Home

>

Reprappers

>

Topic

Best approach to build Mendel when you have a printer

Posted by dob71

|

Best approach to build Mendel when you have a printer August 03, 2011 06:13PM |

Registered: 12 years ago Posts: 47 |

Hi All,

I'm planning to build Mendel and considering available options.

I'll mostly print in ABS and would prefer to use ReplicatorG and Skeinforge (because have experience w/ Cupcake).

I'll need to buy everything except the printed parts and spend not much more than $500, however I'd not want to spare on important parts either (it is planned to be a 3d printer I'll live with for a while).

The TechZone Reprap 3D Printer Unassembled Mendel Kit for Printed Parts seems like the best option (at the moment). It is 100 over my planned budget, but it is probably worth the troubles if it really has everything and not that outdated (I worry about electronics).

Can anybody share their experience with that kit?

In particular things like:

- completness of the kit (i.e. does it really have everything for standard Mendel except the printable parts)?

- quality of the rods?

- is the included gen3 electronics good enough (compatibility, software support)?

- the quality of the included extruder kit (is it ok for ABS printing, does it have all the stuff to make the hot end)?

- is the printing table/platform just an aluminium plate, not heated I guess?

- anuthing else?

Any experience building using this kit versus building w/ less complete kits or individual parts?

P.S. And why their site says about promotional price, but adds items to the cart w/ regular price?

Thanks,

Denis

I'm planning to build Mendel and considering available options.

I'll mostly print in ABS and would prefer to use ReplicatorG and Skeinforge (because have experience w/ Cupcake).

I'll need to buy everything except the printed parts and spend not much more than $500, however I'd not want to spare on important parts either (it is planned to be a 3d printer I'll live with for a while).

The TechZone Reprap 3D Printer Unassembled Mendel Kit for Printed Parts seems like the best option (at the moment). It is 100 over my planned budget, but it is probably worth the troubles if it really has everything and not that outdated (I worry about electronics).

Can anybody share their experience with that kit?

In particular things like:

- completness of the kit (i.e. does it really have everything for standard Mendel except the printable parts)?

- quality of the rods?

- is the included gen3 electronics good enough (compatibility, software support)?

- the quality of the included extruder kit (is it ok for ABS printing, does it have all the stuff to make the hot end)?

- is the printing table/platform just an aluminium plate, not heated I guess?

- anuthing else?

Any experience building using this kit versus building w/ less complete kits or individual parts?

P.S. And why their site says about promotional price, but adds items to the cart w/ regular price?

Thanks,

Denis

|

Re: Best approach to build Mendel when you have a printer August 03, 2011 06:52PM |

Registered: 13 years ago Posts: 1,780 |

That kit is for a standard Mendel, not a Prusa. Prusa is much easier to build and has less printed parts.

I would stay away from Gen 3. I also went this way when I first built my Mendel thinking that it would be the most SW compatible. This was a bad assumption and it ended up wasting time. I recommend RAMPS instead. I switched to this and it fixed all my problems with the printer stopping or the extruder temperature being lost randomly during a prints. Not to mention that almost all firmware out there supports RAMPS. The RS485 communication between the MB and extruder controller in Gen 3 is problematic.

I would stay away from Gen 3. I also went this way when I first built my Mendel thinking that it would be the most SW compatible. This was a bad assumption and it ended up wasting time. I recommend RAMPS instead. I switched to this and it fixed all my problems with the printer stopping or the extruder temperature being lost randomly during a prints. Not to mention that almost all firmware out there supports RAMPS. The RS485 communication between the MB and extruder controller in Gen 3 is problematic.

|

Re: Best approach to build Mendel when you have a printer August 03, 2011 09:14PM |

Registered: 12 years ago Posts: 47 |

|

Re: Best approach to build Mendel when you have a printer August 04, 2011 06:39AM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Best approach to build Mendel when you have a printer August 04, 2011 09:25AM |

Registered: 13 years ago Posts: 485 |

Have you considered MakerGear's Prusa? It uses commercial bushings (not printed PLA) and RAMPS electronics. There are a few improvements too. Z axis is supported from below on bearings, not hanging from the motors. MakerGear's extruder is quite robust. MakerGear also includes a PCB heated bed, while TechZone doesn't seem to include any bed heater.

|

Re: Best approach to build Mendel when you have a printer August 04, 2011 09:44AM |

Registered: 14 years ago Posts: 581 |

Please for the love of God do not buy the Techzone kit. I do teck in the IRC every day and the Techzone bot is trash.

