Home

>

Reprappers

>

Topic

Heated bed glass

Posted by xistix

|

Heated bed glass March 04, 2016 05:09AM |

Registered: 8 years ago Posts: 15 |

Hello All,

I have a RepRap with a heated bed. The PCB heater is rested on four springs at the corners. Each spring is on a screw, and by tightening the bolts I can set the height of each corner. On top of the PCB there is a 2mm glass that I got from a cheap picture frame. The glass is secured with paper clips to the PCB. The same time the clips are also holding some cardboard under the PCB. I think there is nothing unusual in this setup. There is however a slight problem. During Z axis calibration I found that the center of the glass is higher than the corners. The difference is about 0.1-0.2mm. I believe the glass is bent a little bit. Have you seen this kind of problem?

What may be causing this? Is it because of the clips or because of regular heating and cooling, or maybe it is just bad quality glass? What kind of glass do you use? Where do you get it from? Is there a better way to fix the glass? Should I use thicker glass?

I have a RepRap with a heated bed. The PCB heater is rested on four springs at the corners. Each spring is on a screw, and by tightening the bolts I can set the height of each corner. On top of the PCB there is a 2mm glass that I got from a cheap picture frame. The glass is secured with paper clips to the PCB. The same time the clips are also holding some cardboard under the PCB. I think there is nothing unusual in this setup. There is however a slight problem. During Z axis calibration I found that the center of the glass is higher than the corners. The difference is about 0.1-0.2mm. I believe the glass is bent a little bit. Have you seen this kind of problem?

What may be causing this? Is it because of the clips or because of regular heating and cooling, or maybe it is just bad quality glass? What kind of glass do you use? Where do you get it from? Is there a better way to fix the glass? Should I use thicker glass?

|

Re: Heated bed glass March 04, 2016 08:14AM |

Registered: 10 years ago Posts: 14,672 |

2mm glass is not very rigid and will bend with the PCB. Better to use 3mm or preferably 4mm glass, preferably with 1.5mm of aluminium between the PCB and the glass to spread the heat and get more even heating.

However there is another possibility for what you observe, which is that the head is sagging at the centre of the X axis.

btw it's better to use 3 bed supports, not 4.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

However there is another possibility for what you observe, which is that the head is sagging at the centre of the X axis.

btw it's better to use 3 bed supports, not 4.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Heated bed glass March 04, 2016 08:21AM |

Registered: 11 years ago Posts: 5,780 |

Congratulations! You've discovered almost all the flaws in that bed design at once.

You're trying to define a plane using 4 points. In geometry class most people learn that 3 points define a plane. When you adjust one of the "leveling" screws, you are bending the plate/undercarriage, not leveling it. Glass is flexible. Clamping it to a bent object will bend the glass. Using thicker glass may help flatten things by directing the bending force to act on the undercarriage more than the bed plate.

Glass is a thermal insulator and will not spread the heat evenly. People usually add a thin aluminum heat spreader between the heater and the glass to solve that problem.

All the problems can be solved by using a flat, rigid aluminum plate without glass, mounted on a 3 point system that actually levels the plate without bending it or the undercarriage.

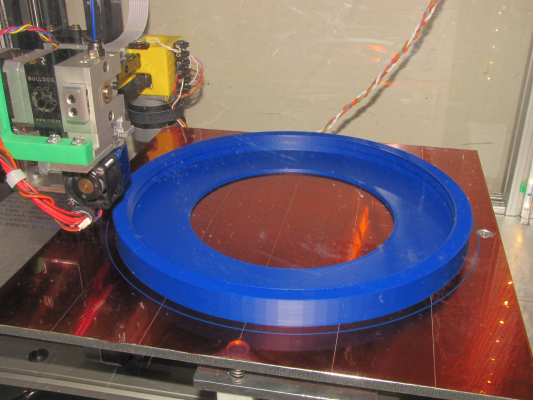

Here is a 250mm dia ABS print on a heated, 1/4" thick cast aluminum tooling plate bed, no glass, with a 3 point leveling system:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

You're trying to define a plane using 4 points. In geometry class most people learn that 3 points define a plane. When you adjust one of the "leveling" screws, you are bending the plate/undercarriage, not leveling it. Glass is flexible. Clamping it to a bent object will bend the glass. Using thicker glass may help flatten things by directing the bending force to act on the undercarriage more than the bed plate.

Glass is a thermal insulator and will not spread the heat evenly. People usually add a thin aluminum heat spreader between the heater and the glass to solve that problem.

All the problems can be solved by using a flat, rigid aluminum plate without glass, mounted on a 3 point system that actually levels the plate without bending it or the undercarriage.

Here is a 250mm dia ABS print on a heated, 1/4" thick cast aluminum tooling plate bed, no glass, with a 3 point leveling system:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Heated bed glass March 04, 2016 10:42AM |

Registered: 8 years ago Posts: 15 |

Thanks, I will try to add an aluminium sheet in between the glass and PCB and try to get a thicker glass. As an alternative I could try to add one more 2mm glass on top, but I'm not sure if that would help much on the rigidity. I see the point to have 3 bed supports instead of 4. Unfortunately changing that would require to dismount the whole y carriage from the frame, which I would like to avoid for now.

