a pinchwheel.

Edited 1 time(s). Last edit at 08/03/2010 03:13PM by steveo290.

((200 x 1)/(3.14159 x 10)) x ((.4/3)squared)

Edit: Another excel sheet calc I found said 0.1131 as well, I couldn't get your feedrate one to work with just a pinchwheel.

Edited 1 time(s). Last edit at 08/03/2010 03:13PM by steveo290.

|

Re: First print pics August 03, 2010 05:09PM |

Registered: 14 years ago Posts: 3,742 |

0.1131 is only valid for 200 step motor when full stepping.

The Gen3 electronics and FW does half stepping on the extruder hence 0.23 steps/mm is what you would need.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

The Gen3 electronics and FW does half stepping on the extruder hence 0.23 steps/mm is what you would need.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: First print pics August 04, 2010 12:35AM |

Registered: 14 years ago Posts: 458 |

steveo290 Wrote:

-------------------------------------------------------

> Ok well perhaps you can show me where my math is

> wrong. I was plugging values into the formula that

> you have on the commissioning page and came up

> with 0.1131. It seems simple enough, I don't know

> why I can't get my fat head wrapped around it.

> Thank you for the assistance so far though.

>

> ((200 x 1)/(3.14159 x 10)) x ((.4/3)squared)

>

> Edit: Another excel sheet calc I found said 0.1131

> as well, I couldn't get your feedrate one to work

> with just a pinchwheel.

Whoops, funny how you check something over and over, and say, "yep, done", only to realize your mistake later on.

0.1131 is correct

What I posted previously of 0.8438, clearly wrong, as I left in mine a ratio of 5 and left the nozzle at 0.5mm, lols.

Effectively ((200 x 5)/(3.14159 x 10)) x ((.5/3)^2)

-------------------------------------------------------

> Ok well perhaps you can show me where my math is

> wrong. I was plugging values into the formula that

> you have on the commissioning page and came up

> with 0.1131. It seems simple enough, I don't know

> why I can't get my fat head wrapped around it.

> Thank you for the assistance so far though.

>

> ((200 x 1)/(3.14159 x 10)) x ((.4/3)squared)

>

> Edit: Another excel sheet calc I found said 0.1131

> as well, I couldn't get your feedrate one to work

> with just a pinchwheel.

Whoops, funny how you check something over and over, and say, "yep, done", only to realize your mistake later on.

0.1131 is correct

What I posted previously of 0.8438, clearly wrong, as I left in mine a ratio of 5 and left the nozzle at 0.5mm, lols.

Effectively ((200 x 5)/(3.14159 x 10)) x ((.5/3)^2)

|

Re: First print pics August 04, 2010 08:44AM |

Registered: 13 years ago Posts: 85 |

No problem Grogyan. Last night I went through and put a bunch of different numbers in the steps per mm variable and could not get the motor to stop 'clicking' or 'jamming' every few seconds. It would be extruding and then i would hear a big click. Like it was jamming or trying to extrude to fast. I ended up taking my heating element off and putting a new one on. Then set the steps per mm to .8488 and the temp to 200c (PLA) and feedrate to 1800/min, and had one of my best prints so far. I printed a small gear, shape was pretty good, but the points were not crisp and the walls were pretty loose or thin. I am going to change the steps per mm to .1131 tonight and then mess with the feedrate. What else do I need to modify or config to get this thing printing perfectly? When I set up and configured the xyz axis I didnt have to change anything in the configs, all axis's were almost spot on.

I tried to print a x and ybar clamp and both seemed really skewed or offset, every time I compiled the to gcode and ran them. I recompiled after every firmware change just to make sure and it happened every time. Perhaps I have bad files.

