Need help building extruder nozzle

Posted by MrJohn

|

Need help building extruder nozzle March 07, 2011 01:31AM |

Registered: 13 years ago Posts: 108 |

|

Re: Need help building extruder nozzle March 07, 2011 01:42AM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Need help building extruder nozzle March 07, 2011 01:55AM |

Admin Registered: 15 years ago Posts: 1,470 |

MrJohn Wrote:

-------------------------------------------------------

> I'm trying to figure out how to build the extruder

> nozzle but I'm confused about how to bond the

> resistor to the heater block. Do I use fire

> cement, epoxy or nothing?

You can just wrap the resistor in aluminum foil and shove it in the hole. That works well if you don't want to mess with fire cement.

-------------------------------------------------------

> I'm trying to figure out how to build the extruder

> nozzle but I'm confused about how to bond the

> resistor to the heater block. Do I use fire

> cement, epoxy or nothing?

You can just wrap the resistor in aluminum foil and shove it in the hole. That works well if you don't want to mess with fire cement.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Need help building extruder nozzle March 07, 2011 04:57AM |

Registered: 13 years ago Posts: 482 |

Hey MrJohn

I simply wrapped a little aluminium foil around my resistor and shoved it in the hole. This works perfectly well.

Might be worth ensuring the aluminium foil does not touch the leads as that may cause a short. Also, insulate your leads so they don't short to the heater block itself. I use heat shrink tubing for this.

Cheers

I simply wrapped a little aluminium foil around my resistor and shoved it in the hole. This works perfectly well.

Might be worth ensuring the aluminium foil does not touch the leads as that may cause a short. Also, insulate your leads so they don't short to the heater block itself. I use heat shrink tubing for this.

Cheers

|

Re: Need help building extruder nozzle March 07, 2011 10:23AM |

Registered: 13 years ago Posts: 108 |

Thanks for the help, I've read the wiki over dozens of times and that's where I learned about the fire cement. A quick google search shows that it isn't sold in local hardware stores. I hate to keep buying stuff online if I don't have to. I'll try the foil, can I use my wife's hair dryer to shrink the tubes?

|

Re: Need help building extruder nozzle March 07, 2011 10:32AM |

Registered: 13 years ago Posts: 482 |

|

Re: Need help building extruder nozzle March 07, 2011 11:08AM |

Admin Registered: 17 years ago Posts: 7,879 |

It will shrink itself the first time you switch it on!

I have never used heat shrink close to the heater or the thermistor because I assumed it wouldn't handle the temperatures but it looks like people get away with it.

[www.hydraraptor.blogspot.com]

I have never used heat shrink close to the heater or the thermistor because I assumed it wouldn't handle the temperatures but it looks like people get away with it.

[www.hydraraptor.blogspot.com]

|

Re: Need help building extruder nozzle March 07, 2011 11:30AM |

Registered: 13 years ago Posts: 108 |

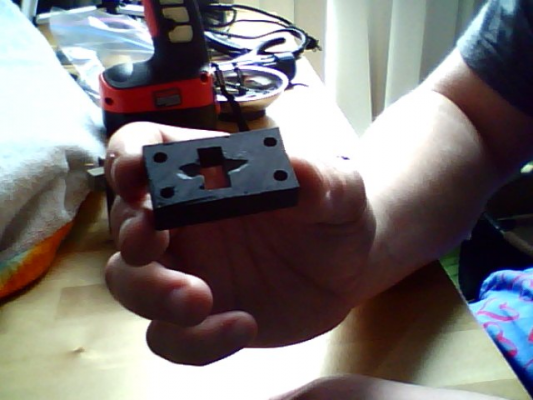

Thanks for the tip on the foil. I cut some into strips and threaded it through the heater block, I had to use 5 or 6 strips before the resistor would stick well inside. I don't have any shrink tube but no foil is touching the leads.

I need to read up on the wiki and I might have more questions about how to attach the thermistor or thermal-couple, whichever I received with my kit.

