|

Dual hobbed extruder December 08, 2018 06:58AM |

Registered: 5 years ago Posts: 26 |

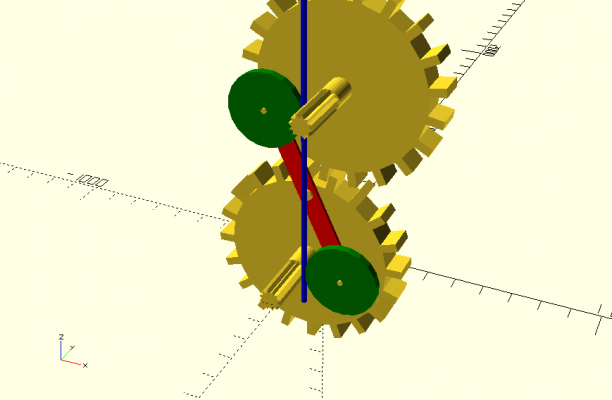

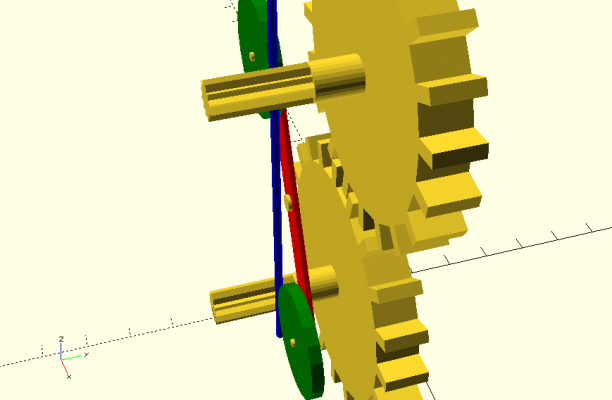

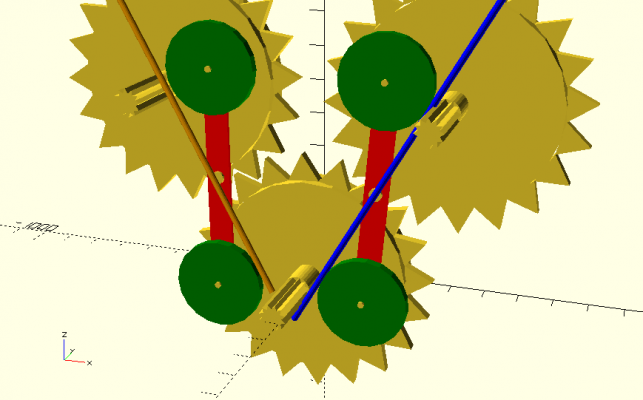

I was wondering about my pantograph printer ( topic here )

when I have think about this thing

why not use a gear of this kind (I have seen many kind of extruder drive but no kind like that):

It's like of some push pull drive and the both side of the filament are be drive

(the pics are just sketchs)

animate pic:

video

(better if you download the file and open it with your browser)

Edited 3 time(s). Last edit at 12/09/2018 03:00AM by herve robert.

when I have think about this thing

why not use a gear of this kind (I have seen many kind of extruder drive but no kind like that):

It's like of some push pull drive and the both side of the filament are be drive

(the pics are just sketchs)

animate pic:

video

(better if you download the file and open it with your browser)

Edited 3 time(s). Last edit at 12/09/2018 03:00AM by herve robert.

|

Re: Dual drive extruder December 08, 2018 07:26AM |

Registered: 12 years ago Posts: 2,470 |

For me a reason to not do it is that it is unnecessary. I have thought about filament transportation with multiple points of contact, but in the end they did not offer any advantage. A well designed classic direct drive will develop enough force for well over 100mm/s. Another issue is size, such a setup will be larger than a single point of contact drive.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Dual drive extruder December 08, 2018 11:46AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Dual drive extruder December 08, 2018 12:51PM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Dual drive extruder December 08, 2018 09:01PM |

Registered: 6 years ago Posts: 93 |

|

Re: Dual drive extruder December 09, 2018 02:31AM |

Registered: 8 years ago Posts: 5,232 |

@Diggrr

Very interesting. Very easy to try out.

