Home

>

Reprappers

>

Topic

Z axis Kinematic or fixed industrial printer

Posted by xmen

|

Z axis Kinematic or fixed industrial printer March 05, 2024 02:49PM |

Registered: 7 weeks ago Posts: 2 |

Hello im building more industrial printer and cannot decide how to approach z axis. Bed size will be 600x600x700mm( thermal expansion at 100° is around 1.5mm will ne compansated on silicone pads betwen bed and frame holder of the bed).I think still best to use 2 ballscrews 4 rods and 2 motors one on each side ( note that linear rods and ballscrew will be 20mm think since this need to be build robust lower part fixed upper part of ballscrew alloved minimum motion). i see a lot of people using 3z axis bed kinematic ? i cannot se any benefit from this since build will be robust and accurate as axis should be build. what is your opinion ?? maby also fixed bed with 3 ballscrews but not kinematic. im seeking advice im more towards fixed dual motor Z axis. i cannot see even for non planar printing on 3 z axis kinematic bed because 20° of angle is to low. how should u approach z axis? what is your opinion? thanks

Edited 2 time(s). Last edit at 03/05/2024 02:53PM by xmen.

Edited 2 time(s). Last edit at 03/05/2024 02:53PM by xmen.

|

Re: Z axis Kinematic or fixed industrial printer March 07, 2024 07:24PM |

Registered: 11 years ago Posts: 5,780 |

Sorry, but I can't quite figure out what you're asking.

A kinematic mount is normally applied to the bed because it allows it to expand when heated without causing anything to flex. It is always a good idea to use a kinematic mount on the bed plate if it is heated.

Three screws are used to lift Z more often than four because any error in the movement of four screws will cause the bed or XY stage frame to flex like a potato chip and could cause binding. With just three screws any error will simply tilt the bed or XY stage frame a little and is less likely to bind. Also, aligning three z axis screws and linear guides parallel to each other is easier than aligning four.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

A kinematic mount is normally applied to the bed because it allows it to expand when heated without causing anything to flex. It is always a good idea to use a kinematic mount on the bed plate if it is heated.

Three screws are used to lift Z more often than four because any error in the movement of four screws will cause the bed or XY stage frame to flex like a potato chip and could cause binding. With just three screws any error will simply tilt the bed or XY stage frame a little and is less likely to bind. Also, aligning three z axis screws and linear guides parallel to each other is easier than aligning four.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Z axis Kinematic or fixed industrial printer March 08, 2024 01:06AM |

Registered: 7 weeks ago Posts: 2 |

hi, thanks for your anwser. i was asking in short that i want to use 4 20mm guiding rods each on one side and 2 ballscrews each on one side this will be made ash it should be accuratebalso i need some kinematic support in the 4 corners and some middle of the beed because of possibilitie of slope.

there for i was asking if i make 3 point with 3ball screws and 3 rails kinematic bed but than you cannostt support middle otherwise you have same build as upper part that i wrote. for me i do not see any benefit to make 3 point versus upper solution that is with 2 ballscrews. that is what i was asking that if there is any more benefit in this to mqke kinematic in 3z. also fram will be steel welded and cnced this will be made robust

Edited 1 time(s). Last edit at 03/08/2024 01:07AM by xmen.

there for i was asking if i make 3 point with 3ball screws and 3 rails kinematic bed but than you cannostt support middle otherwise you have same build as upper part that i wrote. for me i do not see any benefit to make 3 point versus upper solution that is with 2 ballscrews. that is what i was asking that if there is any more benefit in this to mqke kinematic in 3z. also fram will be steel welded and cnced this will be made robust

Edited 1 time(s). Last edit at 03/08/2024 01:07AM by xmen.

|

Re: Z axis Kinematic or fixed industrial printer March 19, 2024 07:41AM |

Registered: 4 years ago Posts: 13 |

Keep in mind you can decouple these designs:

How you mount the bed, be it kinematic with 3 studs or 4 or be it fixed or whatsoever, is not necessarily dependant on how you mount the bed undercarriage.