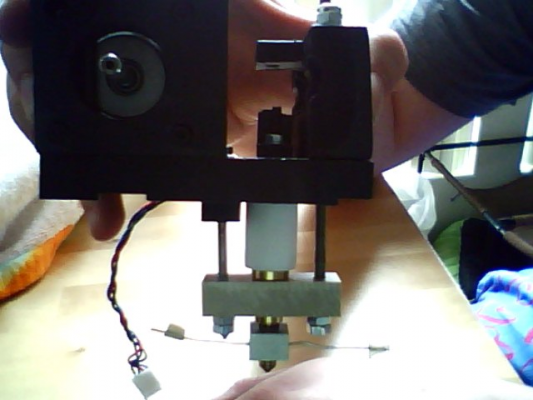

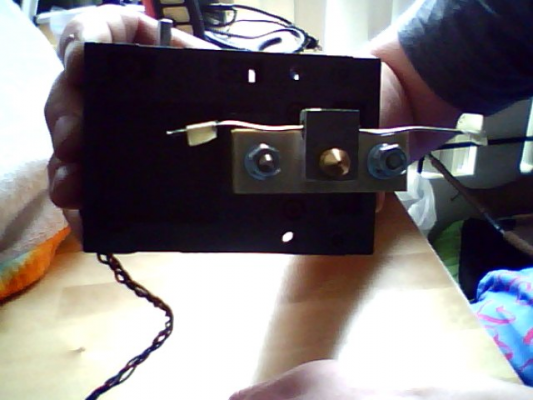

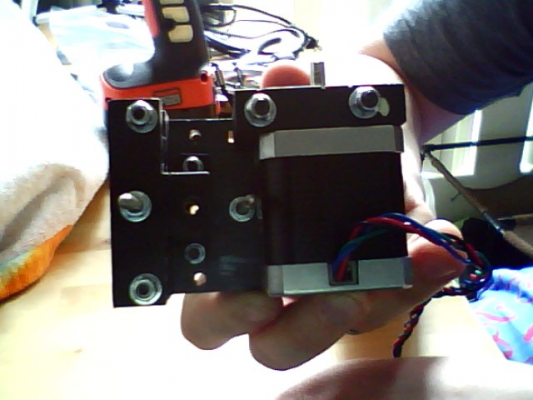

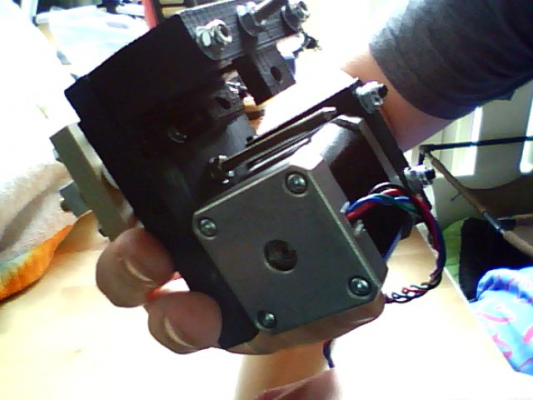

Please look at these photos and tell me if anything looks wrong. There are not a lot of photos about how the inside of the extruder looks and I think I need a replacement plastic piece or to drill out space for a rod to mount the bearing.

(Images are mirrored)

Edited 2 time(s). Last edit at 03/07/2011 09:45PM by MrJohn.

I need to read up on the wiki and I might have more questions about how to attach the thermistor or thermal-couple, whichever I received with my kit.

Please look at these photos and tell me if anything looks wrong. There are not a lot of photos about how the inside of the extruder looks and I think I need a replacement plastic piece or to drill out space for a rod to mount the bearing.

(Images are mirrored)

Edited 2 time(s). Last edit at 03/07/2011 09:45PM by MrJohn.

|

Re: Need help building extruder nozzle March 07, 2011 12:48PM |

Registered: 14 years ago Posts: 195 |

|

Re: Need help building extruder nozzle March 07, 2011 12:52PM |

Registered: 13 years ago Posts: 108 |

Yeah, the pieces I recieved are pretty messy. I don't have that groove on mine. I had to dremel it out and place a M4x20 bolt there.

I was reading the wiki on how to build the hot end and it calls for 2 M3 threaded rods, one is 92mm and the other is 58mm. I have two threaded rods but they are M4. They fit the holes and seem to work fine. Is this an error in the wiki or do I have the wrong parts?

I was reading the wiki on how to build the hot end and it calls for 2 M3 threaded rods, one is 92mm and the other is 58mm. I have two threaded rods but they are M4. They fit the holes and seem to work fine. Is this an error in the wiki or do I have the wrong parts?

|

Re: Need help building extruder nozzle March 07, 2011 12:58PM |

Registered: 14 years ago Posts: 195 |

|

Re: Need help building extruder nozzle March 07, 2011 08:40PM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Need help building extruder nozzle March 07, 2011 09:45PM |

Registered: 13 years ago Posts: 108 |

|

Re: Need help building extruder nozzle March 08, 2011 02:21AM |

Registered: 13 years ago Posts: 108 |

|

Re: Need help building extruder nozzle March 08, 2011 07:04AM |

Registered: 13 years ago Posts: 482 |

Hey MrJohn

You could do either but might find your thermistor is more accurate if you drill a hole for it. I have a 2.5mm hole in which I have inserted a little thermal paste and then the thermistor, taping it up with kapton to keep it in.

Perhaps cementing it in would be better then the kapton would not be required (which is untidy).

A hint re the extruder - When you create your 'junction board/connector' on your extruder don't solder any wires to the stripboard. Use headers and plugs for everything.

I followed the directions on the wiki and soldered the motot, heater and thermistor wires to the board wing headers and plugs for the connections going to the controller board. This is a real bind when you need to dismantle the extruder for maintenance. I do see in the photos of Adrian's micro extruder he must have come to the same conclusion as there are headers and plugs for all connections with no wires soldered to the board.

You could do either but might find your thermistor is more accurate if you drill a hole for it. I have a 2.5mm hole in which I have inserted a little thermal paste and then the thermistor, taping it up with kapton to keep it in.

Perhaps cementing it in would be better then the kapton would not be required (which is untidy).

