“Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures]

[Many Pictures]

Posted by RP Iron Man

“Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 05, 2014 09:10PM |

Registered: 11 years ago Posts: 246 |

Hey Guys!

I am super excited to finally post this! Over the past several months I have been working on developing a unique hot end design that I think will encourage significant innovation within RepRap.

In short, the Prometheus Hot End is a customizable all-metal hot end that will allow users to configure the “melt-zone” length, “transition-zone” length, and thermistor position according to their needs. These parameters traditionally remain fixed in standard hot ends and allow for very little experimentation. My primary goal when designing the Prometheus Hot End was to provide RepRap users with an all-in-one flexible solution that would open up the possibility for experimentation with all of the significant hot end parameters that govern extrusion behavior. I think that this is the next step in hot end design and I believe that it will help us further our understanding of the intricacies of hot end science.

I am posting this now because I want to start a discussion about the technical facets of this design along with the possible future implications. I really want to know what you guys think about this and get your opinion on the design decisions that I made. The discussions on the E3D Hot End thread are an incredible source of information so I hope I can add to that knowledge with this thread.

I have spent the past several months on this project and I have finished designing, prototyping and testing this design. I am now about 1 or 2 weeks away from launching an Indiegogo Campaign to get this project funded so I thought that this would be a good time to start discussing the design with everyone in the RepRap community. There is a lot of information about the Prometheus Hot End in the paragraphs below. I copied several paragraphs directly from my Indiegogo campaign so I apologize if parts of it sound too much like a crowdfunding campaign pitch

Anyway, lots of interesting information and pictures below!

Introduction

As our community continues to explore new boundaries, exciting high-temperature plastics like Polycarbonate and Nylon are becoming widely available. As a result, RepRappers are replacing their old PEEK insulated J-Heads with new all-metal hot ends that are capable of printing at these high-temperatures. With a plethora of new hot end designs and the widespread success of the E3D hot end, all-metal hot ends are becoming the ubiquitous all-in-one solution for RepRap 3D printers around the world.

Despite these recent innovations, I have noticed that the new all-metal hot ends have the same static design features of a fixed "melt-zone", "transition-zone", and thermistor position. While these new designs satisfy the need for reliable high-temperature extrusion, they seem to ignore the fact that users may require different hot end parameters for their specific needs or simply for experimentation.

I started thinking about this when I was reading the E3D hot end thread on the RepRap forums and I stumbled across a post by RepRap user maddox:

It didn't seem like anyone else had solved this problem yet so I decided that I would take on this project. Finally, after months of designing, three generations of prototypes, and hundreds of hours of printing, the Prometheus Hot End was born!

Summary

This bleeding-edge hot end design allows RepRap developers to experiment with all aspects of thermoplastic extrusion. Its actively cooled all-metal construction is very durable and can easily withstand the high temperatures required for extruding thermoplastics like Nylon and Polycarbonate, while its unique modular design enables the user to customize the "melt-zone" length, “transition-zone" length, and thermistor position according to their needs.

Design Features

- Durable, actively cooled, all-metal construction for high-temperature extrusion up to 300C (limited by thermistor reading).

- Modular design with user-variable "melt-zone" length, "transition-zone" length, and thermistor position for your specific need or experimentation.

- Precision CNC-machined parts featuring an internally burnished 1-Piece Stainless Steel Nozzle.

- 1-Piece Stainless Steel Nozzle eliminates all leaks and clogs caused by internal "melt-zone" junctions.

- Compact design conserves z-height, weighs about 30g, and fits standard extruder bodies.

- Printed successfully for hundreds of hours with PLA, ABS, PC, and Nylon 618.

- Number of hot end leaks, clogs, and jams: 0 (zero!).

Modular Design

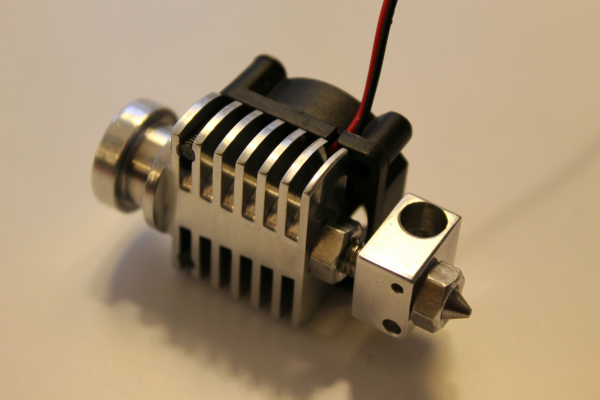

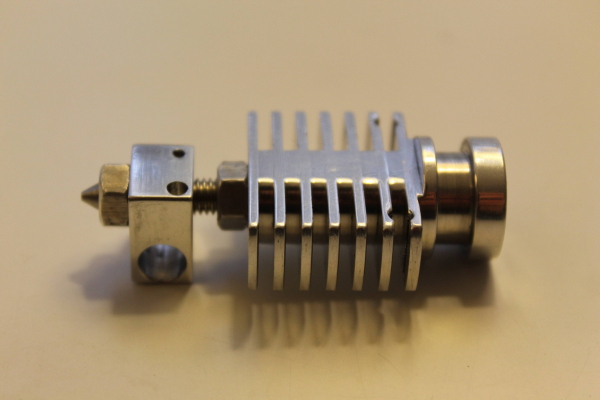

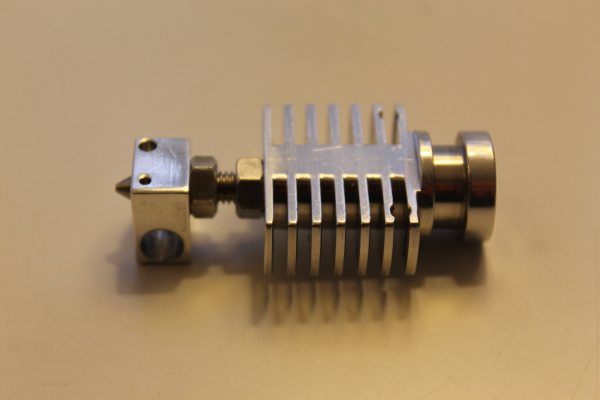

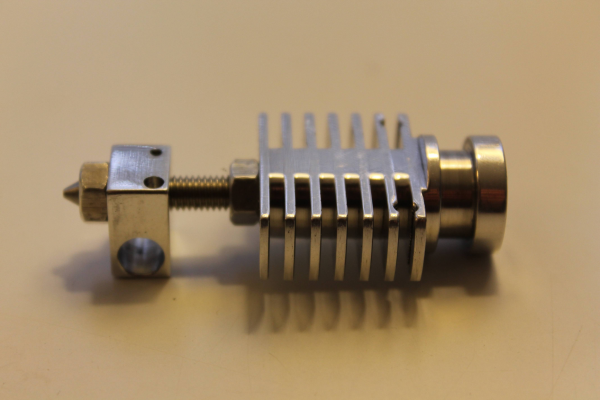

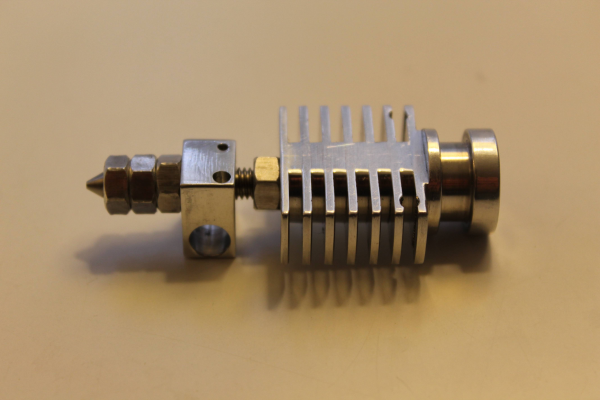

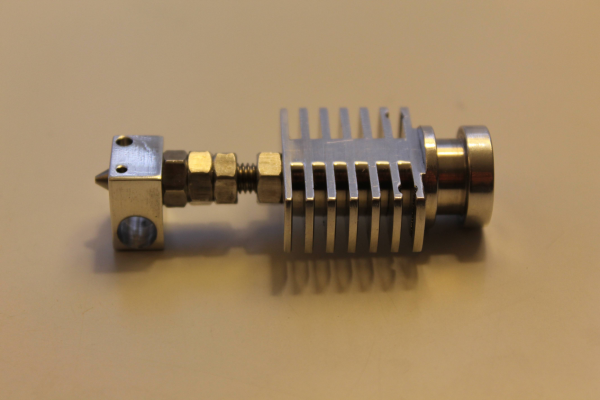

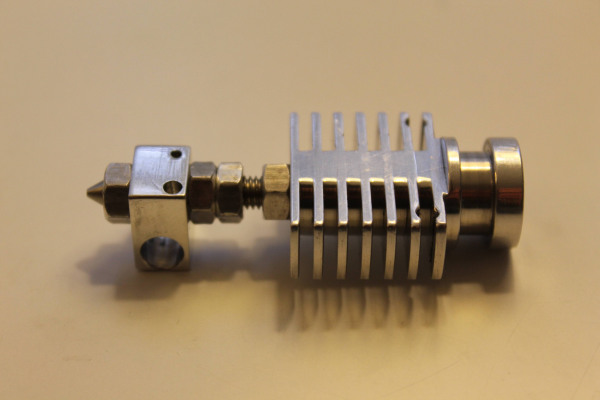

The modular design of the Prometheus Hot End consists of three custom designed and precision CNC-machined components: the Aluminium Heat Sink, the Aluminium Heater Block, and the 1-Piece Stainless Steel Nozzle. Every component of the Prometheus Hot End was carefully engineered for optimum performance.