I'm sure you can reduce the pinch wheel pressure on each extruder, which keeps the filament in round shape.

I'll try it on my Duet Maestro, just in case a single TMC2224 isn't upto it.

Just one question: Does the heatsink on the side of the stepper create more Eddy currents?

Very interesting. Very easy to try out.

I'm sure you can reduce the pinch wheel pressure on each extruder, which keeps the filament in round shape.

I'll try it on my Duet Maestro, just in case a single TMC2224 isn't upto it.

Just one question: Does the heatsink on the side of the stepper create more Eddy currents?

|

Re: Dual hobbed extruder December 09, 2018 03:10AM |

Registered: 5 years ago Posts: 26 |

yes that's it: "dual hobbed" / more accurate name !

a kind of it:

thingiverse

with two motors, seems to be a good solution but to heavy in my case.

Edited 2 time(s). Last edit at 12/09/2018 03:21AM by herve robert.

a kind of it:

thingiverse

with two motors, seems to be a good solution but to heavy in my case.

Edited 2 time(s). Last edit at 12/09/2018 03:21AM by herve robert.

|

Re: Dual hobbed extruder December 09, 2018 03:17AM |

Registered: 6 years ago Posts: 93 |

Copper reflects eddy currents, but I've had no trouble with the aluminum 'sinks. All my motors have them because they can get toasty in the enclosure on long prints despite the ~85% current setting. I've only seen missed steps in pictures online (I also braid my stepper wires, always, so that helps).

I have been able to reduce the spring tension like you said. The nuts are about half of what I used to run.

Note, I also use flat faced bearings instead of the u-groove ones that ship with those extruder drives. The u-grooves were just too deep, so the bearing would ride against the face of the new MK7 gear with almost no pressure on the filament.

I use an Azteeg X5 GT, adding 3 jumpers clones the two extruder ports to each other, so each motor has it's own driver in my setup.

Edited 1 time(s). Last edit at 12/09/2018 03:20AM by Diggrr.

I have been able to reduce the spring tension like you said. The nuts are about half of what I used to run.

Note, I also use flat faced bearings instead of the u-groove ones that ship with those extruder drives. The u-grooves were just too deep, so the bearing would ride against the face of the new MK7 gear with almost no pressure on the filament.

I use an Azteeg X5 GT, adding 3 jumpers clones the two extruder ports to each other, so each motor has it's own driver in my setup.

Edited 1 time(s). Last edit at 12/09/2018 03:20AM by Diggrr.

|

Re: Dual drive extruder December 09, 2018 03:44AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Srek

For me a reason to not do it is that it is unnecessary. I have thought about filament transportation with multiple points of contact, but in the end they did not offer any advantage. A well designed classic direct drive will develop enough force for well over 100mm/s. Another issue is size, such a setup will be larger than a single point of contact drive.

You might find [somei3deas.wordpress.com] interesting. Summary: in the particular case of using a mixing hot end, where the same piece of filament may get moved back and forth many times, the Bondtech (dual drive) extruder performed much better than the Titan (single drive) extruder. This doesn't prove that the dual vs. single aspect is solely responsible for the difference (the shape of the teeth on the hobbed shaft may have been different too), but it seems likely that it was the major factor.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Dual drive extruder December 09, 2018 06:36AM |

Registered: 6 years ago Posts: 1,007 |

Quote

Diggrr

..it was the only way I could get TMC drivers to pull a 4 Kilo roll of PLA..now I just like it, even with new drivers.

Dual hobbed MK7's made for 1.75mm filament only.

What kind of hotend/filament (1.75mm) requires that much force ?

Anyway, the key factor is the hobbed gear/idler. With a good one, it is possible to pull 40N using a geared Nema17 42mm. To push is an other story. You better have a well guided and short path between extruder and hotend.

The MK7 hobbed gears quality can be shitty. So to put two bad extruders in series is a complex, heavy, costly solution.

