Aluminium linear rails instead of steel rods: your (negative) experiences?

Posted by cristian

|

Aluminium linear rails instead of steel rods: your (negative) experiences? May 11, 2015 08:25PM |

Registered: 9 years ago Posts: 344 |

I would like to design yet another printer model with standard printing dimensions (200x200 mm), but without using steel rods nor linear ball bearings. There are really many designs out there, and most of them use steel rods to drive the moving parts, while very few exploit aluminium profiles for the job (not talking about the structure of the printer, of course). It is obvious that stainless steel lasts much longer and is sturdier than aluminium, but I would like to know your experience in this respect, in particular negative ones if you have some. So here are some questions.

If you ever used aluminium rails to drive the moving parts, what problems have you encountered?

Would you strongly advise (against) some particular profile types about cost, insufficient sturdiness, wear, ecc.? Is V-slot (or some other) a "must" or any (straight) aluminium profile can work reasonably well, all things considered?

Cristian

If you ever used aluminium rails to drive the moving parts, what problems have you encountered?

Would you strongly advise (against) some particular profile types about cost, insufficient sturdiness, wear, ecc.? Is V-slot (or some other) a "must" or any (straight) aluminium profile can work reasonably well, all things considered?

Cristian

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 12, 2015 08:41AM |

Registered: 9 years ago Posts: 158 |

I had good results using V slot. Easy to assemble and set up. Smooth running with no wobble. Can be easily tensioned between feather light operation and rock solid stability.

I'd think most extrusion will be (reasonably) straight. Especially over the distance of 200mm you mention.

I've seen some designs that use a slider or wheels in regular (square slot) profile but my reservation is that putting a wheel in a square edged slot will mean that either the wheel binds in the slot or the wheel has clearance to wobble around the slot.

The virtue of that 90º 'v'slot is that the wheel is self centering on the rail and can be clamped tight on there but still free to roll.

-a

edit:typo

Edited 1 time(s). Last edit at 05/12/2015 08:49AM by alan richard.

I'd think most extrusion will be (reasonably) straight. Especially over the distance of 200mm you mention.

I've seen some designs that use a slider or wheels in regular (square slot) profile but my reservation is that putting a wheel in a square edged slot will mean that either the wheel binds in the slot or the wheel has clearance to wobble around the slot.

The virtue of that 90º 'v'slot is that the wheel is self centering on the rail and can be clamped tight on there but still free to roll.

-a

edit:typo

Edited 1 time(s). Last edit at 05/12/2015 08:49AM by alan richard.

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 12, 2015 09:20AM |

Registered: 10 years ago Posts: 869 |

It's obvious that you haven't looked into how obvious it is (or isn't). Without stating all sorts of things like dimensions, profile, alloy, wear surfaces, type of wear (linear bearing, bushing, wheel, etc) it's not at all obvious. In many cases aluminum may be a better choice than stainless steel. It can be lighter, cheaper, easier to machine, and harder surface than stainless steel. Stainless steels advantage is it's corrosion resistance which as long as you take care of your printer, really isn't a concern unless you're printing next to an ocean.Quote

cristian

It is obvious that stainless steel lasts much longer and is sturdier than aluminium

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 12, 2015 11:06AM |

Registered: 11 years ago Posts: 335 |

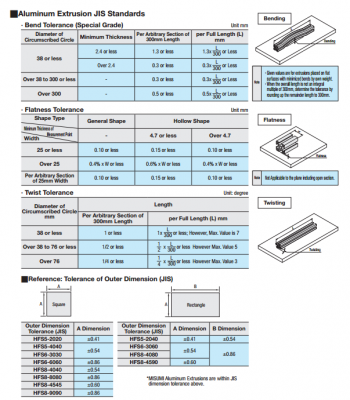

Extrusions are not designed to be straight, and the tolerances are really ugly. Misumi allows up to 4mm of bend in addition to seven degrees of twist per 1m length of extrusion. In practice you will probably never receive a piece that bad.

