i3 Rework variant, no threaded rod frame

Posted by vegasloki

|

i3 Rework variant, no threaded rod frame July 13, 2015 11:33PM |

Registered: 11 years ago Posts: 661 |

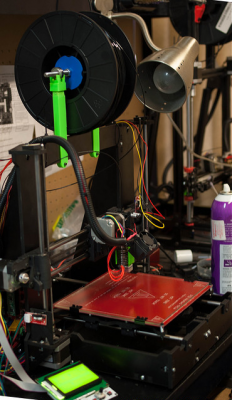

I've put together a new i3 Rework variant. I've had a couple of prototypes running for about a month. It can easily print 100 micron layers and I've used the machine at 60 microns. At 300 microns I've been printing at 100 mm/sec with a .4 nozzle easily.(I plan to test it at faster speeds with a larger nozzle) It's a mashup using the basic design of the Graber i3 frame (with some mods to the size and Y belt motion parts), a modified Wilson/i3 direct drive extruder, a Hephestos based X motor end and a X idler end that employs an adjustable belt tensioner. The assembly goal is to make the machine as easy to assemble as possible with as many "positive fit" parts and assemblies as possible. A positive fit means the part only assembles one way with minimal adjustment needed.

The design is meant to be as DIY friendly as possible allowing those with access to a maker space to build one entirely at the space. The Graber based frame can be either wood, melamine, ACP (Dibond) or metal. I've found laser cut melamine to offer the best bang for the buck. By eliminating the threaded rod frame the design is easier to align and square as it only goes together one way. It also provide more stability compared to a single plate i3 design or a threaded rod frame i3 Rework design. This is technically a Repstrap (as opposed to a Reprap) as such the printed parts count is reduced from about 10-12 hours of printing to about 5 hours. If the only access you have to a printer is at your makerspace you know what a pain it can be to log enough hours to print a set of parts. The design replaces 5-6 hours of printing with 30-40 minutes of laser cutting or CNC routing. The design eliminates the threaded rod frame and a considerable number of fasteners.

Source is at [github.com] with the derivative works listed as well as editable source for the parts that are original to the machine.

Assembly docs are at [roaddoglabs.com] . There is also a more detailed description of the machine and info on what was changed from the derivative parts. Build docs are still a work in progress.

A detailed BOM is still a work in progress though most fasteners are M3 x 14. A starting point for the BOM is at [roaddoglabs.com]. As the build docs are completed the BOM and supporting docs will be updated. I'm still tweaking a few things and those are listed in the issue tracker at Github.

I'll get some more pics once I get the BOM finished and the build docs complete.

Disclosure: I'm Dave Stevens, my wife and I operate Roaddog Labs Ltd, a kit integrator/ digital fabrication shop in Las Vegas, NV. We've been selling kits and parts for the last few years. We will sell this as a full kit or as an upgrade for those with other frame designs that want something more stable but still maintain the geometry of an i3 Rework. That said, the source is available fully open, no restrictions.

The design is meant to be as DIY friendly as possible allowing those with access to a maker space to build one entirely at the space. The Graber based frame can be either wood, melamine, ACP (Dibond) or metal. I've found laser cut melamine to offer the best bang for the buck. By eliminating the threaded rod frame the design is easier to align and square as it only goes together one way. It also provide more stability compared to a single plate i3 design or a threaded rod frame i3 Rework design. This is technically a Repstrap (as opposed to a Reprap) as such the printed parts count is reduced from about 10-12 hours of printing to about 5 hours. If the only access you have to a printer is at your makerspace you know what a pain it can be to log enough hours to print a set of parts. The design replaces 5-6 hours of printing with 30-40 minutes of laser cutting or CNC routing. The design eliminates the threaded rod frame and a considerable number of fasteners.

Source is at [github.com] with the derivative works listed as well as editable source for the parts that are original to the machine.

Assembly docs are at [roaddoglabs.com] . There is also a more detailed description of the machine and info on what was changed from the derivative parts. Build docs are still a work in progress.

A detailed BOM is still a work in progress though most fasteners are M3 x 14. A starting point for the BOM is at [roaddoglabs.com]. As the build docs are completed the BOM and supporting docs will be updated. I'm still tweaking a few things and those are listed in the issue tracker at Github.

I'll get some more pics once I get the BOM finished and the build docs complete.

Disclosure: I'm Dave Stevens, my wife and I operate Roaddog Labs Ltd, a kit integrator/ digital fabrication shop in Las Vegas, NV. We've been selling kits and parts for the last few years. We will sell this as a full kit or as an upgrade for those with other frame designs that want something more stable but still maintain the geometry of an i3 Rework. That said, the source is available fully open, no restrictions.

|

Re: i3 Rework variant, no threaded rod frame July 14, 2015 05:36AM |

Registered: 9 years ago Posts: 977 |

Very nice design! Since it is an open source design based on the Prusa i3, I would suggest you add it to the wiki, with links in the Prusa i3 variants and development pages.