A hint re the extruder - When you create your 'junction board/connector' on your extruder don't solder any wires to the stripboard. Use headers and plugs for everything.

I followed the directions on the wiki and soldered the motot, heater and thermistor wires to the board wing headers and plugs for the connections going to the controller board. This is a real bind when you need to dismantle the extruder for maintenance. I do see in the photos of Adrian's micro extruder he must have come to the same conclusion as there are headers and plugs for all connections with no wires soldered to the board.

|

Re: Need help building extruder nozzle March 09, 2011 08:33AM |

Registered: 14 years ago Posts: 323 |

i soldered to my board then those wires to screw terminals to overcome that obstacle

i would definitely drill a hole for the thermistor, the hole serves to hold it really well and protect it and you're getting a reading much closer to where the plastic passes and without airflow onto the other half of it.

if it ever does fall off and you're not there it will soar to extremely high temperatures and keep soaring...

i would definitely drill a hole for the thermistor, the hole serves to hold it really well and protect it and you're getting a reading much closer to where the plastic passes and without airflow onto the other half of it.

if it ever does fall off and you're not there it will soar to extremely high temperatures and keep soaring...

|

Re: Need help building extruder nozzle March 09, 2011 08:40AM |

Registered: 14 years ago Posts: 3,742 |

Quote

mlagana

if it ever does fall off and you're not there it will soar to extremely high temperatures and keep soaring...

TRUE, but this case should be handled in the firmware!

If heater is on and temperature does not increase with a 5 (or 10) second interval then EMERGENCY HALT - heater/thermister not working properly!

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Need help building extruder nozzle March 09, 2011 08:48AM |

Registered: 13 years ago Posts: 1,780 |

There should be a thermoswitch (thermofuse) on the tip and bed that cuts power off if the temperature gets too high. I don't think it's safe to rely on the firmware for this. My tip was emitting fumes yesterday as it got up to the upper 300's due to a bug in the firmware reading the temperature.

|

Re: Need help building extruder nozzle March 09, 2011 09:00AM |

Registered: 14 years ago Posts: 3,742 |

Adding more hardware that can disconnect or have a malfunction won't really increase the reliability of the device.

If your thermoswitch no longer has contact (or goes bad) you have the same problem.

If done in the firmware then if your thermistor falls off it is detected and halted.

If you are worried about the firmware crashing (or getting in an endless loop) then add a watchdog timer.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

If your thermoswitch no longer has contact (or goes bad) you have the same problem.

If done in the firmware then if your thermistor falls off it is detected and halted.

If you are worried about the firmware crashing (or getting in an endless loop) then add a watchdog timer.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Need help building extruder nozzle March 09, 2011 09:14AM |

Admin Registered: 17 years ago Posts: 7,879 |

The best fail safe is to choose the heater resistance appropriately so that the max temperature is a little below 300C.

My heater designs with 6.8R resistor do that, so nothing really bad happens if the thermistor falls off, or the MOSFET goes short, etc. It would be good to detect it in firmware as well but you can't rely on that for safety.

[www.hydraraptor.blogspot.com]

My heater designs with 6.8R resistor do that, so nothing really bad happens if the thermistor falls off, or the MOSFET goes short, etc. It would be good to detect it in firmware as well but you can't rely on that for safety.

[www.hydraraptor.blogspot.com]

|

Re: Need help building extruder nozzle March 09, 2011 03:41PM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Need help building extruder nozzle March 09, 2011 05:24PM |

Registered: 14 years ago Posts: 195 |

|

Re: Need help building extruder nozzle March 09, 2011 07:46PM |

Admin Registered: 17 years ago Posts: 7,879 |

CdnReprap Wrote:

-------------------------------------------------------

> @nophead: have you ever tried 5ohms? I switched to

> a 5Ohms so I can run in 280~325oC range, its

> working really nice with both ABS and PLA

No I haven't needed temperatures that high yet and none of my extruders would handle it as it is too hot for PTFE, PEEK and thermistors. I do have some UP ABS, so that might need 280C, but I can probably just manage that with 6.8R as I have a 13V supply on HydraRaptor.

Edited 1 time(s). Last edit at 03/10/2011 04:29AM by nophead.

[www.hydraraptor.blogspot.com]

-------------------------------------------------------

> @nophead: have you ever tried 5ohms? I switched to

> a 5Ohms so I can run in 280~325oC range, its

> working really nice with both ABS and PLA

No I haven't needed temperatures that high yet and none of my extruders would handle it as it is too hot for PTFE, PEEK and thermistors. I do have some UP ABS, so that might need 280C, but I can probably just manage that with 6.8R as I have a 13V supply on HydraRaptor.

Edited 1 time(s). Last edit at 03/10/2011 04:29AM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Need help building extruder nozzle March 10, 2011 03:02AM |

Admin Registered: 16 years ago Posts: 13,891 |

... i have 6Ohms and tested until 320°C without problems, could have more, but canceled, as i don't want to wreck the PEEK-insulator ...

Temp-Kurve.jpg

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Temp-Kurve.jpg

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Sorry, only registered users may post in this forum.