Considering a new extruder design

Posted by mung

|

Re: Considering a new extruder design February 17, 2011 02:23PM |

Registered: 13 years ago Posts: 601 |

> When you say "just read all blogs and wikis and

> forums" I think that is not really useful or

> feasible. If the Reprap team wanted to really spur

> development they should provide some real

> scientific and engineering data for 'would be'

> developers to work from and make calculations.

> Most of the blogs may be entertaining reading, but

> from the sample I have seen none have much in the

> way of hard facts based on experiment or

> calculations.

No, it's not really useful. Sorry. but for right now that's all I can suggest.

and like Cefiar said above, reprap is really just a bunch of people building their machines. There is no Team, it's just people contributing whatever they find useful. I've done some wiki editing, and some development work, and i try to document as much as i can on the forums. I'm not an engineer or a scientist, so i can't help you in that regard.

I think we're lucky to have the information that we DO have. But you are right, we NEED that basic information.

Edited 1 time(s). Last edit at 02/17/2011 03:02PM by Buback.

> forums" I think that is not really useful or

> feasible. If the Reprap team wanted to really spur

> development they should provide some real

> scientific and engineering data for 'would be'

> developers to work from and make calculations.

> Most of the blogs may be entertaining reading, but

> from the sample I have seen none have much in the

> way of hard facts based on experiment or

> calculations.

No, it's not really useful. Sorry. but for right now that's all I can suggest.

and like Cefiar said above, reprap is really just a bunch of people building their machines. There is no Team, it's just people contributing whatever they find useful. I've done some wiki editing, and some development work, and i try to document as much as i can on the forums. I'm not an engineer or a scientist, so i can't help you in that regard.

I think we're lucky to have the information that we DO have. But you are right, we NEED that basic information.

Edited 1 time(s). Last edit at 02/17/2011 03:02PM by Buback.

|

Re: Considering a new extruder design February 21, 2011 08:35AM |

Registered: 13 years ago Posts: 38 |

We all use calcs from different places, the skill is in knowing which calc to use when.

The oldest thing in my office (250+ people) is my copy of "Machinery's Handbook" -1939.

£10 off eBay. (Other online retailers are available!)

I use it at least once a week.

A lot of the calcs and units are in Imperial, but most of the principles have not changed since it was printed. More modern versions have metric units, but still contain 95% of the same material. Try and get a copy for yourself.

Other places of interest for calculations are MatWeb and RoyMech (former for material data, latter for calculations similar to Machinery's).

Once you've looked in these places (or look up "Engineering lecture notes" in google) - try your hand at a few calculations and then put them online and I'll have a look and I'm sure other more established reprappers will look and correct too.

Good Luck,

-Andy.

The oldest thing in my office (250+ people) is my copy of "Machinery's Handbook" -1939.

£10 off eBay. (Other online retailers are available!)

I use it at least once a week.

A lot of the calcs and units are in Imperial, but most of the principles have not changed since it was printed. More modern versions have metric units, but still contain 95% of the same material. Try and get a copy for yourself.

Other places of interest for calculations are MatWeb and RoyMech (former for material data, latter for calculations similar to Machinery's).

Once you've looked in these places (or look up "Engineering lecture notes" in google) - try your hand at a few calculations and then put them online and I'll have a look and I'm sure other more established reprappers will look and correct too.

Good Luck,

-Andy.

|

Re: Considering a new extruder design April 03, 2011 08:08AM |

Registered: 13 years ago Posts: 106 |

I had a spare hour this weekend so added a wiki page for the prototype I hope to start in three weeks (hopefully my milling machine should be finished by then?)

[reprap.org]

[reprap.org]

I will probably be ordering the parts this week as I have finally got enough money and parts to get a minimum order quantity

[reprap.org]

[reprap.org]

I will probably be ordering the parts this week as I have finally got enough money and parts to get a minimum order quantity

|

Re: Considering a new extruder design April 04, 2011 05:05AM |

Registered: 13 years ago Posts: 482 |

|

Re: Considering a new extruder design May 03, 2011 10:11AM |

Registered: 13 years ago Posts: 106 |

andysuth Wrote:

-------------------------------------------------------

> We all use calcs from different places, the skill

> is in knowing which calc to use when.

>

> The oldest thing in my office (250+ people) is my

> copy of "Machinery's Handbook" -1939.

>

> £10 off eBay. (Other online retailers are

> available!)

>

> I use it at least once a week.

>

I have my grandads copy of "Machinery's Handbook" in the workshop somewhere I think its a 1928 edition, have not seen it in a couple of years though as the workshop is a mess. I also have a copy of the 26th edition and there are quite a few differences, all the same they are both very useful references, I also have pdf version of the latest "Machinery's Handbook" (I think just a minor update of the 26th edition?)

I also like "Marks standard engineers handbook", and my prize posession is my 7 volume leather bound copys of the encyclopedia of engineering.

But if you are refering to my comment about finding materials and engineering information, I was really thinking in terms of ease of access for everyone thinking of developing something for a reprap. If a person is reading about reprap and thinking of developing would it not make obtaining information much easier if the most important development information was shown on the wiki?

It would save hours of work finding a copy of a book on ebay, or opening a new browser tab to make further google searches, or going to your own book shelf.

I just have this dream of a sort of 'expert system' where all the information could be added to make researching a new design really easy.

> Other places of interest for calculations are

> MatWeb and RoyMech (former for material data,

> latter for calculations similar to Machinery's).

Excellent link matweb materials information, I have not checked the other suggestion yet but will at some point, thanks

I think I may try and add a page starting development

in the wiki with some of my ideas if I get some time.

-------------------------------------------------------

> We all use calcs from different places, the skill

> is in knowing which calc to use when.

>

> The oldest thing in my office (250+ people) is my

> copy of "Machinery's Handbook" -1939.

>

> £10 off eBay. (Other online retailers are

> available!)

>

> I use it at least once a week.

>

I have my grandads copy of "Machinery's Handbook" in the workshop somewhere I think its a 1928 edition, have not seen it in a couple of years though as the workshop is a mess. I also have a copy of the 26th edition and there are quite a few differences, all the same they are both very useful references, I also have pdf version of the latest "Machinery's Handbook" (I think just a minor update of the 26th edition?)

I also like "Marks standard engineers handbook", and my prize posession is my 7 volume leather bound copys of the encyclopedia of engineering.

But if you are refering to my comment about finding materials and engineering information, I was really thinking in terms of ease of access for everyone thinking of developing something for a reprap. If a person is reading about reprap and thinking of developing would it not make obtaining information much easier if the most important development information was shown on the wiki?

It would save hours of work finding a copy of a book on ebay, or opening a new browser tab to make further google searches, or going to your own book shelf.

I just have this dream of a sort of 'expert system' where all the information could be added to make researching a new design really easy.

> Other places of interest for calculations are

> MatWeb and RoyMech (former for material data,

> latter for calculations similar to Machinery's).

Excellent link matweb materials information, I have not checked the other suggestion yet but will at some point, thanks

I think I may try and add a page starting development

in the wiki with some of my ideas if I get some time.

|

Re: Considering a new extruder design May 08, 2011 07:01PM |

Registered: 13 years ago Posts: 106 |

I was going to make a post with some pictures about the extruder last week, but unfortunately everything has gone to shit.

Having problems with my milling machine and some electronics problems and other problems and too many projects that I never get round to finishing.

But I have got some stuff done but nowhere near finished and there have been spec changes and it may all go on the back burner again for a month or so.

The new spec addition are as follows:

4 fillament extruder drive mechanism with auto switchover.

16 station nozzle selector.

quick removal extruder nozzle system.

Weight should be around 140g including the motor.

Still some mechanical stuff to iron out but the majority of the parts have been machined, just 3 parts for the 16 station nozzle selector to be made.

Need to work out a special system for clamping the filaments at switch out.

