Category:MillStrap

Contents

MillStrap

A MillStrap is a commercial or hobby milling machine used as a RepStrap. In other words, you fasten the extruder onto the spindle. A RepRap is basically a 3 axis positioning system, electronics, and an extruder. If you cannot find a set of Mendel parts, then you can buy a new or used Milling machine instead. Then you can either (indirectly) mill out all the parts of some RepStrap capable of printing plastic Mendel parts, or (directly) use the mill with EMCRepRap to print plastic Mendel parts.

What is the difference between a MillStrap and a RouterStrap and a EmcRepStrap ?

(You bolt an extruder to a MillStrap to make plastic Mendel parts. Going the other direction, some people use a Milling and Drilling Head to bolt a rotary tool to a RepRap to make a very light-duty CNC mill).

Costs

Buy-Keep

You can purchase a milling machine, and use it with as a RepStrap. In this case, your cost is the cost of the milling machine, extruder, and electronics.

Buy-Use-Sell (Complicated)

You can buy a used benchtop milling machines, use it to make a set of RepRap parts, and transfer the electronics, extruder, and motors to the new RepRap, and sell the used benchtop milling machine. In this case, your final cost is the shipping cost for the milling machine, plus the cost of the RepRap.

Usage

In this case, you can use the machine as a traditional RepRap, as a CNC Mill, and for Shape_Deposition_Manufacturing.

Extruder

Note that once you have a working CNC mill, you can make many parts of the RepRap Extruder by cutting them out of plastic with the milling spindle.

A simple modification to a QU-BD extruder will allow it to be held by a CNC mill.

This solidworks model can be held by a drill chuck or 5/16 collet. The 5/16inch tube is directly overtop of the hot tip so rotation in the vertical axis of the extruder wont cause the hot tip to move. File:SolidWorks QU-BD Extruder Modification.zip

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

Release status: unknown

Note: I need to clean this up. --Sebastien Bailard 07:58, 22 February 2010 (UTC)

Traditional or CNC-Ready

For RepRapping, we need to mount stepper motors onto the x, y, and z axis of the benchtop mill. When researching a mill to buy, search for:

- model-name and CNC-ready

- model-name and CNC conversion

- model-name and CNC kit

Really Big Mills

- Really Big Mills (RBM) are ~7 feet tall, and made of steel. e.g. the American-made Bridgeport and its clones. Bridgeports weigh 1950 lb (885 kg) and you'll need to pay a team of two or three riggers to move it. Rigger: An advanced-class human who weighs ~200-500 pounds and knows how to move big heavy stuff without pulverizing himself or others. Non-Riggers must roll to save from "Crushed by heavy thing" (4d6 HP damage) with a -2 penalty when they attack an RBM without a Rigger in their party.

- The RepRap electronics may be too low power to move the servos/steppers of a Bridgeport mill. If you have a Bridgeport, dear reader, just knock together a RepStrap. It's a weekend project.

Unimat

- suppliers

- price

- description

Sieg/Generic Mill-Drills

- suppliers

- price

- description

Common conversions include:

- Grizzly G0704

- Conversion kits can be found on ebay or here

- Harbor Freight Mini Mill

- Conversion information can be found here

- These mills have been upgraded to include an articulating head articulating head, 4th axis and, Automatic Tool Changer. Plans are available for purchase.

Tormach, Bridgeport

- suppliers

- price

- description

These are big machines. It will be fun and useful to design the electronic to drive them.

Despite this, they're very handy as RepStraps, bootstrap positioning systems for a RepRap extruder head, and will make great 3D printers.

Small benchtop CNC Mills

Taig Mill

See Taig Mill.

As a RepStrap, "more than adequate for building Mendel parts".

Sherline, Clisby

See Sherline Mill.

Clisby brand mills were somewhat popular modelmaking mills. They were inexpensive, and very small, and you may be able to source a used one and convert them to stepper motor operation. The Australian manufacturer may be out of business, while the American fork, Sherline, is still going strong.

Clisby

Unimat

There are several Unimat models. Unimat 1 This is a children's toy, made from plastic. Unimat 1 was originally designed and released by Emco Maier, an Austrian industrial machine tool company. It is a modular miniature scale machining system, with plastic head- and tailstocks, and (low voltage DC) motor mounts, that can be reconfigured around aluminium extrusions that constitute beds and colums. While it can be considered a child's machine, in the right hands it can produce fine miniature machine work in materials lighter than steel. Unimat 3 was a small-scale, but professional-grade, machining system. It was built around a small lathe with a cast iron bed with ground slides, 46mm centre height, 200mm between centres. It also had provision to fit a milling head to a post that bolts to overhang the bed, and a wide range of accessories. Out of production since 1990, there has been a version called Unimat 4 produced in Taiwan, CNC variations as well.