I'm not a fan of using extrusion for linear motion because linear shaft and bearings are so cheap. Why bother with extrusion when the correct components are easily available?

Wheels on extrusion isn't particularly robust since debris can easily get under the wheel. This isn't a huge problem for 3d printing, but linear bearings at least come with wipers.

I'm not a fan of using extrusion for linear motion because linear shaft and bearings are so cheap. Why bother with extrusion when the correct components are easily available?

Wheels on extrusion isn't particularly robust since debris can easily get under the wheel. This isn't a huge problem for 3d printing, but linear bearings at least come with wipers.

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 12, 2015 12:52PM |

Registered: 10 years ago Posts: 869 |

Short answer is reduced cost (hopefully) and complexity. Using extrusion allows you to reduce your part count. If you can use extrusion that is Good Enough™ for both structural support and linear movement, you kill two birds with one stone. No it might not be the greatest and most precise, but for many the trade offs or limitations are acceptable.Quote

691175002

Why bother with extrusion when the correct components are easily available?

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 12, 2015 02:44PM |

Registered: 10 years ago Posts: 439 |

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 12, 2015 03:52PM |

Registered: 11 years ago Posts: 471 |

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 12, 2015 05:17PM |

Registered: 11 years ago Posts: 5,780 |

Quote

cdru

Short answer is reduced cost (hopefully) and complexity. Using extrusion allows you to reduce your part count. If you can use extrusion that is Good Enough™ for both structural support and linear movement, you kill two birds with one stone. No it might not be the greatest and most precise, but for many the trade offs or limitations are acceptable.

If you were trying to design a printer to be sold as a kit and you were competing with 1000 other kit makers on price, I could understand your motivation to shave a few dollars out of the cost of the machine. If you're building a machine for yourself, presumably there's something you want to do that isn't readily available. Is cost the only factor driving the DIY impulse? Kits are only $300. You're going to have a hard time building for less than that yourself and you'll end up spending many hours chasing ever cheaper parts and figuring out how to incorporate them. So if you're building a machine yourself, why not do it right instead of cheap?

Cheap solutions invariably lead to a lot of time spent trying to coax the machine into producing any print, let alone high quality prints. If you look at these forums and see the problems people keep reporting over and over it almost always comes down to just a couple fundamental issues - a nonrigid structure (including frame and guide rails) resulting from using cheap materials (mdf, acrylic sheet, laser cut plywood, etc.) and/or poor construction and imprecise parts (such as threaded rods) used where precision parts (such as lead screws) should be used.

If you're going to build a machine yourself, don't copy the mistakes made by others who make cheap printers. Look at industrial machines and try to understand why they work as well as they do and emulate them. Instead of searching for ways to make the machine cheesier, spend the time trying to source quality parts at reasonable cost- check your local scrap yards, search ebay (surprise! you can get quality stuff on ebay if you know what to look for), etc. And yes, low cost sources for quality parts will cost more than low cost sources for cheesy parts. You're going to have to spend some money if you want a quality result, but you don't have to spend it all at once.

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 13, 2015 12:31AM |

Registered: 9 years ago Posts: 396 |

Quote

cdru

Short answer is reduced cost (hopefully) and complexity. Using extrusion allows you to reduce your part count. If you can use extrusion that is Good Enough™ for both structural support and linear movement, you kill two birds with one stone. No it might not be the greatest and most precise, but for many the trade offs or limitations are acceptable.Quote

691175002

Why bother with extrusion when the correct components are easily available?

using extrusion does not reduce parts count at all.

one rod, two linear bearings.... three parts, compared to one extrusion, mounting hardware, and roller mechanism which, if printed parts involved, already will be more complicated.

However, cost is a factor.

Good linear rod should cost around $12 each. good linear bearings are expensive, so maybe some igus bushings or printed delrin or nylon.

if you are heart set on Al, consider standard square Al tubing but turn it such that the profile looks like a diamond, so pointy corner facing up. Then engineer a roller bearing using delrin bearings. the change in profile direction provides measurable strength and flatness.