Some electronics issues need to be solved(as a side note does anyone think a positive earth system for reprap would be a problem?).

I have some how lost some electronics somewhere so have to order some op amps.

I also wonder about possible problems dragging 4 filaments around from spools overloading the axis drive on the reprap (I doubt I will ever use a reprap of course)

The main filament drive seems fairly solid but the filament switchover possibly need refactoring with higher precision machining.

I probably should not have changed the spec as I almost got close to a working system with the simpler spec but I always suckered into creature feep.

So I don't know how things will go, there is a possibilityI will have a look at trying to assemble most of the parts I have made this week, but I will probably be waiting for some more components before I can make any tests.

I don't have enough time for most of this of course but it may get done eventually?.

Having problems with my milling machine and some electronics problems and other problems and too many projects that I never get round to finishing.

But I have got some stuff done but nowhere near finished and there have been spec changes and it may all go on the back burner again for a month or so.

The new spec addition are as follows:

4 fillament extruder drive mechanism with auto switchover.

16 station nozzle selector.

quick removal extruder nozzle system.

Weight should be around 140g including the motor.

Still some mechanical stuff to iron out but the majority of the parts have been machined, just 3 parts for the 16 station nozzle selector to be made.

Need to work out a special system for clamping the filaments at switch out.

Some electronics issues need to be solved(as a side note does anyone think a positive earth system for reprap would be a problem?).

I have some how lost some electronics somewhere so have to order some op amps.

I also wonder about possible problems dragging 4 filaments around from spools overloading the axis drive on the reprap (I doubt I will ever use a reprap of course)

The main filament drive seems fairly solid but the filament switchover possibly need refactoring with higher precision machining.

I probably should not have changed the spec as I almost got close to a working system with the simpler spec but I always suckered into creature feep.

So I don't know how things will go, there is a possibilityI will have a look at trying to assemble most of the parts I have made this week, but I will probably be waiting for some more components before I can make any tests.

I don't have enough time for most of this of course but it may get done eventually?.

|

Re: Considering a new extruder design May 16, 2011 09:25AM |

Registered: 13 years ago Posts: 106 |

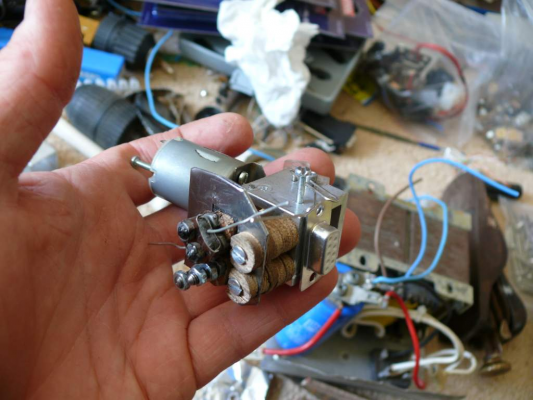

Just thought I should show the extruder as far as I got with what should have been the final design(now I have canned the idea as i can see improvements that would make it far more flexible).

brief description:

Very low cost (could be sold for under $20 if volumes of 1/4 million could be sold),

Very simple (parts count less than 40 pieces for entire extruder and electronics),

Moderately reliable (I would guess it is as reliable as the average Reprap extruder currently available),

Fairly light (100g for extruder (4 hot ends, motor, drive mechanisms, electronics, etc..)

The extruder uses a very cheap £0.50 motor, alloy, wood insulators, ptfe insulator, all screws are M2.5, panel pins used for shafts and links, 10R resistors for heating.

I have run the top two tips for a 2 hour hot test (tips are grouped in twos as the idea was to be able to run up to 4 types of polymer but cut down on seperate heating elements for each tip and one resistor will heat two tips easily). I left the tips on for 10 minutes then ran about 100mm of filament through each one, let them cool and repeated again thee times, then left them on current limited at 1.4 amps for an hour then did a final repeat filament feed.

I have tested a number of resistor types and think that 0.5w rated may be sufficient for most heating applications (I have not had any blow yet and have done a 5 hour burn in test at 310 degrees celcius running about 8 watts into it).

Also should add that the nozzles have a quick mount system so can be slid in and out of the extruder in about 2 seconds.

Unfortunately I really don't have any time or money to continue at the moment.

I made a mistake in ordering electronics as I thought I had some comparators in my parts bin and the mistake sort of put a damper on the whole thing which made me rethink the entire design.

Edited 1 time(s). Last edit at 05/16/2011 09:47AM by mung.

brief description:

Very low cost (could be sold for under $20 if volumes of 1/4 million could be sold),

Very simple (parts count less than 40 pieces for entire extruder and electronics),

Moderately reliable (I would guess it is as reliable as the average Reprap extruder currently available),

Fairly light (100g for extruder (4 hot ends, motor, drive mechanisms, electronics, etc..)

The extruder uses a very cheap £0.50 motor, alloy, wood insulators, ptfe insulator, all screws are M2.5, panel pins used for shafts and links, 10R resistors for heating.

I have run the top two tips for a 2 hour hot test (tips are grouped in twos as the idea was to be able to run up to 4 types of polymer but cut down on seperate heating elements for each tip and one resistor will heat two tips easily). I left the tips on for 10 minutes then ran about 100mm of filament through each one, let them cool and repeated again thee times, then left them on current limited at 1.4 amps for an hour then did a final repeat filament feed.

I have tested a number of resistor types and think that 0.5w rated may be sufficient for most heating applications (I have not had any blow yet and have done a 5 hour burn in test at 310 degrees celcius running about 8 watts into it).

Also should add that the nozzles have a quick mount system so can be slid in and out of the extruder in about 2 seconds.

Unfortunately I really don't have any time or money to continue at the moment.

I made a mistake in ordering electronics as I thought I had some comparators in my parts bin and the mistake sort of put a damper on the whole thing which made me rethink the entire design.

Edited 1 time(s). Last edit at 05/16/2011 09:47AM by mung.

|

Re: Considering a new extruder design May 16, 2011 02:02PM |

Registered: 13 years ago Posts: 7,616 |

Quote

if volumes of 1/4 million could be sold

Huh, 250'000 RepRap Extruders ?!? 250 perhaps, if you're good.

Other that, nice prototype! Do you have a video of this extruder working? The design is apparently very different from the existing ones, so people want so seee how it works :-)

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Considering a new extruder design May 16, 2011 04:19PM |

Registered: 13 years ago Posts: 818 |

Hi Mung,

How do you intend to control the extruder motor, it's a tiny DC type with virtually no torque?

Filament control is about the most important thing for quality output, if it's not really well controlled (like a stepper motor) then the prints will be very poor indeed.

[richrap.blogspot.com]

How do you intend to control the extruder motor, it's a tiny DC type with virtually no torque?

Filament control is about the most important thing for quality output, if it's not really well controlled (like a stepper motor) then the prints will be very poor indeed.

[richrap.blogspot.com]

|

Re: Considering a new extruder design May 16, 2011 06:21PM |

Registered: 13 years ago Posts: 106 |

Traumflug Wrote:

-------------------------------------------------------

> if volumes of 1/4 million could be sold

>

> Huh, 250'000 RepRap Extruders ?!? 250 perhaps, if

> you're good.

I would not bother making these myself to sell unless there was a decent profit in it, and this means doing a production run setting up jigs and tooling.

The idea of this is to create the best design then mass produce to get reasonable economies of scale.

Generally what you pay for is the time it takes to produce an item, raw materials are fairly cheap, in bulk the materials for this extruder are probably less than £2.

Buying 100 M3 machine screws costs £0.02 per screw

Buying 2 million machine screws costs £0.003 per screw

Setting up a machine to precision drill 4 holes in alloy box section takes 30 minutes and 10 seconds to drill.