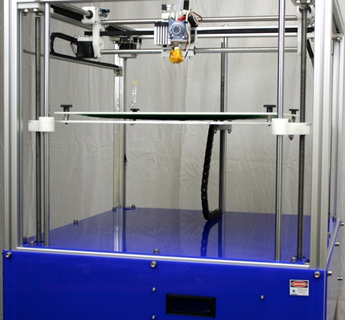

E. g. here the bed is mounted in 4 places but the undercarriage is on 3 leadscrews:

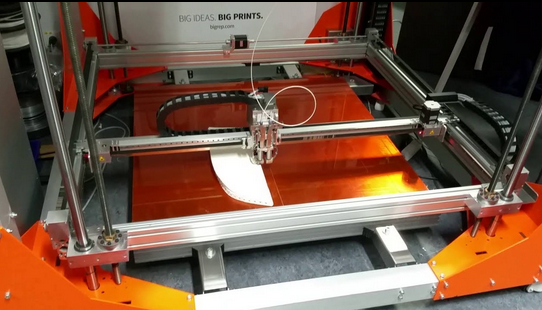

In the end it is all about stability. If you are using CNC parts and you can properly align everything I would go for 4 linear shafts and 4 leadscrews like here, as you also have a quite large build volume (notice they are moving the gantry here though, the bed is fixed):

As far as I understood your design you are asking for an mount like in that picture but with 2 leadscrews instead of 4 (while still using 4 linear shafts). If you have a generally rigid construction I think that may work just fine. Keep in mind to position the linear shafts as close as possible to the leadscrews - so they would be on the sides center, just besides the leadscrew, in your design. If you intend to print very heavy parts (idk, maybe you print 100% infill with metal-filled filaments) I would go for at least 3 if not 4 leadscrews or switch to two beefy linear rails instead of four closely positioned linear shafts for more rigidity considering momentum around the axis from one leadscrew mount to the other.

Mounting the bed in the undercarriage with three points of contact is beneficial considering its alignment, if done properly (kinematic mount, e. g. used in optics for lenses or on laboratory positioning tables). However, if your bed is quite large (just like yours) that would require it to be comparably thick for the unsupported corners to stay flat under load, which adds weight, which may lead to the point where it's more viable to have a fixed bed and move your gantry in Z. So considering your size I would go for a 4 mount bed while still following the kinematic mount principle, just use two instead of one screw for the roll axis. More hassle to align properly but more stable and lighter.

EDIT: It is also very important to mechanically couple the leadscrews imho. The printers in the pictures do that via a closed belt and pulley system you cannot see direcly, utilizing a single motor for Z. You can use multiple motors though (idk, maybe because you have limitations considering drivers or space) - but couple them mechanically so they stay in sync. Every industrial printer I know has that coupling - despite the fact most consumer machines don't, mainly for budget reasons while still gaslightning you into "auto alignment due to independant Z motors" marketing-wise.

Best regards, Demo.

Edited 3 time(s). Last edit at 03/19/2024 07:54AM by Demolux_D1.

How you mount the bed, be it kinematic with 3 studs or 4 or be it fixed or whatsoever, is not necessarily dependant on how you mount the bed undercarriage.

E. g. here the bed is mounted in 4 places but the undercarriage is on 3 leadscrews:

In the end it is all about stability. If you are using CNC parts and you can properly align everything I would go for 4 linear shafts and 4 leadscrews like here, as you also have a quite large build volume (notice they are moving the gantry here though, the bed is fixed):

As far as I understood your design you are asking for an mount like in that picture but with 2 leadscrews instead of 4 (while still using 4 linear shafts). If you have a generally rigid construction I think that may work just fine. Keep in mind to position the linear shafts as close as possible to the leadscrews - so they would be on the sides center, just besides the leadscrew, in your design. If you intend to print very heavy parts (idk, maybe you print 100% infill with metal-filled filaments) I would go for at least 3 if not 4 leadscrews or switch to two beefy linear rails instead of four closely positioned linear shafts for more rigidity considering momentum around the axis from one leadscrew mount to the other.

Mounting the bed in the undercarriage with three points of contact is beneficial considering its alignment, if done properly (kinematic mount, e. g. used in optics for lenses or on laboratory positioning tables). However, if your bed is quite large (just like yours) that would require it to be comparably thick for the unsupported corners to stay flat under load, which adds weight, which may lead to the point where it's more viable to have a fixed bed and move your gantry in Z. So considering your size I would go for a 4 mount bed while still following the kinematic mount principle, just use two instead of one screw for the roll axis. More hassle to align properly but more stable and lighter.

EDIT: It is also very important to mechanically couple the leadscrews imho. The printers in the pictures do that via a closed belt and pulley system you cannot see direcly, utilizing a single motor for Z. You can use multiple motors though (idk, maybe because you have limitations considering drivers or space) - but couple them mechanically so they stay in sync. Every industrial printer I know has that coupling - despite the fact most consumer machines don't, mainly for budget reasons while still gaslightning you into "auto alignment due to independant Z motors" marketing-wise.

Best regards, Demo.

Edited 3 time(s). Last edit at 03/19/2024 07:54AM by Demolux_D1.

Sorry, only registered users may post in this forum.