The Bondtech is based on a good design used for more than a century in the steel industry notably. You get the extra force and in addition it lessens the damage to the filament, comes handy when there is a lot of retraction.

Edited 1 time(s). Last edit at 12/09/2018 06:37AM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Dual hobbed extruder December 09, 2018 08:35AM |

Registered: 5 years ago Posts: 26 |

Eric's Wade's Collaborative Dual Feed Extruder

Double hobbed extruder

Rubber drive wheel

triple hobbed:

video

Edited 1 time(s). Last edit at 12/09/2018 08:36AM by herve robert.

Double hobbed extruder

Rubber drive wheel

triple hobbed:

video

Edited 1 time(s). Last edit at 12/09/2018 08:36AM by herve robert.

|

Re: Dual drive extruder December 09, 2018 01:58PM |

Registered: 6 years ago Posts: 93 |

Quote

MKSA

What kind of hotend/filament (1.75mm) requires that much force ?

Anyway, the key factor is the hobbed gear/idler. With a good one, it is possible to pull 40N using a geared Nema17 42mm. To push is an other story. You better have a well guided and short path between extruder and hotend.

The MK7 hobbed gears quality can be shitty. So to put two bad extruders in series is a complex, heavy, costly solution.

The Bondtech is based on a good design used for more than a century in the steel industry notably. You get the extra force and in addition it lessens the damage to the filament, comes handy when there is a lot of retraction.

In silent mode, the TMC drivers were not able to pull a 4 kilogram roll of filament, even with the rated 2A to the motor.

I had another identical setup on the shelf, so I used it inline. It still skipped steps occasionally, unless I kept the line slack by hand for a whole 5 hour print.

I've since changed drivers, but really see no reason to remove my experiment. Now I can't make it skip, it pulls the filament through my fingers. I have the fittings drilled and the PTFE trimmed and extending to the gears, so there's no other place for filament to go but up the Bowden tube--the single one would print flex filament just fine, fast enough to keep a volcano fed at speed.

Bondtech extruders are popular, but I've never seen the value, TBH.

$190 for a plastic extruder with a $36 geared stepper, seems a little over the top.

5.18:1 planetary gearbox? Who thought that up? I've never seen a gearbox without backlash (effects are negligable, but still..).

I do not like non-integer step rates (492.45 per mm). I'd rather have the controller rounding corners than rounding math.

4.3mH is getting higher than I like, it limits RPM for a motor that really needs it to retract at useful speed (like 5.18 times faster).

I don't judge, people use what they use. Personally I can afford a QR, but I won't do it.

BTW, the hobbed MK7 drive gears on RobotDigg are of excellent quality and finish. Much much better than eBay specials that are really made for 3mm filament, but claim to be usable for both...that's rubbish.

Edited 1 time(s). Last edit at 12/09/2018 02:11PM by Diggrr.

|

Re: Dual drive extruder December 09, 2018 02:39PM |

Registered: 12 years ago Posts: 2,470 |

I can see the use of a dual hobbed extruder to minimize the damage to the filament, but tbh a well adjusted idler strength will do the job 99% of the time just as good.

For me the two most important things to maximize extruder strength and speed are exact guidance of the filament, no kinks around the hobbed idler or similar, and a hotend that requires minimal pressure.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

For me the two most important things to maximize extruder strength and speed are exact guidance of the filament, no kinks around the hobbed idler or similar, and a hotend that requires minimal pressure.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Dual hobbed extruder December 09, 2018 02:48PM |

Registered: 9 years ago Posts: 383 |

Used Bondtech bmg after getting thoroughly frustrated by the under powered and unreliable unit from a competitor. The BMG is geared, but nit with the gearbox you see on the earlier models. The difference between the BMG and the more traditional design of the previous competitors unit (hobbed shaft forcing filament onto plane undriven roller) was clear. A lattce like structure failled each attempt before the swap and the new extruder worked great on the same build with only e-steps calibration.

Edited 1 time(s). Last edit at 12/09/2018 02:48PM by WesBrooks.

