UNOFFICIAL: Top 10 needs of the RepRap community (a bit USA centric)

Posted by RoundSparrow

|

Re: UNOFFICIAL: Top 10 needs of the RepRap community (a bit USA centric) March 19, 2008 05:46PM |

Admin Registered: 17 years ago Posts: 7,879 |

Victor,

Can you really do injection molding with 1 bar or is that 1000 bar?

[www.hydraraptor.blogspot.com]

Can you really do injection molding with 1 bar or is that 1000 bar?

[www.hydraraptor.blogspot.com]

|

Re: UNOFFICIAL: Top 10 needs of the RepRap community (a bit USA centric) March 19, 2008 05:50PM |

Admin Registered: 16 years ago Posts: 13,891 |

Hi Forrest,

... got the point

Maybe i'll try to make a molding form from aluminium with my CNC-mill and shoot some plastic-parts with the drill-press ...

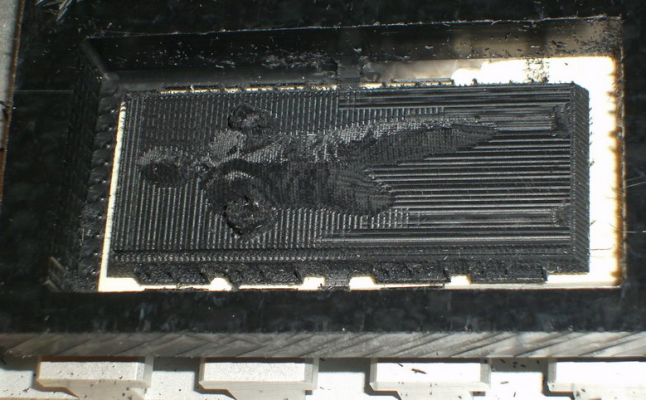

In the mean-time my older son ordered some StarWars-toys:

Viktor

... got the point

Maybe i'll try to make a molding form from aluminium with my CNC-mill and shoot some plastic-parts with the drill-press ...

In the mean-time my older son ordered some StarWars-toys:

Viktor

|

Re: UNOFFICIAL: Top 10 needs of the RepRap community (a bit USA centric) March 19, 2008 06:02PM |

Admin Registered: 16 years ago Posts: 13,891 |

Hi nophead,

the Drader Injectiweld/Orbi-Tech-injection-press works with 1000 bar pressure!

I think you need at least 5 to 10 bar for a coarse fitting, better some 100 bar, which could be made with a drill-press and metal forms.

This high pressures are most made with small pistons pressed in the fluid plastic - you can calculate the end-pressure by the diameter of the piston and the force you apply with the press.

I think a form made from aluminium with some centimeter thick walls an some cubic-centimeters molding volume should withstand 1000 bar pressure - the guy at Orbi-Tech demonstrated this on every fair i saw him with a small mold-form where the company-logo was molded with different coloured ABS-plastic ...

Viktor

the Drader Injectiweld/Orbi-Tech-injection-press works with 1000 bar pressure!

I think you need at least 5 to 10 bar for a coarse fitting, better some 100 bar, which could be made with a drill-press and metal forms.

This high pressures are most made with small pistons pressed in the fluid plastic - you can calculate the end-pressure by the diameter of the piston and the force you apply with the press.

I think a form made from aluminium with some centimeter thick walls an some cubic-centimeters molding volume should withstand 1000 bar pressure - the guy at Orbi-Tech demonstrated this on every fair i saw him with a small mold-form where the company-logo was molded with different coloured ABS-plastic ...

Viktor

|

Re: UNOFFICIAL: Top 10 needs of the RepRap community (a bit USA centric) March 19, 2008 07:39PM |

Admin Registered: 17 years ago Posts: 7,879 |

Ah yes it must be an English / German thing, the site uses . where we use , and visa versa.

Is that Delrin (Acetal) you are milling?

[www.hydraraptor.blogspot.com]

Is that Delrin (Acetal) you are milling?

[www.hydraraptor.blogspot.com]

|

Re: UNOFFICIAL: Top 10 needs of the RepRap community (a bit USA centric) March 20, 2008 05:57AM |

Admin Registered: 16 years ago Posts: 13,891 |

Hi nophead,

yes, i milled the "Han Solo in Carbon"-thingy out from black DELRIN/POM because it should be REAL BLACK ...

It's my best material - stiff for construction, elastic when used for solid-state-hinges and very good and accurate milling without any coolant in any cutting speed (my millhead runs with 11000 until 25000 RPS and until 50mm per second travelling speed).

The next selection is MgAlxx (Duralum or such) - then with alcohol as coolant.

And sometimes wood and other materials ...

Viktor

yes, i milled the "Han Solo in Carbon"-thingy out from black DELRIN/POM because it should be REAL BLACK ...

It's my best material - stiff for construction, elastic when used for solid-state-hinges and very good and accurate milling without any coolant in any cutting speed (my millhead runs with 11000 until 25000 RPS and until 50mm per second travelling speed).

The next selection is MgAlxx (Duralum or such) - then with alcohol as coolant.

And sometimes wood and other materials ...

Viktor

Sorry, only registered users may post in this forum.