ABS adhesion - major issues - going insane

Posted by JBFUK

|

ABS adhesion - major issues - going insane September 29, 2015 06:38AM |

Registered: 8 years ago Posts: 30 |

Hi,

Having some serious issues with what I have now come to call my frustration generating machine (some might call it a 3D printer).

I am using an aluminium build plate as I have a proximity sensor which won't work with my glass plate. I have the aluminum MK3 bed with a 2mm sheet of aluminum on top which i actually print on. With the glass plate I found that ABS juice kept my prints held down however it fails to get a solid grip on the aluminum plate. I have tried PVA, hairspray and glue stick - all of which stick to the build plate fine but don't cling on to the ABS. The only thing I've had luck with is glue stick with ABS juice which actually clings on too well and also leaves a horrible rough finish on the bottom layer.

I am printing with my ABS at 245'C and the bed at 105'C for the first layer and 100'C thereafter. I can't get the hotbed any hotter - I set it to 110'C and it sat there for an hour trying to reach temp but maxed out at 108'C. My printer is in an enclosure which I built to try to help it maintain temperature and avoid drafts. That has helped as none of the prints I've made since have shown any sign of cracking between layers. I'm not using any parts fans the only one I have is the E3D hotend fan which should only be blowing warm air around as it's sealed in the enclosure.

Very frustrating.... I have ordered some blue scotch painters tape which will be here in a few days time but I'm not expecting that to work miracles (most expensive painters tape in the world?!?). Any suggestions on what else I can try?

JBF.

Having some serious issues with what I have now come to call my frustration generating machine (some might call it a 3D printer).

I am using an aluminium build plate as I have a proximity sensor which won't work with my glass plate. I have the aluminum MK3 bed with a 2mm sheet of aluminum on top which i actually print on. With the glass plate I found that ABS juice kept my prints held down however it fails to get a solid grip on the aluminum plate. I have tried PVA, hairspray and glue stick - all of which stick to the build plate fine but don't cling on to the ABS. The only thing I've had luck with is glue stick with ABS juice which actually clings on too well and also leaves a horrible rough finish on the bottom layer.

I am printing with my ABS at 245'C and the bed at 105'C for the first layer and 100'C thereafter. I can't get the hotbed any hotter - I set it to 110'C and it sat there for an hour trying to reach temp but maxed out at 108'C. My printer is in an enclosure which I built to try to help it maintain temperature and avoid drafts. That has helped as none of the prints I've made since have shown any sign of cracking between layers. I'm not using any parts fans the only one I have is the E3D hotend fan which should only be blowing warm air around as it's sealed in the enclosure.

Very frustrating.... I have ordered some blue scotch painters tape which will be here in a few days time but I'm not expecting that to work miracles (most expensive painters tape in the world?!?). Any suggestions on what else I can try?

JBF.

|

Re: ABS adhesion - major issues - going insane September 29, 2015 09:49AM |

Registered: 9 years ago Posts: 722 |

Hi,

You should not cool down to 100°C

and keep on with 105°C from start to end.

Stick to ABS juice but just raise ABS percentage in solution.

Try a temporary outlet fan for the hotend

to prenvent cooling air to reach the part.

If you're a newbie with 3D printing.

Keep Calm, store your ABS

wait for a brand new PETG filament spool.

ABS needs some skills to understand what's wrong with it.

It's not a beginer job.

++JM

Edited 1 time(s). Last edit at 09/29/2015 09:49AM by J-Max.

You should not cool down to 100°C

and keep on with 105°C from start to end.

Stick to ABS juice but just raise ABS percentage in solution.

Try a temporary outlet fan for the hotend

to prenvent cooling air to reach the part.

If you're a newbie with 3D printing.

Keep Calm, store your ABS

wait for a brand new PETG filament spool.

ABS needs some skills to understand what's wrong with it.

It's not a beginer job.

++JM

Edited 1 time(s). Last edit at 09/29/2015 09:49AM by J-Max.

|

Re: ABS adhesion - major issues - going insane September 29, 2015 10:10AM |

Registered: 11 years ago Posts: 114 |

I have used kapton tape for long years (with my old makerbot tom) without any issue. If I notice any curling I just stop the print and apply a bit of acetone to clean the tape.