Please before you make a purchase go into the RepRap IRC and consult with actual users/developers.

[webchat.freenode.net]

Gen3 are 3 year old electronics in a community that get's new electronics every 3-4 months at this point.

A reprap can be put together from between $400 for a very basic Prusa Mendel, to $825 for a Makergear kit that has all the bells and whistles you could ever want.

repraplogphase.blogspot.com

Please before you make a purchase go into the RepRap IRC and consult with actual users/developers.

[webchat.freenode.net]

Gen3 are 3 year old electronics in a community that get's new electronics every 3-4 months at this point.

A reprap can be put together from between $400 for a very basic Prusa Mendel, to $825 for a Makergear kit that has all the bells and whistles you could ever want.

repraplogphase.blogspot.com

|

Re: Best approach to build Mendel when you have a printer August 04, 2011 12:32PM |

Registered: 12 years ago Posts: 47 |

I did consider Makergear's kit, but rejected for 3 reasons:

- price

- it's Prusa (by that time I already decided to make Mendel)

- it doesn't allow me to save on printing my own plastic parts

I'll probably will use Makergear's hot end though (if coudn't find a good kit that includes the hot end). Still hesitating between 0.35 mm nozzle w/ 1.75mm filament and 0.5mm nozzle w/ 3mm filament. I only have the experience with the latter configuration and it worked fine for me so far (printing in ABS). I'm leaning to keeping the same setup for the Mendel (at least to start with).

- price

- it's Prusa (by that time I already decided to make Mendel)

- it doesn't allow me to save on printing my own plastic parts

I'll probably will use Makergear's hot end though (if coudn't find a good kit that includes the hot end). Still hesitating between 0.35 mm nozzle w/ 1.75mm filament and 0.5mm nozzle w/ 3mm filament. I only have the experience with the latter configuration and it worked fine for me so far (printing in ABS). I'm leaning to keeping the same setup for the Mendel (at least to start with).

|

Re: Best approach to build Mendel when you have a printer August 04, 2011 04:55PM |

Registered: 14 years ago Posts: 581 |

dob71 your going to print a Sells mendel instead of a Prusa? Wow, ok, strange choice.

Also $825 get's you a heated build plate stainless rods and fasteners, a metal geared extruder, good Power Supply, and all the proper wiring... Do as you want, but Printing a Sells Mendel is just daft.

repraplogphase.blogspot.com

Also $825 get's you a heated build plate stainless rods and fasteners, a metal geared extruder, good Power Supply, and all the proper wiring... Do as you want, but Printing a Sells Mendel is just daft.

repraplogphase.blogspot.com

|

Re: Best approach to build Mendel when you have a printer August 04, 2011 06:42PM |

Registered: 17 years ago Posts: 824 |

dob71 Wrote:

-------------------------------------------------------

> I was looking at Prusa first, but when saw that

> plastic bushings are used for traction decided to

> build the standard Mendel.

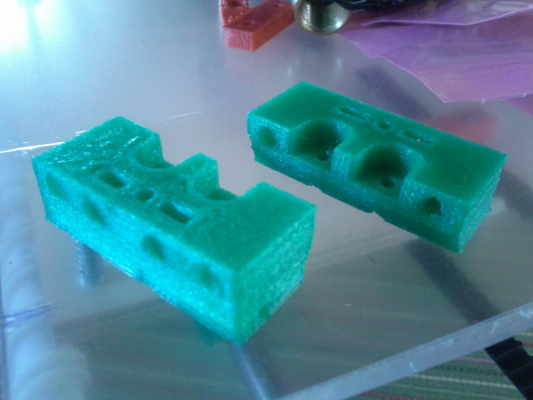

Nothing wrong with PLA bushings. Have a look at the parts below. They are for a Huxley, and contain some very small features. Those were printed on a stock Prusa with PLA bushings an a 0.18mm nozzle.

-------------------------------------------------------

> I was looking at Prusa first, but when saw that

> plastic bushings are used for traction decided to

> build the standard Mendel.

