Heatbed relay questions

Posted by davedavedave

|

Heatbed relay questions June 07, 2015 04:33AM |

Registered: 8 years ago Posts: 78 |

Hi again reprappers. I was wondering about using relays and such. at first I was turned off by the though, but now ive realized that I will most likely need one as my printbed is about 17x17. So to get to the point, so far what I have learned from electronics(mainly what you awesome people have taught me) is that if I want something bigger, I will most likely need to run a relay and different psu. ok how would I go about connecting stuff up? so far what I got is that I will be connecting the heatbed to the relay and seprate psu while I will connect the thermistor to the ramps. am I missing something here? what kind of psu do you guys recommend for a 16x16 heatbed using a relay?

also, I plan on using aluminum sheet metal I found at my local hardware store as the bed. Would buying a 8x8 and placing it in the center work, as the aluminum would distribute the heat evenly across the plate? I would of course place the thermistor on the aluminum. of course this would then cause false reading and maybe the bed would heat higher than what the thermistor says probably causing a long wait time or worse, the bed to burn out or something. thanks for your input guys.

also, I plan on using aluminum sheet metal I found at my local hardware store as the bed. Would buying a 8x8 and placing it in the center work, as the aluminum would distribute the heat evenly across the plate? I would of course place the thermistor on the aluminum. of course this would then cause false reading and maybe the bed would heat higher than what the thermistor says probably causing a long wait time or worse, the bed to burn out or something. thanks for your input guys.

|

Re: Heatbed relay questions June 07, 2015 08:26AM |

Registered: 11 years ago Posts: 5,780 |

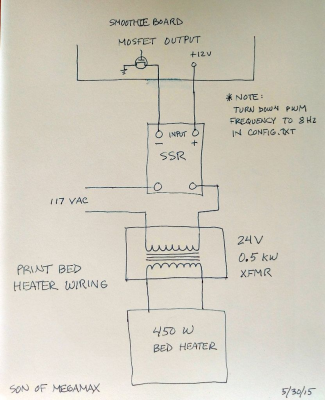

This is how it gets wired. RAMPS and smoothie are the same- the MOSFET on the controller board provides a switched ground. If you're using a DC supply for the bed, it goes where I have a transformer- you're going to switch the DC side of the supply, NOT the AC side. Use an SSR designed for DC power switching.

Thin sheet will help, but if the bed is 17x17 and the heater is 8x8, no, it won't be good enough. How are you going to get it flat over 17x17?

Edited 3 time(s). Last edit at 06/07/2015 09:29AM by the_digital_dentist.

Thin sheet will help, but if the bed is 17x17 and the heater is 8x8, no, it won't be good enough. How are you going to get it flat over 17x17?

Edited 3 time(s). Last edit at 06/07/2015 09:29AM by the_digital_dentist.

|

Re: Heatbed relay questions June 07, 2015 08:52AM |

Registered: 10 years ago Posts: 14,672 |

Just be warned, if you use an SSR to switch 10A or 20A to a heated bed, it will need a massive heatsink.

Edited 1 time(s). Last edit at 06/07/2015 08:54AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 06/07/2015 08:54AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Heatbed relay questions June 07, 2015 09:36AM |

Registered: 11 years ago Posts: 5,780 |

Not sure about DC SSRs, but the SSR I use to switch the 5A or so AC into the transformer under PID control has no heatsink and doesn't get warm.

I would NOT recommend trying to switch the AC input to a switching DC supply under PID control. It will probably cause a few blown circuit breakers until it ultimately kills the power supply, which probably won't take long at all.

I would NOT recommend trying to switch the AC input to a switching DC supply under PID control. It will probably cause a few blown circuit breakers until it ultimately kills the power supply, which probably won't take long at all.

|

Re: Heatbed relay questions June 07, 2015 11:12AM |

Registered: 9 years ago Posts: 5,232 |

|

Re: Heatbed relay questions June 07, 2015 01:52PM |

Registered: 10 years ago Posts: 14,672 |

Quote

the_digital_dentist

Not sure about DC SSRs, but the SSR I use to switch the 5A or so AC into the transformer under PID control has no heatsink and doesn't get warm.

