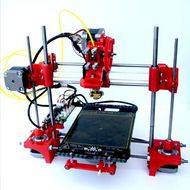

Portabee

Release status: Working

| Description | Printrbot variant that could be packed in a laptop bag

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | Printrbot variations

|

| CAD Models | hhmmm...

|

| External Link |

The portabee, is a Printrbot / Wallace variant which was designed to be able to be packed into a laptop bag. It has a 3mm FR4 matte black heated longbed, default gen6.d electronics which allows direct SD card printing, use of heated longbed as well as a channel for a micro fan. The build area is 120mm x 120mm x 120mm.

Contents

- 1 Specifications

- 2 Building Documentation

- 3 Where To Purchase

- 4 Where To Get Source Files

- 5 Updated information for 2021

Specifications

- Printed Parts: ???

- Non-Printed Parts: ???

- Printing Size: 12cm x 12cm x 12cm (apprx. 4.75"x4.75"x4.75")

- Material Costs: ???

- Precision: ??? (position), ??? (printing)

- Speed: ??? (position), ??? (printing)

Building Documentation

as looked up at RomScraj.com (if documentation links are outdated, look up again new links).

Where To Purchase

- http://romscraj.com - USD 490 unassembled, USD 640 assembled

- http://portabee3dprinter.com - USD 499 unassembled, USD 699 assembled

Where To Get Source Files

Updated information for 2021

This somewhat older printer unfortunately seems no longer to be available, making it hard to find relevant information. This section will summarise relevant information that is still available on the web as of 2021.

Latest corporate homepage from 2018

https://web.archive.org/web/20181031151948/http://portabee3dprinter.com/

Official setup page

https://web.archive.org/web/20180919005414/http://portabee3dprinter.com/support/portabee-kit-docs/

This page includes:

- Assembly manual

- First print using Pronterface and Cura software

- STL files for printer parts

- Upgrades for the printer such as:

- Y-axis brace

- Filament guide

- Fan frame

Firmware

https://web.archive.org/20160604072127/http://portabee3dprinter.com:80/portabee-firmware-guide/

slic3r settings

The following settings come from the file https://github.com/downloads/Lunavast/Portabee/config_300_portabee_2.ini. Save this file and then import it into slic3r via File->Load Config.

In particular, pay attention to the below settings concerning maximum print speed for the Portabee (40 mm/s or less) and the retraction settings.

acceleration = 0 bed_size = 120,120 bed_temperature = 0 bridge_fan_speed = 100 bridge_flow_ratio = 1 bridge_speed = 40 brim_width = 0 complete_objects = 0 cooling = 0 disable_fan_first_layers = 1 duplicate = 1 duplicate_distance = 6 duplicate_grid = 1,1 end_gcode = M104 S0 ; turn off temperature\nM1140 S0\nG28 X0 ; home X axis\nM84 ; disable motors extra_perimeters = 1 extruder_clearance_height = 20 extruder_clearance_radius = 20 extrusion_axis = E extrusion_multiplier = 1 extrusion_width = 0 fan_always_on = 0 fan_below_layer_time = 60 filament_diameter = 3.0 fill_angle = 45 fill_density = 0.2 fill_pattern = rectilinear first_layer_bed_temperature = 0 first_layer_extrusion_width = 0 first_layer_height = 100% first_layer_speed = 36% first_layer_temperature = 0 g0 = 0 gcode_arcs = 0 gcode_comments = 0 gcode_flavor = reprap infill_acceleration = 50 infill_every_layers = 1 infill_extrusion_width = 0 infill_speed = 40 layer_gcode = layer_height = 0.36 max_fan_speed = 100 min_fan_speed = 35 min_print_speed = 10 notes = nozzle_diameter = 0.5 output_filename_format = [input_filename_base].gcode perimeter_acceleration = 25 perimeter_speed = 36 perimeters = 2 perimeters_extrusion_width = 0 post_process = print_center = 60,60 randomize_start = 1 retract_before_travel = 2 retract_length = 1 retract_lift = 0 retract_restart_extra = 0 retract_speed = 10 rotate = 0 scale = 1 skirt_distance = 3 skirt_height = 1 skirts = 1 slowdown_below_layer_time = 15 small_perimeter_speed = 36 solid_fill_pattern = rectilinear solid_infill_speed = 40 solid_layers = 3 start_gcode = G28 ; home all axes support_material = 0 support_material_angle = 0 support_material_pattern = rectilinear support_material_spacing = 2.5 support_material_threshold = 45 support_material_tool = 0 temperature = 0 threads = 2 top_solid_infill_speed = 38 travel_speed = 128 use_relative_e_distances = 0 z_offset = 0