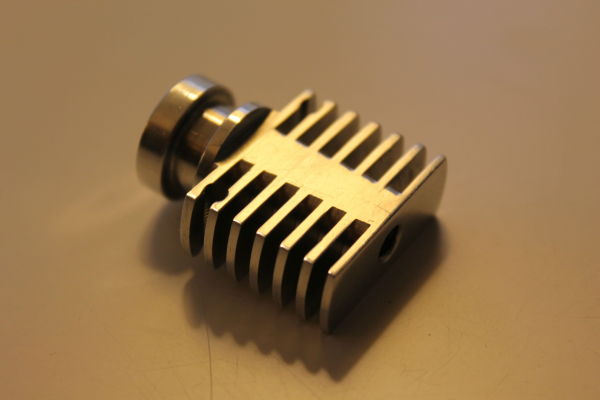

Aluminium Heat Sink

The Aluminium Heat Sink is precision CNC-machined and polished for a beautiful surface finish. Aluminium was chosen as the material for the heat sink due to its high thermal conductivity and high machinability. The heat sink incorporates a standard groove mount design for compatibility with standard extruder bodies. Fins are turned into the heat sink to maximize cooling and symmetrical faces are milled on each side to allow a 25mm cooling fan to be mounted directly to the heat sink. This design feature eliminates the plastic fan duct, decreases mass, and increases cooling efficiency.

The heat sink is also threaded from top to bottom to allow the 1-Piece Stainless Steel Nozzle to be threaded into the heat sink and fastened at the bottom with an aluminium hex nut. A PTFE tube is inserted from the top and meets with the nozzle in the threaded portion of the heat sink to facilitate a low friction filament path into the nozzle.

*Note: This PTFE tube is inserted in the “cold-zone” of the hot end in the actively-cooled heat sink so it is NOT subjected to high temperatures.

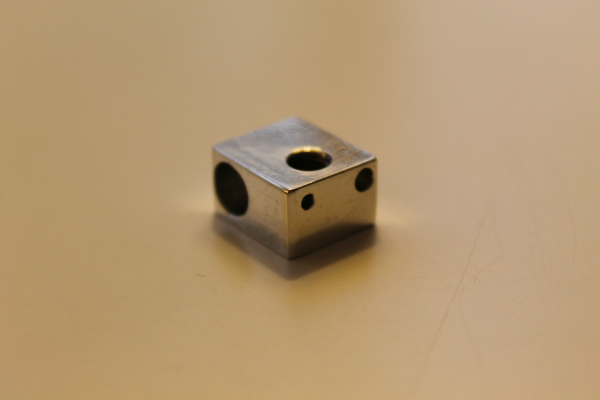

Aluminium Heater Block

The Aluminium Heater Block is precision CNC-machined and polished for a beautiful surface finish. Aluminium was also chosen as the material for the heater block due to its high thermal conductivity and high machinability. The Aluminium Heater Block is simply designed with a 6mm hole for the heater, two thermistor mounting holes, and a top-to-bottom threaded hole for the 1-Piece Stainless Steel Nozzle. The nozzle is threaded through the top and secured with an aluminium hex nut. Additional aluminium hex nuts can be used to customize the “melt-zone” length.

The heater is a 12V 30W through-hole resistor heater and the thermistor is a Semitec 100K glass bead thermistor which measures up to 300C. The heater block features an additional thermistor hole which is useful if you want to use a slightly larger standard EPCOS thermistor.

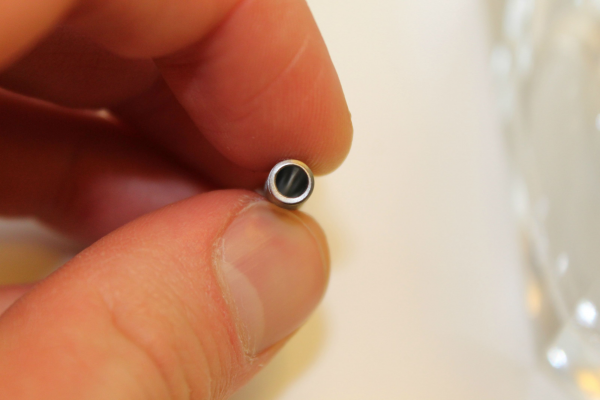

1-Piece Stainless Steel Nozzle

The 1-Piece Stainless Steel Nozzle is precision CNC-machined and polished for a beautiful surface finish. Stainless Steel was chosen as the material for the 1-piece nozzle due to its low thermal conductivity, low thermal expansion, and high strength. This design replaces the standard nozzle and heat break combination in most all-metal hot end designs with a 1-piece nozzle that eliminates all internal "melt-zone" junctions.

Internal "melt-zone" junctions are the leading cause of leaks and clogs in conventional hot end designs. Molten plastic can leak through the junction or can get stuck in the junction, decompose, and the charred remains can then flow down and clog the nozzle orifice. I have experienced these problems even with the best hot end designs. With my 1-piece nozzle/heat-break design I have completely eliminated all internal “melt-zone” junctions and thus eliminated the possibility of leaking or clogging. With several hundred hours of printing and not a single leak or clog, the empirical results speak for themselves.

In addition to the 1-piece design, I was meticulous about custom burnishing the internal pathway of the nozzle to avoid the possibility of the filament jamming. Filament jamming is the most significant problem associated with all-metal hot ends. While hot end “clogging” relates to the obstruction of the nozzle orifice, hot end “jamming” is associated with the forces involved in filament extrusion. In order to extrude filament successfully, the applied force of the extruder drive must be greater than the opposing force of friction.

Friction occurs most prominently in the “transition-zone” of the hot end where the plastic is changing from solid, to rubbery, to liquid. The plastic remains solid until it is heated above its “Glass Transition Temperature” (Tg) at which point it is rubbery until it is heated above its “Melting Temperature” (Tm) and turns to liquid. In its “rubbery” state at temperatures between Tg and Tm, the plastic turns soft and expands to form a plug in the “transition-zone”. This plug of rubbery plastic is the most significant source of friction in the hot end and is the leading cause of hot end jams.

The standard J-Head hot end design features a low friction PTFE liner that extends the full length of the “transition-zone” and greatly reduces the friction caused by this plug. However, all-metal hot ends do not have a PTFE lined “transition-zone” so friction becomes a significant issue especially when printing PLA. To overcome this problem I custom burnished the full length of the internal bore of the nozzle. The burnishing procedure polishes the internal pathway of the nozzle to a near mirror finish ensuring that it is smooth enough to eliminate jamming.

Customizing the “Melt-Zone”, “Transition-Zone”, and Thermistor Position

Introducing the "melt-zone", "transition-zone", and thermistor position as fully customizable variables is what makes the Prometheus Hot End truly unique. The "melt-zone" and "transition-zone" length are two of the most significant design features of a hot end which govern the extrusion behavior while the position of the thermistor greatly influences the thermal control of the "melt-zone". In conventional hot ends these design features remain fixed and are optimized for a specific need, which allows for very little flexibility and experimentation. The Prometheus Hot End was designed specifically as a flexible platform that would enable RepRap developers to experiment with the effects of different "melt-zone", "transition-zone", and thermistor configurations on the extrusion behavior.

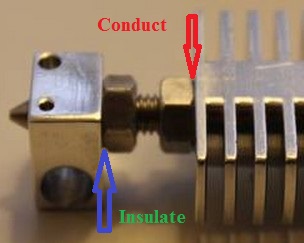

The Prometheus Hot End was purposely designed so that these three parameters could be adjusted as easily as possible. The “melt-zone” can be lengthened simply by threading additional aluminium hex nuts against the heater block. As a result, the position of the thermistor in the “melt-zone” is user-customizable based on how you position the heater block and additional hex nuts on the nozzle. The “transition-zone” is easily set by increasing the distance between the heat sink and the heater block.