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 13, 2015 09:57AM |

Registered: 10 years ago Posts: 869 |

It's going to depend very much on the what design you're using and how exactly you count things. How are things fastened? Number of fasteners? Are standoffs used or are the rods/extrusion an integral component of the overall frame?Quote

thetazzbot

using extrusion does not reduce parts count at all.

one rod, two linear bearings.... three parts, compared to one extrusion, mounting hardware, and roller mechanism which, if printed parts involved, already will be more complicated.

For instance, lets compare a Rostock with a Cherry Pi III

In common with both designs is that there is a printed carriage that moves in a vertical direction and a printed top and bottom bracket. They are different between models, but both models utilize them to their own advantage. We're only looking at what is directly a component of the linear movement constraint, not belts, motors, pulleys, etc or other parts that attach to brackets or the carriages that serve functions other than linear movement.

The Rostock has:

2 linear rods

2 linear bearings

2 zip ties to attach the linear bearings to the carriage

10 screws (4 top bracket, 6 bottom)

10 washers (4 top bracket, 6 bottom)

10 nuts (4 top bracket, 6 bottom)

Total: 36

The Cherry Pi III has:

1 piece extrusion

3 screws (1 top bracket, 2 bottom bracket)

3 washers (1 top bracket, 2 bottom bracket)

2 t-nuts (bottom bracket)

3 V-wheel kits (each has 6 individual parts so 18 parts total)

3 screws to attach v-wheels

Total: 30 parts (15 if you count the kits as a single part)

Now I'm sure that an example can be found that reverses which one has the lower part count. And either design I'm sure could be made that has fewer nuts, screws, and washers. But it's just an example where extrusion DOES have fewer parts that make up the assembly. Plus I'm willing to venture that the overall rigidity of the Cherry Pi III with extrusion is greater than the Rostock design.

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 13, 2015 10:34AM |

Registered: 10 years ago Posts: 869 |

I agree with you mostly with what you wrote (including what I didn't include in the quote). And that's what I've done with my personal printer when I made my Mendel90 (although I must admit some of my initial attempts at "improvements" weren't so much).Quote

the_digital_dentist

If you were trying to design a printer to be sold as a kit and you were competing with 1000 other kit makers on price, I could understand your motivation to shave a few dollars out of the cost of the machine. If you're building a machine for yourself, presumably there's something you want to do that isn't readily available. Is cost the only factor driving the DIY impulse? Kits are only $300. You're going to have a hard time building for less than that yourself and you'll end up spending many hours chasing ever cheaper parts and figuring out how to incorporate them. So if you're building a machine yourself, why not do it right instead of cheap?

But I've also seen outstanding prints performed by printers that use extrusion. SeeMeCNC is a semi-local company to me and have very strong presence at the Midwest RepRap Festival with their commercial delta printers, all of which use extrusion in their designs. Honestly I'm not sure that their designs would be improved upon much if they switched to linear rail or rod arrangement. I think I would have very little standing to go up to one of their designers or engineers and tell them that they are doing it wrong and that they should use the "right" part for linear movement.

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 13, 2015 12:48PM |

Registered: 10 years ago Posts: 1,401 |

I'm an engineer and Industrial designer, the problem is not the material chosen but using it wrongly.

You can have a great 500 dollars printer or a piece of junk 4000 dollars one. Linear shafts and extrusion rails have their pros and cons, but as long as you design around their limitations and exploit its benefits, you wil allways end up having a good design.

Excuse my English.

You can have a great 500 dollars printer or a piece of junk 4000 dollars one. Linear shafts and extrusion rails have their pros and cons, but as long as you design around their limitations and exploit its benefits, you wil allways end up having a good design.

Excuse my English.

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 13, 2015 05:28PM |

Registered: 9 years ago Posts: 978 |

There's only one reason why good has to be expensive and cheap has to be bad... that no-one has (so far) found a way to do it cheap *and* good. So I applaud @cristian for looking in this direction... I think it's bad engineering to just accept the status quo rather than to innovate and find a better way (or even a just-as-good way) for a lower price.