Buying a decent automated cnc drilling machine may take a week to setup but will drill 1 million holes unattended in a week and probably be to higher precision.

The idea behind the Raprap is nice, but mass production works better in most products.

I like Reprap as an interesting hobby but as you say '250 perhaps' unless more people want to buy 3d printer parts there will only be the option of bespoke expensive individually produced parts.

Of course most of what I am saying is just guesswork based on what I have heard on random internet forums, as I have never worked in product development or production manufacturing I don't really know.

-------------------------------------------------------

> if volumes of 1/4 million could be sold

>

> Huh, 250'000 RepRap Extruders ?!? 250 perhaps, if

> you're good.

I would not bother making these myself to sell unless there was a decent profit in it, and this means doing a production run setting up jigs and tooling.

The idea of this is to create the best design then mass produce to get reasonable economies of scale.

Generally what you pay for is the time it takes to produce an item, raw materials are fairly cheap, in bulk the materials for this extruder are probably less than £2.

Buying 100 M3 machine screws costs £0.02 per screw

Buying 2 million machine screws costs £0.003 per screw

Setting up a machine to precision drill 4 holes in alloy box section takes 30 minutes and 10 seconds to drill.

Buying a decent automated cnc drilling machine may take a week to setup but will drill 1 million holes unattended in a week and probably be to higher precision.

The idea behind the Raprap is nice, but mass production works better in most products.

I like Reprap as an interesting hobby but as you say '250 perhaps' unless more people want to buy 3d printer parts there will only be the option of bespoke expensive individually produced parts.

Of course most of what I am saying is just guesswork based on what I have heard on random internet forums, as I have never worked in product development or production manufacturing I don't really know.

|

Re: Considering a new extruder design May 16, 2011 06:48PM |

Registered: 13 years ago Posts: 106 |

richrap Wrote:

-------------------------------------------------------

> Hi Mung,

>

> How do you intend to control the extruder motor,

> it's a tiny DC type with virtually no torque?

>

> Filament control is about the most important thing

> for quality output, if it's not really well

> controlled (like a stepper motor) then the prints

> will be very poor indeed.

I am going to use servo control of the motor, there will be a simple quadrature encoder mounted on the motor and it will be controlled using the EMC2 etch servo system to supply rough PWM.

The torque should be sufficient, I think its rated at 45g/cm stall but I will run it slightly over current with a lower duty cycle to give higher torque, the gearing is fairly high at around 80:1 and this should give a filament motion of 0.1mm per motor revolution.

Using 2mm filament and a 0.3mm nozzle that is roughly 0.66mm of extruded filament so for a resolution of 0.1mm the encoder wheel will need 7 sections.

Of course I have not actually done any work on the servo yet although I have run EMC2 etch servo systems before and hope it should only be a few hours work.

-------------------------------------------------------

> Hi Mung,

>

> How do you intend to control the extruder motor,

> it's a tiny DC type with virtually no torque?

>

> Filament control is about the most important thing

> for quality output, if it's not really well

> controlled (like a stepper motor) then the prints

> will be very poor indeed.

I am going to use servo control of the motor, there will be a simple quadrature encoder mounted on the motor and it will be controlled using the EMC2 etch servo system to supply rough PWM.

The torque should be sufficient, I think its rated at 45g/cm stall but I will run it slightly over current with a lower duty cycle to give higher torque, the gearing is fairly high at around 80:1 and this should give a filament motion of 0.1mm per motor revolution.

Using 2mm filament and a 0.3mm nozzle that is roughly 0.66mm of extruded filament so for a resolution of 0.1mm the encoder wheel will need 7 sections.

Of course I have not actually done any work on the servo yet although I have run EMC2 etch servo systems before and hope it should only be a few hours work.

|

Re: Considering a new extruder design May 17, 2011 01:39AM |

Registered: 13 years ago Posts: 7,616 |

Quote

The idea behind the Raprap is nice, but mass production works better in most products.

Then, perhaps, you should look for a project which requests mass production.

Quote

it will be controlled using the EMC2 etch servo system

Then, perhaps, you should look for a project where EMC is used in significant numbers. Some 95% of RepRappers use an ATmega based controller.

Please don't get me wrong. A simplified extruder design is highly appreciated. However, mass production neither matches the project goals, nor does it match the habits of users. RepRappers are used to adjust the design to their needs, not the other way around. New extruder designs surface on an almost daily basis. That's why some mass produced parts exist, but don't play a significant role.

So, try to make the design a bit simpler, at an extrusion quality equal to existing designs and you're in business. No need to be super cheap. A RepRap is low cost, but for other reasons than getting screws for €0.003 instead of €0.02

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Considering a new extruder design May 17, 2011 06:11PM |

Registered: 13 years ago Posts: 106 |

Traumflug Wrote:

-------------------------------------------------------

> Then, perhaps, you should look for a project which

> requests mass production.

I hope you don't use any mass produced items like nuts and bolts or electronic components in your reprap

> Then, perhaps, you should look for a project where

> EMC is used in significant numbers. Some 95% of

> RepRappers use an ATmega based controller.

If you cannot work out how to write some servo control PID code for an atmega then you should not be using a reprap, I am sure there must be some example code for such things available to work from?

> However, mass

> production neither matches the project goals, nor

> does it match the habits of users. RepRappers are

> used to adjust the design to their needs, not the

> other way around.

I don't actually care about the project goals, I care more about price, quality, and efficiency.

I find it hard to believe you can define the habits of all reprap users?

I also do not see how anyone has to adjust their needs to the extruder design?

An extruder is designed to extrude melted plastic if you need to extrude melted plastic you need an extruder?

>

> So, try to make the design a bit simpler, at an

> extrusion quality equal to existing designs and

> you're in business. No need to be super cheap. A

> RepRap is low cost, but for other reasons than

> getting screws for €0.003 instead of €0.02

I must say a reprap is not cheap, a reprap is very poor value for money.

I could start ranting about economics and efficiency and redundancy and education and reasons for doing stuff but I don't really think it would do any good.

I would like to help make reprap better but unfortunatly like most people I don't have time to do most of what I would like.

Lastly I know we all do this when we want others to do things our way, but I know my analysis of the situation has given me the most efficient solutions to the problems that effect me, and although I want to help, I will not make it harder to reach my own goals in order make your life easier.

i.e. I will not be a slave to you erroneous ideas, and I am not going to spend £25 on an atmega when I already need a pc to run reprap software and all the control can be better done by EMC2 on the same pc.

Why reinvent the wheel. etc........

Do you think people would prefer to buy extruder kits for £100 or ready made ones for £20 or would they prefer to spend hours building them from scratch?

Do you think reprap will be relevant when HP and other printer manufacturers are selling 3d printers for £100?

Its a hobby dude

Do you really want to know how the extruder works?

-------------------------------------------------------

> Then, perhaps, you should look for a project which

> requests mass production.

I hope you don't use any mass produced items like nuts and bolts or electronic components in your reprap

> Then, perhaps, you should look for a project where

> EMC is used in significant numbers. Some 95% of

> RepRappers use an ATmega based controller.

If you cannot work out how to write some servo control PID code for an atmega then you should not be using a reprap, I am sure there must be some example code for such things available to work from?

> However, mass

> production neither matches the project goals, nor

> does it match the habits of users. RepRappers are

> used to adjust the design to their needs, not the

> other way around.

I don't actually care about the project goals, I care more about price, quality, and efficiency.

I find it hard to believe you can define the habits of all reprap users?

I also do not see how anyone has to adjust their needs to the extruder design?

An extruder is designed to extrude melted plastic if you need to extrude melted plastic you need an extruder?

>

> So, try to make the design a bit simpler, at an

> extrusion quality equal to existing designs and

> you're in business. No need to be super cheap. A

> RepRap is low cost, but for other reasons than

> getting screws for €0.003 instead of €0.02

I must say a reprap is not cheap, a reprap is very poor value for money.

