Would 300x300mm glass plate bow if only supported by the 3 screws for leveling?

Posted by realthor

|

Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 11:41AM |

Registered: 9 years ago Posts: 1,035 |

Hi guys,

My quick question is the one in the subject:

Would 300x300mm glass plate bow if only supported by the 3 screws for leveling?

I am trying to get my bed as light as possible and was planning a stack of cork < silicone heater < heat spreader alu 1.5mm plate < 6mm glass. All this stack would be supported by a 3-point leveling system. But the strongest in the stack is the glass itself, so to avoid adding a MDF or another ALU support I am thinking of directly clamp the glass by the 3 point leveling screws.

Considering the heat and maybe even a heated chamber, will the glass bow when heated under its own weight?

Thanks.

Edited 1 time(s). Last edit at 05/26/2016 11:58AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

My quick question is the one in the subject:

Would 300x300mm glass plate bow if only supported by the 3 screws for leveling?

I am trying to get my bed as light as possible and was planning a stack of cork < silicone heater < heat spreader alu 1.5mm plate < 6mm glass. All this stack would be supported by a 3-point leveling system. But the strongest in the stack is the glass itself, so to avoid adding a MDF or another ALU support I am thinking of directly clamp the glass by the 3 point leveling screws.

Considering the heat and maybe even a heated chamber, will the glass bow when heated under its own weight?

Thanks.

Edited 1 time(s). Last edit at 05/26/2016 11:58AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 11:58AM |

Admin Registered: 16 years ago Posts: 13,902 |

... how thick?

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 11:59AM |

Registered: 9 years ago Posts: 1,035 |

Quote

VDX

... how thick?

I edited my post, something related to the "<" was picked up by the markup engine and I was showing the signature in the post :-/ ...

As said above, 6mm glass...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 12:16PM |

Admin Registered: 16 years ago Posts: 13,902 |

... the glass should be stiff enough, but the thin aluminium plate can warp, so the height of the bed can change between cold and heated ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 12:59PM |

Registered: 9 years ago Posts: 1,035 |

The glass will not float on the aluminum but the aluminum will be glued underneath the glass and the silicone heater will be glued to the aluminum. The glass will be directly supported on the bed frame 3-point-screws so if aluminum warps (and i hope the adhesive will keep it stuck to the glass) it will not affect the glass' position.

Now I wonder where can I find some double adhesive tape that is heat conductive and resistand to the temps of a heated bed while being thin enough to efficiently transfer the heat from the aluminum to the glass....

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Now I wonder where can I find some double adhesive tape that is heat conductive and resistand to the temps of a heated bed while being thin enough to efficiently transfer the heat from the aluminum to the glass....

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 01:05PM |

Registered: 9 years ago Posts: 483 |

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 01:10PM |

Registered: 9 years ago Posts: 1,035 |

I wasn't very specific. I am referring to the technique @amigob described here: http://forums.reprap.org/read.php?4,666554,667750#msg-667750

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Quote

amigob

i uses boro glass and 1.5 mm head spreader with silicon heater. it works very well.

But be care full aluminum will expand 2 times of the boro glass.

I used 10x10cm squares and used dubble side tape to stick these squares to the glass with 1mm spacing

This is to avoid deformation of the glass when the alluminium is expanding more then the boro glass

No fir image but measured heat map

and on aly express you can get the dubble side tape sheets for a good price

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 01:14PM |

Registered: 11 years ago Posts: 564 |

Quote

realthor

The glass will not float on the aluminum but the aluminum will be glued underneath the glass and the silicone heater will be glued to the aluminum. The glass will be directly supported on the bed frame 3-point-screws so if aluminum warps (and i hope the adhesive will keep it stuck to the glass) it will not affect the glass' position.

Now I wonder where can I find some double adhesive tape that is heat conductive and resistand to the temps of a heated bed while being thin enough to efficiently transfer the heat from the aluminum to the glass....

Gluing the aluminum to the glass will likely cause more warping that if the aluminum sheet were left unconstrained, due to the large difference in the thermal expansion coefficients between aluminum and glass. With the glass acting as an insulator, and if your silicone heater covers the entire back of the aluminum sheet, you'll probably get pretty even heat distribution across the aluminum and hence minimal warping. Also switching to 1mm thick aluminum will only reduce the heat spreading efficiency only slightly, but it will dramatically reduce the force required to keep the aluminum sheet pressed flat.