Nothing wrong with PLA bushings. Have a look at the parts below. They are for a Huxley, and contain some very small features. Those were printed on a stock Prusa with PLA bushings an a 0.18mm nozzle.

|

Re: Best approach to build Mendel when you have a printer August 06, 2011 09:48PM |

Registered: 12 years ago Posts: 47 |

Ok. I went ahead w/ Prusa Mendel. The "get the parts yourself" approach didn't save me as much as I was hoping. I ended up spendig $602 for all the parts except plastic (and I bet something is going to be missing). It was for a bit more than just the standard minimalistic version though (ordered things like heated bed, SD card module for RAMPS, got motors w/ long wires and high torque when could have gotten a bit less expansive ones - not big savings though). Now every bit and piece has to be assembled, looking back at it all seems like Makergear's kit is a better option (unless you want to appreciate all the gory details of the DIY process).

I'm planning to make SAE version, but use 8mm rods and LM8UU linear bearings.

It's time to start printing the parts. I just have to figure out now which ones...

It seems like I should be able to print all the SAE parts except

- x-carriage

- x-end idler

- x-end motor

- bushings

those I'd need to print from mod's for LM8UUs on thingverse:

[www.thingiverse.com]

[www.thingiverse.com]

[www.thingiverse.com]

Now, I just don't have a clue how those are going to play w/ the SAE Prusa version (hopefully I won't have to change much, just the nut holes).

I'd appreciate an advice on that (maybe there already mods for SAE version I didn't find).

Also, is the standard Wade's extruder the way to go or is it better to use Greg's [www.thingiverse.com] mod (I'll be using Makergear's hotend pack)?

And the last question, should I use the files from reprap.org or is it better to pull from github, maybe it even makes sense to go after the "experimental" or "felt" branch of PrusaMendel?

I'm planning to make SAE version, but use 8mm rods and LM8UU linear bearings.

It's time to start printing the parts. I just have to figure out now which ones...

It seems like I should be able to print all the SAE parts except

- x-carriage

- x-end idler

- x-end motor

- bushings

those I'd need to print from mod's for LM8UUs on thingverse:

[www.thingiverse.com]

[www.thingiverse.com]

[www.thingiverse.com]

Now, I just don't have a clue how those are going to play w/ the SAE Prusa version (hopefully I won't have to change much, just the nut holes).

I'd appreciate an advice on that (maybe there already mods for SAE version I didn't find).

Also, is the standard Wade's extruder the way to go or is it better to use Greg's [www.thingiverse.com] mod (I'll be using Makergear's hotend pack)?

And the last question, should I use the files from reprap.org or is it better to pull from github, maybe it even makes sense to go after the "experimental" or "felt" branch of PrusaMendel?

|

Re: Best approach to build Mendel when you have a printer August 07, 2011 08:24AM |

Registered: 12 years ago Posts: 1 |

Have you considered MakerGear's Prusa? It uses commercial bushings (not printed PLA) and RAMPS electronics. There are a few improvements too. Z axis is supported from below on bearings, not hanging from the motors. MakerGear's extruder is quite robust. MakerGear also includes a PCB heated bed, while TechZone doesn't seem to include any bed heater.

________________________________________

sbobet-คาสิโนออนไลน์-ผลบอล-gclub

Edited 1 time(s). Last edit at 08/08/2011 01:33AM by prid.

________________________________________

sbobet-คาสิโนออนไลน์-ผลบอล-gclub

Edited 1 time(s). Last edit at 08/08/2011 01:33AM by prid.

|

Re: Best approach to build Mendel when you have a printer August 07, 2011 12:16PM |

Registered: 12 years ago Posts: 47 |

|

Re: Best approach to build Mendel when you have a printer August 23, 2011 09:15PM |

Registered: 13 years ago Posts: 7 |

Just my two cents about Techzone:

- completness of the kit (i.e. does it really have everything for standard Mendel except the printable parts)?

I purchased the complete laser cut kit. It was mostly complete. The wire included was a bare minimum in length and the way I hooked it up I had to supply my own. Not a big deal except if you consider that I spent over $1000 with them it's pretty ridiculous to get cheap over a few inches of wire.

- quality of the rods?

They are good. Straight and pretty smooth

- is the included gen3 electronics good enough (compatibility, software support)?

The electronics are an absolute nightmare. The whole setup is garbage, the documentation on the forums is unfinished, and the one wire heating setup is bad. I can get all my axes to work and the extruder moves but the tip doesn't heat up consistently. I've gone over and over with it. Sometimes it works, sometimes it shows 2000 degrees and sometimes it shows 0 B:0 I have installed a ton of different firmwares and used shielded cable to replace the cat5 wire included with it and it just isn't reliable.

- the quality of the included extruder kit (is it ok for ABS printing, does it have all the stuff to make the hot end)?