I could start ranting about economics and efficiency and redundancy and education and reasons for doing stuff but I don't really think it would do any good.

I would like to help make reprap better but unfortunatly like most people I don't have time to do most of what I would like.

Lastly I know we all do this when we want others to do things our way, but I know my analysis of the situation has given me the most efficient solutions to the problems that effect me, and although I want to help, I will not make it harder to reach my own goals in order make your life easier.

i.e. I will not be a slave to you erroneous ideas, and I am not going to spend £25 on an atmega when I already need a pc to run reprap software and all the control can be better done by EMC2 on the same pc.

Why reinvent the wheel. etc........

Do you think people would prefer to buy extruder kits for £100 or ready made ones for £20 or would they prefer to spend hours building them from scratch?

Do you think reprap will be relevant when HP and other printer manufacturers are selling 3d printers for £100?

Its a hobby dude

Do you really want to know how the extruder works?

|

Re: Considering a new extruder design May 17, 2011 06:43PM |

Admin Registered: 17 years ago Posts: 1,791 |

A simplified extruder design is highly appreciated. However, mass production neither matches the project goals, nor does it match the habits of users.

Hmmm ... I know that along with self-built extruders, we've got a few entrepreneurs who do up and sell ... ?90%? of the extruders? Dunno. Big % of the total, I imagine, since most of us don't have lathes and mills.

Then, perhaps, you should look for a project where EMC is used in significant numbers.

Markus, we've got a dedicated EMC forum. And we almost have decent documentation on the subject in the wiki:

http://reprap.org/wiki/EMCRepRap

("almost decent" = needs some love from emc-using folk.)

Do you think reprap will be relevant when HP and other printer manufacturers are selling 3d printers for £100?

Tough to say. The economics are tricky. HP would have trouble making money off feedstock, unlike the paper printer business model. And I imagine an HP machine would still be printing daughter repraps to do stuff like deposit clay, or really big pieces, or carbon fiber ...

By the way, you guys are getting a little fighty with each other. Please be a bit more gentle and patient, eh?

Edited 1 time(s). Last edit at 05/18/2011 12:24AM by SebastienBailard.

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

Hmmm ... I know that along with self-built extruders, we've got a few entrepreneurs who do up and sell ... ?90%? of the extruders? Dunno. Big % of the total, I imagine, since most of us don't have lathes and mills.

Then, perhaps, you should look for a project where EMC is used in significant numbers.

Markus, we've got a dedicated EMC forum. And we almost have decent documentation on the subject in the wiki:

http://reprap.org/wiki/EMCRepRap

("almost decent" = needs some love from emc-using folk.)

Do you think reprap will be relevant when HP and other printer manufacturers are selling 3d printers for £100?

Tough to say. The economics are tricky. HP would have trouble making money off feedstock, unlike the paper printer business model. And I imagine an HP machine would still be printing daughter repraps to do stuff like deposit clay, or really big pieces, or carbon fiber ...

By the way, you guys are getting a little fighty with each other. Please be a bit more gentle and patient, eh?

Edited 1 time(s). Last edit at 05/18/2011 12:24AM by SebastienBailard.

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

|

Re: Considering a new extruder design May 18, 2011 01:38AM |

Registered: 13 years ago Posts: 7,616 |

Quote

I find it hard to believe you can define the habits of all reprap users?

It's not me defining the habits, it's in part the stated project goals and in part observation of what happens so far.

Quote

Do you really want to know how the extruder works?

Sure I do. I just thought comparing your 250'000 extruders idea with the reality whould be a good idea. Now I did, so please go ahead and do what you think is best.

Quote

I know that along with self-built extruders, we've got a few entrepreneurs who do up and sell ... ?90%? of the extruders?

Well aware of that, but neither of them uses mass production in the sense Mung described it. No injection molded parts, no automated lathes, materials as commonly available as possible.

That's the most interesting aspect of RepRap, IMHO: while using manufacturing methods usually meant to be for small volume production (3D printing, hand lathe, etc.), we get cheaper than mass products and innovation is so fast and plentiful it's sometimes hard to follow. That's just great!

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Considering a new extruder design May 18, 2011 03:43PM |

Registered: 13 years ago Posts: 601 |

|

Re: Considering a new extruder design May 18, 2011 06:44PM |

Registered: 13 years ago Posts: 106 |

Buback Wrote:

-------------------------------------------------------

> mung Wrote:

> --------------------------------------------------

> -----

> > If you cannot work out how to write some servo

> > control PID code for an atmega then you should

> not

> > be using a reprap

>

> i must say i'm a little insulted by this

> statement.

I must apologise if you feel insulted by my statement, it was a spur of the moment comment which I really did not consider properly.

I just assumed that most reprap users built all parts of the system and loaded up the control system onto their atmega boards, I thought that it was normal practice to edit and modify the control code for the atmega. I have heard that servo control code was available that could be modified to run the DC motor PWM and read quadrature signals from encoders, enabling the extruder I have designed to be run on a standard reprap.

I did not mean to insult you in any way, I just meant that 'RepRappers are used to adjust the design to their needs', and that modifying the atmega code to run the servo of the extruder would be possible.

I now realise that I was wrong in using EMC2 for this and I am going to change my design to use standard reprap control electronics and motors.

As soon as I can afford to get the atmega board, stepper motor, and stepper driver I will continue with development.

Reading back through my posts in this thread I now see that some of my posts could be misconstrued as over demanding and possibly telling people what to do. I do not mean to boss people about, make unreasonable suggestions, or belittle the work of others. I have only been saying what problems I have found, what information I would find helpful, and the work that I have done.

I like the reprap project and would like to help, but as I said before I really don't have the time to do much of what I would like to see done, and also I feel if I were to add more to the project it may take it away from the projects stated goals.

I see now that reprap is more than just a 3D printer and there are vast amounts of information that I have not read about the project.

I came here only thinking 'I WANT A POLYMER EXTRUDER TO FIT TO MY CNC MILL'.

I would like to thank reprap for the very useful information that it provides, and I do not mean to insult its goals.

-------------------------------------------------------

> mung Wrote:

> --------------------------------------------------

> -----

> > If you cannot work out how to write some servo

> > control PID code for an atmega then you should

> not

> > be using a reprap

>

> i must say i'm a little insulted by this

> statement.

I must apologise if you feel insulted by my statement, it was a spur of the moment comment which I really did not consider properly.

I just assumed that most reprap users built all parts of the system and loaded up the control system onto their atmega boards, I thought that it was normal practice to edit and modify the control code for the atmega. I have heard that servo control code was available that could be modified to run the DC motor PWM and read quadrature signals from encoders, enabling the extruder I have designed to be run on a standard reprap.

I did not mean to insult you in any way, I just meant that 'RepRappers are used to adjust the design to their needs', and that modifying the atmega code to run the servo of the extruder would be possible.

I now realise that I was wrong in using EMC2 for this and I am going to change my design to use standard reprap control electronics and motors.

As soon as I can afford to get the atmega board, stepper motor, and stepper driver I will continue with development.

Reading back through my posts in this thread I now see that some of my posts could be misconstrued as over demanding and possibly telling people what to do. I do not mean to boss people about, make unreasonable suggestions, or belittle the work of others. I have only been saying what problems I have found, what information I would find helpful, and the work that I have done.

I like the reprap project and would like to help, but as I said before I really don't have the time to do much of what I would like to see done, and also I feel if I were to add more to the project it may take it away from the projects stated goals.

I see now that reprap is more than just a 3D printer and there are vast amounts of information that I have not read about the project.

I came here only thinking 'I WANT A POLYMER EXTRUDER TO FIT TO MY CNC MILL'.