Detailed review and usage guide

Includes images of sample prints from the Portabee, troubleshooting guide, and tips about what to expect.

http://www.cygig.com/2013/08/review-portabee-3d-printer-most.html

Alternate URL: https://forums.vrzone.com/chit-chatting/2904838-review-portabee-3d-printer-the-most-afforable-singapore.html

Portabee print troubleshooting guide

https://i.imgur.com/iSEdqeM.jpg

Basic configuration

Basic hardware configuration

Insert filament

- Fully loosen the 4 nuts on idler block until the nuts are at the end of their respective screws, but do not remove the nuts from the screws. This step is easier if you replace the original hex nuts (which must be adjusted with a tool) with finger-adjustable knurled nuts (https://en.wikipedia.org/wiki/Knurled_nut).

- Pull idler block away from the extruder so that there is a clear path from the filament feed hole at the top of the extruder, all the way down to the hot end. The path for the filament should not be obstructed by the extruder bearing (because the idler block has been pulled away from the extruder so as not to block the filament feed path).

- Heat the hot end to the desired extrusion temperature (180 degrees for PLA).

- Push the filament all the way through the extruder hole, all the way down until it reaches the end of the hot end. The filament should be unobstructed by the extruder's internal bearing. As you push down on the filament, it should melt and ooze out of the hot end.

- Tighten the 4 nuts on the idler block, so that the extruder's bearing now grips the filament (by pressing it against the extruder's internal toothed brass gear).

- Clean the tip of the hot end.

Remove filament

- Fully loosen the 4 nuts on idler block until the nuts are at the end of their respective screws, but do not remove the nuts from the screws.

- Pull idler block away from the extruder, so that the extruder no longer grips the filament.

- Set the hot end to 90 degrees (for PLA) to soften, but not melt, the filament, and wait for the temperature to stabilize.

- After the temperature stabilizes, pull the filament out vertically from the filament feed hole.

Basic firmware configuration

Calibrate E-steps

Updating the firmware

- warning: multiple board variants

Basic software configuration

Speed limitations

- Limit speed to less than 40 mm/second, or else print quality may suffer.

- Reference 1: Initial slow speed for test prints is recommended as 30 mm/second. https://web.archive.org/web/20180919005414/http://portabee3dprinter.com/support/portabee-kit-docs/

- Reference 2: slic3r configuration file at https://github.com/downloads/Lunavast/Portabee/config_300_portabee_2.ini limits maximum print speed to 40 mm/second.

- Reference 3: Portabee review at https://reprap.org/wiki/Portabee#Detailed_review_and_usage_guide states that print quality suffers above 40 mm/second.

Temperature configuration

It seems to work better if you manually heat the nozzle and confirm good filament flow, instead of allowing the slic3r-generated gcode to automatically heat the nozzle and wait for the nozzle to reach the appropriate temperature. The reason is that the slic3r-generated gcode, which attempts to control the nozzle temperature, may wait unpredictably long before starting the print, and this unpredictable wait may lead to poor flow and insufficient extrusion at the beginning of the print.

- In slic3r, set temperature settings to zero, meaning the generated gcode will ignore the temperature.

- In slic3r, enable printing one skirt around the object.

- Warning: this means it will be possible to start the print from the generated gcode instantly, even if the nozzle is cold. This could damage the extruder gears. Always heat the nozzle to extrusion temperature before starting the print.

- In Pronterface, manually set the nozzle temperature to extrusion temperature, before the print.

- Manually extrude enough filament before the print to ensure it flows smoothly.

- As soon as smooth filament flow has been confirmed, immediately start the print (with the gcode file from step 1 that ignores temperature settings).