The pictures below illustrate various "melt-zone", "transition-zone", and thermistor configurations that are possible with the Prometheus Hot End.

Testing

To ensure reliable precise performance the Prometheus Hot End has been tested extensively. Prometheus has printed successfully for hundreds of hours in PLA, ABS, Polycarbonate, and Nylon on several Prusa I2 printers without any leaks, clogs, or jams. I have tested the Prometheus Hot End with various high stress printing scenarios without any issues: I have printed PLA at very low extrusion rates for long periods of time; I have printed Polycarbonate at 300C above a 140C heat bed in an enclosed print chamber; I have tested rapid successive retractions and 10+ hour long prints.

I have also tested the Prometheus Hot End with the lowest quality PLA on the market. I had an old roll of neon green ESUN PLA that had been left in an uncontrolled environment throughout a very hot and humid summer in Toronto. It was wavy and swollen yet I still managed to print a decent looking Yoda head and Bhudda bust at 100 microns without any issues!

In addition to its admirable reliability, Prometheus has demonstrated great precision in the prints that it produces. I have managed to print down to 50 microns on my wobbly Prusa I2 printers! Most of my test objects were printed at 100 microns with amazing results that easily match objects I printed with my E3D hot end.

YouTube: On my YouTube Channel you can watch several videos of the Prometheus Hot End printing PLA, ABS, Polycarbonate, and Nylon 618.

Flickr: On my Flickr Photostream you can view over 300 pictures of objects that Prometheus has printed. The pictures below are a few examples of objects I have printed with Prometheus.

*Keep in mind that ALL of these objects were printed on my wobbly old Prusa I2 printers. If I can get these results on my old printers, just imagine how well Prometheus will perform on a rigid Prusa I3 or Mendel 90!

Open-Source Design

Of course, I could not have created the Prometheus Hot End without the help the RepRap community. Browsing the RepRap wiki, reading RepRap forum threads (especially the E3D Hot End thread), and discussing various hot end designs with other forum members has taught me so much about the intricacies of hot end engineering.

I hope that I can help refuel innovation within RepRap by making the technical drawings of the Prometheus Hot End available to everyone. I am releasing the Prometheus Hot End design under the Creative Commons Attribution-NonCommercial-ShareAlike 3.0 Unported License (CC BY-NC-SA 3.0). The drawings are available here on my Flickr Photostream so feel free to check them out!

I am really excited to hear from you guys! Let me know what you think

Eric

I am super excited to finally post this! Over the past several months I have been working on developing a unique hot end design that I think will encourage significant innovation within RepRap.

In short, the Prometheus Hot End is a customizable all-metal hot end that will allow users to configure the “melt-zone” length, “transition-zone” length, and thermistor position according to their needs. These parameters traditionally remain fixed in standard hot ends and allow for very little experimentation. My primary goal when designing the Prometheus Hot End was to provide RepRap users with an all-in-one flexible solution that would open up the possibility for experimentation with all of the significant hot end parameters that govern extrusion behavior. I think that this is the next step in hot end design and I believe that it will help us further our understanding of the intricacies of hot end science.

I am posting this now because I want to start a discussion about the technical facets of this design along with the possible future implications. I really want to know what you guys think about this and get your opinion on the design decisions that I made. The discussions on the E3D Hot End thread are an incredible source of information so I hope I can add to that knowledge with this thread.

I have spent the past several months on this project and I have finished designing, prototyping and testing this design. I am now about 1 or 2 weeks away from launching an Indiegogo Campaign to get this project funded so I thought that this would be a good time to start discussing the design with everyone in the RepRap community. There is a lot of information about the Prometheus Hot End in the paragraphs below. I copied several paragraphs directly from my Indiegogo campaign so I apologize if parts of it sound too much like a crowdfunding campaign pitch

Anyway, lots of interesting information and pictures below!

Introduction

As our community continues to explore new boundaries, exciting high-temperature plastics like Polycarbonate and Nylon are becoming widely available. As a result, RepRappers are replacing their old PEEK insulated J-Heads with new all-metal hot ends that are capable of printing at these high-temperatures. With a plethora of new hot end designs and the widespread success of the E3D hot end, all-metal hot ends are becoming the ubiquitous all-in-one solution for RepRap 3D printers around the world.

Despite these recent innovations, I have noticed that the new all-metal hot ends have the same static design features of a fixed "melt-zone", "transition-zone", and thermistor position. While these new designs satisfy the need for reliable high-temperature extrusion, they seem to ignore the fact that users may require different hot end parameters for their specific needs or simply for experimentation.

I started thinking about this when I was reading the E3D hot end thread on the RepRap forums and I stumbled across a post by RepRap user maddox:

Quote

maddox

...The one thing that I'm not necessarily the most stoked about, or rather that I have questions about and would love to hear some conversation on, is that the melt zone length is pre-determined, and it is whatever it is. With this hot end, you can't lengthen the melt zone if desired...

It didn't seem like anyone else had solved this problem yet so I decided that I would take on this project. Finally, after months of designing, three generations of prototypes, and hundreds of hours of printing, the Prometheus Hot End was born!

Summary

This bleeding-edge hot end design allows RepRap developers to experiment with all aspects of thermoplastic extrusion. Its actively cooled all-metal construction is very durable and can easily withstand the high temperatures required for extruding thermoplastics like Nylon and Polycarbonate, while its unique modular design enables the user to customize the "melt-zone" length, “transition-zone" length, and thermistor position according to their needs.

Design Features

- Durable, actively cooled, all-metal construction for high-temperature extrusion up to 300C (limited by thermistor reading).

- Modular design with user-variable "melt-zone" length, "transition-zone" length, and thermistor position for your specific need or experimentation.

- Precision CNC-machined parts featuring an internally burnished 1-Piece Stainless Steel Nozzle.

- 1-Piece Stainless Steel Nozzle eliminates all leaks and clogs caused by internal "melt-zone" junctions.

- Compact design conserves z-height, weighs about 30g, and fits standard extruder bodies.

- Printed successfully for hundreds of hours with PLA, ABS, PC, and Nylon 618.

- Number of hot end leaks, clogs, and jams: 0 (zero!).

Modular Design

The modular design of the Prometheus Hot End consists of three custom designed and precision CNC-machined components: the Aluminium Heat Sink, the Aluminium Heater Block, and the 1-Piece Stainless Steel Nozzle. Every component of the Prometheus Hot End was carefully engineered for optimum performance.

Aluminium Heat Sink

The Aluminium Heat Sink is precision CNC-machined and polished for a beautiful surface finish. Aluminium was chosen as the material for the heat sink due to its high thermal conductivity and high machinability. The heat sink incorporates a standard groove mount design for compatibility with standard extruder bodies. Fins are turned into the heat sink to maximize cooling and symmetrical faces are milled on each side to allow a 25mm cooling fan to be mounted directly to the heat sink. This design feature eliminates the plastic fan duct, decreases mass, and increases cooling efficiency.

The heat sink is also threaded from top to bottom to allow the 1-Piece Stainless Steel Nozzle to be threaded into the heat sink and fastened at the bottom with an aluminium hex nut. A PTFE tube is inserted from the top and meets with the nozzle in the threaded portion of the heat sink to facilitate a low friction filament path into the nozzle.

*Note: This PTFE tube is inserted in the “cold-zone” of the hot end in the actively-cooled heat sink so it is NOT subjected to high temperatures.

Aluminium Heater Block

The Aluminium Heater Block is precision CNC-machined and polished for a beautiful surface finish. Aluminium was also chosen as the material for the heater block due to its high thermal conductivity and high machinability. The Aluminium Heater Block is simply designed with a 6mm hole for the heater, two thermistor mounting holes, and a top-to-bottom threaded hole for the 1-Piece Stainless Steel Nozzle. The nozzle is threaded through the top and secured with an aluminium hex nut. Additional aluminium hex nuts can be used to customize the “melt-zone” length.

The heater is a 12V 30W through-hole resistor heater and the thermistor is a Semitec 100K glass bead thermistor which measures up to 300C. The heater block features an additional thermistor hole which is useful if you want to use a slightly larger standard EPCOS thermistor.

1-Piece Stainless Steel Nozzle

The 1-Piece Stainless Steel Nozzle is precision CNC-machined and polished for a beautiful surface finish. Stainless Steel was chosen as the material for the 1-piece nozzle due to its low thermal conductivity, low thermal expansion, and high strength. This design replaces the standard nozzle and heat break combination in most all-metal hot end designs with a 1-piece nozzle that eliminates all internal "melt-zone" junctions.