I would like to thank reprap for the very useful information that it provides, and I do not mean to insult its goals.

|

Re: Considering a new extruder design May 18, 2011 10:24PM |

Registered: 13 years ago Posts: 601 |

|

Re: Considering a new extruder design May 18, 2011 11:29PM |

Admin Registered: 17 years ago Posts: 1,791 |

I now realise that I was wrong in using EMC2 for this and I am going to change my design to use standard reprap control electronics and motors.

AAAAAAAAAAAAAAAAAARRRRRRRRRRRRRRRRRRRRRGGGGGGGGGGGGGGGGGGGHHHHHHHHHHH!

We almost had a chance for good documentation in

http://reprap.org/wiki/EMCRepRap

We were so close.

So close.

So close.

So close

So close

So close

So close

I would like to thank reprap for the very useful information that it provides, and I do not mean to insult its goals.

No worries.

But as penance, you have to join reprap-dev and stay on top of the literature.

It's compulsory since you're probably an official developer.

Also, if you're serious about using the Mung License

http://reprap.org/wiki/Mung_license

for

http://reprap.org/wiki/MungStruder

then you should let us know what it is. Otherwise, I'd suggest the good old GPL, since that makes things simple.

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

AAAAAAAAAAAAAAAAAARRRRRRRRRRRRRRRRRRRRRGGGGGGGGGGGGGGGGGGGHHHHHHHHHHH!

We almost had a chance for good documentation in

http://reprap.org/wiki/EMCRepRap

So close.

So close.

So close

So close

So close

So close

I would like to thank reprap for the very useful information that it provides, and I do not mean to insult its goals.

No worries.

But as penance, you have to join reprap-dev and stay on top of the literature.

It's compulsory since you're probably an official developer.

Also, if you're serious about using the Mung License

http://reprap.org/wiki/Mung_license

for

http://reprap.org/wiki/MungStruder

then you should let us know what it is. Otherwise, I'd suggest the good old GPL, since that makes things simple.

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

|

Re: Considering a new extruder design May 19, 2011 03:28AM |

Registered: 13 years ago Posts: 7,616 |

Quote

I just meant that 'RepRappers are used to adjust the design to their needs', and that modifying the atmega code to run the servo of the extruder would be possible.

RepRap somehow managed to attract a lot of users which are used to "Plug & Play" and the knowledge of these users doesn't go far beyond that. Maybe a disappointing thing, maybe a great thing, I have no firm opinion about that.

Anyways, if one manages to make an attractive piece of hardware, this person should also expect a storm of where-should-I-click-to-make-this-work-quickly-type questions. So, ideal hardware is prepared to answer such questions easily. And yes, my Gen7 pet project suffers in this area.

So, can we get a few drawings about this extruder now?

Another experience of Gen7 is, offering drawings in advance is a good thing, because you get user opinions before plunking down money and the copycats wait until the wider reception is confirmed, anyways.

Another experience of Gen7 is, offering drawings in advance is a good thing, because you get user opinions before plunking down money and the copycats wait until the wider reception is confirmed, anyways.P.S.: Now I feel a bit like being culprit of laying a brick into EMC's way, so sorry, Sebastien.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Considering a new extruder design June 27, 2011 11:29AM |

Registered: 13 years ago Posts: 106 |

I just thought I should show the parts of what should be the absolute total final revision of the extruder hot end.

As far as I can see there should be no further changes to the hot end (I can see a few improvements but they would increase cost and not really add much)

I hope to show a video of assembly at the weekend (I may work on the bugs in the extruder cam engagement mechs instead though)

I should note that I have been running the extruder hot end at ~7Watts and it seems to give ~0.7cc per minute of molten nylon with a 0.35mm nozzle, I can see a few improvements that will increase this, and running at higher wattage will give higher flow but shorter resistor life. I have run a burn in test of 50 hours at 1.5A so far with no problems but the resistors will only last an hour or so at above 2.5A.

Weight 5.8g

There are a few invisible parts of the extruder that give it performance improvements, there is a chemical treatment to the barrel, a fireproofing treatment for the plywood, and also a secret barrel insert.

Unfortunatly the extruder is still nowhere near complete as there is a problem with the filament changing cams and loads to do with the electronics and I have to get a MCU from somewhere.

Probably in the region of 100 hours work so should be finished by christmas.

Edited 1 time(s). Last edit at 06/27/2011 11:34AM by mung.

|

Re: Considering a new extruder design June 27, 2011 04:52PM |

Registered: 12 years ago Posts: 179 |

First, you might find that vitreous enamel resistors are less prone to failure.

Second, my experience with a TechZone hot end leads me to believe that using wood as an insulator is just going to be problematic, regardless of fireproofing - fireproof coatings generally are designed to stop flame, but don't always do much to stop charring, which is what proved to be TechZone's hotend design's downfall. Admittedly, TechZone didn't attempt to fireproof their oak block so who knows, you might have better luck.

I'd try running the temperature of your hot end up to 230c or 240c for a few hours, and see how the wood holds up up when stressed.

Third, it looks like you're using a printed circuit board as an insulator? The resin used in PCBs tends to break down at hotend temperatures.

Second, my experience with a TechZone hot end leads me to believe that using wood as an insulator is just going to be problematic, regardless of fireproofing - fireproof coatings generally are designed to stop flame, but don't always do much to stop charring, which is what proved to be TechZone's hotend design's downfall. Admittedly, TechZone didn't attempt to fireproof their oak block so who knows, you might have better luck.

I'd try running the temperature of your hot end up to 230c or 240c for a few hours, and see how the wood holds up up when stressed.

Third, it looks like you're using a printed circuit board as an insulator? The resin used in PCBs tends to break down at hotend temperatures.

|

Re: Considering a new extruder design June 28, 2011 11:05AM |

Registered: 13 years ago Posts: 106 |

Thanks for the reply raldrich, have you read the things that have been said in this forum thread?

I think I have covered all of your suggestions already, can you double check for me and let me know if I have not?????

I am not sure if my English or grammar is correct maybe I did not express myself properly, if there is anyone that can better help me explain myself I would be pleased of the help.

The extruder works, if for example someone else tried to use this extruder hotend and it did not work within the limits of my specification, that would be because someone were not using it properly (i.e. someone were trying to run the extruder at 2.5amps when it is designed for a maximum current of 2Amps)!

The problems with wood and FR4 you mention do not effect the design, I am not sure if it is a good idea to design a hotend that can carbonise the polymer it is supposed to extrude?

My design is supposed to be exceptionally efficient, that means only using the minimum energy required and the cheapest components that will do the job.

All the experiments and tests are aimed at reducing the energy and cost of the components, but also finding out the failure point of the components, this is why I mention failures sometimes in posts.

If you read the post heading you will see it says "considering a new extruder design" this is because the posts are about considering new and improved designs of extruder.

If we were to always use for example "vitreous enamel resistors" and never try anything new there would be no progress or improvement, but by trying to use different components in better ways there can be new and improved developments.

I have made some calculations and experiments and come to the conclusion that an extruder can be made that is more efficient than current designs, and just as reliable.

From my calculations I have selected the components that should work reliably within the specifications I have set.

Of course my ideas, conclusions, and calculations may be wrong, but it would seem that currently my extruder will extrude for at least 68 hours without blocking or burning out and can easily extrude .7cc of polymer per minute though a 0.35mm nozzle with 7Watts of power.

I wonder why light bulbs do not blow when they are heated to thousands of degrees celcius??

I thought I should add a photo of the hotend assembled (though not bonded), I should also mention that EVERYTHING on the extruder is there and in the position it is in for a reason.

Edited 1 time(s). Last edit at 06/28/2011 12:00PM by mung.

Edited 1 time(s). Last edit at 06/28/2011 12:00PM by mung.

I think I have covered all of your suggestions already, can you double check for me and let me know if I have not?????

I am not sure if my English or grammar is correct maybe I did not express myself properly, if there is anyone that can better help me explain myself I would be pleased of the help.