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 01:28PM |

Registered: 9 years ago Posts: 1,035 |

Quote

LoboCNC

Quote

realthor

The glass will not float on the aluminum but the aluminum will be glued underneath the glass and the silicone heater will be glued to the aluminum. The glass will be directly supported on the bed frame 3-point-screws so if aluminum warps (and i hope the adhesive will keep it stuck to the glass) it will not affect the glass' position.

Now I wonder where can I find some double adhesive tape that is heat conductive and resistant to the temps of a heated bed while being thin enough to efficiently transfer the heat from the aluminum to the glass....

Gluing the aluminum to the glass will likely cause more warping that if the aluminum sheet were left unconstrained, due to the large difference in the thermal expansion coefficients between aluminum and glass. With the glass acting as an insulator, and if your silicone heater covers the entire back of the aluminum sheet, you'll probably get pretty even heat distribution across the aluminum and hence minimal warping. Also switching to 1mm thick aluminum will only reduce the heat spreading efficiency only slightly, but it will dramatically reduce the force required to keep the aluminum sheet pressed flat.

Will this happen with the technique described above?

Also, if the aluminum gets so thin and if not glued to glass, there must be some sort of sandwich to keep the silicone heater and the aluminum pressed to the underside of the glass and that means again another layer that only makes the bed heavier as there must be something pretty strong to keep the sandwich.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 01:56PM |

Registered: 11 years ago Posts: 564 |

Gluing the aluminum to the glass across the entire surface will definitely cause warping - you are creating something very much like a bimetalic strip that is specifically designed to warp when heated. One solution to avoid a huge sandwich i you don't use any glue is to glue the aluminum to the glass in just a small spot in the center of the plate. With the the heater on the opposite side, the edges of the of the aluminum will want to warp upwards towards the glass and thus make good contact. This then leaves the aluminum to expand in length without trying to force the glass to expand at the same rate.

Also note that most aluminum sheet is not particularly flat to begin with. With 1mm sheet, I'd recommend gluing the center of the concave side to the glass so that the glass will pull it flat. With 1.5mm sheet, though, this may start to cause some significant warping of the glass.

BTW, I'm currently wrestling with the same issues with a 350mm^2 heated bed. I'm planning on skipping the glass altogether, but this gives me another set of headaches with keeping a relatively thin aluminum plate flat when heated. I'll let you know how that works out.

Also note that most aluminum sheet is not particularly flat to begin with. With 1mm sheet, I'd recommend gluing the center of the concave side to the glass so that the glass will pull it flat. With 1.5mm sheet, though, this may start to cause some significant warping of the glass.

BTW, I'm currently wrestling with the same issues with a 350mm^2 heated bed. I'm planning on skipping the glass altogether, but this gives me another set of headaches with keeping a relatively thin aluminum plate flat when heated. I'll let you know how that works out.

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 02:10PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 02:36PM |

Registered: 12 years ago Posts: 2,470 |

Get rid of the glass, use a thicker plate made from cast aluminum and milled from both sides. It will warp very little, especially if you fix it in a way that it has a bit of give.

Use gluestick or 3dLac to make prints stick.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

Use gluestick or 3dLac to make prints stick.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 02:51PM |

Registered: 9 years ago Posts: 1,035 |

Quote

LoboCNC

Gluing the aluminum to the glass across the entire surface will definitely cause warping - you are creating something very much like a bimetalic strip that is specifically designed to warp when heated. One solution to avoid a huge sandwich i you don't use any glue is to glue the aluminum to the glass in just a small spot in the center of the plate. With the the heater on the opposite side, the edges of the of the aluminum will want to warp upwards towards the glass and thus make good contact. This then leaves the aluminum to expand in length without trying to force the glass to expand at the same rate.

Also note that most aluminum sheet is not particularly flat to begin with. With 1mm sheet, I'd recommend gluing the center of the concave side to the glass so that the glass will pull it flat. With 1.5mm sheet, though, this may start to cause some significant warping of the glass.