Edited 1 time(s). Last edit at 12/09/2018 02:48PM by WesBrooks.

|

Re: Dual drive extruder December 09, 2018 03:00PM |

Registered: 6 years ago Posts: 93 |

For me, it wasn't the gear slipping on the filament, it was the motor losing steps against the weight of the much larger roll of filament. Two motors doubled the power to pull it, and it let me use even less tension on the idler(s), and it didn't require a gearbox to do it. The BMG does look more interesting to me than the QR.

I still may build a NEMA23 extruder, and uncomplicate my setup though. I have a nice one on hand, and a 3A driver to push it with.

...all this mess for trying a giant roll of filament instead of having multiple rolls laying about. LOL

I still may build a NEMA23 extruder, and uncomplicate my setup though. I have a nice one on hand, and a 3A driver to push it with.

...all this mess for trying a giant roll of filament instead of having multiple rolls laying about. LOL

|

Re: Dual hobbed extruder December 09, 2018 03:20PM |

Registered: 6 years ago Posts: 1,007 |

Diggrr:

I am pretty sure that with a proper filament guide from spool to extruder, with built in elasticity a unique good geared extruder would work with these 4kg spool.

My filament guide is just a piece of PTFE tube attached with a rubber band to the frame, simple.

Geared extruders work, the ratio is not strange, not an integer is normal (Good Engineers thought that !). Anyway, you will never get an integer "step rate" due to the hobbed gear.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

I am pretty sure that with a proper filament guide from spool to extruder, with built in elasticity a unique good geared extruder would work with these 4kg spool.

My filament guide is just a piece of PTFE tube attached with a rubber band to the frame, simple.

Geared extruders work, the ratio is not strange, not an integer is normal (Good Engineers thought that !). Anyway, you will never get an integer "step rate" due to the hobbed gear.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Dual hobbed extruder December 09, 2018 03:30PM |

Registered: 8 years ago Posts: 19 |

I found that multiple contact points between the drive system and the filament to be distinct advantage and also started using two hob gears in line, then thought if 2 is better what about 3 or even 4, but that's when it really starts becoming impractical.

So I designed a larger single drive wheel with soft flexible flanges that envelope the filament ever so gently. As far as pulling power it can easily tackle a 4 kg spool, I just tested the latest reiteration and reached 11 kg's of pulling power (which seems to be the breaking strain of 1.75 PLA) using a RUMBA control and 4988 stepper driver. The 3 mm test was conducted with a higher power stepper driver @ 24v and achieved even more.

vid of demo here

www.flexwheelextruder.com

So I designed a larger single drive wheel with soft flexible flanges that envelope the filament ever so gently. As far as pulling power it can easily tackle a 4 kg spool, I just tested the latest reiteration and reached 11 kg's of pulling power (which seems to be the breaking strain of 1.75 PLA) using a RUMBA control and 4988 stepper driver. The 3 mm test was conducted with a higher power stepper driver @ 24v and achieved even more.

vid of demo here

www.flexwheelextruder.com

|

Re: Dual hobbed extruder December 09, 2018 03:34PM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Dual hobbed extruder December 09, 2018 03:52PM |

Registered: 6 years ago Posts: 93 |

@MKSA, I know integer is normal, I know too that it changes dynamically as the system moves, because the filament is not of constant diameter or density along it's length. And to be honest it's "over-sciensing", because it's really just globbing melted plastic in rows and stacks...but it annoys. Really I could skip entering the .45 altogether and it would not make a difference in the print. But it's like that fly in the corner..not doing anything to you, but you have to get up and smack it anyway.

The fact remains that the little motor has to travel 5.18 times further, and 5.18 times faster for each move it makes, to be equivalent to a direct drive.

@Arnold, cool!

Edited 1 time(s). Last edit at 12/09/2018 04:06PM by Diggrr.

The fact remains that the little motor has to travel 5.18 times further, and 5.18 times faster for each move it makes, to be equivalent to a direct drive.

@Arnold, cool!