Cheaper is a worthy goal, so long the quality of the final product is still "good enough". It can change the entire paradigm (e.g. Henry Ford producing cheap cars).

Cheaper is a worthy goal, so long the quality of the final product is still "good enough". It can change the entire paradigm (e.g. Henry Ford producing cheap cars).

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 13, 2015 11:39PM |

Registered: 9 years ago Posts: 344 |

I would like to thank you all for your replies, I read your experiences, advices and comments (and encouragements  ) with great interest. You answered many of my unwritten questions and gave me a lot to think about, so that new questions arise.

) with great interest. You answered many of my unwritten questions and gave me a lot to think about, so that new questions arise.

As I think many other newbies, I am torn between having a good printer, saving money and having fun in creating and building something "new". The dilemma is always the same: one would like cheap&good, but this is not that easy. And at the same time one would like to contribute with "improvements" of what is out there, and this is even more difficult since probably all the mistakes have been made and fixed already and our improvements represent just a naive, unaware repetition of those mistakes. Reality is complex, many needs/constraints have to be taken into account and compromises are unavoidable (if one has a limited budget) in relation to printing volume, speed, precision (repeatability), accuracy, local availability and cost of parts and possibility to machine them on one's own, filaments that may be used...

And I am also aware of the 1000 printer models and kits that have already been developed, not only the cheap ones: I considered many of them, and still I have not found the model that would fit perfectly my needs, although some printers are not that far.

My concern is: how can I optimize my design and purchases to obtain the highest printing "quality" with my budget? What I mean is that all the components should be coherent with the desired printing quality, neither too crappy nor too "good" (unless they are good and cheapest).

To come back to the topic, after reading some of your replies I tried to get a sense of the precision and robustness of cheap aluminum profiles from a local hardware store. Robustness is indeed quite poor, they bend very easily but I agree that this may be overcome with proper countermeasures. However they are not straight at all, with deviations of more than 0.5mm every 10cm in length from what I can see with rudimentary measures, not to mention possible twist that I don't know how to measure. This is enough to kill the first layer of a print with a standard 0.5mm nozzle on a 200x200mm bed. So, even if it has to be aluminum rail, it will not be the cheap one from the local hardware store, I guess.

But here is another question then: how do you measure the precision of parts, if the vendor is not providing already this information? Measuring distances and diameters is easy in most of the cases, with a good caliper. But what if I wanted to measure (and I mean really measure, not just get a sense of) the tolerance of the straightness of an aluminum profile or of a stainless steel smooth rod, how may I do that? What about the twist? I am aware this is probably an extreme newbie question, please be patient .

.

One obvious reply would be to buy from vendors that give information about tolerances. But then the question remains if I want to check the quality of what I bought.

However, thanks to your replies I think I almost made up my mind about the kind of printer I want to build. I started my experience about one year ago with a low-budget, young printer, that allowed me to experiment a lot and become aware of *all* the possible problems a 3d printer may ever have. I think now I am ready to value a more reliable (and possibly expensive) one.

Of course this does not mean I will desist from having fun, i.e. looking for cheap&good -- I have some new ideas (naive mistakes?) to try already and some other questions to pose in a new thread -- it just means that I will do while building some not-so-cheap*but*good printer too (and I will pose other questions about this as well...).

Thank you all again and please continue this interesting discussion, since I am still undecided between aluminum only structure (I love this metal) and classic structure with SS smooth rods.

) with great interest. You answered many of my unwritten questions and gave me a lot to think about, so that new questions arise.

) with great interest. You answered many of my unwritten questions and gave me a lot to think about, so that new questions arise.As I think many other newbies, I am torn between having a good printer, saving money and having fun in creating and building something "new". The dilemma is always the same: one would like cheap&good, but this is not that easy. And at the same time one would like to contribute with "improvements" of what is out there, and this is even more difficult since probably all the mistakes have been made and fixed already and our improvements represent just a naive, unaware repetition of those mistakes. Reality is complex, many needs/constraints have to be taken into account and compromises are unavoidable (if one has a limited budget) in relation to printing volume, speed, precision (repeatability), accuracy, local availability and cost of parts and possibility to machine them on one's own, filaments that may be used...

