DIY tech shop defective hotends

Posted by dwalker

|

Re: DIY tech shop defective hotends March 03, 2014 01:59AM |

Registered: 10 years ago Posts: 1,381 |

|

Re: DIY tech shop defective hotends March 03, 2014 07:49AM |

Registered: 10 years ago Posts: 5 |

Quote

A2

Coating the bore with thermal compound will improve the heat transfer, periodically replace it when it dries out.

Don't do this. There is no inexpensive thermal compound that won't break down at the temps we print at. Most of the stuff you'll find is rated at no more than 100C. All you're doing is burning it, making a mess and probably making some nasty fumes.

Edited 1 time(s). Last edit at 03/03/2014 07:49AM by TedMilker.

|

Re: DIY tech shop defective hotends March 03, 2014 11:01AM |

Registered: 10 years ago Posts: 1,381 |

Quote

TedMilker

There is no inexpensive thermal compound that won't break down at the temps we print at.

I agree that some are very expensive, messy, smelly and can even equal the cost of a new hot end.

There are thermal greases for high temps, and at a low cost.

870°C (1600°F) Anti Seize Compound, Silver.

7g Pouch, $1.59/ each.

20g Stick Semi-Solid, $9.06/ each

[www.grainger.com]

@thatsme:

Another suggestion, to avoid using the thermal compound, you can peen with a punch and hammer the bore of the heater block,

only on the side that the set screw is located.

This will add minimal but additional metal contact with the nozzle, and snug up the fit.

|

Re: DIY tech shop defective hotends March 03, 2014 11:44AM |

Registered: 10 years ago Posts: 56 |

Lets see i took mine off and cooked it with a plumbing tourch until it was pretty damm hot reassembled it and poof no leak.

but based on that your heating up plastic screwed into brass i dont think i can blame DIY for this one. I think just over time my back pressure issue caused the head to come loose.

Fixed that as well by limiting my .4 nozzle to .32 which is probably something i should have done long ago. That said the head still so lose in the block every time pressure it applied it moves which turned my ring into a very nice oval. So figure i will have to get that darn washer back in there maybe two of them to keep it from moving but problem solved... Also orderd a .5 hot end from hotends.com just to see the diffrence.

but based on that your heating up plastic screwed into brass i dont think i can blame DIY for this one. I think just over time my back pressure issue caused the head to come loose.

Fixed that as well by limiting my .4 nozzle to .32 which is probably something i should have done long ago. That said the head still so lose in the block every time pressure it applied it moves which turned my ring into a very nice oval. So figure i will have to get that darn washer back in there maybe two of them to keep it from moving but problem solved... Also orderd a .5 hot end from hotends.com just to see the diffrence.

|

Re: DIY tech shop defective hotends March 03, 2014 02:04PM |

Registered: 10 years ago Posts: 553 |

Quote

A2

Quote

TedMilker

There is no inexpensive thermal compound that won't break down at the temps we print at.

I agree that some are very expensive, messy, smelly and can even equal the cost of a new hot end.

There are thermal greases for high temps, and at a low cost.

870°C (1600°F) Anti Seize Compound, Silver.

7g Pouch, $1.59/ each.

20g Stick Semi-Solid, $9.06/ each

[www.grainger.com]

@thatsme:

Another suggestion, to avoid using the thermal compound, you can peen with a punch and hammer the bore of the heater block,

only on the side that the set screw is located.

This will add minimal but additional metal contact with the nozzle, and snug up the fit.

That's anti seize, not a thermal compound. The only stuff I have found that is thermally conductive and can withstand the temps we use is from McMaster - http://www.mcmaster.com/#3568k11/=qxpaof but it hardens at the temperatures we need. I have purchased exhaust putty to try from Advanced Auto but have not got around to trying it.

There are no compounds made for computers that can withstand temperatures that we need (that I could find).

|

Re: DIY tech shop defective hotends March 03, 2014 07:19PM |

Registered: 10 years ago Posts: 1,381 |

@tjb1:

Not all but Some anti-seize products can be used as a thermal compound.