Internal "melt-zone" junctions are the leading cause of leaks and clogs in conventional hot end designs. Molten plastic can leak through the junction or can get stuck in the junction, decompose, and the charred remains can then flow down and clog the nozzle orifice. I have experienced these problems even with the best hot end designs. With my 1-piece nozzle/heat-break design I have completely eliminated all internal “melt-zone” junctions and thus eliminated the possibility of leaking or clogging. With several hundred hours of printing and not a single leak or clog, the empirical results speak for themselves.

In addition to the 1-piece design, I was meticulous about custom burnishing the internal pathway of the nozzle to avoid the possibility of the filament jamming. Filament jamming is the most significant problem associated with all-metal hot ends. While hot end “clogging” relates to the obstruction of the nozzle orifice, hot end “jamming” is associated with the forces involved in filament extrusion. In order to extrude filament successfully, the applied force of the extruder drive must be greater than the opposing force of friction.

Friction occurs most prominently in the “transition-zone” of the hot end where the plastic is changing from solid, to rubbery, to liquid. The plastic remains solid until it is heated above its “Glass Transition Temperature” (Tg) at which point it is rubbery until it is heated above its “Melting Temperature” (Tm) and turns to liquid. In its “rubbery” state at temperatures between Tg and Tm, the plastic turns soft and expands to form a plug in the “transition-zone”. This plug of rubbery plastic is the most significant source of friction in the hot end and is the leading cause of hot end jams.

The standard J-Head hot end design features a low friction PTFE liner that extends the full length of the “transition-zone” and greatly reduces the friction caused by this plug. However, all-metal hot ends do not have a PTFE lined “transition-zone” so friction becomes a significant issue especially when printing PLA. To overcome this problem I custom burnished the full length of the internal bore of the nozzle. The burnishing procedure polishes the internal pathway of the nozzle to a near mirror finish ensuring that it is smooth enough to eliminate jamming.

Customizing the “Melt-Zone”, “Transition-Zone”, and Thermistor Position

Introducing the "melt-zone", "transition-zone", and thermistor position as fully customizable variables is what makes the Prometheus Hot End truly unique. The "melt-zone" and "transition-zone" length are two of the most significant design features of a hot end which govern the extrusion behavior while the position of the thermistor greatly influences the thermal control of the "melt-zone". In conventional hot ends these design features remain fixed and are optimized for a specific need, which allows for very little flexibility and experimentation. The Prometheus Hot End was designed specifically as a flexible platform that would enable RepRap developers to experiment with the effects of different "melt-zone", "transition-zone", and thermistor configurations on the extrusion behavior.

The Prometheus Hot End was purposely designed so that these three parameters could be adjusted as easily as possible. The “melt-zone” can be lengthened simply by threading additional aluminium hex nuts against the heater block. As a result, the position of the thermistor in the “melt-zone” is user-customizable based on how you position the heater block and additional hex nuts on the nozzle. The “transition-zone” is easily set by increasing the distance between the heat sink and the heater block.

The pictures below illustrate various "melt-zone", "transition-zone", and thermistor configurations that are possible with the Prometheus Hot End.

Testing

To ensure reliable precise performance the Prometheus Hot End has been tested extensively. Prometheus has printed successfully for hundreds of hours in PLA, ABS, Polycarbonate, and Nylon on several Prusa I2 printers without any leaks, clogs, or jams. I have tested the Prometheus Hot End with various high stress printing scenarios without any issues: I have printed PLA at very low extrusion rates for long periods of time; I have printed Polycarbonate at 300C above a 140C heat bed in an enclosed print chamber; I have tested rapid successive retractions and 10+ hour long prints.

I have also tested the Prometheus Hot End with the lowest quality PLA on the market. I had an old roll of neon green ESUN PLA that had been left in an uncontrolled environment throughout a very hot and humid summer in Toronto. It was wavy and swollen yet I still managed to print a decent looking Yoda head and Bhudda bust at 100 microns without any issues!

In addition to its admirable reliability, Prometheus has demonstrated great precision in the prints that it produces. I have managed to print down to 50 microns on my wobbly Prusa I2 printers! Most of my test objects were printed at 100 microns with amazing results that easily match objects I printed with my E3D hot end.

YouTube: On my YouTube Channel you can watch several videos of the Prometheus Hot End printing PLA, ABS, Polycarbonate, and Nylon 618.

Flickr: On my Flickr Photostream you can view over 300 pictures of objects that Prometheus has printed. The pictures below are a few examples of objects I have printed with Prometheus.

*Keep in mind that ALL of these objects were printed on my wobbly old Prusa I2 printers. If I can get these results on my old printers, just imagine how well Prometheus will perform on a rigid Prusa I3 or Mendel 90!

Open-Source Design

Of course, I could not have created the Prometheus Hot End without the help the RepRap community. Browsing the RepRap wiki, reading RepRap forum threads (especially the E3D Hot End thread), and discussing various hot end designs with other forum members has taught me so much about the intricacies of hot end engineering.

I hope that I can help refuel innovation within RepRap by making the technical drawings of the Prometheus Hot End available to everyone. I am releasing the Prometheus Hot End design under the Creative Commons Attribution-NonCommercial-ShareAlike 3.0 Unported License (CC BY-NC-SA 3.0). The drawings are available here on my Flickr Photostream so feel free to check them out!

I am really excited to hear from you guys! Let me know what you think

Eric

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 05, 2014 09:27PM |

Registered: 10 years ago Posts: 99 |

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 05, 2014 09:41PM |

Admin Registered: 15 years ago Posts: 1,470 |

First off, and I want to get this out of the way because someone will inevitably bring it up, is that CC BY-NC-SA 3.0 is not an open source hardware license. See: [freedomdefined.org]

Besides that without a patent, you can't enforce the NC aspect of your license on a hardware design. The Creative Commons licenses are copyright licenses, which do not apply to hardware and mechanical designs.

Still, this is a very cool design, and I like the adjustability and compactness of it.

(emphasis mine)Quote

Open source hardware is hardware whose design is made publicly available so that anyone can study, modify, distribute, make, and sell the design or hardware based on that design.

Besides that without a patent, you can't enforce the NC aspect of your license on a hardware design. The Creative Commons licenses are copyright licenses, which do not apply to hardware and mechanical designs.

Still, this is a very cool design, and I like the adjustability and compactness of it.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 05, 2014 09:48PM |

Registered: 10 years ago Posts: 553 |

Is there a performance advantage to being able to adjust the zones? What zones settings did you do those test prints at?

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Anonymous User

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 05, 2014 09:54PM |

I like this design a little bit. The adjustable heater block is a nice feature. The stainless steel nozzle could lead to some problems, as it did with the Prusa hot end. The aluminum radiator looks like the aluhotend from JGR. I'm interested in where the ptfe liner stops and were the stainless steel starts. Do you use a mill bit to even the transition, or do you taper the ptfe? The main thing I have objection with is the allusion that this is a jam-proof hot end. There's always going to be jams somewhere.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 05, 2014 10:48PM |

Registered: 11 years ago Posts: 246 |

Quote

cfy7

Looks pretty neat.

What is the cost going to be?

Not exactly sure yet as I am still sorting out some pricing details. I am trying to make this hot end as affordable as I reasonably can so that it can be accessible rather than a luxury.

I will get back to you as soon as I have sorted this out.

Quote

NewPerfection

First off, and I want to get this out of the way because someone will inevitably bring it up, is that CC BY-NC-SA 3.0 is not an open source hardware license. See: [freedomdefined.org]

Quote

Open source hardware is hardware whose design is made publicly available so that anyone can study, modify, distribute, make, and sell the design or hardware based on that design.

(emphasis mine)

Besides that without a patent, you can't enforce the NC aspect of your license on a hardware design. The Creative Commons licenses are copyright licenses, which do not apply to hardware and mechanical designs.

Still, this is a very cool design, and I like the adjustability and compactness of it.

I understand why you brought this up and it is an important piece of information that needs to clearly understood.

I am fully aware of the details and this is precisely why I was very explicit about what licence I am going to use for this design. There have been several in depth discussions on this that occurred a few months back and there was some dissonance with regards to restrictions on open source designs. If you read those threads you can find my posts and you will understand why I chose this licence.

In brief, the NC clause does go against a part of the open source definition. I am aware of that and I am not trying to hide that. The NC clause is a way of me asking people to please respect my work by not exploiting it for their own monetary benefit. I do not plan on trying to enforce the NC restriction and if a copy shop started selling the Prometheus Hot End tomorrow there would be no way for me to stop them. I just hope that fellow RepRappers will respect my wishes and abide by the NC licence. I have spent an insane amount of time, money (lots of it) and effort on this project and selling the hot ends is the only way for me to make any of that back. If people by the Prometheus Hot End from me, they are helping account for the resources that I have already put into this project and also helping to fund my future development work. On the other hand, money eared by copy shops just goes to their owner's personal accounts. I stand behind the licence I chose and I think it is the safest way to develop "open source" hardware.