And I am also aware of the 1000 printer models and kits that have already been developed, not only the cheap ones: I considered many of them, and still I have not found the model that would fit perfectly my needs, although some printers are not that far.

My concern is: how can I optimize my design and purchases to obtain the highest printing "quality" with my budget? What I mean is that all the components should be coherent with the desired printing quality, neither too crappy nor too "good" (unless they are good and cheapest).

To come back to the topic, after reading some of your replies I tried to get a sense of the precision and robustness of cheap aluminum profiles from a local hardware store. Robustness is indeed quite poor, they bend very easily but I agree that this may be overcome with proper countermeasures. However they are not straight at all, with deviations of more than 0.5mm every 10cm in length from what I can see with rudimentary measures, not to mention possible twist that I don't know how to measure. This is enough to kill the first layer of a print with a standard 0.5mm nozzle on a 200x200mm bed. So, even if it has to be aluminum rail, it will not be the cheap one from the local hardware store, I guess.

But here is another question then: how do you measure the precision of parts, if the vendor is not providing already this information? Measuring distances and diameters is easy in most of the cases, with a good caliper. But what if I wanted to measure (and I mean really measure, not just get a sense of) the tolerance of the straightness of an aluminum profile or of a stainless steel smooth rod, how may I do that? What about the twist? I am aware this is probably an extreme newbie question, please be patient

.

.One obvious reply would be to buy from vendors that give information about tolerances. But then the question remains if I want to check the quality of what I bought.

However, thanks to your replies I think I almost made up my mind about the kind of printer I want to build. I started my experience about one year ago with a low-budget, young printer, that allowed me to experiment a lot and become aware of *all* the possible problems a 3d printer may ever have. I think now I am ready to value a more reliable (and possibly expensive) one.

Of course this does not mean I will desist from having fun, i.e. looking for cheap&good -- I have some new ideas (naive mistakes?) to try already and some other questions to pose in a new thread -- it just means that I will do while building some not-so-cheap*but*good printer too (and I will pose other questions about this as well...).

Thank you all again and please continue this interesting discussion, since I am still undecided between aluminum only structure (I love this metal) and classic structure with SS smooth rods.

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 14, 2015 01:02AM |

Registered: 9 years ago Posts: 978 |

Yeah.... cheap, good, soon --- choose any two.

Another question is what you're prepared to spend on the process... Are you happy to throw away a $100 part because an experiment failed? How about a $20 part? How about a year's work? A month's work? If you're not willing to throw those away, how crappy a printer are you prepared to put up with?

And what is it you want at the end of the process? A 3D printer? A 3D printed object of some specified quality? Some skills? Some knowledge? Applause? Wealth? Kim Kardashian?

And is there a more efficient (in terms of cheap, good, soon) way to get what you want than trying to straighten out a crooked aluminium extrusion??

Finally, remember you don't really own something until you've put some blood, some sweat, and some tears into it. Do you really want to own a 3D printer?

Another question is what you're prepared to spend on the process... Are you happy to throw away a $100 part because an experiment failed? How about a $20 part? How about a year's work? A month's work? If you're not willing to throw those away, how crappy a printer are you prepared to put up with?

And what is it you want at the end of the process? A 3D printer? A 3D printed object of some specified quality? Some skills? Some knowledge? Applause? Wealth? Kim Kardashian?

And is there a more efficient (in terms of cheap, good, soon) way to get what you want than trying to straighten out a crooked aluminium extrusion??

Finally, remember you don't really own something until you've put some blood, some sweat, and some tears into it. Do you really want to own a 3D printer?