The extruder and hot end are another nightmare. The tip is screwed into an oak block which will eventually turn to dust. The extruder I received was the only parts in this kit that were printed and they were low quality. A piece I instantly wanted to upgrade.

- is the printing table/platform just an aluminium plate, not heated I guess?

Not heated. Thin aluminum and another part I started thinking about upgrading the second I saw it.

- anuthing else?

I spent over $1000 with techzone and there were times they were helpful and times they didn't respond to which I finally gave up. I did this right before the Prusa came out which was about the same time parts showed up in large quantities on ebay. It was hard to get certain parts for the reprap and I figured my best chance at getting a working printer was to get the whole setup at once. It's been months. I've walked away from it for long periods of time. I've spent well over 100 hours of my time assembling and then trying to get this thing printing and while I cane get all the axes to go home and the extruder moves I still can't get a print.

The best part that doesn't sting at all?

My plan the whole time was to print plastic parts to replace all the laser cut parts as soon as I got it run.

End result?

I still don't have a working printer and I'm out twice as much money as I would have been to get a Prusa going.

My next step?

Purchase Gen 6 electronics from a good supplier, rip apart my reprap and replace as much of the crappy, low quality laser cut parts I bought from Techzone with decent plastic parts I bought from another supplier.

My suggestion?

Research, research, research! Buy your parts from somebody whom everyone raves about on here. I wanted parts from Nophead when I started. I should have waited. In my opinion Techzone is a complete waste of money on outdated parts that will only frustrate you. You'll likely end up just like me with a very expensive piece of garbage sitting in your garage waiting for some cash to buy the right parts while you watch other people who come along later on here talk about assembling their printer and then begin printing parts. Some people get Techzone electronics to work but from all the complaints and frustration I've seen on these forums and others blog posts I think there are a lot of people who have had similar experiences to me. Had I only talked to spacexula before buying my kit I'd probably have been printing parts for months now. Instead I blew my expendable cash with Techzone who decided to begin ignoring my emails after a while. I initially gave them a good review and talked well about them on here. Not anymore. I hope Lambert and Kimberly had a lot of fun with my money. More fun than I had with the pile of garbage they sent me anyway.

Edited 1 time(s). Last edit at 08/23/2011 09:18PM by Roaddog.

- completness of the kit (i.e. does it really have everything for standard Mendel except the printable parts)?

I purchased the complete laser cut kit. It was mostly complete. The wire included was a bare minimum in length and the way I hooked it up I had to supply my own. Not a big deal except if you consider that I spent over $1000 with them it's pretty ridiculous to get cheap over a few inches of wire.

- quality of the rods?

They are good. Straight and pretty smooth

- is the included gen3 electronics good enough (compatibility, software support)?

The electronics are an absolute nightmare. The whole setup is garbage, the documentation on the forums is unfinished, and the one wire heating setup is bad. I can get all my axes to work and the extruder moves but the tip doesn't heat up consistently. I've gone over and over with it. Sometimes it works, sometimes it shows 2000 degrees and sometimes it shows 0 B:0 I have installed a ton of different firmwares and used shielded cable to replace the cat5 wire included with it and it just isn't reliable.

- the quality of the included extruder kit (is it ok for ABS printing, does it have all the stuff to make the hot end)?

The extruder and hot end are another nightmare. The tip is screwed into an oak block which will eventually turn to dust. The extruder I received was the only parts in this kit that were printed and they were low quality. A piece I instantly wanted to upgrade.

- is the printing table/platform just an aluminium plate, not heated I guess?

Not heated. Thin aluminum and another part I started thinking about upgrading the second I saw it.

- anuthing else?

I spent over $1000 with techzone and there were times they were helpful and times they didn't respond to which I finally gave up. I did this right before the Prusa came out which was about the same time parts showed up in large quantities on ebay. It was hard to get certain parts for the reprap and I figured my best chance at getting a working printer was to get the whole setup at once. It's been months. I've walked away from it for long periods of time. I've spent well over 100 hours of my time assembling and then trying to get this thing printing and while I cane get all the axes to go home and the extruder moves I still can't get a print.

The best part that doesn't sting at all?

My plan the whole time was to print plastic parts to replace all the laser cut parts as soon as I got it run.

End result?

I still don't have a working printer and I'm out twice as much money as I would have been to get a Prusa going.

My next step?

Purchase Gen 6 electronics from a good supplier, rip apart my reprap and replace as much of the crappy, low quality laser cut parts I bought from Techzone with decent plastic parts I bought from another supplier.