If people object to me using the specific term: "Open Source Design" I will replace it with something else...

"The drawings of the Prometheus Hot End are available for all at no cost as long as you do not use them for commercial purposes"

You can make your own, you can even make one for a friend...you just can't charge your friend for it

Quote

gmh39

Is there a performance advantage to being able to adjust the zones? What zones settings did you do those test prints at?

The "melt-zone", "transition-zone", and thermistor position are three key hot end features that are actually relatively unexplored (which is why I made this design!).

Generally speaking:

SHORT "melt-zone" = more precise and immediate extrusion

SHORT "transition-zone" = low friction in the hot end and more immediate extrusion

LONG "melt-zone" = higher extrusion rate but lower precision

LONG "transition-zone" = higher friction in the hot end and less immediate extrusion (more prone to jamming but less heat loss through the thermal break)

These are the very basic theoretical assumptions, some of which have been vaguely empirically tested.

For all of the test prints, I replicated the E3D hot end configuration of 14mm M-Z and 2-3mm T-Z just to see how the print quality compares.

The idea is that this hot end will allow us to start testing the effects of these parameters on hot end performance

Quote

techshop

I like this design a little bit. The adjustable heater block is a nice feature. The stainless steel nozzle could lead to some problems, as it did with the Prusa hot end. The aluminum radiator looks like the aluhotend from JGR. I'm interested in where the ptfe liner stops and were the stainless steel starts. Do you use a mill bit to even the transition, or do you taper the ptfe? The main thing I have objection with is the allusion that this is a jam-proof hot end. There's always going to be jams somewhere.

The SS Nozzle and the PTFE insert meet in the heat sink. The top of the SS Nozzle is tapered so that the filament passes smoothly from the PTFE into the SS nozzle. Depending on the length of the M-Z and T-Z the junction will be at different points in the heat sink though this is not a problem because the heat sink is uniformly cooled.

As for the allusion to a "jam-free" hot end, this was definitely not my intention. I was simple stating that is my empirical testing I have never had a jam (and I have done extensive testing). Of course there is always a possibility that someone else may have problems with their confirguration. That cannot be prevented. Looking at what I wrote, I see that I left it too ambiguous. What I meant was that:

In several hundred hours of extensive empirical testing, I have never experienced a jam. Of course my results may not reflect the performance of the Prometheus Hot End in every possible printer setup.

I hope this clears everything up

Eric

|

Anonymous User

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 05, 2014 11:19PM |

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 05, 2014 11:27PM |

Admin Registered: 15 years ago Posts: 1,470 |

Quote

RP Iron Man

I understand why you brought this up and it is an important piece of information that needs to clearly understood.

I am fully aware of the details and this is precisely why I was very explicit about what licence I am going to use for this design. There have been several in depth discussions on this that occurred a few months back and there was some dissonance with regards to restrictions on open source designs. If you read those threads you can find my posts and you will understand why I chose this licence.

In brief, the NC clause does go against a part of the open source definition. I am aware of that and I am not trying to hide that. The NC clause is a way of me asking people to please respect my work by not exploiting it for their own monetary benefit. I do not plan on trying to enforce the NC restriction and if a copy shop started selling the Prometheus Hot End tomorrow there would be no way for me to stop them. I just hope that fellow RepRappers will respect my wishes and abide by the NC licence. I have spent an insane amount of time, money (lots of it) and effort on this project and selling the hot ends is the only way for me to make any of that back. If people by the Prometheus Hot End from me, they are helping account for the resources that I have already put into this project and also helping to fund my future development work. On the other hand, money eared by copy shops just goes to their owner's personal accounts. I stand behind the licence I chose and I think it is the safest way to develop "open source" hardware.

If people object to me using the specific term: "Open Source Design" I will replace it with something else...

"The drawings of the Prometheus Hot End are available for all at no cost as long as you do not use them for commercial purposes"

You can make your own, you can even make one for a friend...you just can't charge your friend for it

There is some debate of course as to whether a design with an -NC clause can be called Open Source Hardware. I personally don't have a problem with -NC clauses, but just wanted to bring up the topic before someone else did. I was somewhat playing Devil's advocate to see if you had properly thought about the license, which it appears you have. There are some very interesting discussions on the topic, a particularly good read is Traumflug's (Markus Hitter) view on -NC licenses: [reprap.org] and [reprap.org]

I totally understand why you would want to use an -NC clause, and I hope you don't get crucified for it. It is most certainly your right to choose the license you feel is most appropriate.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 06, 2014 02:30AM |

Registered: 11 years ago Posts: 246 |

Quote

techshop

I apreciate the need for protecting your intellectual property, but the heat sink looks to be about 25mm long. Is the transition in the middle, the top, or the bottom? I don't know if this can be considered an "All Metal Hot End." The PTFE liner is a critical part.

In this design, the PTFE liner is not subjected to high temperatures so it is not a problem.

If you look at the first picture in my post, you will see that the 25mm cooling fan blows air over the entire heat sink along with the hex nut threaded at the bottom of the heat sink. Since the heat sink and hex nut are both aluminium, the heat that conducts from the heater block through the 1-piece SS nozzle to the heat sink is quickly dissipated throughout the heat sink which is cooled by the constant air flow produced by the fan. Consequently, the heat sink and the threaded hex nut are at temperatures only slightly above the room temperature and they constitute the "cold-zone" of the hot end. Since the junction between the PTFE liner and the top of the 1-piece nozzle is always within the heat sink, the PTFE liner remains in the "cold-zone" of the hot end and never experiences high temperatures.

To clear things up, the "transition-zone" is the distance between the bottom of the "cold-zone" and the top of the "melt-zone" (the length of visible threads)

And of course the "melt-zone" is the remaining heated portion of the hot end.

Quote

NewPerfection

There is some debate of course as to whether a design with an -NC clause can be called Open Source Hardware. I personally don't have a problem with -NC clauses, but just wanted to bring up the topic before someone else did. I was somewhat playing Devil's advocate to see if you had properly thought about the license, which it appears you have. There are some very interesting discussions on the topic, a particularly good read is Traumflug's (Markus Hitter) view on -NC licenses: [reprap.org] and [reprap.org]

I totally understand why you would want to use an -NC clause, and I hope you don't get crucified for it. It is most certainly your right to choose the license you feel is most appropriate.

Yeah, I totally agree with Markus' views on this. I first read Markus' posts on NC licenses about 6 months ago and that is when I decided that they were the most appropriate license to use in this project. Unfortunately some people cannot accept the use of any NC clause whatsoever within RepRap. I hope people reading this thread realize that I am not trying to be selfish or anything like that, I am just trying to be as "open source" (not Open Source by definition) as possible while still protecting my work from exploitation.

Eric

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 06, 2014 03:14AM |

Registered: 11 years ago Posts: 246 |

Quote

techshop

...The stainless steel nozzle could lead to some problems, as it did with the Prusa hot end...

I overlooked this before so I should respond to it now.

The reason the Prusa MKI has so many issues was not actually a particular result of the SS nozzle, but rather a consequence of the completely uncontrolled "transition-zone". If you look at the Prusa MKI design, you will see that there is no heat sink to dissipate the heat that creeps up the SS nozzle from the heater block. As a result, heat travels up the nozzle creating an incredibly long TZ. This elongated TZ increases the friction in the hot end to a point where the filament jams.

The TZ must be kept relatively short in all-metal hot ends to prevent jamming. In my design, the TZ is controlled by the actively cooled heat sink and the length can even be customized!

My design does not suffer from the same defects of the Prusa MKI and the empirical printing results illustrate its reliability.

Eric

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 06, 2014 08:22AM |

Registered: 10 years ago Posts: 1,381 |

Quote

RP Iron Man

I really want to know what you guys think about this and get your opinion on the design decisions that I made.

Your new business is going to receive a lot of reviews.

Employ some one with a degree in English, is a native English speaker, and has experience editing advertising copy.

Quote

RP Iron Man

Open-Source Design

I wouldn't call this an open source project unless you are 100% sure that it is.

I don't know what the rules are for using the RepRap logo, I haven't read the CC's, you should verify.

Quote

RP Iron Man

“Prometheus Hot End”: New Customizable All-Metal Hot End! smiling bouncing smiley[Many Pictures]

Because you use a Teflon liner, I wouldn't claim an all metal hot end, you will confuse the consumer.

You should change the title of your thread to reflect this.

Quote

RP Iron Man

Durable, actively cooled, all-metal construction for high-temperature extrusion up to 300C (limited by thermistor reading).

I wouldn't clam that the upper temperature range is limited by the thermistor.