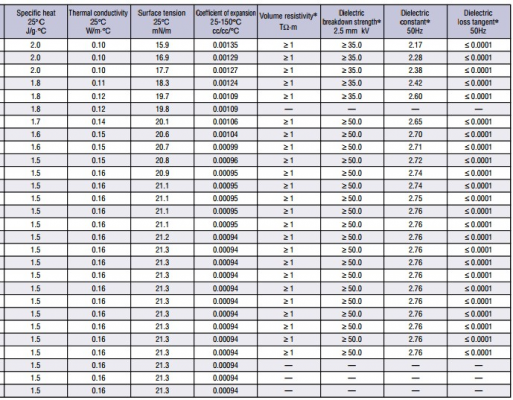

In general the coefficient of thermal conductivity less than 0.16 is considered the start of being insulative.

Typically one material thermal property is not used to determine what material is best for a specific application.

For example, I use thermal effusivity, and thermal diffusivity to help me find a material for temperature sensitive applications.

I also use statistics to normalize, weight, and then combine material thermal, and physical properties, (e.g. density)

to help me contrast their differences, and find an appropriate material.

Thermal effusivity

[en.wikipedia.org]

Thermal diffusivity

[en.wikipedia.org]

An example of an anti-seize being used for heat transfer for a heater cartridge:

BNS Anti-Seize Cartridge Heater Coating

This high temperature electrically insulating and thermally conductive coating will minimize oxidation and

improve heat transfer from heater to the object being heated.

[www.tempco.com]

LOCTITE SILVER GRADE ANTI-SEIZE

Heavy duty, temperature resistant, petroleum-based lubricant compound fortified with graphite and metallic flake.

Inert, will not evaporate or harden in extreme cold or heat. For use in assemblies up to 1600°F (871°C).

[www.sealanddesign.com]

Materials used in high temp anti-seize compounds:

399°C (750°F), molybdenum disulfide.

400°C (750°F), Zinc.

871°C (1600°F), aluminum, copper and graphite.

982°C (1800°F), copper.

982°C (1800°F), copper, graphite, aluminum.

1204°C (2200°F), stainless steel, graphite, aluminum.

1316°C (2400°F), Nickel.

1316°C (2400°F), nickel, graphite.

1343°C (2450°F), graphite, calcium fluoride.

[www.neverseezproducts.com]

[www.henkelna.com]

[www.loctite.ph]

Quote

tjb1

That's anti seize, not a thermal compound.

Not all but Some anti-seize products can be used as a thermal compound.

In general the coefficient of thermal conductivity less than 0.16 is considered the start of being insulative.

Typically one material thermal property is not used to determine what material is best for a specific application.

For example, I use thermal effusivity, and thermal diffusivity to help me find a material for temperature sensitive applications.

I also use statistics to normalize, weight, and then combine material thermal, and physical properties, (e.g. density)

to help me contrast their differences, and find an appropriate material.

Thermal effusivity

[en.wikipedia.org]

Thermal diffusivity

[en.wikipedia.org]

An example of an anti-seize being used for heat transfer for a heater cartridge:

BNS Anti-Seize Cartridge Heater Coating

This high temperature electrically insulating and thermally conductive coating will minimize oxidation and

improve heat transfer from heater to the object being heated.

[www.tempco.com]

LOCTITE SILVER GRADE ANTI-SEIZE

Heavy duty, temperature resistant, petroleum-based lubricant compound fortified with graphite and metallic flake.

Inert, will not evaporate or harden in extreme cold or heat. For use in assemblies up to 1600°F (871°C).

[www.sealanddesign.com]

Materials used in high temp anti-seize compounds:

399°C (750°F), molybdenum disulfide.

400°C (750°F), Zinc.

871°C (1600°F), aluminum, copper and graphite.

982°C (1800°F), copper.

982°C (1800°F), copper, graphite, aluminum.

1204°C (2200°F), stainless steel, graphite, aluminum.

1316°C (2400°F), Nickel.

1316°C (2400°F), nickel, graphite.

1343°C (2450°F), graphite, calcium fluoride.