The extruder works, if for example someone else tried to use this extruder hotend and it did not work within the limits of my specification, that would be because someone were not using it properly (i.e. someone were trying to run the extruder at 2.5amps when it is designed for a maximum current of 2Amps)!

The problems with wood and FR4 you mention do not effect the design, I am not sure if it is a good idea to design a hotend that can carbonise the polymer it is supposed to extrude?

My design is supposed to be exceptionally efficient, that means only using the minimum energy required and the cheapest components that will do the job.

All the experiments and tests are aimed at reducing the energy and cost of the components, but also finding out the failure point of the components, this is why I mention failures sometimes in posts.

If you read the post heading you will see it says "considering a new extruder design" this is because the posts are about considering new and improved designs of extruder.

If we were to always use for example "vitreous enamel resistors" and never try anything new there would be no progress or improvement, but by trying to use different components in better ways there can be new and improved developments.

I have made some calculations and experiments and come to the conclusion that an extruder can be made that is more efficient than current designs, and just as reliable.

From my calculations I have selected the components that should work reliably within the specifications I have set.

Of course my ideas, conclusions, and calculations may be wrong, but it would seem that currently my extruder will extrude for at least 68 hours without blocking or burning out and can easily extrude .7cc of polymer per minute though a 0.35mm nozzle with 7Watts of power.

I wonder why light bulbs do not blow when they are heated to thousands of degrees celcius??

I thought I should add a photo of the hotend assembled (though not bonded), I should also mention that EVERYTHING on the extruder is there and in the position it is in for a reason.

Edited 1 time(s). Last edit at 06/28/2011 12:00PM by mung.

Edited 1 time(s). Last edit at 06/28/2011 12:00PM by mung.

|

Re: Considering a new extruder design July 01, 2011 08:41PM |

Registered: 13 years ago Posts: 106 |

I spoke too soon maybe 0.5W is too low, as my testing cycle got to 80 hours at 1.5A I stupidly turned the current up to 1.8A (around 15Watts) and the resistors blew somewhere between 85 and 90 hours.

So maybe I will go back to 1W resistors (£0.04 each) which are double the price of the 0.5W.

Of course this adds weight and thermal inertia to the hotend......

Using lower power resistors could be a good way of adding a consumable part to the printer so manufacturers can have a constant revenue stream from the required replacement parts (also nozzles do get blocked and eroded).

I hoped the resistors would last 200hours as this would be a minimum reasonable time for a consumable part to last.

I should really have continued testing at 1.5A for the full test as this gives more than necessary power for most current extrusion speeds, and my guess is that it will stand up to at least 200hours of use at this amperage.

So maybe I will go back to 1W resistors (£0.04 each) which are double the price of the 0.5W.

Of course this adds weight and thermal inertia to the hotend......

Using lower power resistors could be a good way of adding a consumable part to the printer so manufacturers can have a constant revenue stream from the required replacement parts (also nozzles do get blocked and eroded).

I hoped the resistors would last 200hours as this would be a minimum reasonable time for a consumable part to last.

I should really have continued testing at 1.5A for the full test as this gives more than necessary power for most current extrusion speeds, and my guess is that it will stand up to at least 200hours of use at this amperage.

|

Re: Considering a new extruder design July 04, 2011 02:53AM |

Registered: 15 years ago Posts: 96 |

your extruder idea looks interesting and i just noticed this thread today so my question may be out of date.

are you still using the 2mm trimmer line that you posted about early in the thread? the reason I as is most trimmer line is nylon and tends to be hygroscopic so it absorbs a significant amount of water from the air and typicaly requires drying before usage, or at least this is the best info i have found on the subject.

I know there is a thread on the forums regarding the subject but i dont know where it is right now.

Next question is if your test was under load or just the barrel its self. I have found that extruder barrel response during extrusion is much different than just heating the barrel and letting it sit there for a period of time.

Good luck and I hope you continue with the emc2 setup. what controler you use it entirely your own choice mate

are you still using the 2mm trimmer line that you posted about early in the thread? the reason I as is most trimmer line is nylon and tends to be hygroscopic so it absorbs a significant amount of water from the air and typicaly requires drying before usage, or at least this is the best info i have found on the subject.

I know there is a thread on the forums regarding the subject but i dont know where it is right now.

Next question is if your test was under load or just the barrel its self. I have found that extruder barrel response during extrusion is much different than just heating the barrel and letting it sit there for a period of time.

Good luck and I hope you continue with the emc2 setup. what controler you use it entirely your own choice mate

|

Re: Considering a new extruder design July 07, 2011 05:32AM |

Registered: 13 years ago Posts: 106 |

RBisping Wrote:

-------------------------------------------------------

> are you still using the 2mm trimmer line that you

> posted about early in the thread?

Yes I am testing only with what I originally found in the garden shed which are 2mm and 3mm nylon trimmer line (I also have some star section line)

> I know there is a thread on the forums regarding

> the subject but i dont know where it is right now.

I may have a search again and see what I can find on the forum about drying, I did not find anything when I started this project.

I currently don't really bother drying the line I have experimented drying it in the oven on very low heat for 30 minutes and by putting it in the microwave on 300watts for about 90 seconds. Both these methods make the line much harder, but it still seems to feed through the extruder.

I mostly run the the extruder with the line as it comes as it is more slippery flexible and soft that makes it more easily gripped by the drive mechanism.

When running the line as it comes I think temperature becomes very important as to whether a good quality filament is extruded as the water causes steam bubbles to occur at some temperatures.

I think it is best to run undried nylon either low or high temperature low means the water does not get hot enought to cause steam bubbles and high means the waters is so hot it is totally evaporated from the nylon before it gets extruded......

Of course I have no solid evidence for the above remark, it is just my feeling from looking at things as I have tested and I have made no specific tests for bubbling and quality of extrusion yet...

I am still worried that my extruder may not function correctly with other harder plastics like ABS and PLA, I doubt I will be testing such plastics for at least a year as at the current rate I think fixing my milling machine and adding an extruder to it will probably take that long.

> Next question is if your test was under load or

> just the barrel its self. I have found that

> extruder barrel response during extrusion is much

> different than just heating the barrel and letting

> it sit there for a period of time.

Sorry you question is a little ill defined, I think I have defined my tests reasonably well, I may check back in my posts to make sure.

There have been a number of tests made.

I have never made any tests that would exactly simulate extrusion on a printer.

I have made tests of extrusion using the first full prototype into free air.

I have made extrusion tests of two nozzles on to a surface with a predefined distance between nozzle and surface (0.5mm) using a test rig that did not function very well.

I have made many many hand force tests to check nozzles heat and extrude filament.

Most recently I have been burn testing heating resistors on nozzles and this consists of hand forcing a few mm of line through the nozzle then leaving the heater on for a number of hours until I have to leave (don't want to leave things unattended due to fire risk), then hand forcing a few more mm of line through and switching off the heater.

I am hoping to maybe make a rough finish of what has been shown so far and get a video showing extrusion and nozzle switching this weekend, if things go to plan (which they virtually never do).

Edited 1 time(s). Last edit at 07/11/2011 07:19AM by mung.

-------------------------------------------------------

> are you still using the 2mm trimmer line that you

> posted about early in the thread?

Yes I am testing only with what I originally found in the garden shed which are 2mm and 3mm nylon trimmer line (I also have some star section line)

> I know there is a thread on the forums regarding

> the subject but i dont know where it is right now.

I may have a search again and see what I can find on the forum about drying, I did not find anything when I started this project.

I currently don't really bother drying the line I have experimented drying it in the oven on very low heat for 30 minutes and by putting it in the microwave on 300watts for about 90 seconds. Both these methods make the line much harder, but it still seems to feed through the extruder.

I mostly run the the extruder with the line as it comes as it is more slippery flexible and soft that makes it more easily gripped by the drive mechanism.