MetalLine

The Metaline is made from aluminium extrusions. The CNC version of the Unimat is probably an excellent RepStrap base. http://www.thecooltool.com/produktgruppe.php?pg_id=7

Uniturn

This is a larger machine made by unimat, a small benchtop mill. http://www.thecooltool.com/produktgruppe.php?language=d&pg_id=4

Xendoll

This is a Unimat1 clone with digital readout. It does not have stepper motor mounts. http://www.probotix.com/index.php?view=product&path=25&product_id=37

Acra

Inexpensive, and look like a good bit of kit. There's no information about doing cnc conversions on them. http://www.vanda-layindustries.com/html/acra_mill_plus.html

Smithy

Smithy Industries http://www.smithy.com/

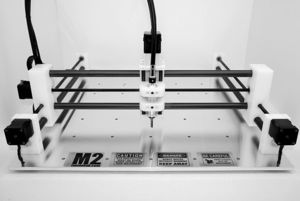

micRo & M3

No longer produced, Lumenlab is in bankruptcy, but they are everywhere and they're still working fine.

"micRo ... can be used for both additive (printing) and subtractive (milling, cutting) fabrication."

Work Area: 10.5" x 12.5" x 2.75-4" ; $1294 (includes mechanical parts, motors) + cost of spindle or other tool, motor controller electronics, and the computer running EMC

It looks like the micRo supports toolheads of about the same size and weight as the Mendel. Does it make any sense to try to adapt RepRap toolheads to the micRo or vice versa?

Comunity

In Yahoo groups are an active group

Next Wave Automation

Rockler Woodworking sells several CNC routers for under $4000 -- not including the spindle -- the CNC Shark from Next Wave Automation.

Really small mill

EBay (and Taobao for China) are potential sources for cheap CNC machines. Search eBay for CNC.

There are lot of plans for building your own small desktop CNC machine. It seems that even a relatively cheap, flimsy milling machine is more than adequate as a RepStraps.

- Solsylva CNC Router Plans. One RepRap researcher used it to mill RepRap electronics PCBs (Gen7 Stories); another RepRap researcher seemed to find it useful.

- "Shapeoko, the Affordable CNC Mill Kit", the "Mechanical Kit" was originally $299, the complete Shapeoko 2 kit (mechanical + electrical + basic tools) was $649 (110V) or $685 (220V). Initially launched on Kickstarter, the ShapeOko is an open-source project, documented on the main web site http://www.shapeoko.com with full b.o.m., cad files and instructions. The new v3 is available starting at $999 and Sparkfun sells a mechanical-only kit (in red) for $849.95. The Shapeoko wiki has a page on a RepStrapOko with complete details of converting it into a 3D printer.

- Bluumax CNC sells a gantry router CNC mill kit with Bipolar Drive & Motors $370 (not including MDF work surface, not including 24 V power supply). (Used to sell on eBay).

- "Build your own CNC"

- Cerebralmeltdown: "CNC_Machine_Builds" and "More CNC Machine Builds"

- search Instructables for "CNC" gives a surprisingly large number of CNC machines with detailed build instructions. (Is there a way to get a list of the "build a CNC" Instructables, not including the "here's how to build (something else) using a CNC machine" Instructables?)

- "How to Make a Three Axis CNC Machine (Cheaply and Easily)" for under $600 in parts (including motors and controllers; cost doesn't include a computer with a parallel port; cost doesn't include the Dremel tool to bolt onto its head)

- Instructables: "Easy to Build Desk Top 3 Axis CNC Milling Machine" (looks much like the Development:McWire)

- CNCzone.com: "DIY-CNC Router Table Machines" has a lot of discussion on building CNC machines. Some of them are for quite large, expensive machines; other threads discuss under-$1000 machines[1][2][3]. Also: CNCzone.com: "FAQ of CNC Machine building".

- FireBall V90 CNC Router

- The Make Your Bot wiki is the home of the under $100 Mantis 3-axis CNC milling machine. Is this adequate to make a RepStrap? Whether it is or not, is its "Low Cost Spindle 2.0" easy to mount on a Mendel?

- The "machines that make" project at MIT has many interesting machines, many of them tiny low-cost CNC mills.

- In particular, the Fab in a box, a MIT "Machines that Make" project, proposes a "multifab" that fits in a suitcase and includes a variety of tools including an XYZ gantry that supports a machining spindle milling head and a RepRap plastic extruder head, all under the control of a Fabnet, a RS-485-based multi-drop network with any number of motors and sensors can be attached to it. Fabnet sounds reminiscent of SNAPComms.

- The DIYLILCNC project is a free & open-source set of plans for an inexpensive, fully functional 3-axis CNC mill that can be built by an individual with basic shop skills and tool access. "The DIYLILCNC can be built for around $700."

- dubsworld DIY CNC; mostly built from MDF.

- Proxxon Mf70 repstrap

- The Ponoko "Pricing guide to DIY CNC mill and router kits" lists 18 different CNC kits from a variety of companies.

Pages in category "MillStrap"

The following 7 pages are in this category, out of 7 total.