[www.neverseezproducts.com]

[www.henkelna.com]

[www.loctite.ph]

|

Re: DIY tech shop defective hotends March 04, 2014 07:19AM |

Registered: 10 years ago Posts: 553 |

Quote

A2

@tjb1:

Quote

tjb1

That's anti seize, not a thermal compound.

Not all but Some anti-seize products can be used as a thermal compound.

In general the coefficient of thermal conductivity less than 0.16 is considered the start of being insulative.

Typically one material thermal property is not used to determine what material is best for a specific application.

For example, I use thermal effusivity, and thermal diffusivity to help me find a material for temperature sensitive applications.

I also use statistics to normalize, weight, and then combine material thermal, and physical properties, (e.g. density)

to help me contrast their differences, and find an appropriate material.

Thermal effusivity

[en.wikipedia.org]

Thermal diffusivity

[en.wikipedia.org]

An example of an anti-seize being used for heat transfer for a heater cartridge:

BNS Anti-Seize Cartridge Heater Coating

This high temperature electrically insulating and thermally conductive coating will minimize oxidation and

improve heat transfer from heater to the object being heated.

[www.tempco.com]

LOCTITE SILVER GRADE ANTI-SEIZE

Heavy duty, temperature resistant, petroleum-based lubricant compound fortified with graphite and metallic flake.

Inert, will not evaporate or harden in extreme cold or heat. For use in assemblies up to 1600°F (871°C).

[www.sealanddesign.com]

Materials used in high temp anti-seize compounds:

399°C (750°F), molybdenum disulfide.

400°C (750°F), Zinc.

871°C (1600°F), aluminum, copper and graphite.

982°C (1800°F), copper.

982°C (1800°F), copper, graphite, aluminum.

1204°C (2200°F), stainless steel, graphite, aluminum.

1316°C (2400°F), Nickel.

1316°C (2400°F), nickel, graphite.

1343°C (2450°F), graphite, calcium fluoride.

[www.neverseezproducts.com]

[www.henkelna.com]

[www.loctite.ph]

Maybe you should link the thermally conductive compound the first time rather than standard anti seize.

The Loctite one says nothing about being thermally conductive, just because it can withstand heat doesn't mean it conducts it. You can bold and color all you want, by your logic I can stuff a piece of silicone in there (because it can withstand high heat) and expect it to transfer it efficiently.

Edited 2 time(s). Last edit at 03/04/2014 07:22AM by tjb1.

|

Re: DIY tech shop defective hotends March 04, 2014 07:37AM |

Registered: 10 years ago Posts: 1,381 |

|

Re: DIY tech shop defective hotends March 04, 2014 08:18AM |

Registered: 10 years ago Posts: 553 |

Quote

A2

Quote

tjb1

by your logic I can stuff a piece of silicone in there (because it can withstand high heat) and expect it to transfer it efficiently

Correct, silicone rubber, rtv thermal conductivity 0.272 is greater than 0.16, which makes it useful as a thermal conductor.

Oh yes, why is it used for pot grippers? Because it is terrible at conducting heat.

|

Re: DIY tech shop defective hotends March 04, 2014 08:27AM |

Registered: 10 years ago Posts: 1,381 |

Quote

tjb1

Oh yes, why is it used for pot grippers? Because it is terrible at conducting heat.

Silicone is very useful as a thermal compound for high temperature applications.

Ceramic-based thermal grease has generally good thermal conductivity and is usually composed of a ceramic powder

suspended in a liquid or gelatinous silicone compound, which may be described as 'silicone paste' or 'silicone thermal compound'.

[en.wikipedia.org]

Edited 1 time(s). Last edit at 03/04/2014 08:28AM by A2.

|

Re: DIY tech shop defective hotends March 04, 2014 08:35AM |

Registered: 10 years ago Posts: 553 |

Quote

A2

Quote

tjb1

Oh yes, why is it used for pot grippers? Because it is terrible at conducting heat.

Silicone is very useful as a thermal compound for high temperature applications.