When running the line as it comes I think temperature becomes very important as to whether a good quality filament is extruded as the water causes steam bubbles to occur at some temperatures.

I think it is best to run undried nylon either low or high temperature low means the water does not get hot enought to cause steam bubbles and high means the waters is so hot it is totally evaporated from the nylon before it gets extruded......

Of course I have no solid evidence for the above remark, it is just my feeling from looking at things as I have tested and I have made no specific tests for bubbling and quality of extrusion yet...

I am still worried that my extruder may not function correctly with other harder plastics like ABS and PLA, I doubt I will be testing such plastics for at least a year as at the current rate I think fixing my milling machine and adding an extruder to it will probably take that long.

> Next question is if your test was under load or

> just the barrel its self. I have found that

> extruder barrel response during extrusion is much

> different than just heating the barrel and letting

> it sit there for a period of time.

Sorry you question is a little ill defined, I think I have defined my tests reasonably well, I may check back in my posts to make sure.

There have been a number of tests made.

I have never made any tests that would exactly simulate extrusion on a printer.

I have made tests of extrusion using the first full prototype into free air.

I have made extrusion tests of two nozzles on to a surface with a predefined distance between nozzle and surface (0.5mm) using a test rig that did not function very well.

I have made many many hand force tests to check nozzles heat and extrude filament.

Most recently I have been burn testing heating resistors on nozzles and this consists of hand forcing a few mm of line through the nozzle then leaving the heater on for a number of hours until I have to leave (don't want to leave things unattended due to fire risk), then hand forcing a few more mm of line through and switching off the heater.

I am hoping to maybe make a rough finish of what has been shown so far and get a video showing extrusion and nozzle switching this weekend, if things go to plan (which they virtually never do).

Edited 1 time(s). Last edit at 07/11/2011 07:19AM by mung.

|

Re: Considering a new extruder design July 08, 2011 05:12AM |

Registered: 13 years ago Posts: 106 |

Just a photo of the virtually complete initial prototype extruder (encoder and electronics need to be worked on).

I have had this sat on the side for a few weeks but it needs a few hours of tweeking and adjustment to finish it off, I should do that at the weekend and make some video of the initial tests.

Of course there are so many botches made that I am rather dissatisfied with it, most of the ideas for my initial prototype are working but I had hoped to make something that was suitable for release as a final production model. Unfortunately as I said before things go to shit and ideas change when you actually try and realise a design, I have totally changed how I would like to make the extruder adding many improvements, but I have decided to try and finish off this first prototype even though it is sub optimal.

I was going to write a little javascript app to calculate heater power required to melt a given mass of polymer, and allow other people to post further data to the forum thread that could be automatically added to the database.

Unfortunatly it took me an hour just to workout how to insert a script in the page and avoid the server side post processing problems, maybe I will try again next time I have a spare hour......

The current app should give people some ideas about what I hoped would be possible.....

Edited 21 time(s). Last edit at 10/05/2011 07:46PM by mung.

I have had this sat on the side for a few weeks but it needs a few hours of tweeking and adjustment to finish it off, I should do that at the weekend and make some video of the initial tests.

Of course there are so many botches made that I am rather dissatisfied with it, most of the ideas for my initial prototype are working but I had hoped to make something that was suitable for release as a final production model. Unfortunately as I said before things go to shit and ideas change when you actually try and realise a design, I have totally changed how I would like to make the extruder adding many improvements, but I have decided to try and finish off this first prototype even though it is sub optimal.

I was going to write a little javascript app to calculate heater power required to melt a given mass of polymer, and allow other people to post further data to the forum thread that could be automatically added to the database.

Unfortunatly it took me an hour just to workout how to insert a script in the page and avoid the server side post processing problems, maybe I will try again next time I have a spare hour......

The current app should give people some ideas about what I hoped would be possible.....

Thermoplastic,Specific Gravity,Tensile Yield Strength Mpa,Tensile Modulus Gpa,Coefficients of Linear Expansion (10-6 'C),Thermal Conductivity W/(m·K),Specific Heat (J/kg K),Maximum Temperature Limit(oC),Melting point ABS-AcrylonitrileButadieneStyrene,1.08,48.0,2.34,108, 7.7,1420,80,- PVC-Polyvinyl Chloride,1.4, 55.0, 2.83, 54,6.3,1040,65,- CPVC-Chlorinated Polyvinyl Chloride,1.54,55.0,2.89,63,5.7,840,100,- PE-Polyethylene,.95,22.0,0.83,162,18.2,2300,70,- PEX-Polyethylene Cross Linked,.94,19.3,.,162,18.2,2300,100,- PB-Polybutylene,.92,29.0,0.38,129.6,8.5,1880,100,- PVDF-Polyvinylidene Fluoride,1.76,48.0,1.52,126,8.5,1210,150,- PEEK-Polyetheretherketone,1.27,97.0,3.59,46.8,-,-,240,340, PP-Polypropylene,0.91- 0.93,30-55,-,130,1.4-2.8,1850,80,160 PA-polyamide,1.15,82,2.93,99,0.25,2200,98,260, PC-Polycarbonate,1.2,60,-,65,0.90,1450,135,

/// the script does not currently scan the entire document (so all future posts are used), but should be possible to search for every occurence of the preformatted text with id 'myD' then format it all into a table in a popup window

function cv(a){ return window.open('','1311161654195','width=700,height=500,toolbar=0,menubar=0,location=0,status=1,scrollbars=1,resizable=1,left=0,top=0');return false;}

var pp=document.getElementById('myD').innerHTML.split("\n");

var v = String.fromCharCode(60); var A = String.fromCharCode(62);

var tb= v + 'table name=pday' + A; var ntb= v + '/table' + A;

var td= v + 'td' + A; var ntd= v + '/td' + A;

var tr= v + 'tr' + A; var ntr= v + '/tr' + A;

function tg(a) { return v + a + A; }

var p=pp;

var kk= v + 'pre id=myD style="visibility:hidden; height:1px;"' + A + document.getElementById('myD').innerHTML + v + '/pre' + A + v + 'h1 ' + A + 'polymer data' + v + '/h1' + A + v + 'form id=F name=F' + A + tb ;

var yy= p.length;

var i=0;

while ( i != yy)

{

kk = kk + tr + td + v + 'input type=radio name=s value=' + i + A + ntd;

row= p[ i ].split(",");

if( row[0] )

for( o = 0 ; o!=row.length; o++)

{

kk= kk + td + row[ o ] + ntd + ' ';

}

kk= kk + ntr + ' \n';

i++;

}

kk = kk + ntb + v + 'br' + A;

// now we should create a form to take the nozzle size and extrusion speed, and polymer type

// calculate -------- extrusion volume = (nozzle diameter / 2) * (nozzle diameter / 2) * 3.141

// calculate -------- mass in grams per second = specific gravity * extrusion volume in cc

// calculate -------- energy required = heat increase * specific heat * mass

/// all the above is wrong as there are other factors involved but it is a rough approximation........

rr="\"function d(a){return document.getElementById(\'F\').elements[a].value;} f=d(\'erate\'); g=d(\'noz\'); function ll(){var i=0; while(i!=" + i + "-1){ if( document.F.s[ i ].checked == true){ var gj = document.getElementById('myD').innerHTML; var gk=gj.split('\\n'); alert( gk[i-0] );} i++; }}; ll(); ";

scrr= rr + "alert(\'this script currently give no results \\n \' + f + '\\n' + g ); \" ";

kk = kk + "Pleased input the hotend parameters " + "nozzle diameter : " + v + "input type='text' name='noz' /" + A + "extrusion speed: " + v + "input type='text' name='erate' /" + A ;

kk = kk + v + "input type='button' value='Calculate' onclick=" + scrr + A + v + "/form" + A;

f= cv(''); //window.open();

f.document.write(kk);

//cv(kk);

Edited 21 time(s). Last edit at 10/05/2011 07:46PM by mung.

|

Re: Considering a new extruder design July 10, 2011 01:20PM |

Registered: 13 years ago Posts: 106 |

Video of rought test made today.....