I tried to print a x and ybar clamp and both seemed really skewed or offset, every time I compiled the to gcode and ran them. I recompiled after every firmware change just to make sure and it happened every time. Perhaps I have bad files.

|

Re: First print pics August 05, 2010 09:50PM |

Registered: 13 years ago Posts: 85 |

Ok I have made some progress. I set the steps per mm to .1131 and it barely extruded anything. I set it to .8488 and it extruded a good amount. I had a legible print with .706 (steps per mm) with extrusion speed at 2500 mm/m. Still it wasn't good enough. I started printing the z bar clamps since they are long and have a few holes in them, figure it would be a good test print. The shape and holes are really good but the walls are full of gaps as well as the infill. Which setting should I adjust? Max feedrate for x and y? or steps per mm and extrusion speed? The guide on the wiki references properties that are legacy so I thought they wouldn't help. Also, the Extrusion_size is set to .4 and was .7, I have a .4 nozzle. What should I set this to?

I want my prints to look like everyone else's, is the .4 nozzle to small to do this?

One more thing, how far off the bed should the tip of the nozzle be? I cannot find a concrete answer. Thanks!

Edited 1 time(s). Last edit at 08/05/2010 09:53PM by steveo290.

I want my prints to look like everyone else's, is the .4 nozzle to small to do this?

One more thing, how far off the bed should the tip of the nozzle be? I cannot find a concrete answer. Thanks!

Edited 1 time(s). Last edit at 08/05/2010 09:53PM by steveo290.

|

Re: First print pics August 05, 2010 10:56PM |

Registered: 14 years ago Posts: 458 |

|

Re: First print pics August 05, 2010 11:02PM |

Registered: 13 years ago Posts: 85 |

|

Re: First print pics August 06, 2010 02:11AM |

Registered: 14 years ago Posts: 3,742 |

See the RepRapSoftwareTweakingManual wiki page written by Ed Sells.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: First print pics August 06, 2010 12:01PM |

Registered: 13 years ago Posts: 85 |

Yeah I have seen that Bob, thanks though, I am going to read through it again anyway, I think it answers some of my questions. I think maybe my above questions can be reorganized and better asked as this. When I did the math for my extruder steps per mm, ((200 x 1)/(3.14159 x 10)) x ((.4/3)squared), the answer was 0.1131. When I put that number into the firmware and uploaded it, nothing came out when I was extruding at 3000. Should I be changing the steps per mm to something higher or adjust the other settings like extruder_xyspeed and extruderSpeed to make 0.1131 steps per mm work?

|

Re: First print pics August 06, 2010 12:57PM |

Registered: 14 years ago Posts: 3,742 |

Your extruder is using half steps i.e. your number should be 0.2264 steps/mm.

Ideal Head Feedrate is 17670.94 mm/min!

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Ideal Head Feedrate is 17670.94 mm/min!

Description Value Units Inputs: Stepper # of steps 200 steps Full/half stepping 0.5 Drive Gear Teeth 39 teeth Driven Gear Teeth 39 teeth Diameter of Pinchwheel 10 mm Feedstock Diameter 3 mm Filament Diameter 0.4 mm Motor Speed 10 rpm Motor Speed 66.67 steps/s Outputs: Steps/mm of feedstock 12.73 steps/mm Steps/mm of filament 0.2264 steps/mm Flow rate of feedstock 37.01 mm^3/s Ideal Head Feedrate 294.52 mm/s Ideal Head Feedrate 17670.94 mm/min

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: First print pics August 06, 2010 01:32PM |

Registered: 13 years ago Posts: 85 |

Do those numbers look high? That is like laying down a ruler length a second right?

The stepper motor has a step of 1.8 deg, I thought that would mean 200 steps.

Does that 17670.94 go into extrusion speed? Thank you for the referring to the excel sheet. I had been toying around with it but all the numbers seemed wrong...

Edited 1 time(s). Last edit at 08/06/2010 02:33PM by steveo290.

The stepper motor has a step of 1.8 deg, I thought that would mean 200 steps.

Does that 17670.94 go into extrusion speed? Thank you for the referring to the excel sheet. I had been toying around with it but all the numbers seemed wrong...

Edited 1 time(s). Last edit at 08/06/2010 02:33PM by steveo290.

|

Re: First print pics August 06, 2010 03:21PM |

Registered: 14 years ago Posts: 3,742 |

YES they do

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Sorry, only registered users may post in this forum.