Ceramic-based thermal grease has generally good thermal conductivity and is usually composed of a ceramic powder

suspended in a liquid or gelatinous silicone compound, which may be described as 'silicone paste' or 'silicone thermal compound'.

[en.wikipedia.org]

http://www.engineeringtoolbox.com/thermal-conductivity-d_429.html

Silicone cast resin 0.15 - 0.32

Cork 0.07

Aluminum 205

"Ceramic-based thermal grease has generally good thermal conductivity and is usually composed of a ceramic powder suspended in a liquid or gelatinous silicone compound, which may be described as 'silicone paste' or 'silicone thermal compound'."

"All but the last classification of compound usually use silicone grease as a medium, a slightly heat conductor in itself (0.2 W/(m·K)), though some manufacturers prefer use[citation needed] of fractions of mineral oil (0.1-0.2 W/(m·K))."

The most commonly used ceramics and their thermal conductivities in units of W/(m·K) are:[4]

beryllium oxide 218

aluminum nitride 170

aluminum oxide 39

zinc oxide 21

silicon dioxide 1

The silicone is just to hold the conductors together.

http://en.wikipedia.org/wiki/Thermal_grease#Thermal_conductor_types

Edited 2 time(s). Last edit at 03/04/2014 08:38AM by tjb1.

|

Re: DIY tech shop defective hotends March 04, 2014 10:00AM |

Registered: 10 years ago Posts: 1,381 |

Quote

tjb1

The silicone is just to hold the conductors together.

a slightly heat conductor in itself (0.2 W/(m·K))

No silicone is not chosen only because it can suspend some thing.

It's also chosen because of it's ability to conduct heat, some silicone's are considered a thermal conductor.

A simple test that you can perform to experience the thermal conductivity of silicone:

Purchase a silicone mitt, and immerse your whole hand into boiling water up to your wrist,

you'll discover that you can't do it for very long before it burns you.

I have one of these gloves, and I tested this, I have first hand experience with it.

I've never used the glove because of how well it conducts heat, it's too painful.

Edited 1 time(s). Last edit at 03/04/2014 10:00AM by A2.

|

Re: DIY tech shop defective hotends March 04, 2014 10:26AM |

Registered: 10 years ago Posts: 553 |

Quote

A2

Quote

tjb1

The silicone is just to hold the conductors together.

a slightly heat conductor in itself (0.2 W/(m·K))

No silicone is not chosen only because it can suspend some thing.

It's also chosen because of it's ability to conduct heat, some silicone's are considered a thermal conductor.

A simple test that you can perform to experience the thermal conductivity of silicone:

Purchase a silicone mitt, and immerse your whole hand into boiling water up to your wrist,

you'll discover that you can't do it for very long before it burns you.

I have one of these gloves, and I tested this, I have first hand experience with it.

I've never used the glove because of how well it conducts heat, it's too painful.

Keep living in your fantasy world, silicone is a terrible conductor. That is the exact reason that all the pot grippers, handles and anything made to grab moderately hot objects is made from silicone because it doesn't transfer heat effectively.

It seems you don't realize that the closer to 0 it is, the worse it is at conducting heat.

Edited 1 time(s). Last edit at 03/04/2014 10:31AM by tjb1.

|

Re: DIY tech shop defective hotends March 04, 2014 06:05PM |

Registered: 10 years ago Posts: 1,381 |

Quote

tjb1

That is the exact reason that all the pot grippers, handles and anything made to grab moderately

hot objects is made from silicone because it doesn't transfer heat effectively.

Silicone can transfer heat well enough that 50% of a thermal compound is silicone.

The silicone on your frying pan handle is formulated to reduce the thermal conductivity.

The silicone used in thermal compound is formulated to enhance thermal conductivity.

Silicone has a range of properties, and when the thermal conductivity is >0.16 it's regarded as a thermal conductor.

An example of a silicone fluid with dimethylpolysiloxane structure that has a range of thermal properties.

Notice how this silicone fluid thermal conductivity can be formulated between a

thermal insulator and a thermal conductor (0.10 to 0.16 W/m-C).