I use an AC SSR to switch a 230V 350W heat bed, and it doesn't need a heatsink either. Both AC and DC SSRs drop about 2V at maximum current. Your AC SSR passing 5A will drop 1 to 2V, so will dissipate between 5 to 10W. But a DC SSR switching a 20A low voltage heat bed will probably drop 2V and dissipate about 40W - hence it needs a big heatsink.

Quote

1. Would it be necessary to control the heatbed via PID? I have mine in bang-bang mode and that would work too for the big SSD-controlled one?!

2. When a SSD relais gets hot, would it be possible to put it under the aluminum bed acting as heatsink? 110°C would be OK for the SSD?

1. No. Unless you get serious overshoot in bang-bang mode (which could be because the bed heater is overpowered, or the thermistor is not in good contact with the heat bed), bang-bang should be sufficient.

2. 110C would probably be too high a case temperature for the SSR, unless it was operating at about 1/3 its rated current or less.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Heatbed relay questions June 07, 2015 03:47PM |

Registered: 11 years ago Posts: 5,780 |

Regarding bang-bang, I'd say measure the temperature swings you get with your heater (put a thermocouple on the bed). If it's just a few degees, it's probably OK. After an initial overshoot of 1C, PID keeps my bed within +/- 0.5C, and that can't be bad for print quality.

Bang-bang control is one of the many small compromises that contribute to reduced overall print quality and reliability. It's an easy, usually low cost, one to fix.

Bang-bang control is one of the many small compromises that contribute to reduced overall print quality and reliability. It's an easy, usually low cost, one to fix.

|

Re: Heatbed relay questions June 07, 2015 06:30PM |

Registered: 9 years ago Posts: 125 |

|

Re: Heatbed relay questions June 08, 2015 04:12AM |

Registered: 10 years ago Posts: 14,672 |

Quote

itchytweed

Running my heat bed (14 volts, 32 amps) using just an IRF4905 mosfet and a small heatsink from a celeron processor in PID mode. Barely gets warm.

Yes, a suitable mosfet, or 2 or 3 in parallel, is much better for driving a high current DC heated bed than a DC SSR because the voltage drop is much less.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Heatbed relay questions June 12, 2015 02:41AM |

Registered: 8 years ago Posts: 78 |

|

Re: Heatbed relay questions June 20, 2015 05:26PM |

Registered: 8 years ago Posts: 78 |

Ok ive found some time. and this topic is very confusing and I still want to go through with it since it will be a learning experience I can take with me to class. so one other question is, instead of using a relay. is it possible to just connect the whole system to a stronger atx psu? something with more amps or am I just delusional ha. thanks guys.

|

Re: Heatbed relay questions June 21, 2015 03:41AM |

Registered: 9 years ago Posts: 5,232 |

The limiting factor is the current and voltage that the smoothyboard can max. pass through to the heatbed. A bigger PSU does not change that.

But an external switching unit does ( mech. relais, SSR or paralleled MOSFETs )

You should get a heater for the bed first, then we can guide you through the installation. It varies, depending on the voltage the heater needs. ( 120/230Vac or 12/24Vdc ? )

If you order a tailormade silicone heater, you´d get a DC heater with as high voltage as possible. ( 48Vdc or even 60Vdc is considered to be non lethal )

-Olaf

Edited 1 time(s). Last edit at 06/21/2015 03:46AM by o_lampe.

But an external switching unit does ( mech. relais, SSR or paralleled MOSFETs )

You should get a heater for the bed first, then we can guide you through the installation. It varies, depending on the voltage the heater needs. ( 120/230Vac or 12/24Vdc ? )

If you order a tailormade silicone heater, you´d get a DC heater with as high voltage as possible. ( 48Vdc or even 60Vdc is considered to be non lethal )

-Olaf

Edited 1 time(s). Last edit at 06/21/2015 03:46AM by o_lampe.

|

Re: Heatbed relay questions June 22, 2015 02:18AM |

Registered: 8 years ago Posts: 78 |

Sorry, only registered users may post in this forum.