Some one might modify your design, and mount a heater cartridge, with a thermal couple thinking your hot end can handle high heat.

Set a safe maximum upper temperature limit such that the device never fails catastrophically.

Have you tested the hot end without a fan.

Some clients will be interested if the hot end can operate without being actively cooled, and the effects of the print quality, and the potential for jamming.

Your using a Teflon liner so it might work with out the fan.

Quote

RP Iron Man

Precision CNC-machined parts featuring an internally burnished 1-Piece Stainless Steel Nozzle.

I custom burnished the full length of the internal bore of the nozzle.

The burnishing procedure polishes the internal pathway of the nozzle to a near mirror finish

Cut the nozzle in half to demonstrate to your potential clients the quality of the surface finish.

I think this is a salable feature to show case.

Are you removing (honing) or reshaping (burnishing) the metal to achieve a near mirror finish on the barrel?

Removing vs. Reshaping:

Burnishing: reshapes the peaks of the tooling marks into the trough.

Polishing: reshapes or removes material, typically the finish of the surface is dictated by the size of the medium.

Honing: removes material, and the finish of the surface is dictated by the size of the medium.

Lapping: removes material, and the finish of the surface is dictated by the size of the medium.

Quote

RP Iron Man

The burnishing procedure polishes the internal pathway of the nozzle to a near mirror finish ensuring that it is smooth enough to eliminate jamming.

I wouldn't make a subjective claim, quantify the allowable range of the surface finish on the blueprints.

Surface Finish Cross Reference Chart

[jvnw.com]

Quote

RP Iron Man

As a result, the position of the thermistor in the “melt-zone” is user-customizable based on how you position the heater block and additional hex nuts on the nozzle.

This doesn't make sense.

The thermistor position is dependent upon the position of the heater block, and the hex nuts?

Quote

RP Iron Man"

The "melt-zone" and "transition-zone" length are two of the most significant design features of a hot end which govern the extrusion behavior

Can you support this statement?

Some one might argue that the extrudate behavior is dictated by the orifice land length, orifice diameter, temperature, and extrusion rate.

Quote

RP Iron Man

The “melt-zone” can be lengthened simply by threading additional aluminium hex nuts against the heater block.

The “transition-zone” is easily set by increasing the distance between the heat sink and the heater block.

Depending on the length of the M-Z and T-Z the junction will be at different points in the heat sink

though this is not a problem because the heat sink is uniformly cooled.

I wouldn't argue that the “melt-zone” or “transition-zone” can't be modified.

But after conducting 1000's of experiments, and discovering that the results of my experiments don't always match my expectations, I'm a little skeptical.

My guess is that regardless of the filament material, your experiments will always end up with the same conclusion.

For best performance, the length of the glass transition zone will always be minimized.

I don't think (but don't know) that there is an example of a longer glass transition zone being an advantage.

"In God we trust; all others must bring data."

Can you provide empirical data to support a claim that a longer glass transition zone is preferable.

If not, then I would eliminate the adjustable thermal break, and simplify the design.

After 100's of hours of printing, share a few stories of how adjusting the thermal break, melt zone, and heat sink improved the print.

Provide before and after pictures/video.

Quote

RP Iron Man

Prometheus has printed successfully for hundreds of hours in PLA, ABS, Polycarbonate, and Nylon on several Prusa I2 printers without any leaks, clogs, or jams.

Are you implying that the client can't adjust the glass, and melt transition-zones to cause the filament to jam?

If it's not possible to recreate a jam, what do you attribute this too, this is a sell point.

From what I have read, the filament jams after a period of time of inactivity.

Given enough time the heat migrates up the filament, lengthening the glass transition zone creating a larger plug.

Does your design over come all scenarios of jamming, have you tested this.

Your videos are not in focus, it's difficult to see your hot end, don't advertise with out of focus images.

Mount the camera to the carriage that the hot end is mounted to so the hot end stays in focus.

You are selling the hot end, not the printer, or the printed object.

I would also like to see an in focus close up video of only the extrudate exiting the nozzle, (stationary, don't print an object) with different configurations of the hot end.

Demonstrate and document with a video that adjusting the different parameters has an effect on the extrudate.

HTH, and good luck with your Indiegogo campaign.

Edited 1 time(s). Last edit at 03/06/2014 08:27AM by A2.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 06, 2014 02:07PM |

Registered: 11 years ago Posts: 661 |

Quote

RP Iron Man

Yeah, I totally agree with Markus' views on this. I first read Markus' posts on NC licenses about 6 months ago and that is when I decided that they were the most appropriate license to use in this project. Unfortunately some people cannot accept the use of any NC clause whatsoever within RepRap. I hope people reading this thread realize that I am not trying to be selfish or anything like that, I am just trying to be as "open source" (not Open Source by definition) as possible while still protecting my work from exploitation.

I can respect that and agree that others within the community are taking a short view of any license other than fully open. I would though point out that protecting your investment and opening it up fully are not mutually exclusive. Fully open means more smart people may want to contribute particularly users with manufacturing expertise/capability. Plenty of folks have sustainable businesses and fully open the project. Prusa, Johnny RAMPS/RAMbO, Brian JHead and Maxbots. All of those designs are available from others but the developers seem to be more or less working at capacity. I think in the end I think an NC license is more about making the developer feel protected however false the reality may be. There is nothing you can do to protect the design. You could trademark Prometheus Hot End and protect that but your basic mechanical concept is not going to be protected by an NC or any sort of user license. I think the concept of adjustability for various conditions and materials is the key and rather than having others help build on your design will only cause them to fork your design and not fully allow you to reap one of the great benefits of open hardware.

I like it. I'll get one when you start shipping.

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 06, 2014 02:31PM |

Registered: 11 years ago Posts: 246 |

@A2

First of all, thank you very much for taking the time to write this critique. I will try to answer every one of your statements. Maybe not all in this one post, but I will work my way through them.

I am not sure what exactly you mean by this? Are you implying that the text I copied from my campaign pitch was unclear? I hope not, because I wrote all of it and looked it over before I posted it. And I am a native English speaker

I hope not, because I wrote all of it and looked it over before I posted it. And I am a native English speaker

As we discussed above, it is not Open Source strictly speaking by definition due to the NC clause. However, I think not calling it an open source project would confuse people even more as all the drawings are available for all and for any use (with the exception of commercial uses). Many developers within RepRap call their work open source even when they use the same license as I am using (CC BY-NC-SA). Examples include the E3D Hot End, Bulldog Extruder, among many many others.

I think it is safe to call it open source so long as I clearly indicate the license that I am using (everyone else does this).

My hot end design still classifies as an "all-metal hot end" because the PTFE liner in in the "cold-zone" of the hot end. Many all metal hot end designs have PTFE in the "cold-zone". All-metal hot ends are designs that do not feature PTFE in the "melt-zone" or "transition-zone". If having a plastic in the "cold-zone" disqualified a hot end design from being categorized as "all-metal" then there would be no such thing as an "all-metal hot end" as all hot ends mount to a plastic carriage and some (namely the E3D) also have plastic fan shrouds. If the Prometheus Hot End were to overheat, it would melt through the ABS carriage long before the PTFE insert melted.

I think it would confuse the customer a lot more if I said that it wasn't an all-metal hot end. It meets all of the high temperature requirements so this will not be a problem.

You are right about this detail being ambiguous. I should include that maybe it shouldn't be heated above 400C (I don't see how anybody would need to go above 400C for any reason)

This hot end cannot be used without a fan. This would lead to the heat sink overheating and would result in an uncontrolled "transition-zone" which would lead to jamming. The Prometheus Hot End is designed to be actively cooled.

Unfortunately, I do not have the tools required for this. Believe it or not, I do not have access to a machine shop. All my prototyping is done straight from the manufacturer, which is why this project has been so expensive for me. I wish I had these tools but unfortunately they are way out of my budget. If I am successful enough with the Indiegogo campaign I will be able to start investing in some small hobby CNC machines.

BTW, I do have access to a woodworking shop and I have worked with industrial CNC Routers, but of course these tools are useless for this project

--

I will answer the remaining statements shortly, I just gotta get some lunch!

Eric

First of all, thank you very much for taking the time to write this critique. I will try to answer every one of your statements. Maybe not all in this one post, but I will work my way through them.

Quote

A2

Your new business is going to receive a lot of reviews.

Employ some one with a degree in English, is a native English speaker, and has experience editing advertising copy.

I am not sure what exactly you mean by this? Are you implying that the text I copied from my campaign pitch was unclear?

I hope not, because I wrote all of it and looked it over before I posted it. And I am a native English speaker

I hope not, because I wrote all of it and looked it over before I posted it. And I am a native English speaker

Quote

A2

I wouldn't call this an open source project unless you are 100% sure that it is.