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 14, 2015 06:36AM |

Registered: 13 years ago Posts: 268 |

What an awesome question, and one that far too few people ask. Regardless of manufacturer spec its always a good idea to verify. The "right" way to measure the things you ask about would be a to start with a known flat plane, like a granite surface plate. You then use a dial indicator on a stand and check spots on the bar to see where it is. From these point measurements you can see what is twisted or warped and by how much. Please note for twist and similar measurements you need to specify over what length or the measurement is meaningless. There are other tools that will help quantity specifics, but a surface plate and dial indicator is a great multi purpose tool that will serve for far more than measuring one thing.

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 14, 2015 07:57AM |

Registered: 11 years ago Posts: 5,780 |

If you're getting into 3D printing thinking you can just push a button and receive your part you've been drinking too much of the marketing dept kool-aid. You're going to spend a lot of time messing around no matter what. You can spend that time trying to get your machine working each time you try to print, or you can put the time (and a few more $) in up-front to make the machine more reliable so you don't have to spend so much time teasing prints from it. Most people don't know what problems need to be fixed until they get a printer and find out all the things that can go wrong. They show up at forums like this after they get a printer and start having problems. It would be better to look at these forums before buying/building a printer/kit and pay attention to the problems people report and use that to inform your decision. For most that would probably inform a decision no to bother...

Back in the early days of computing, people put up with a lot of horrible/stupid stuff because there were few alternatives. Eventually, 3D printing will get sorted out, too, and the garbage will disappear. It's happening already- you don't see many machines made using laser cut plywood any more, so clearly people are learning.

You don't have to throw away parts. Use them in the next printer or other project, or sell them to someone else who is working on a printer. I pulled 1/2" guide rails out of my machine along with their bearings, mounts, idler pulleys, belts, motor mounts, etc. and gave them to someone at the makerspace who is planning to use them to make another printer. My unused 8020 is waiting for my next project- that stuff is so useful you'll never throw it away, even pieces that are a few cm long can be put to good use.

Join a makerspace- your old parts can go into someone else's project, and their's can go into yours. I got a lot of parts for my printer from the hack-rack at the Milwaukee Makerspace.

Back in the early days of computing, people put up with a lot of horrible/stupid stuff because there were few alternatives. Eventually, 3D printing will get sorted out, too, and the garbage will disappear. It's happening already- you don't see many machines made using laser cut plywood any more, so clearly people are learning.

You don't have to throw away parts. Use them in the next printer or other project, or sell them to someone else who is working on a printer. I pulled 1/2" guide rails out of my machine along with their bearings, mounts, idler pulleys, belts, motor mounts, etc. and gave them to someone at the makerspace who is planning to use them to make another printer. My unused 8020 is waiting for my next project- that stuff is so useful you'll never throw it away, even pieces that are a few cm long can be put to good use.

Join a makerspace- your old parts can go into someone else's project, and their's can go into yours. I got a lot of parts for my printer from the hack-rack at the Milwaukee Makerspace.

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 14, 2015 09:20AM |

Registered: 10 years ago Posts: 869 |

If you want an actual number for what the tolerance is, I can't help you any more than what koko76 said with a dial indicator and a surface plate. But if you're asking these questions I'm going to guess you don't already have a surface plate, nor do you want to spend the chunk of change to get one.Quote

cristian

But here is another question then: how do you measure the precision of parts, if the vendor is not providing already this information? Measuring distances and diameters is easy in most of the cases, with a good caliper. But what if I wanted to measure (and I mean really measure, not just get a sense of) the tolerance of the straightness of an aluminum profile or of a stainless steel smooth rod, how may I do that? What about the twist?

Find a thick, solid, smooth flat surface. A laminated counter top or desk likely will work. Set the extrusion or rod on it and shine a line on the backside. Look underneath for any light that shines through. Rotate or roll it and see if that changes. Ideally you don't want any light to shine through, indicating that the piece is at least as flat as the surface it's on. If light shines through on one side but not 180 degrees, then it's likely slightly bent. If light shines through the same on all sides, then your surface isn't really flat and you should try somewhere else. If you can push on one edge or corner of the extrusion and it rocks even a little, than it's warped/twisted.