Edited 1 time(s). Last edit at 12/09/2018 04:06PM by Diggrr.

|

Re: Dual hobbed extruder December 09, 2018 07:01PM |

Registered: 11 years ago Posts: 5,780 |

When I switched from ungeared to a bulldog XL extruder (5.18:1 gears) about 4 or 5 years ago, all my hot end jamming problems instantly went away. Having the extra push provided by a gear-reduced motor keeps the filament flowing even when things get less than ideal in the hot-end. I ran that extruder for about two years of daily printing before it had its first jam. Ungeared extruders often produce waves in the print surface that can be shifted by changing the extruder motor current (not the same as ringing). Gear reduced extruders provide smoother flow in the plastic and those lines don't form. 5:1 gearing might limit print speed, but having to restart a print because of a jammed hot-end limits print speed, too. I've been using Titans for the last couple years and they seem to work pretty reliably, though they aren't perfect.

If you're having trouble pulling filament from the spool because of the spool's mass, maybe the design of the spool holder could use some improvement.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

If you're having trouble pulling filament from the spool because of the spool's mass, maybe the design of the spool holder could use some improvement.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Dual hobbed extruder December 09, 2018 08:56PM |

Registered: 6 years ago Posts: 93 |

No argument that the spool feeder needs improving, but it's sufficient. A flick of the finger is all it takes to spin it. The PTFE runs to the spool, so the filament isn't dragging on anything.

Perhaps my first and last large spool though, it's been a PITA from the start. I spent more than the bulk discount on drivers. Oy.

Interesting info about the waves in the prints. That I do see sometimes. Perhaps willing to try a 2:1 belt drive, just to see if it's a decoupling that's needed. 5:1, likely not.

Thanks for the info!

Perhaps my first and last large spool though, it's been a PITA from the start. I spent more than the bulk discount on drivers. Oy.

Interesting info about the waves in the prints. That I do see sometimes. Perhaps willing to try a 2:1 belt drive, just to see if it's a decoupling that's needed. 5:1, likely not.

Thanks for the info!

|

Re: Dual hobbed extruder December 09, 2018 09:36PM |

Registered: 11 years ago Posts: 5,780 |

Pulling filament through a tube, even a teflon tube, requires extra oomph from the extruder. I have always fed filament straight down from the top of the printer to the extruder and never had problems (I don't use 4 kg spools). My printers are enclosed, so the spools can sit on top easily and feed down into the printer through a hole in the top. The feed paths are short and have minimal friction. I use spool holders in which the spools sit on rollers with ball bearings. The rollers span the width of the spools so the filament can't jump off the flanges and tie itself into knots.

I have a Titan in my corexy machine and have been able to run it as high at 200mm/sec with 10k acceleration (not how I normally run it, but the 3:1 gear reduction doesn't prevent running at that speed).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I have a Titan in my corexy machine and have been able to run it as high at 200mm/sec with 10k acceleration (not how I normally run it, but the 3:1 gear reduction doesn't prevent running at that speed).

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Dual drive extruder December 10, 2018 04:48AM |

Registered: 8 years ago Posts: 622 |

Quote

dc42

Quote

Srek

For me a reason to not do it is that it is unnecessary. I have thought about filament transportation with multiple points of contact, but in the end they did not offer any advantage. A well designed classic direct drive will develop enough force for well over 100mm/s. Another issue is size, such a setup will be larger than a single point of contact drive.

You might find [somei3deas.wordpress.com] interesting. Summary: in the particular case of using a mixing hot end, where the same piece of filament may get moved back and forth many times, the Bondtech (dual drive) extruder performed much better than the Titan (single drive) extruder. This doesn't prove that the dual vs. single aspect is solely responsible for the difference (the shape of the teeth on the hobbed shaft may have been different too), but it seems likely that it was the major factor.

For my particular usage case which is linked to above, I'm inclined to think that the reason the Bondtech performed better than the Titan is that there is no appreciable spring tension on the Bondtech. What seems to happen is that, with a sprung loaded extruder, multiple retract and un-retract cycles over the same piece of filament cause the filament to wear which reduces the diameter. The spring tension then pushes the hobbed bolt against this reduced diameter which causes it to wear even more until eventually (several thousand cycles), it grinds right though the filament. Whereas with the Bondtech using a fixed distance between the two hobbed bolts, what seems to happen is that the teeth cut grooves in the filament but because there is no spring, these grooves don't get any deeper. So it acts like a rack and pinion gear (with the filament being the rack and the hobbed bolts the gear).