BTW, I'm currently wrestling with the same issues with a 350mm^2 heated bed. I'm planning on skipping the glass altogether, but this gives me another set of headaches with keeping a relatively thin aluminum plate flat when heated. I'll let you know how that works out.

I wasn't going to glue the whole underglass to the aluminum, but, as I said, have several thin alu pads (say 10x10cm like @amigob reported to be using). I can sand the underglass or buy already sanded (one side or both) so that there is greater chance that the alu will stick to the glass.

Your technique is intriguing, to only glue the center of each pad, or the single larger plate as you put it, but how can you make sure that the concave side is up so that when warping it will actually warp up to contact the glass better?

And what glue is heat resistant enough and still conductive to easily allow the heat transfer.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 02:57PM |

Registered: 9 years ago Posts: 1,035 |

Quote

Srek

Get rid of the glass, use a thicker plate made from cast aluminum and milled from both sides. It will warp very little, especially if you fix it in a way that it has a bit of give.

Use gluestick or 3dLac to make prints stick.

I've found this, which isn't too expensive...

Would this be good enough?

http://www.ebay.de/itm/121254993166?clk_rvr_id=1035323292601&rmvSB=true

What techniques are there to " fix it in a way that it has a bit of give". Larger screw holes than the actual screws?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 04:01PM |

Registered: 12 years ago Posts: 2,470 |

That looks pretty good.

Personaly i mount the printplate on a dibond plate using four screws and hard springs or silicone blocks. The idea to only use three mount points is tempting, but you buy a little bit of convinience with a lot of instability. Yes three points are easier to adjust, but four is not so bad and much easier to build stable.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

Personaly i mount the printplate on a dibond plate using four screws and hard springs or silicone blocks. The idea to only use three mount points is tempting, but you buy a little bit of convinience with a lot of instability. Yes three points are easier to adjust, but four is not so bad and much easier to build stable.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 04:07PM |

Registered: 9 years ago Posts: 1,035 |

Why is three point adjusting unstable?

I don't see it as unstable and would even venture to float the aluminum/glass plate on silicone-capped adjusting screws (with a silicone cap 10mm diameter). But this is just an idea, I haven't tested it yet.

I hear some mount plates (not alu though) with magnets. So the above should work similarly I guess...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

I don't see it as unstable and would even venture to float the aluminum/glass plate on silicone-capped adjusting screws (with a silicone cap 10mm diameter). But this is just an idea, I haven't tested it yet.

I hear some mount plates (not alu though) with magnets. So the above should work similarly I guess...

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 04:15PM |

Registered: 13 years ago Posts: 268 |

Quote

realthor

Quote

Srek

Get rid of the glass, use a thicker plate made from cast aluminum and milled from both sides. It will warp very little, especially if you fix it in a way that it has a bit of give.

Use gluestick or 3dLac to make prints stick.

I've found this, which isn't too expensive...

Would this be good enough?

http://www.ebay.de/itm/121254993166?clk_rvr_id=1035323292601&rmvSB=true

What techniques are there to " fix it in a way that it has a bit of give". Larger screw holes than the actual screws?

I use slotted counterbores in the plate (technically not a counterbore, since I have slots to the edge of the round bed). Shoulder screws in the holes. Bed rests on standoff. Shoulder screw and standoff are sized to allow the right space to load a wave washer to desired pressure. Plate is held down against the standoff with the wave washer, the head of the screw and the washer fit in the counterbore portion, nothing protrudes from the surface.

New build will be slight variation on that theme, with the addition of leveling adjustment, and no breaks in the surface whatsoever.

I use Mic6 for my beds, pretty flat and I want to say over 200mm a rise from 30deg to 100deg is in the neighborhood of .3mm change in length (calced not measured, but my arrangement keeps itself flat)

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 04:19PM |

Registered: 9 years ago Posts: 1,035 |

Quote

Koko76

Quote

realthor

Quote

Srek

Get rid of the glass, use a thicker plate made from cast aluminum and milled from both sides. It will warp very little, especially if you fix it in a way that it has a bit of give.

Use gluestick or 3dLac to make prints stick.

I've found this, which isn't too expensive...