But now I am worried about how to do that with a new prusa I assembled because the bed never reaches 110C (it takes like 25 mins to 80C, and even I replaced the wire with a big one, stills warms up) so I will try soon with window glass+kapton

But now I am worried about how to do that with a new prusa I assembled because the bed never reaches 110C (it takes like 25 mins to 80C, and even I replaced the wire with a big one, stills warms up) so I will try soon with window glass+kapton

|

Re: ABS adhesion - major issues - going insane September 29, 2015 01:20PM |

Registered: 8 years ago Posts: 30 |

Yeah bed temp is an issue, mine takes ages to get to 105'C even after building an enclosure - really don't want to have to go down the 24v route.

So in theory should ABS slurry be able to cling on to the aluminum plate without any additional help? I just got my second non-warped print this time using PVA and ABS juice over that; again the finish on the first layer is not pretty. I'm going to try now with straight ABS slurry.

So in theory should ABS slurry be able to cling on to the aluminum plate without any additional help? I just got my second non-warped print this time using PVA and ABS juice over that; again the finish on the first layer is not pretty. I'm going to try now with straight ABS slurry.

|

Re: ABS adhesion - major issues - going insane September 29, 2015 02:02PM |

Registered: 11 years ago Posts: 114 |

|

Re: ABS adhesion - major issues - going insane September 29, 2015 03:11PM |

Registered: 8 years ago Posts: 57 |

I stuffed a piece of reflectix between the carriage and bed - really reduced heatup time and also helped retain temperature.

I print on kapton tape + ABS juice. Still trying to learn how much juice but I've had parts on there so damn hard they are impossible to get off without a lot of force. Never had a part curl up yet (235 extruder, 110bed)

therippa in the folgertech thread posted about BuildTak + Aluminum bed. looks awesome.

I print on kapton tape + ABS juice. Still trying to learn how much juice but I've had parts on there so damn hard they are impossible to get off without a lot of force. Never had a part curl up yet (235 extruder, 110bed)

therippa in the folgertech thread posted about BuildTak + Aluminum bed. looks awesome.

|

Re: ABS adhesion - major issues - going insane September 29, 2015 06:02PM |

Registered: 8 years ago Posts: 30 |

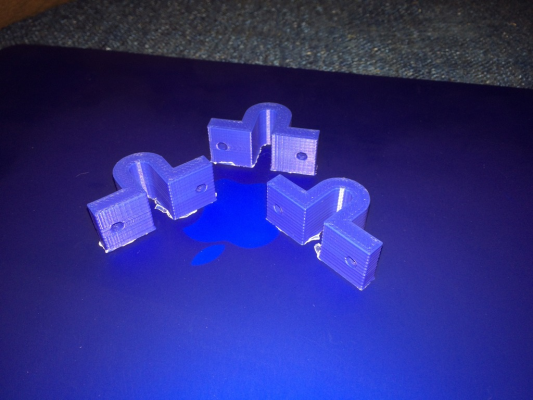

Some progress - these came out flat using a pretty thick ABS slurry, bed set to 105 for the whole print.

Going to try something else - this is encouraging. I did order a reel of PETG which should arrive tomorrow along with scotch tape. If the PETG can give me some of the strength of ABS without the hassle or the brittleness of PLA then it might be just the thing for prints prone to warping a lot.

Now to get the bed heating up more quickly. I'm thinking a piece of thin cardboard covered in foil between the heat-bed and carriage might help. Also need to work out what's causing the ripple.

Going to try something else - this is encouraging. I did order a reel of PETG which should arrive tomorrow along with scotch tape. If the PETG can give me some of the strength of ABS without the hassle or the brittleness of PLA then it might be just the thing for prints prone to warping a lot.

Now to get the bed heating up more quickly. I'm thinking a piece of thin cardboard covered in foil between the heat-bed and carriage might help. Also need to work out what's causing the ripple.

|

Re: ABS adhesion - major issues - going insane September 30, 2015 02:42AM |

Registered: 8 years ago Posts: 30 |

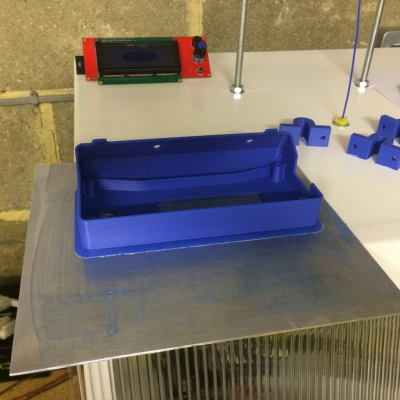

More success - thick ABS slurry with bed at 105 throughout and I used an 8mm float. Now have a case for my LCD

Things are looking up.