I've used both Titans and BMGs on my printer and found that both will handle 4Kg reels and at print speeds up to 300mm/sec. Both are about the same size and cost. Having said that, I prefer the BMGs because they are much much easier to fit and maintain. Also retraction is more consistent, especially when doing lots of small moves with retraction between them. On my machine, I needed 5mm of retraction on the Titans but only need 3.5mm on the BMGs. I suspect this is due to the spring tensioner causing some wear of the filament during the retract so it needs higher un-retract due to the reduced filament diameter. I didn't get around to playing with different retract / un-retract distances but that may have been a cure.

[somei3deas.wordpress.com]

[www.youtube.com]

|

Re: Dual hobbed extruder December 10, 2018 05:24AM |

Registered: 6 years ago Posts: 93 |

@TDD, my spool usually sits on rollers similar to yours, the PTFE intake normally curls around under the spool so the force is downward keeping the spool in place. The 300mm diameter spool wouldn't fit in my enclosure, so I had to rig a horizontal PVC pipe with printed bushings to center it, located under the machine. There's my rub (pun intended). The spool isn't on bearings. It spins easily enough though with a little oil. I added about 300mm of PTFE to guide it upward around the frame and through a hole into the enclosure...not ideal, but it beats groove bearings all along the path for time involved.

Really, since the TMC2660 drivers proved to be weak while depending on someone else's config apparently with smaller motors (damn I wish smoothie was more thoroughly documented!!!) I had to play to get it running at all.

At the least I've been having fun doing something I've not seen before, but I really do think that since I now have full powered drivers on it, the dual extruder drive would pull Chicago closer if given the chance (I'm in Michigan).

I would like to mess around with a belt driven 2:1 though. I still can see marks in my prints that look almost like the MK tooth imprints, but faint and shallow. Perhaps decoupling can solve that on it's own without the need for large gear ratios...I'll see.

Really, since the TMC2660 drivers proved to be weak while depending on someone else's config apparently with smaller motors (damn I wish smoothie was more thoroughly documented!!!) I had to play to get it running at all.

At the least I've been having fun doing something I've not seen before, but I really do think that since I now have full powered drivers on it, the dual extruder drive would pull Chicago closer if given the chance (I'm in Michigan).

I would like to mess around with a belt driven 2:1 though. I still can see marks in my prints that look almost like the MK tooth imprints, but faint and shallow. Perhaps decoupling can solve that on it's own without the need for large gear ratios...I'll see.

|

Re: Dual hobbed extruder December 10, 2018 10:31AM |

Registered: 5 years ago Posts: 26 |

Quote

MKSA

Quote

herve robert

triple hobbed:

[attachment 108576 frame00015.png]

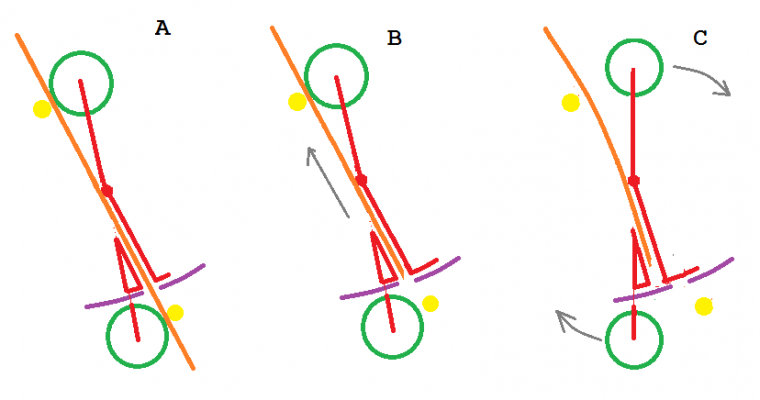

Just wondering why the "idlers" are set that way, on the same articulated arm ?