I don't know what the rules are for using the RepRap logo, I haven't read the CC's, you should verify.

As we discussed above, it is not Open Source strictly speaking by definition due to the NC clause. However, I think not calling it an open source project would confuse people even more as all the drawings are available for all and for any use (with the exception of commercial uses). Many developers within RepRap call their work open source even when they use the same license as I am using (CC BY-NC-SA). Examples include the E3D Hot End, Bulldog Extruder, among many many others.

I think it is safe to call it open source so long as I clearly indicate the license that I am using (everyone else does this).

Quote

A2

Because you use a Teflon liner, I wouldn't claim an all metal hot end, you will confuse the consumer.

You should change the title of your thread to reflect this.

My hot end design still classifies as an "all-metal hot end" because the PTFE liner in in the "cold-zone" of the hot end. Many all metal hot end designs have PTFE in the "cold-zone". All-metal hot ends are designs that do not feature PTFE in the "melt-zone" or "transition-zone". If having a plastic in the "cold-zone" disqualified a hot end design from being categorized as "all-metal" then there would be no such thing as an "all-metal hot end" as all hot ends mount to a plastic carriage and some (namely the E3D) also have plastic fan shrouds. If the Prometheus Hot End were to overheat, it would melt through the ABS carriage long before the PTFE insert melted.

I think it would confuse the customer a lot more if I said that it wasn't an all-metal hot end. It meets all of the high temperature requirements so this will not be a problem.

Quote

A2

I wouldn't clam that the upper temperature range is limited by the thermistor.

Some one might modify your design, and mount a heater cartridge, with a thermal couple thinking your hot end can handle high heat.

Set a safe maximum upper temperature limit such that the device never fails catastrophically.

You are right about this detail being ambiguous. I should include that maybe it shouldn't be heated above 400C (I don't see how anybody would need to go above 400C for any reason)

Quote

A2

Have you tested the hot end without a fan.

Some clients will be interested if the hot end can operate without being actively cooled, and the effects of the print quality, and the potential for jamming.

Your using a Teflon liner so it might work with out the fan.

This hot end cannot be used without a fan. This would lead to the heat sink overheating and would result in an uncontrolled "transition-zone" which would lead to jamming. The Prometheus Hot End is designed to be actively cooled.

Quote

A2

Cut the nozzle in half to demonstrate to your potential clients the quality of the surface finish.

I think this is a salable feature to show case.

Unfortunately, I do not have the tools required for this. Believe it or not, I do not have access to a machine shop. All my prototyping is done straight from the manufacturer, which is why this project has been so expensive for me. I wish I had these tools but unfortunately they are way out of my budget. If I am successful enough with the Indiegogo campaign I will be able to start investing in some small hobby CNC machines.

BTW, I do have access to a woodworking shop and I have worked with industrial CNC Routers, but of course these tools are useless for this project

--

I will answer the remaining statements shortly, I just gotta get some lunch!

Eric

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 06, 2014 04:23PM |

Registered: 11 years ago Posts: 246 |

Ok, I will try to answer the rest of the questions now:

I believe the polishing process that my manufacturer uses is actually a combination of honing and burnishing. The hole is drilled, then abrasively honed and burnished.

Unfortunately, precise objective surface finish data is not really possible. I just ask my manufacturer to polish the internal pathway in an economical way and the honing/burnishing process is what they came up with. If I got into specifics with requirements on exact surface texture the cost would increase significantly. The manufacturing cost are already quite high and I want to be able to offer this hot end at an affordable price.

Take a look at the several pictures I included under the "Customizing the “Melt-Zone”, “Transition-Zone”, and Thermistor Position" section of my post. These pictures illustrate the various thermistor positions within the "melt-zone" (ie. at the bottom of the MZ, at the top of the MZ, and in the middle of the MZ)

Yes, of course the parameters you listed also influence the extrudate behaviour, but the MZ, TZ and Thermistor position are still some of the most significant parameters which affect the properties of extrusion. The MZ, TZ and therm position are parameters that have not been significantly explored due to the fixed designs of conventional hot ends (which is why I came up with this design).

The control of the TZ can easily make or break an all metal hot end (as we noticed with the Prusanozzle MKI)

The MZ dictates the maximum flow rate and affects extrusion response time

There is much more to it but we really need to start experimenting before we can make any more than theoretical assumptions.

I agree that for performance, it is best to minimize the TZ. Having a variable TZ is a consequence of the modular design and I think it will be useful for us to start experimenting with the TZ length "point of failure" (when the filament jams) with various plastics. The only advantage I stated with regards to a longer TZ is that there is less heat loss through the nozzle to the heat sink (higher heater efficiency).

If I was to eliminate the adjustable thermal break, It would not be possible to adjust the MZ length or therm position and this hot end would be like every other all metal hot end on the market. I am trying to push some boundaries with this design rather than just recreate the E3D hot end.

As for the testing you are referring to, what I discussed in the "Testing" section of my post is the only testing I have done. It is really not possible for me to test every TZ, MZ and therm position configuration possible and provide videos and pictures of every modification to my parameters. Believe it or not, this is actually an incredible amount of work and I am just a 1-man operation My idea was to focus on getting this hot end design into the wild so that this kind of testing can be crowdsourced throughout the RepRap community.

My idea was to focus on getting this hot end design into the wild so that this kind of testing can be crowdsourced throughout the RepRap community.

I am not implying that the TZ cannot be lengthened to a point of failure where the filament jams. Of course this is possible, I just haven't had the opportunity to test it. In my testing (all of which with about 16mm MZ and 2-3mm TZ) I did not experience jamming with my specific printer set up. As I mentioned earlier, this does not guarantee that the hot end will never jam. I was trying to state my empirical results as clearly as possible.

My pictures are taken with a DSLR camera and I tried to make sure they are clear (I think most of them look very clear). As for the videos, I do not have a camcorder so I had to use my DSLR camera which only takes 720P video and does not focus properly during videotaping Not to mention the sound is awful. There is also no way I can mount the camera to the carriage as it is quite large and would get in the way of the print moves. Given the tools I have, I really tried my best with the pictures and videos. In fact, if you look at various hardware projects like the E3D hot end, PICO hot end, Bulldog Extruder, etc. you will see that I provided MUCH more extensive empirical results ( about 300 pics and 10 videos) than any of these projects. The PICO received almost 60 thousand on Kickstarter and they did not even show a single video of it printing!

Not to mention the sound is awful. There is also no way I can mount the camera to the carriage as it is quite large and would get in the way of the print moves. Given the tools I have, I really tried my best with the pictures and videos. In fact, if you look at various hardware projects like the E3D hot end, PICO hot end, Bulldog Extruder, etc. you will see that I provided MUCH more extensive empirical results ( about 300 pics and 10 videos) than any of these projects. The PICO received almost 60 thousand on Kickstarter and they did not even show a single video of it printing!

I am trying to be as open about this project as possible but please understand that documenting testing is A LOT of work.

Thanks!

I understand what you are saying. Initially I am going to retain the NC license. I will not have a problem keeping up the demand as I am working with a large scale manufacturer. Initially I will need all of the orders I can get. Once the finances have evened themselves out, I may consider removing the NC clause. I am not sure about this yet though. I will think on it.

BTW thank you very much for your support! I really appreciate it

--

Eric

Quote

A2

Are you removing (honing) or reshaping (burnishing) the metal to achieve a near mirror finish on the barrel?

Removing vs. Reshaping:

Burnishing: reshapes the peaks of the tooling marks into the trough.

Polishing: reshapes or removes material, typically the finish of the surface is dictated by the size of the medium.

Honing: removes material, and the finish of the surface is dictated by the size of the medium.

Lapping: removes material, and the finish of the surface is dictated by the size of the medium.

I believe the polishing process that my manufacturer uses is actually a combination of honing and burnishing. The hole is drilled, then abrasively honed and burnished.

Quote

A2

I wouldn't make a subjective claim, quantify the allowable range of the surface finish on the blueprints.

Surface Finish Cross Reference Chart

[jvnw.com]

Unfortunately, precise objective surface finish data is not really possible. I just ask my manufacturer to polish the internal pathway in an economical way and the honing/burnishing process is what they came up with. If I got into specifics with requirements on exact surface texture the cost would increase significantly. The manufacturing cost are already quite high and I want to be able to offer this hot end at an affordable price.

Quote

A2

This doesn't make sense.

The thermistor position is dependent upon the position of the heater block, and the hex nuts?

Take a look at the several pictures I included under the "Customizing the “Melt-Zone”, “Transition-Zone”, and Thermistor Position" section of my post. These pictures illustrate the various thermistor positions within the "melt-zone" (ie. at the bottom of the MZ, at the top of the MZ, and in the middle of the MZ)

Quote

A2

Can you support this statement?