Its 8 minutes long but should have only been half that length, sorry to waste your time, but I don't have time to try and record it again..

I tried to show how everything moves and works, but it is still in development and is not prefected yet.

I think this is all I am going to do on this project maybe until the end of the year, I'm sure if anyone is interested in the way this extruder works they can make a reasonable copy from what is shown in the video.

I do not think I will finish this prototype and probably will start a new extruder design next year which will be far more efficient with a new thermal insulation method (I noticed from this development that heat transfer to the nozzle mounting points almost doubled due to the way the electrical connections are made).

As always I am interested in comments and questions but I doubt most will cause any change to my design as I currently have fairly solid ideas and calculations for the next prototype.

Edited 1 time(s). Last edit at 07/10/2011 01:37PM by mung.

Its 8 minutes long but should have only been half that length, sorry to waste your time, but I don't have time to try and record it again..

I tried to show how everything moves and works, but it is still in development and is not prefected yet.

I think this is all I am going to do on this project maybe until the end of the year, I'm sure if anyone is interested in the way this extruder works they can make a reasonable copy from what is shown in the video.

I do not think I will finish this prototype and probably will start a new extruder design next year which will be far more efficient with a new thermal insulation method (I noticed from this development that heat transfer to the nozzle mounting points almost doubled due to the way the electrical connections are made).

As always I am interested in comments and questions but I doubt most will cause any change to my design as I currently have fairly solid ideas and calculations for the next prototype.

Edited 1 time(s). Last edit at 07/10/2011 01:37PM by mung.

|

Re: Considering a new extruder design July 10, 2011 01:50PM |

Registered: 13 years ago Posts: 2,947 |

I have not read every word of the above posts but I have skimmed through them.

The thing I found with all my attempts at hotend designs were they all work great for testing but running a hotend at 200+c for 4+hrs while pushing 3mm diameter filament through it at 1.5+mm/s is another thing entirely. (50+mm/s extruded @ .4mm dia)

1) For PLA you need the entrance of the heater to stay below 60c all the time. For the current designs out there this is done using the PTFE as a thermal barrier.

2) Needs some thermal mass to deal with the cooling effect of pushing filament through it at a high rate.

3) Needs to be safe. We use 6.8ohm resistors because they should never be able to start a hotend fire @ 12volts.

4) Needs to be able to handle the pressures inside the hotend @ 50mm/s @ 200+c for 4hrs to 24hrs

5) Can't transfer a large amount of heat to the plastic carriage it has to be mounted to.

Have a look at my plumbstruder variation in the links below.

The thing I found with all my attempts at hotend designs were they all work great for testing but running a hotend at 200+c for 4+hrs while pushing 3mm diameter filament through it at 1.5+mm/s is another thing entirely. (50+mm/s extruded @ .4mm dia)

1) For PLA you need the entrance of the heater to stay below 60c all the time. For the current designs out there this is done using the PTFE as a thermal barrier.

2) Needs some thermal mass to deal with the cooling effect of pushing filament through it at a high rate.

3) Needs to be safe. We use 6.8ohm resistors because they should never be able to start a hotend fire @ 12volts.

4) Needs to be able to handle the pressures inside the hotend @ 50mm/s @ 200+c for 4hrs to 24hrs

5) Can't transfer a large amount of heat to the plastic carriage it has to be mounted to.

Have a look at my plumbstruder variation in the links below.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Considering a new extruder design July 11, 2011 04:13AM |

Registered: 13 years ago Posts: 106 |

Sublime Wrote:

> 1) For PLA you need the entrance of the heater to

> stay below 60c all the time.

Why do you say this?

What happens if the entrance is not below 60C?

Where are the calculations and experimental evidence that set this limit of 60C

> 2) Needs some thermal mass to deal with the

> cooling effect of pushing filament through it at a

> high rate.

Why do you need thermal mass, and what function does the thermal mass do to effect the temperature of the filament?

I could answer your question for you, but I think if you could answer it you may better understand thermodynamics.

input = output

> 3) Needs to be safe. We use 6.8ohm resistors

> because they should never be able to start a

> hotend fire @ 12volts.

What makes you think 6.8R resistors would never be able to start a fire????

I think in the right circumstances any resistors could start a fire, but in most cases hotend fires are rather unlikely if there is nothing inflamable nearby. Of course there are always the unknown unknowns like a magnitude 9 earthquake at the fukashima nuclear power plant, or melting polymer producing a flammable gas and a build up of pyrophoric carbon igniting the gas in a confined space causing an explosion???

> 4) Needs to be able to handle the pressures inside

> the hotend @ 50mm/s @ 200+c for 4hrs to 24hrs

I doubt this is a problem, but I am beginning to think speed could be a problem as many machines are running much faster than 50mm/s, I imagine that 500mm/s could be the upper limit.

E = (t2 - t1) * M * S.H. + any latent heat required for phase change

The speed problem is due to speed of heat conduction within the polymer, and this is why smaller diameter feed stock are better and I initially did some calculations that showed 1.25mm could be about optimum.

> 5) Can't transfer a large amount of heat to the

> plastic carriage it has to be mounted to.

I think thermal management is quite important in a heating device, I really have no expertise in mechanical engineering or thermodynamics, but I do remember a few things from A level physics. heat in = heat out, heat moves from hotter places to cooler places until everything is the same temperature, heat will travel mainly by conduction or convection, surface area and airflow are important in convection, thermal conductivity of a material is important in conduction.

Ideally you want all your heat to go into the polymer you are melting the closer to this ideal the closer to the calculated heating energy for a given mass of polymer your extruders power requirements will be.

Heat loss is a bad thing, you want to minimise convection by minimising surface area and airflow, you want to minimise conduction away from the polymer by using good geometric design and correct materials in the right areas.

Finally it must be economically manufacturable......

Without the right tools you will not be able to make the most efficient machine.

I would like to see someone make a better extruder, but I think I do not have the time or the expertise, and to actually make a self replicatable extruder is although possible not feasible with present technology.

> 1) For PLA you need the entrance of the heater to

> stay below 60c all the time.

Why do you say this?

What happens if the entrance is not below 60C?

Where are the calculations and experimental evidence that set this limit of 60C

> 2) Needs some thermal mass to deal with the

> cooling effect of pushing filament through it at a

> high rate.

Why do you need thermal mass, and what function does the thermal mass do to effect the temperature of the filament?

I could answer your question for you, but I think if you could answer it you may better understand thermodynamics.

input = output

> 3) Needs to be safe. We use 6.8ohm resistors

> because they should never be able to start a

> hotend fire @ 12volts.

What makes you think 6.8R resistors would never be able to start a fire????

I think in the right circumstances any resistors could start a fire, but in most cases hotend fires are rather unlikely if there is nothing inflamable nearby. Of course there are always the unknown unknowns like a magnitude 9 earthquake at the fukashima nuclear power plant, or melting polymer producing a flammable gas and a build up of pyrophoric carbon igniting the gas in a confined space causing an explosion???

> 4) Needs to be able to handle the pressures inside

> the hotend @ 50mm/s @ 200+c for 4hrs to 24hrs

I doubt this is a problem, but I am beginning to think speed could be a problem as many machines are running much faster than 50mm/s, I imagine that 500mm/s could be the upper limit.

E = (t2 - t1) * M * S.H. + any latent heat required for phase change

The speed problem is due to speed of heat conduction within the polymer, and this is why smaller diameter feed stock are better and I initially did some calculations that showed 1.25mm could be about optimum.

> 5) Can't transfer a large amount of heat to the

> plastic carriage it has to be mounted to.