"idler" wheels can be set on individual independant mechanisms.

but for each arm you need a push spring.

another purpose is:

to build an automatic or semi-automatic filament loading.

on the video the sequence isn't exact.

first, the unloading:

step (B ), the "orange" filament go back.

then the arm is moving (C).

but in the same time the filament is hold by the arm and it's get motionless.

second, the loading:

reverse mode with the "blue" filament...(C,B,A).

(utopic work not in real life. must make for talking more about it)

Edited 3 time(s). Last edit at 12/10/2018 10:39AM by herve robert.

|

Re: Dual hobbed extruder December 10, 2018 11:24AM |

Registered: 6 years ago Posts: 1,007 |

-With independ idlers, you just reinvent the two extruders in series with one motor, one step further, no idler, and you reinvent the concept used in Bontech that is a century old at least.

-As shown however, idlers will interact and one may prevent proper push of the other against its hobbed gear.

I recommend pursuing the first approach. Competiton to the Bontech may lead to cheaper ones for people who really need the extra force and likely to put a stop to all these clumsy extruders popping out regularly.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

-As shown however, idlers will interact and one may prevent proper push of the other against its hobbed gear.

I recommend pursuing the first approach. Competiton to the Bontech may lead to cheaper ones for people who really need the extra force and likely to put a stop to all these clumsy extruders popping out regularly.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Dual hobbed extruder December 10, 2018 12:56PM |

Registered: 11 years ago Posts: 5,780 |

Here's something I was working on about 5 years ago- very smooth extrusion...

More here: [vimeo.com] and here: [www.thingiverse.com]

My design used counter rotating #6-32 nuts to drive 3mm filament. It had very strong grip and push force, but didn't work well when retracting.

And I see that someone at MIT recently used a similar technique to drive the filament: [3dprinting.com]

MIT's extruder uses a single nut to drive the filament and some anti-twist rollers instead of a counter-rotating nut.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

More here: [vimeo.com] and here: [www.thingiverse.com]

My design used counter rotating #6-32 nuts to drive 3mm filament. It had very strong grip and push force, but didn't work well when retracting.

And I see that someone at MIT recently used a similar technique to drive the filament: [3dprinting.com]

MIT's extruder uses a single nut to drive the filament and some anti-twist rollers instead of a counter-rotating nut.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Dual hobbed extruder December 10, 2018 02:50PM |

Registered: 5 years ago Posts: 26 |

|

Re: Dual drive extruder December 10, 2018 11:10PM |

Registered: 8 years ago Posts: 5,232 |

Quote

Deckingman

On my machine, I needed 5mm of retraction on the Titans but only need 3.5mm on the BMGs. I suspect this is due to the spring tensioner causing some wear of the filament during the retract so it needs higher un-retract due to the reduced filament diameter. I didn't get around to playing with different retract / un-retract distances but that may have been a cure.

I believe the Titan deforms filament more and therefor needs to push harder to overcome Bowden tube friction. That also has an effect on retraction length IMHO.

There's simply more zigzag-filament in the same Bowden length.

|

Re: Dual drive extruder December 11, 2018 06:02AM |

Registered: 6 years ago Posts: 1,007 |

Quote

o_lampe

Quote

Deckingman

On my machine, I needed 5mm of retraction on the Titans but only need 3.5mm on the BMGs. I suspect this is due to the spring tensioner causing some wear of the filament during the retract so it needs higher un-retract due to the reduced filament diameter. I didn't get around to playing with different retract / un-retract distances but that may have been a cure.

I believe the Titan deforms filament more and therefor needs to push harder to overcome Bowden tube friction. That also has an effect on retraction length IMHO.

There's simply more zigzag-filament in the same Bowden length.

Hobbed gear diam is too small. Most current extruders are non geared, therefore the usual hobbed gear effective diam is around 8.5mm. I make my own, diam 12mm (14mm planned eventually), better grip as more teeth are engaged and less filament deformation due to the bigger diam.

Bondtech also use a bigger diam and goes one step further, two of them. So far didn't feel the need to go that extra step.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

Sorry, only registered users may post in this forum.