Would this be good enough?

http://www.ebay.de/itm/121254993166?clk_rvr_id=1035323292601&rmvSB=true

What techniques are there to " fix it in a way that it has a bit of give". Larger screw holes than the actual screws?

I use slotted counterbores in the plate (technically not a counterbore, since I have slots to the edge of the round bed). Shoulder screws in the holes. Bed rests on standoff. Shoulder screw and standoff are sized to allow the right space to load a wave washer to desired pressure. Plate is held down against the standoff with the wave washer, the head of the screw and the washer fit in the counterbore portion, nothing protrudes from the surface.

New build will be slight variation on that theme, with the addition of leveling adjustment, and no breaks in the surface whatsoever.

I use Mic6 for my beds, pretty flat and I want to say over 200mm a rise from 30deg to 100deg is in the neighborhood of .3mm change in length (calced not measured, but my arrangement keeps itself flat)

Could you post a pic or two? I am sure images would help me and others better understand the descriptions. Or at least confirm i got it right (or not).

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 04:26PM |

Registered: 10 years ago Posts: 14,672 |

I use 4mm glass clamped to a 5mm thick alu plate at the edges, and it works well. 5mm thickness for the alu plate is probably overkill.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 06:19PM |

Registered: 11 years ago Posts: 5,780 |

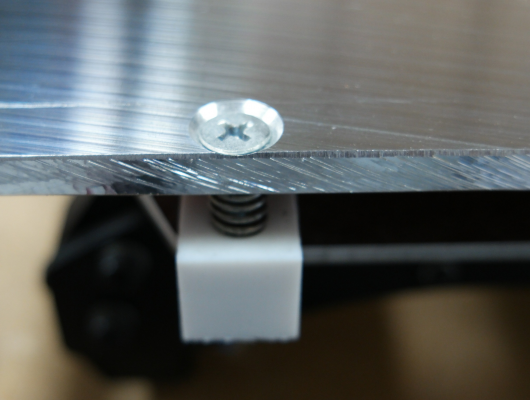

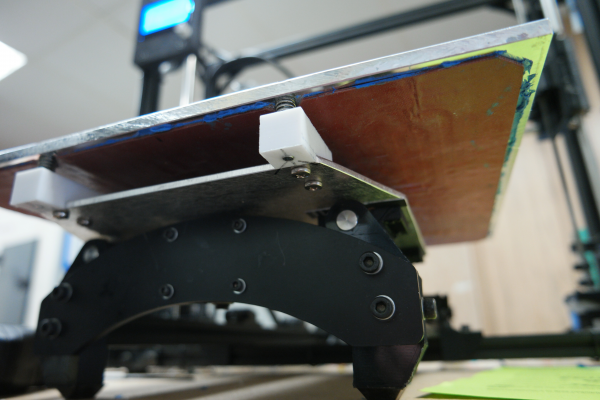

Here's how I made screws for tooling plate bed in my printer and a Taz that I recently converted from glass to aluminum:

Countersunk, flat head screw in an oversized hole (about 1-2 mm larger diameter than the screw itself), spring, and Teflon block. Countersinking prevents the screw heads from standing above the bed surface and becoming a hazard for the extruder. Oversizing the holes allows the bed to pivot freely as you adjust the screw. The screws are threaded into undersized holes in the teflon which hold them tightly and doesn't allow them to wobble when the bed reverses direction. The springs are very strong and keep the bed plate pushed up against the screw heads. In my machine I used thumbwheels to turn the screws from under the bed, in the Taz there was no room under the bed so the screws are turned from the top side of the bed.

Edited 1 time(s). Last edit at 05/26/2016 06:20PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Countersunk, flat head screw in an oversized hole (about 1-2 mm larger diameter than the screw itself), spring, and Teflon block. Countersinking prevents the screw heads from standing above the bed surface and becoming a hazard for the extruder. Oversizing the holes allows the bed to pivot freely as you adjust the screw. The screws are threaded into undersized holes in the teflon which hold them tightly and doesn't allow them to wobble when the bed reverses direction. The springs are very strong and keep the bed plate pushed up against the screw heads. In my machine I used thumbwheels to turn the screws from under the bed, in the Taz there was no room under the bed so the screws are turned from the top side of the bed.