0.10 W/m-C Thermal insulator.

0.16 W/m-C, Thermal conductor.

Polydimethylsiloxane

[en.wikipedia.org]

An example of silicone used as an effective thermal conductor.

Designed to provide heat transfer, Good thermal conductivity (1.6 W/m-K)

[solutions.3m.com]

DOWTHERM J Fluid for Superior Heat Transfer and Pumpability

DOWTHERM J heat transfer fluid is a mixture of isomers of an alkylated aromatic hydrocarbon fluid specially engineered for demanding low-temperature applications. It has long been used in the chemical process industry for cooling to-110°F as well as heating to temperatures as high as 600°F.

Because of its low viscosity at extremely low temperatures, DOWTHERM J fluid provides the best heat transfer of the three fluids described in this guide. It is usually the fluid of choice to retrofit systems which were initially designed to use chlorinated solvents. In addition, its excellent fluid characteristics usually result in lower operational and engineering costs.

[msdssearch.dow.com]

Edited 1 time(s). Last edit at 03/04/2014 06:08PM by A2.

|

Re: DIY tech shop defective hotends March 05, 2014 07:21AM |

Registered: 10 years ago Posts: 5 |

Except now you're changing the argument. You're not using any of the junk you're bringing up as a "thermal compound" for your hotend. That DOWTHERM J fluid is a heat transfer medium for a closed heat pipe system, not something you stick in a hotend to improve heat transfer efficiency. It's designed to not expand and burst a copper heat pipe like what would happen if you used water(or freeze, in the case of the sub-zero application paper you linked to, hah!)

Bottom line: The hotpad was a laugh riot and I'm glad you've learned more about the properties of silicone but stop recommending "thermal compound" for hotends.

Edited 1 time(s). Last edit at 03/05/2014 07:21AM by TedMilker.

Bottom line: The hotpad was a laugh riot and I'm glad you've learned more about the properties of silicone but stop recommending "thermal compound" for hotends.

Edited 1 time(s). Last edit at 03/05/2014 07:21AM by TedMilker.

|

Re: DIY tech shop defective hotends March 05, 2014 07:45AM |

Registered: 10 years ago Posts: 553 |

Quote

A2

Quote

tjb1

That is the exact reason that all the pot grippers, handles and anything made to grab moderately

hot objects is made from silicone because it doesn't transfer heat effectively.

Silicone can transfer heat well enough that 50% of a thermal compound is silicone.

Silicone has a range of properties, and when the thermal conductivity is >0.16 it's regarded as a thermal conductor.

An example of silicone used as an effective thermal conductor.

Designed to provide heat transfer, Good thermal conductivity (1.6 W/m-K)

DOWTHERM J Fluid for Superior Heat Transfer and Pumpability

DOWTHERM J heat transfer fluid is a mixture of isomers of an alkylated aromatic hydrocarbon fluid specially engineered for demanding low-temperature applications. It has long been used in the chemical process industry for cooling to-110°F as well as heating to temperatures as high as 600°F.

1. No, 50% of it is used as a MEDIUM for the actual ingredients with higher thermal conductivity. Water has a higher thermal conductivity than silicone, why don't they use it?

2. Yes, >0.16. That doesn't change the fact that it is a TERRIBLE thermal conductor. Man you are all about definitions but can't accept any hard logic.

3. Now you are using two different units... W/m-K vs W/m-C, you think you can slip that by with your bold and colored text that is suppose to push it as hard evidence?

4. So now we are going to submerge our cartridge in this DOWTHERM? Might as well submerge the whole printer in deionized water.

The only thing you have posted that is even useful is the cartridge coating, everything else is just rubbish and you are grasping at straws.

|

Re: DIY tech shop defective hotends March 05, 2014 07:48AM |

Registered: 10 years ago Posts: 553 |

Anyone that finds this, the only things suitable for the cartridge or thermistor/thermocouple are -

[www.mcmaster.com] - Pick the right temperature, may be conductive so use with common sense.

or

[www.tempco.com] - Use with common sense.

No, you can not use computer thermal compound.

[www.mcmaster.com] - Pick the right temperature, may be conductive so use with common sense.

or

[www.tempco.com] - Use with common sense.