I still don't get the lovely smooth finish that I get from a glass plate as the aluminium has lots of tiny scratches from scouring clean. Any tips on cleaning up? Sanding leaves horrible white scratches. I've seen people suggest brushing lightly with acetone and leaving to dry?

Things are looking up.

I still don't get the lovely smooth finish that I get from a glass plate as the aluminium has lots of tiny scratches from scouring clean. Any tips on cleaning up? Sanding leaves horrible white scratches. I've seen people suggest brushing lightly with acetone and leaving to dry?

|

Re: ABS adhesion - major issues - going insane October 01, 2015 09:23AM |

Registered: 10 years ago Posts: 444 |

|

Re: ABS adhesion - major issues - going insane October 07, 2015 03:05AM |

Registered: 8 years ago Posts: 30 |

I started getting decent results with ABS back on glass but my nozzle got blocked yesterday so I figured after cleaning the hot end I'd switch filament and try out the PETG. Having trouble with getting it to stick - 240'c hot end, 85'c bed with hairspray on the glass. Parts pull off as soon as it starts putting down the second layer.

|

Re: ABS adhesion - major issues - going insane October 08, 2015 06:07AM |

Registered: 10 years ago Posts: 444 |

|

Re: ABS adhesion - major issues - going insane October 08, 2015 06:10AM |

Registered: 8 years ago Posts: 30 |

And wait an hour for it to get up to temp... 85'C seems good - I changed the brand of hairspray and now sticks well (from cheap supermarket 'super strength' to my wife's Elnett 'Supreme Hold'). Seems to print quite well just need to tune the extrusion as it's over-extruding a bit. Only gripe I have with it is the translucent property I'd prefer it more opaque.

|

Re: ABS adhesion - major issues - going insane October 09, 2015 09:23AM |

Registered: 9 years ago Posts: 7 |

I use kapton tape which i rugged with some very fine sandpaper and a 7mm brim, bed temperature set to 100C.

It's very important to keep the bed absolutely clean, for example if you have touched the bed with your fingers (leaves fat) you then need to clean it.

I found brake cleaner (used to clean car brakes) to be very effective.

To make the bed warm up quicker i place a piece of rubber foam on top of the bed and when it's 100C remove it and start the print.

It's very important to keep the bed absolutely clean, for example if you have touched the bed with your fingers (leaves fat) you then need to clean it.

I found brake cleaner (used to clean car brakes) to be very effective.

To make the bed warm up quicker i place a piece of rubber foam on top of the bed and when it's 100C remove it and start the print.

|

Re: ABS adhesion - major issues - going insane October 09, 2015 09:37AM |

Registered: 9 years ago Posts: 251 |

If you're tired of hair sprays and slurries I'd recommend getting a piece of PEI to print on. It's a little expensive for one sheet, I bought a 12x12 sheet and cut it down to 8x8 [www.amazon.com] but I haven't had to spray ANYTHING onto it to get PLA or ABS to stick, also once it cools the parts pop right off with a nice glossy finish. 60C for PLA, 110C for ABS. If your bed is having trouble getting to temp insulate the underside with cardboard or silicon sheet, but also cut a piece to sit on the bed while it heats to reflect the heat back down, this trick has got my i3 bed to 110C < 10min, obviously removing this piece when you start printing.

Edited 1 time(s). Last edit at 10/09/2015 09:38AM by widespreaddeadhead.

Edited 1 time(s). Last edit at 10/09/2015 09:38AM by widespreaddeadhead.

|

Re: ABS adhesion - major issues - going insane October 09, 2015 11:41AM |

Registered: 8 years ago Posts: 30 |

|

Re: ABS adhesion - major issues - going insane October 09, 2015 11:00PM |

Registered: 8 years ago Posts: 430 |

|

Re: ABS adhesion - major issues - going insane October 11, 2015 12:18PM |

Registered: 8 years ago Posts: 30 |

|

Re: ABS adhesion - major issues - going insane October 11, 2015 02:21PM |

Registered: 10 years ago Posts: 444 |

Sorry, only registered users may post in this forum.