One Motor+Belt on Z-axis

Posted by jpan

|

One Motor+Belt on Z-axis January 13, 2014 08:27PM |

Registered: 10 years ago Posts: 125 |

Hi guys,

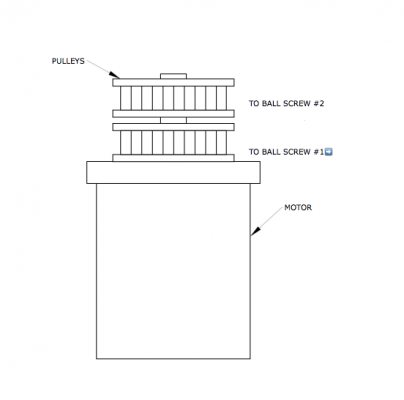

I saw a design like this. As a noob I'm not really sure how it works. Note that there's only ONE z motor.

I guess the guy pressed the belt pulley really tight with the nuts (and maybe even with threadlocker?) to try to keep it fixed.(maybe not)

Can anyone tell me if it's worthy to do so? Is it reliable at all?

Thanks

Edited 2 time(s). Last edit at 01/13/2014 08:47PM by jpan.

I saw a design like this. As a noob I'm not really sure how it works. Note that there's only ONE z motor.

I guess the guy pressed the belt pulley really tight with the nuts (and maybe even with threadlocker?) to try to keep it fixed.(maybe not)

Can anyone tell me if it's worthy to do so? Is it reliable at all?

Thanks

Edited 2 time(s). Last edit at 01/13/2014 08:47PM by jpan.

|

Re: One Motor+Belt on Z-axis January 15, 2014 04:34AM |

Registered: 11 years ago Posts: 72 |

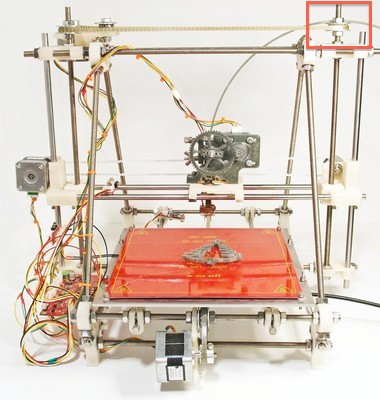

It works good! Need for controllers with 4 drivers - sanguinololu.

i made belt system for my prusa i3 and works fine ! =)

[www.thingiverse.com]

i made belt system for my prusa i3 and works fine ! =)

[www.thingiverse.com]

|

Re: One Motor+Belt on Z-axis January 15, 2014 12:19PM |

Registered: 10 years ago Posts: 553 |

systems like this have been used way back to the Darwin days. I had a Rapman that used one motor for the Z and ran a belt to each corner.

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: One Motor+Belt on Z-axis January 15, 2014 04:48PM |

Registered: 10 years ago Posts: 125 |

|

Re: One Motor+Belt on Z-axis January 15, 2014 04:51PM |

Registered: 10 years ago Posts: 474 |

I built one that uses a single motor for the Z but I would suggest you need a very stiff guide rail system for Z and stiff frame not just one single ride per side preferably something supported all the way

|

Re: One Motor+Belt on Z-axis January 15, 2014 08:13PM |

Registered: 10 years ago Posts: 125 |

|

Re: One Motor+Belt on Z-axis January 16, 2014 01:32PM |

Registered: 10 years ago Posts: 474 |

Thank you I have just one pulley on the motor and one for each of the screws. So the belt is on a triangular path the pully on one of Z ballscrews has to have a nice easily adjustable pulley mine I made is a split collar design so you can adjust the two screws. The reason I did it in a triangular belt path was so you can move the motor to tighten the belt

Edited 1 time(s). Last edit at 01/16/2014 01:37PM by cnc dick.

Edited 1 time(s). Last edit at 01/16/2014 01:37PM by cnc dick.

Sorry, only registered users may post in this forum.

Absolutely a professional one.

Absolutely a professional one.