Category:Extruders/ru

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Принтеры Darwin и Mendel были спроектированы для печати PLA пластиком. People have developed many ways of improving on the original extruder. It didn't take long before people starting trying to make them extrude other stuff often ABS and even delicious frosting: Frostruder[1]. RepRap forums: "Frostruder MK2 = Granular extruder?"[2].

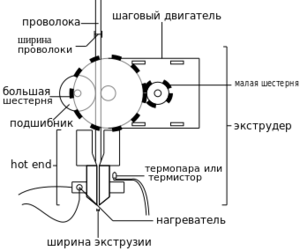

To extrude plastic filament, you need to force the raw material (usually a 1.75mm or 3mm diameter filament) with the drive of the "cold end" of the extruder, through the "hot end" of the extruder with heater and out of the nozzle at a reasonable speed first onto the build platform (sometimes heated) and then layer by layer onto the part as it is built up.

The "cold end" is usually the bulk of the extruder, often the actual carriage on one axis and supports the rest of the parts. In some designs the "cold end" is split into two parts, one that does the driving of the filament that is stationary and connected to the carriage portion, of a lighter weight design for easier movement, with a flexible tube. The drive is a motor that rotates a knurled, hobbed or toothed pinch wheel against a pressure plate or bearing with the filament forced between them. Usually the motor is geared to the pinch wheel to increase available torque and extrusion control (smoothness). The gearing can be a 3D printed pinion and gear, stock worm wheel and gear or a more expensive integral motor gearbox. Stepper motors are used almost universally after initial trials with DC motors did not achieve the required repeatability, servo motors are an option though not seen in the literature yet. The final function to keep the "cold end" cold is some form of cooling. With the close proximity to the "hot end", possible heated build platforms and enclosures it is sometimes necessary to have additional passive or active cooling of the cold end parts. Heat sinks and fans are often used, water and Peltier effect cooling is also discussed. Much of this bulk is usually made from 3D printed parts and the temperature is maintained within safe limits.

The "cold end" is connected to the "hot end" across a thermal break or insulator (the Bowden tube if used is on the cold side of this thermal break). This has to be rigid and accurate enough to reliably pass the filament from one side to the other but still prevent much of the heat transfer. The materials of choice are usually PEEK plastic with PTFE liners or PTFE with stainless steel mechanical supports or a combination of all three.

The "hot end" is the active part of the 3D printer and melts the filament and allows it to exit from the small nozzle to form a thin and tacky bead of plastic that will adhere to the material it is laid on. Usually made of brass though sometimes glass or aluminium is used. It consists of a barrel with a melting zone or chamber near the tip closed off with a fixed or removable nozzle with a diameter of between 0.3mm and 1.0mm with typical size of 0.5mm with present generation extruders. Outside the tip of the barrel is a heating means, either a wire element or a standard wire wound resistor. The heat required is of the order of 20W and temperatures around 150 to 250 degrees Centigrade is typical. For feedback control of the nozzle temperature a thermistor is usually attached close to the nozzle though a thermocouple may serve with suitable control hardware. High temperature materials are needed here and include metals, cements and glues, glass and mineral fibre materials, PEEK, PTFE and Kapton Tape.

Pages in category "Extruders/ru"

The following 2 pages are in this category, out of 2 total.