No, you can not use computer thermal compound.

|

Re: DIY tech shop defective hotends March 05, 2014 10:28AM |

Admin Registered: 15 years ago Posts: 1,470 |

Quote

tjb1

3. Now you are using two different units... W/m-K vs W/m-C, you think you can slip that by with your bold and colored text that is suppose to push it as hard evidence?

Since we are talking about deltaT, not absolute temperatures, W/m-K and W/m-C are identical. 1 degree K temperature change = 1 degree C temperature change.

Basically, we just want something that is a better heat conductor than air. Virtually anything that has a better conductance than air (at about 0.038 W/m-C (or W/m-K) at 200 degrees C), and can handle the high temperatures we use, will improve the heat conduction from the heating element to the rest of the hot end.

So yes, even pure silicone will be better than nothing. Obviously some materials will be better suited for our application than others, including the thermal putty you linked to.

I use furnace cement for securing the thermistor and resistor into my hot ends. It's probably not near as good a conductor as thermal putty or something else, but it's rated at much higher temperatures than the hot end will ever see and it works far better than just wrapping the whole thing in Kapton tape like most people do and leaving air gaps everywhere.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: DIY tech shop defective hotends March 05, 2014 10:33AM |

Registered: 11 years ago Posts: 250 |

Quote

tjb1

Quote

A2

Quote

tjb1

The silicone is just to hold the conductors together.

a slightly heat conductor in itself (0.2 W/(m·K))

No silicone is not chosen only because it can suspend some thing.

It's also chosen because of it's ability to conduct heat, some silicone's are considered a thermal conductor.

A simple test that you can perform to experience the thermal conductivity of silicone:

Purchase a silicone mitt, and immerse your whole hand into boiling water up to your wrist,

you'll discover that you can't do it for very long before it burns you.

I have one of these gloves, and I tested this, I have first hand experience with it.

I've never used the glove because of how well it conducts heat, it's too painful.

Keep living in your fantasy world, silicone is a terrible conductor. That is the exact reason that all the pot grippers, handles and anything made to grab moderately hot objects is made from silicone because it doesn't transfer heat effectively.

It seems you don't realize that the closer to 0 it is, the worse it is at conducting heat.

Sorry, I really LOL'd at this!

You guys are funny.

--------------------------------------------------------

Custom all metal CoreXY

- Duet 2 Wifi w/ PanelDue 7i

- 330mm x 360mm x 500mm

- 750w Silicon heater

Custom Mendel90

(Backup printer - Old reliable!) - Sold

|

Re: DIY tech shop defective hotends March 05, 2014 02:11PM |

Registered: 10 years ago Posts: 1,381 |

Quote

Mogal

Sorry, I really LOL'd at this!

The purpose of the silicone mitt was to handle a prototype mold that I built for expanded polystyrene (EPS) beads.

The mold was immersed in boiling water, and was molding a device to be used as a thermal barrier in preparation for U.L. certification.

I needed to manipulate the mold to encourage the EPS beads into narrow channels.

It was not possible to manipulate the mold in boiling water with the silicone kitchen mitt, I was burning my hand.

It's only useful for brief immersions, and for it's anti stick properties.

Mogal have you preformed a similar test, please describe your experience.

I sorted my materials list for silicone.

I included air, and glass as they were very near the extreme range of silicone thermal conductivity.

Red = thermal conductivity.

Blue = thermal insulative.

Quote

TedMilker

Bottom line: The hotpad was a laugh riot

Why is the 3M thermally conductive pad a laugh, it was only meant as an example for tjb1 to see that there is a range of thermally conductive silicone products.

TedMilker are you aware that 3d printers use glass beds placed on top of a silicone heating pad?

You can see that one type of glass 0.753 (K = W/mK) is equal to a silicone 0.753 (K = W/mK) for thermal conductivity.

Quote

NewPerfection

Basically, we just want something that is a better heat conductor than air.

Virtually anything that has a better conductance than air

Tks for the nice examples.

I only have about a dozen materials in my collection that have thermal conductivity values less than air, and they're gasses.