Just one remark: I am not sure why you say it is derived from the i3 Rework, the way I see it, it is more of a derivative of the Graber i3, which is itself a derivative of the Prusa i3 Twelvepro, which is a direct derivative of the Prusa i3.

Also, for the X-axis, you may want to use my improved set of printed parts, which you can find here: [www.thingiverse.com]

These are quite probably a drop-in replacement for the parts you are using right now, with a few small improvements and fixes.

Also, does it have a name yet?

Just one remark: I am not sure why you say it is derived from the i3 Rework, the way I see it, it is more of a derivative of the Graber i3, which is itself a derivative of the Prusa i3 Twelvepro, which is a direct derivative of the Prusa i3.

Also, for the X-axis, you may want to use my improved set of printed parts, which you can find here: [www.thingiverse.com]

These are quite probably a drop-in replacement for the parts you are using right now, with a few small improvements and fixes.

Also, does it have a name yet?

|

Re: i3 Rework variant, no threaded rod frame July 14, 2015 06:25AM |

Registered: 9 years ago Posts: 476 |

|

Re: i3 Rework variant, no threaded rod frame July 14, 2015 03:57PM |

Registered: 11 years ago Posts: 661 |

Thanks for the comments.

I used the Rework as a variant as it uses the same geometry and printed motion parts for the X but with a Graber frame. I see the point about how it could derive more from the Graber or at least 50/50. To be fair I think I'll mention both and while it is different than either of those, I'd like to make sure that Jo, Shane and the gang at bq and the others get the nod because it's really a Repstrap mashup with some mod parts. I think a good case could be made for it ultimately being an i3 derivative as those others came from the i3. It's called a Bart. We've been naming machines after our animals instead of evolution scientists. We currently have an quality parts, entry level i3 Rework (pretty much a straight ahead Rework with a modified Graber LC frame) that is named after our dog Baja. [roaddoglabs.com]

I didn't use the Hephestos X idler because I wanted all of the endstop mounts to be positive fit. We're selling kits and parts for a couple thousand machines a year. I'm taking what we've learned from those that have assembled the kits and trying to make the assembly as user friendly as possible. Positive fit parts and minimal squaring and levling are part of that design philosophy. A lot of kit integrators don't see the assembly from the point of view of the new builder. Part of what we do is provide OEM parts (frames, rods, etc) to maker groups and schools so we've been able to see first hand how new builders (particuarly young teens and college students) and those new to using tools in the first place go about the builds. We also do a fair amount with college students and we try to make it as easy as possible to assembly on a dorm room desk, though you really should have more space. In addition to learning about 3D printing it's also a great way to get started with CNC tools and learning the various sub assemblies that comprise those tools in addition to learning how to use basic hand tools.

I'll have a look at Andrew's parts and see what I can integrate. I like the knob on the X idler adjuster.

Dave

[roaddoglabs.com]

I used the Rework as a variant as it uses the same geometry and printed motion parts for the X but with a Graber frame. I see the point about how it could derive more from the Graber or at least 50/50. To be fair I think I'll mention both and while it is different than either of those, I'd like to make sure that Jo, Shane and the gang at bq and the others get the nod because it's really a Repstrap mashup with some mod parts. I think a good case could be made for it ultimately being an i3 derivative as those others came from the i3. It's called a Bart. We've been naming machines after our animals instead of evolution scientists. We currently have an quality parts, entry level i3 Rework (pretty much a straight ahead Rework with a modified Graber LC frame) that is named after our dog Baja. [roaddoglabs.com]

I didn't use the Hephestos X idler because I wanted all of the endstop mounts to be positive fit. We're selling kits and parts for a couple thousand machines a year. I'm taking what we've learned from those that have assembled the kits and trying to make the assembly as user friendly as possible. Positive fit parts and minimal squaring and levling are part of that design philosophy. A lot of kit integrators don't see the assembly from the point of view of the new builder. Part of what we do is provide OEM parts (frames, rods, etc) to maker groups and schools so we've been able to see first hand how new builders (particuarly young teens and college students) and those new to using tools in the first place go about the builds. We also do a fair amount with college students and we try to make it as easy as possible to assembly on a dorm room desk, though you really should have more space. In addition to learning about 3D printing it's also a great way to get started with CNC tools and learning the various sub assemblies that comprise those tools in addition to learning how to use basic hand tools.

I'll have a look at Andrew's parts and see what I can integrate. I like the knob on the X idler adjuster.

Dave

[roaddoglabs.com]

Sorry, only registered users may post in this forum.

and this one based on box frame, I only know rework frame is a single plate type (correct me on this)

and this one based on box frame, I only know rework frame is a single plate type (correct me on this)