My suggestion?

Research, research, research! Buy your parts from somebody whom everyone raves about on here. I wanted parts from Nophead when I started. I should have waited. In my opinion Techzone is a complete waste of money on outdated parts that will only frustrate you. You'll likely end up just like me with a very expensive piece of garbage sitting in your garage waiting for some cash to buy the right parts while you watch other people who come along later on here talk about assembling their printer and then begin printing parts. Some people get Techzone electronics to work but from all the complaints and frustration I've seen on these forums and others blog posts I think there are a lot of people who have had similar experiences to me. Had I only talked to spacexula before buying my kit I'd probably have been printing parts for months now. Instead I blew my expendable cash with Techzone who decided to begin ignoring my emails after a while. I initially gave them a good review and talked well about them on here. Not anymore. I hope Lambert and Kimberly had a lot of fun with my money. More fun than I had with the pile of garbage they sent me anyway.

Edited 1 time(s). Last edit at 08/23/2011 09:18PM by Roaddog.

|

Re: Best approach to build Mendel when you have a printer August 23, 2011 11:01PM |

Registered: 12 years ago Posts: 47 |

Sorry to hear that you went through all those troubles.

By the way, my first printer (that I'm using for printing parts now) is Makerbot's Cupcake CNC.

It also runs on the gen3 electronics, but the only serious troubles I've had were w/ driving the extruder DC motor. I've just made a small extension board w/ mosfets suitable for for the job and had no issues after that. Eventually the extruder and HBP heater switching moved to mosfets on that board too. I'm pretty happy with it now, so maybe it is doable, just too time consuming (or whatever is called "gen3" is qite different). Given the frustration and time already spent I'm guessing I'd also go ahead w/ something like gen6 that is already prebuilt.

By the way, my first printer (that I'm using for printing parts now) is Makerbot's Cupcake CNC.

It also runs on the gen3 electronics, but the only serious troubles I've had were w/ driving the extruder DC motor. I've just made a small extension board w/ mosfets suitable for for the job and had no issues after that. Eventually the extruder and HBP heater switching moved to mosfets on that board too. I'm pretty happy with it now, so maybe it is doable, just too time consuming (or whatever is called "gen3" is qite different). Given the frustration and time already spent I'm guessing I'd also go ahead w/ something like gen6 that is already prebuilt.

|

Re: Best approach to build Mendel when you have a printer August 29, 2011 12:13AM |

Registered: 12 years ago Posts: 411 |

I was in a similar boat. I have a Makerbot TOM and I used it to print all the parts for a Prusa, mostly in PLA with a few ABS parts near the extruder. I went with Thingfarm's Prusa kit and motors, some LM8UU bearings from a Chinese company selling stuff on eBay, a Sanguinololu kit straight from JoeM, and a hot end from makergear. No heated bed so far. Total cost: $464.

|

Re: Best approach to build Mendel when you have a printer August 29, 2011 08:51PM |

Registered: 12 years ago Posts: 47 |

Looks good. You didn't mention the extruder hardware and the print beds. Are they included in the price?

I've completed the build and moving on to the bring up stage. The only necessary part I forgot about is the thermistor for the heated bed. I also decided to buy PTFE tubing + a matching nuts for bowden mount. Then also spent extra on aluminium pulleys (e-bay from China) and a 5lb roll of ABS on a spool (plastic should probably also be considered a necessry part). The total has now reached $700...

What's done is done, my concerns are now with the software. Can't realy find RAMPS firmware that is claimed to work reliably w/ ReplicatorG, leaving alone support for kliment's SD ramps module at the same time... Not sure either I should move on to printrun+sprinter or try to use RepG+teacup and attempt to add SD support there...

I've completed the build and moving on to the bring up stage. The only necessary part I forgot about is the thermistor for the heated bed. I also decided to buy PTFE tubing + a matching nuts for bowden mount. Then also spent extra on aluminium pulleys (e-bay from China) and a 5lb roll of ABS on a spool (plastic should probably also be considered a necessry part). The total has now reached $700...

What's done is done, my concerns are now with the software. Can't realy find RAMPS firmware that is claimed to work reliably w/ ReplicatorG, leaving alone support for kliment's SD ramps module at the same time... Not sure either I should move on to printrun+sprinter or try to use RepG+teacup and attempt to add SD support there...

Sorry, only registered users may post in this forum.