It's very difficult to beat air as an insulator, and like you said using almost any material is better than having an air gap.

Edited 2 time(s). Last edit at 03/05/2014 02:23PM by A2.

|

Re: DIY tech shop defective hotends March 06, 2014 09:07AM |

Registered: 10 years ago Posts: 5 |

Quote

NewPerfection

it works far better than just wrapping the whole thing in Kapton tape like most people do and leaving air gaps everywhere.

The smart ones fix the tolerance issues before wrapping in kapton so air gaps aren't an issue. Furnace cement and RTV silicone just make it look like way too much of a mess and your hotend look like it was assembled with trash.

Edited 2 time(s). Last edit at 03/06/2014 09:08AM by TedMilker.

|

Re: DIY tech shop defective hotends March 06, 2014 10:16AM |

Registered: 10 years ago Posts: 553 |

Quote

TedMilker

Quote

NewPerfection

it works far better than just wrapping the whole thing in Kapton tape like most people do and leaving air gaps everywhere.

The smart ones fix the tolerance issues before wrapping in kapton so air gaps aren't an issue. Furnace cement and RTV silicone just make it look like way too much of a mess and your hotend look like it was assembled with trash.

What does tolerance have to do with kapton?

|

Re: DIY tech shop defective hotends March 06, 2014 04:39PM |

Admin Registered: 15 years ago Posts: 1,470 |

Quote

TedMilker

Quote

NewPerfection

it works far better than just wrapping the whole thing in Kapton tape like most people do and leaving air gaps everywhere.

The smart ones fix the tolerance issues before wrapping in kapton so air gaps aren't an issue. Furnace cement and RTV silicone just make it look like way too much of a mess and your hotend look like it was assembled with trash.

IMHO, the furnace cement that I use makes it look far more professional than wrapping in Kapton. It's black, and dries to a nice smooth matte finish. You could even wrap the result in Kapton if that's your thing.

Good luck drilling a hole to tightly fit a glass bead thermistor or wire-wound resistor, or even a cartridge heater for that matter. None of those have tight dimensional tolerances to start with, so getting a proper fit isn't trivial.

Besides, no matter how perfect the match between mating surfaces is, a thermal compound of some type will always help heat transmission. Why do you think that thermal paste is necessary on CPU heat sinks, even though the mating surfaces are nearly perfectly flat?

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: DIY tech shop defective hotends March 07, 2014 12:54PM |

Registered: 10 years ago Posts: 553 |

Quote

TedMilker

Quote

NewPerfection

it works far better than just wrapping the whole thing in Kapton tape like most people do and leaving air gaps everywhere.

The smart ones fix the tolerance issues before wrapping in kapton so air gaps aren't an issue. Furnace cement and RTV silicone just make it look like way too much of a mess and your hotend look like it was assembled with trash.

I'll take performance over looks any day. It's a printer, who cares that the tape has creases in it or if there is putty on it?

|

Re: DIY tech shop defective hotends March 07, 2014 01:46PM |

Registered: 10 years ago Posts: 99 |

|

Re: DIY tech shop defective hotends March 07, 2014 01:49PM |

Admin Registered: 15 years ago Posts: 1,470 |

You can try PTFE tape to seal the threads, but personally I would just call up DIY Tech Shop and have them replace the hot end for you.Quote

cfy7

Any ideas for a fix, or should I just call up Diytechshop?

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: DIY tech shop defective hotends March 07, 2014 05:44PM |

Registered: 10 years ago Posts: 99 |

My thought is that tape is just a bandaid. It's still leaking, it's just being held in.

I emailed them and I'll have to give them a call later.

Edit: I didn't have to call, they emailed me back pretty quickly. They're going to send out a new hotend and recommended cleaning up some of the leaked plastic and wrapping it with kapton tape for now to stop the leak. Says pretty much it'll just plug itself up with leaked plastic and that they've tried this on one of their machines and it's worked decently for a while.

They also mentioned that they've been looking in on the milling shop to ensure that they are making everything up to their standards now.