Edited 1 time(s). Last edit at 05/26/2016 06:20PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 06:24PM |

Registered: 9 years ago Posts: 1,035 |

Thanks d_d, that works great for aluminum plate.

Where did you get the teflon blocks from? I don't know a place that would sell those in a brick and mortar shop.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Where did you get the teflon blocks from? I don't know a place that would sell those in a brick and mortar shop.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 26, 2016 06:33PM |

Registered: 11 years ago Posts: 5,780 |

I cut them from a scrap piece that was purchased at a local plastics shop. Teflon is pretty expensive if you buy a big piece, but scrap pieces can be quite reasonable. The piece from which these were cut was either $5 or $8, and I still have left over pieces to use for other things. Teflon is very easy to machine.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 27, 2016 02:00AM |

Registered: 12 years ago Posts: 2,470 |

Instead of the Teflon you can use the silicone i mentioned, it's the same though i would use smaller blocks since silicone is more elastic.

What the dentist shows is similar to how i solved this for my Dual Cube, the sunk screws are a simple and well working solution.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

What the dentist shows is similar to how i solved this for my Dual Cube, the sunk screws are a simple and well working solution.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 27, 2016 02:20AM |

Registered: 9 years ago Posts: 1,035 |

Quote

Srek

Instead of the Teflon you can use the silicone i mentioned, it's the same though i would use smaller blocks since silicone is more elastic.

What the dentist shows is similar to how i solved this for my Dual Cube, the sunk screws are a simple and well working solution.

I am talking about a corexy where the bed goes up and down, and was actually thinking about silicone caps on bolt heads (thus thin enough 1-2mm). If I was to use the glass method described above, can't it just float it on the silicone caps with no fastening? The silicone is anti-slip and will not allow it to move unless something hits it. I don't know how silicone behaves with an aluminum plate but I would guess it's kind of the same as with glass... it will not slip on the silicone caps.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 27, 2016 02:42AM |

Registered: 12 years ago Posts: 2,470 |

It might work, but it is difficult to glue silicone to anything.

My comment on the stability only realy applies if the bed is moving along Y.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

My comment on the stability only realy applies if the bed is moving along Y.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 27, 2016 03:14AM |

Registered: 9 years ago Posts: 1,035 |

Quote

Srek

It might work, but it is difficult to glue silicone to anything.

My comment on the stability only realy applies if the bed is moving along Y.

By floating I meant Not-Glueing, just placing the glass/ALU plate ontop of three silicone-covered flathead bolts. I don't see it moving during normal printing only if the print speed is such great that the vibrations and/or movement of the frame causes the plate to shift position. in which case the frame is the weak link and should be dealt with. If the bolts are inserted from above in larger holes than the actual bolt, the springs being very strong, will keep it more stable and the larger holes will allow for thermal expansion.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 27, 2016 07:09AM |

Registered: 11 years ago Posts: 5,780 |

Quote

Srek

It might work, but it is difficult to glue silicone to anything.

It's actually pretty easy. I made a plunger for a 3" diameter syringe by 3D printing a core, a mold and a jig, then set the core in the mold with the jig and poured in two-part silicone. Once the silicone had cured, I broke the mold off. It works fine. It would be even easier to do with bolts that are much smaller.

That said, my experience tells me that if you allow something to move by not physically restraining it, it will move. Maybe gravity would be enough in this case.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Would 300x300mm glass plate bow if only supported by the 3 screws for leveling? May 27, 2016 07:18AM |

Registered: 12 years ago Posts: 2,470 |

I found that a rough surface will give a usefull grip for silicone sometimes, but if the connection experiences any kind of mechanical stress it will give over time. In theory 3D printing is ideal to create a shape that allows for optimal mechanical interconnection, but it is tedious to design and print.

To connect silicone and 3D printed parts i drill holes in the connecting surface and let the silicone spill inside of the part. This gives a pretty good connection, provided the silicone is not to soft and rips.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

To connect silicone and 3D printed parts i drill holes in the connecting surface and let the silicone spill inside of the part. This gives a pretty good connection, provided the silicone is not to soft and rips.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

Sorry, only registered users may post in this forum.