Some one might argue that the extrudate behavior is dictated by the orifice land length, orifice diameter, temperature, and extrusion rate.

Yes, of course the parameters you listed also influence the extrudate behaviour, but the MZ, TZ and Thermistor position are still some of the most significant parameters which affect the properties of extrusion. The MZ, TZ and therm position are parameters that have not been significantly explored due to the fixed designs of conventional hot ends (which is why I came up with this design).

The control of the TZ can easily make or break an all metal hot end (as we noticed with the Prusanozzle MKI)

The MZ dictates the maximum flow rate and affects extrusion response time

There is much more to it but we really need to start experimenting before we can make any more than theoretical assumptions.

Quote

A2

I wouldn't argue that the “melt-zone” or “transition-zone” can't be modified.

But after conducting 1000's of experiments, and discovering that the results of my experiments don't always match my expectations, I'm a little skeptical.

My guess is that regardless of the filament material, your experiments will always end up with the same conclusion.

For best performance, the length of the glass transition zone will always be minimized.

I don't think (but don't know) that there is an example of a longer glass transition zone being an advantage.

"In God we trust; all others must bring data."

Can you provide empirical data to support a claim that a longer glass transition zone is preferable.

If not, then I would eliminate the adjustable thermal break, and simplify the design.

After 100's of hours of printing, share a few stories of how adjusting the thermal break, melt zone, and heat sink improved the print.

Provide before and after pictures/video.

I agree that for performance, it is best to minimize the TZ. Having a variable TZ is a consequence of the modular design and I think it will be useful for us to start experimenting with the TZ length "point of failure" (when the filament jams) with various plastics. The only advantage I stated with regards to a longer TZ is that there is less heat loss through the nozzle to the heat sink (higher heater efficiency).

If I was to eliminate the adjustable thermal break, It would not be possible to adjust the MZ length or therm position and this hot end would be like every other all metal hot end on the market. I am trying to push some boundaries with this design rather than just recreate the E3D hot end.

As for the testing you are referring to, what I discussed in the "Testing" section of my post is the only testing I have done. It is really not possible for me to test every TZ, MZ and therm position configuration possible and provide videos and pictures of every modification to my parameters. Believe it or not, this is actually an incredible amount of work and I am just a 1-man operation

My idea was to focus on getting this hot end design into the wild so that this kind of testing can be crowdsourced throughout the RepRap community.

My idea was to focus on getting this hot end design into the wild so that this kind of testing can be crowdsourced throughout the RepRap community. Quote

A2

Are you implying that the client can't adjust the glass, and melt transition-zones to cause the filament to jam?

If it's not possible to recreate a jam, what do you attribute this too, this is a sell point.

From what I have read, the filament jams after a period of time of inactivity.

Given enough time the heat migrates up the filament, lengthening the glass transition zone creating a larger plug.

Does your design over come all scenarios of jamming, have you tested this.

Your videos are not in focus, it's difficult to see your hot end, don't advertise with out of focus images.

Mount the camera to the carriage that the hot end is mounted to so the hot end stays in focus.

You are selling the hot end, not the printer, or the printed object.

I would also like to see an in focus close up video of only the extrudate exiting the nozzle, (stationary, don't print an object) with different configurations of the hot end.

Demonstrate and document with a video that adjusting the different parameters has an effect on the extrudate.

I am not implying that the TZ cannot be lengthened to a point of failure where the filament jams. Of course this is possible, I just haven't had the opportunity to test it. In my testing (all of which with about 16mm MZ and 2-3mm TZ) I did not experience jamming with my specific printer set up. As I mentioned earlier, this does not guarantee that the hot end will never jam. I was trying to state my empirical results as clearly as possible.

My pictures are taken with a DSLR camera and I tried to make sure they are clear (I think most of them look very clear). As for the videos, I do not have a camcorder so I had to use my DSLR camera which only takes 720P video and does not focus properly during videotaping

Not to mention the sound is awful. There is also no way I can mount the camera to the carriage as it is quite large and would get in the way of the print moves. Given the tools I have, I really tried my best with the pictures and videos. In fact, if you look at various hardware projects like the E3D hot end, PICO hot end, Bulldog Extruder, etc. you will see that I provided MUCH more extensive empirical results ( about 300 pics and 10 videos) than any of these projects. The PICO received almost 60 thousand on Kickstarter and they did not even show a single video of it printing!

Not to mention the sound is awful. There is also no way I can mount the camera to the carriage as it is quite large and would get in the way of the print moves. Given the tools I have, I really tried my best with the pictures and videos. In fact, if you look at various hardware projects like the E3D hot end, PICO hot end, Bulldog Extruder, etc. you will see that I provided MUCH more extensive empirical results ( about 300 pics and 10 videos) than any of these projects. The PICO received almost 60 thousand on Kickstarter and they did not even show a single video of it printing! I am trying to be as open about this project as possible but please understand that documenting testing is A LOT of work.

Quote

A2

HTH, and good luck with your Indiegogo campaign.

Thanks!

Quote

vegasloki

I can respect that and agree that others within the community are taking a short view of any license other than fully open. I would though point out that protecting your investment and opening it up fully are not mutually exclusive. Fully open means more smart people may want to contribute particularly users with manufacturing expertise/capability. Plenty of folks have sustainable businesses and fully open the project. Prusa, Johnny RAMPS/RAMbO, Brian JHead and Maxbots. All of those designs are available from others but the developers seem to be more or less working at capacity. I think in the end I think an NC license is more about making the developer feel protected however false the reality may be. There is nothing you can do to protect the design. You could trademark Prometheus Hot End and protect that but your basic mechanical concept is not going to be protected by an NC or any sort of user license. I think the concept of adjustability for various conditions and materials is the key and rather than having others help build on your design will only cause them to fork your design and not fully allow you to reap one of the great benefits of open hardware.

I like it. I'll get one when you start shipping.

I understand what you are saying. Initially I am going to retain the NC license. I will not have a problem keeping up the demand as I am working with a large scale manufacturer. Initially I will need all of the orders I can get. Once the finances have evened themselves out, I may consider removing the NC clause. I am not sure about this yet though. I will think on it.

BTW thank you very much for your support! I really appreciate it

--

Eric

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 06, 2014 05:38PM |

Registered: 11 years ago Posts: 246 |

Quote

A2

Some one might argue that the extrudate behavior is dictated by the orifice land length, orifice diameter, temperature, and extrusion rate.

I forgot to mention that I was also very careful about designing the Orifice length and Orifice landing diameter of the nozzle.

If you look at the technical drawings, I designed the orifice length to be 1mm (for a 0.4mm diameter orifice) as this has been determined through Sanjay's work (and the work of others) to be the approximate optimal orifice length for a 0.4mm nozzle. Like many others, I have observed that this orifice length minimizes the ooze while not increasing the extrusion force significantly.

As for the orifice landing diameter. My decision to have a 1.2mm landing is also largely based off the empirical results of the E3D hot end. This 1.2mm landing diameter greatly helps ensure that the top infill layers are smooth and uniform especially with very wide infill traces.

Eric

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 06, 2014 06:33PM |

Admin Registered: 11 years ago Posts: 3,096 |

I think your hotend is very interesting.

Not going to criticize anything, I see others do that enough already so I hope you take it as constructive criticism and maybe one day I'll be able to order your hotend!

I would like a 1.75mm version please, and one that prints PLA well, this is mandatory! I like to print my 1.75mm PLA with a 0.5mm nozzle. If you are able to provide me with a similar hotend that would make me a happy user! And what would be even better, if it has good shipping cost to the Netherlands

Good luck!

- Marinus

Not going to criticize anything, I see others do that enough already so I hope you take it as constructive criticism and maybe one day I'll be able to order your hotend!

I would like a 1.75mm version please, and one that prints PLA well, this is mandatory! I like to print my 1.75mm PLA with a 0.5mm nozzle. If you are able to provide me with a similar hotend that would make me a happy user! And what would be even better, if it has good shipping cost to the Netherlands

Good luck!

- Marinus

Re: “Prometheus Hot End”: New Customizable All-Metal Hot End!  [Many Pictures] [Many Pictures] March 06, 2014 07:57PM |

Registered: 11 years ago Posts: 246 |

Quote

Ohmarinus

I think your hotend is very interesting.

Not going to criticize anything, I see others do that enough already so I hope you take it as constructive criticism and maybe one day I'll be able to order your hotend!

I would like a 1.75mm version please, and one that prints PLA well, this is mandatory! I like to print my 1.75mm PLA with a 0.5mm nozzle. If you are able to provide me with a similar hotend that would make me a happy user! And what would be even better, if it has good shipping cost to the Netherlands

Good luck!

- Marinus

Thanks Marinus!