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 14, 2015 10:40AM |

Registered: 11 years ago Posts: 335 |

Here is Misumi's data. The pictures show how each tolerance is measured. I'd use a feeler gauge on a glass table, I suspect most countertops/desks will be less flat than the extrusion. Technically a dial gauge will measure the width/height of the extrusion as well as its straightness so you may overestimate the error.

As I mentioned, the official tolerances are awful but in practice they seem to be pretty damn straight. I've put short pieces on a surface plate before and they were within a few thou.

Edited 2 time(s). Last edit at 05/14/2015 10:42AM by 691175002.

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 14, 2015 12:29PM |

Registered: 13 years ago Posts: 268 |

Quote

691175002

Technically a dial gauge will measure the width/height of the extrusion as well as its straightness so you may overestimate the error.

Constrain one end of the part up on a parallel on the plate. Zero the indicator resting on the part at that end. Move the indicator across the surface plate touching the part. Take readings, interpret. No measurement of width or height at all.

|

Re: Aluminium linear rails instead of steel rods: your (negative) experiences? May 14, 2015 01:22PM |

Registered: 9 years ago Posts: 344 |

Thank you all again, the read has been very instructive. Actually I don't need a printer so precise that it can print Kim Kardashian: not sure suitable filaments have been invented for that yet, but I am confident that people smarter than me will manage sooner or later. For sure, the most valuable thing I want from all this is to learn new stuff, as I have been constantly doing since I bought my first printer kit (definitely sweat, tears, blood but also some surprising results).

Besides that, I would like a printer that can exploit the whole surface of the bed for big pieces (as my current printer cannot do, despite a miraculous hotend that never clogs even if I let the nozzle scrape the bed for ages), but that can also print smaller pieces at 0.05mm layer thickness with a 0.3mm nozzle (or even 0.2mm maybe?). Of course, almost any printer can (claim to) print at 0.05mm layer thickness, even the one I own. But as you know already, if tolerances are bad, printing quality (in particular for visible surfaces) will not improve: it will get worse. On the other hand, I don't have particular needs in terms of printing speed, I am happy with my current 40mm/s.

I agree that tolerances specified by vendors may be often worse than reality (since they are for all the pieces, not for the single piece), this also supports the idea that we should be able to make our own judgments on those tolerances. I was not aware of the various measuring tools and how to use them. I am probably not going to spend more than 100 euro to get a 0.001mm dial indicator, but 10 euro for a 0.01mm one may be a good deal.

I started attending the local Makerspace some weeks ago, it is indeed and interesting place to exchange not only parts but also knowledge.

Edited 1 time(s). Last edit at 05/14/2015 01:39PM by cristian.

Besides that, I would like a printer that can exploit the whole surface of the bed for big pieces (as my current printer cannot do, despite a miraculous hotend that never clogs even if I let the nozzle scrape the bed for ages), but that can also print smaller pieces at 0.05mm layer thickness with a 0.3mm nozzle (or even 0.2mm maybe?). Of course, almost any printer can (claim to) print at 0.05mm layer thickness, even the one I own. But as you know already, if tolerances are bad, printing quality (in particular for visible surfaces) will not improve: it will get worse. On the other hand, I don't have particular needs in terms of printing speed, I am happy with my current 40mm/s.

I agree that tolerances specified by vendors may be often worse than reality (since they are for all the pieces, not for the single piece), this also supports the idea that we should be able to make our own judgments on those tolerances. I was not aware of the various measuring tools and how to use them. I am probably not going to spend more than 100 euro to get a 0.001mm dial indicator, but 10 euro for a 0.01mm one may be a good deal.

I started attending the local Makerspace some weeks ago, it is indeed and interesting place to exchange not only parts but also knowledge.

Edited 1 time(s). Last edit at 05/14/2015 01:39PM by cristian.

Sorry, only registered users may post in this forum.