I gotta say this, there may have been some problems with my machine, but they've been very good at fixing them.

Edited 1 time(s). Last edit at 03/07/2014 06:16PM by cfy7.

I emailed them and I'll have to give them a call later.

Edit: I didn't have to call, they emailed me back pretty quickly. They're going to send out a new hotend and recommended cleaning up some of the leaked plastic and wrapping it with kapton tape for now to stop the leak. Says pretty much it'll just plug itself up with leaked plastic and that they've tried this on one of their machines and it's worked decently for a while.

They also mentioned that they've been looking in on the milling shop to ensure that they are making everything up to their standards now.

I gotta say this, there may have been some problems with my machine, but they've been very good at fixing them.

Edited 1 time(s). Last edit at 03/07/2014 06:16PM by cfy7.

|

Re: DIY tech shop defective hotends March 07, 2014 07:36PM |

Registered: 10 years ago Posts: 1,381 |

@cfy7:

DIY tech shop defective hot end

Looks like a fire hazard.

DIY tech shop suggested using Kapton tape?

Kapton tape wont stop a leak, you could try Teflon tape.

For real? "for a while"....

Does the distal end of the hot end look like J-head?

If they copied (hotends.com) insulator correctly you could replace your nozzle with a Brass Nozzle (Mk V), it might fix your problem.

[www.hotends.com]

Edited 1 time(s). Last edit at 03/07/2014 07:37PM by A2.

DIY tech shop defective hot end

Looks like a fire hazard.

Quote

cfy7

wrapping it with kapton tape for now to stop the leak.

DIY tech shop suggested using Kapton tape?

Kapton tape wont stop a leak, you could try Teflon tape.

Quote

cfy7

Says pretty much it'll just plug itself up with leaked plastic and

that they've tried this on one of their machines and it's worked decently for a while.

For real? "for a while"....

Does the distal end of the hot end look like J-head?

If they copied (hotends.com) insulator correctly you could replace your nozzle with a Brass Nozzle (Mk V), it might fix your problem.

[www.hotends.com]

Edited 1 time(s). Last edit at 03/07/2014 07:37PM by A2.

|

Re: DIY tech shop defective hotends March 07, 2014 08:09PM |

Registered: 10 years ago Posts: 99 |

A2

That's the plan, I'm going to put Teflon tape in the threads. I get what he meant by using kapton to try and seal it up from the outside. I think it could work... Maybe. Lol.

It doesn't really matter though, he was just trying to help me keep the machine going while they ship out the new part. They've been good about shipping me items via overnight and priority mail so I'm not too worried.

N9jcv has a post on the first page of this thread with a picture of all the parts. The j head from hotends.com is at the top of my list if the replacement fails as well. I think the end looks a little different then your picture.

The fire hazard pard scares me though, what do you consider a fire hazard? The pla sitting on top of the brass block? Would that reach temperatures hot enough to ignite? Thanks for the warning.

Thanks for the advice.

That's the plan, I'm going to put Teflon tape in the threads. I get what he meant by using kapton to try and seal it up from the outside. I think it could work... Maybe. Lol.

It doesn't really matter though, he was just trying to help me keep the machine going while they ship out the new part. They've been good about shipping me items via overnight and priority mail so I'm not too worried.

N9jcv has a post on the first page of this thread with a picture of all the parts. The j head from hotends.com is at the top of my list if the replacement fails as well. I think the end looks a little different then your picture.

The fire hazard pard scares me though, what do you consider a fire hazard? The pla sitting on top of the brass block? Would that reach temperatures hot enough to ignite? Thanks for the warning.

Thanks for the advice.

|

Re: DIY tech shop defective hotends March 07, 2014 10:19PM |

Registered: 10 years ago Posts: 211 |

That is the exact leaking issue i had. Diy sent me a new hotend that they checked the milling on. Now 1 week later not 1 single drop has leaked. I did put teflon tape on the replacement hotend for insurance. I think they did a good job fixing it. I dont believe leaking is a fire hazard as pla melts inside the hot end anyway, just my 2 cents

Sorry, only registered users may post in this forum.