I also like the full aluminium bed idea, but I live in Finland and here is to find anything that you cannot get in one of the hardware stores is difficult. The hardware stores have very limited selection. I'm sure I will not find that thick aluminium sheet which is so large. Even if I find someone to sell the thing or the material for it, the cost will be ridiculously high. On the other hand I also like to print straight to the glass. At my workplace we have printer with aluminium bed and kapton tape similar to the picture above. ABS sticks to the kapton + ABS glue so much that we have to change the kapton quite frequently. I do not have that problem with the glass.

I also like the full aluminium bed idea, but I live in Finland and here is to find anything that you cannot get in one of the hardware stores is difficult. The hardware stores have very limited selection. I'm sure I will not find that thick aluminium sheet which is so large. Even if I find someone to sell the thing or the material for it, the cost will be ridiculously high. On the other hand I also like to print straight to the glass. At my workplace we have printer with aluminium bed and kapton tape similar to the picture above. ABS sticks to the kapton + ABS glue so much that we have to change the kapton quite frequently. I do not have that problem with the glass.

|

Re: Heated bed glass March 04, 2016 01:58PM |

Registered: 11 years ago Posts: 5,780 |

I use 5 mil ( a mil is 1/1000th of an inch) thick tape on the bed and it lasts for months. The really thin stuff (1 or 2 mil) tears easily.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Heated bed glass March 05, 2016 05:05AM |

Registered: 8 years ago Posts: 15 |

|

Re: Heated bed glass March 05, 2016 07:16AM |

Registered: 11 years ago Posts: 5,780 |

Just kapton tape. Clean it with pure acetone (NOT finger nail polish remover!) at room temperature before printing.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Heated bed glass March 05, 2016 01:24PM |

Registered: 8 years ago Posts: 1,671 |

Wonder if anyone's used gorilla glass, is it to flexible?

I have an old screen I pulled to bits, and there is a really nice thin piece, not sure if it is gorilla,

[www.corninggorillaglass.com]

cool test video and more

[www.corninggorillaglass.com]

Edited 1 time(s). Last edit at 03/05/2016 01:25PM by MechaBits.

I have an old screen I pulled to bits, and there is a really nice thin piece, not sure if it is gorilla,

[www.corninggorillaglass.com]

cool test video and more

[www.corninggorillaglass.com]

Edited 1 time(s). Last edit at 03/05/2016 01:25PM by MechaBits.

|

Re: Heated bed glass March 05, 2016 02:24PM |

Registered: 10 years ago Posts: 651 |

There's a guy that used an iPad screen, which I believe is Gorilla Glass.

http://www.instructables.com/id/IPad-glass-as-3D-printing-build-platform/

http://www.instructables.com/id/IPad-glass-as-3D-printing-build-platform/

|

Re: Heated bed glass March 07, 2016 04:29PM |

Registered: 8 years ago Posts: 15 |

Today I disassembled my Y carriage and the bed. I changed to 3 point support and also tried to add a 1.5mm aluminum sheet between the PCB hetaer and the glass. The 3 point support greatly improved the leveling process and also solved my bending issue. However the aluminum sheet did not work well. Since I cut it about 1cm larger than the glass on each side, there was a large uncovered surface which cooled so much that it took mach longer to heat up. I also had to heat the PCB to higher temperature than without the aluminum sheet. Even on the higher temperature I had sticking problems which I could not solve. Since I only have some hand tools I could not cut the sheet without bending it a bit, which did not help my original bending issue. Finally I removed the aluminum sheet and my printer works again.

|

Re: Heated bed glass March 14, 2016 05:43PM |

Registered: 8 years ago Posts: 8 |

I received a heated bed PCB that I had ordered today. I'm surprised to see that it isn't perfectly flat. Should it be? When laid on a flat surface, the middle is 1 - 2mm above the edges. Is this a normal variation within the product or is mine faulty?

The pcb is quite flexible and I think it will be held flat by clipping it to a rigid piece of glass, will a 3mm glass correct this bowing without itself being pulled out of shape? Will evenness of heating be affected ?

The pcb is quite flexible and I think it will be held flat by clipping it to a rigid piece of glass, will a 3mm glass correct this bowing without itself being pulled out of shape? Will evenness of heating be affected ?

|

Re: Heated bed glass March 14, 2016 06:28PM |

Registered: 10 years ago Posts: 14,672 |

It's common for PCB heaters not to be quite flat. Also they bow as they heat up. I suggest a sheet of 1.5mm thick aluminium on top of the PCB heater as a heat spreader, and 4mm glass on top of that. Some people leave out the heat spreader, but if you do that and you want to heat the bed to 100C for printing ABS, then you should use borosilicate glass.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Heated bed glass March 14, 2016 06:44PM |

Registered: 8 years ago Posts: 8 |

|

Re: Heated bed glass March 15, 2016 11:34PM |

Registered: 8 years ago Posts: 430 |

Not sure if you can get one but I got this plate and my bed is now flat. [www.ebay.com]

I had the same issue as you before I added this.

Newbie with Folgertech 2020 i3.

I had the same issue as you before I added this.

Newbie with Folgertech 2020 i3.

|

Re: Heated bed glass March 17, 2016 03:20AM |

Registered: 8 years ago Posts: 15 |

|

Re: Heated bed glass March 17, 2016 04:40AM |

Registered: 10 years ago Posts: 14,672 |

The heat spreader has a notch cut out of it where the connections are made. Here is an example:

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.