- The printer should immediately start printing and the first skirt should be drawn. The skirt should show perfectly smooth and continuous extrusion, leading to a clean and unbroken skirt line that adheres well to the print bed.

- Abort the print immediately if the skirt shows gaps or other signs of poor extrusion. Then, increase the Z height to about 4 cm, and again manually extrude a few cm of filament until the flow again becomes smooth. Also, check the bed level and home Z height to ensure good adhesion of the initial skirt and first layer.

Tips on using and printing with Portabee

Before moving the printer

- Confirm all screws and belts are tightened appropriately. Items prone to come loose due to vibration in normal use are:

- The set screw on the plastic drive gear on the extruder motor shaft

- The set screws on the Z leadscrews

- The screws holding the smooth Z rods in place

- The nuts securing the Y-axis support rods to the plastic base

- The screws holding the motors (X, Y, and Z) in place

When moving the printer

- Confirm all screws and belts are tight.

- Use two hands, one to grasp each z stepper motor. Be careful not to twist the assembly.

- It is inadvisable to grasp the Z rods (either the Z leadscrews, or the smooth Z rods), because this may cause them to become loose and/or misaligned.

Before turning on the printer

- Confirm all screws and belts are tight.

- Prepare an emergency-stop switch to cut the power to the printer immediately (or be prepared to yank the power cord if needed).

- Confirm the end stop switches are physically mounted so that they will activate when the print head reaches the start of each axis. If the switches are wrongly mounted so they do not activate, then the motors may try to drive the print head past the physical dimensions, causing a crash into and physical damage of plastic parts securing the X, Y, and/or Z axes.

After turning on the printer

- Turn on the extruder barrel fan with M106. It should always be on.

- Adjust the Z endstop so the nozzle is an appropriate distance from the print bed.

- Using Pronterface software, move the print head to the home position on the X, Y, and Z axes. Be prepared to cut power instantly (via the emergency-stop power switch) if the print head crashes into the printer sides or the print bed.

- Level the print bed.

- Calibrate the E-steps.

- Recommended starting value is 514 (reference: https://web.archive.org/web/20180919005414/http://portabee3dprinter.com/support/portabee-kit-docs/).

- Should be possible to set via M92 command (reference: https://marlinfw.org/docs/gcode/M092.html).

Before starting the print

- Load your gcode file (created with your slicer software, such as slic3r) into Pronterface.

- Ensure the print dimensions do not exceed the print bed size (12cm x 12cm x 12cm), or else the motors may try to drive the print head past the physical dimensions, causing a crash into and physical damage the X, Y, and/or Z axes and/or the print bed.

- Ensure that filament flows freely.

- Manually heat the hot end to desired temperature.

- Manually set Z to 4 cm above the print bed, and repeatedly extrude filament until it flows smoothly.

- After the filament flows smoothly, immediately (within a few seconds):

- Clean the excess filament from the print bed.

- Clean the nozzle of excess filament (e.g. wipe it quickly with a thick paper towel, taking care not to get burned by the hot end!).

- Start the print. If you wait too long (a minute or more) after the smooth filament flow begins, then the flow may again become poor, requiring re-extrusion to get the filament flowing freely again.

During the print

- Confirm the extruder barrel fan is always on.

- If the fan stops when the print starts:

- Abort the print -- in Pronterface, press "Pause", then "Reset printer".

- Turn on the fan with M106.

- In slic3r, check the option to turn the fan always on.

- Re-slice the 3D model, re-import into Pronterface, and try printing again. This time, the fan should be on.

- If the fan stops when the print starts:

Printing replacement parts for the Portabee

- Issues with too-small hole diameter

Improvements

Leveling the print bed

- Replace the upper locking nuts with wing nuts or thumb nuts for easier adjustment by hand.

- Replace the lower locking nuts with springs.

- Clip a glass pane on top of the print bed for a flatter surface (since the original print bed, with 4-point leveling, may warp and become uneven)

Releasing the idler block

- Replace the M4 nuts with M4 knurled nuts (thumb nuts) that can be gripped and loosened or tightened by hand.

- This makes it much easier/faster to loosen the idler block to enable removal or insertion of filament.