Introducing the Prism Mendel

Posted by Buback

|

Re: Introducing the Prism Mendel July 12, 2012 10:54AM |

Admin Registered: 12 years ago Posts: 2,569 |

|

Re: Introducing the Prism Mendel July 12, 2012 11:27AM |

Registered: 12 years ago Posts: 809 |

I wish - it would give me an excuse to build a Linux box. Windows only I'm afraid. 123D is a light modeler. It's a bit of a memory pig as well. But once you get the hang of it (and don't ask it to do too much at once) then it's a pretty decent program. It will output to:

.svg

.dwg

.dxf

.sat

.stl

.iges

.step

Not too bad, but could be better.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

.svg

.dwg

.dxf

.sat

.stl

.iges

.step

Not too bad, but could be better.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Introducing the Prism Mendel July 13, 2012 11:38AM |

Registered: 13 years ago Posts: 601 |

|

Re: Introducing the Prism Mendel July 13, 2012 05:02PM |

Admin Registered: 12 years ago Posts: 2,569 |

Need to replace that floppy Y plate, so had some fun with the local fablab laser cutter

edit : Just wondering, maybe we should ask for a new subforum like Tantillus and Foldarap recently did ? That single topic is growing huge. On the other hand, it would separate us from the Mendel crowd, less chance to contaminate new Prismers.

Edited 2 time(s). Last edit at 11/22/2013 08:21AM by DeuxVis.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

edit : Just wondering, maybe we should ask for a new subforum like Tantillus and Foldarap recently did ? That single topic is growing huge. On the other hand, it would separate us from the Mendel crowd, less chance to contaminate new Prismers.

Edited 2 time(s). Last edit at 11/22/2013 08:21AM by DeuxVis.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

|

Re: Introducing the Prism Mendel July 13, 2012 06:53PM |

Registered: 12 years ago Posts: 809 |

I really like the acrylic plates! Fantastic job with the design! Wish I lived near a fablab...

I kinda like the idea of a separate forum for the Prism. It might get the name out there a bit more. I'd vote for it if this thread could be copied into that sub-forum.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

I kinda like the idea of a separate forum for the Prism. It might get the name out there a bit more. I'd vote for it if this thread could be copied into that sub-forum.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Introducing the Prism Mendel July 21, 2012 03:08PM |

Registered: 11 years ago Posts: 1 |

Hello,

I am just gathering the info needed to start ordering parts. I decided to want a Prism. I will probably get all of the parts I can from Ultimachine because shipping is expensive to Alaska. The thing holding me back is I don't have access to a printer to get the printed parts. Anyone know of a source. Thanks in advance and I am excited to build one of these.

I am just gathering the info needed to start ordering parts. I decided to want a Prism. I will probably get all of the parts I can from Ultimachine because shipping is expensive to Alaska. The thing holding me back is I don't have access to a printer to get the printed parts. Anyone know of a source. Thanks in advance and I am excited to build one of these.

|

Re: Introducing the Prism Mendel July 25, 2012 08:46AM |

Admin Registered: 12 years ago Posts: 2,569 |

Congratulations on your choice, Prism rocks.

If you don't find a solution nearest to you, contact me back, I'm willing to print your Prism parts at cost price to help a fellow "Prismer", but I'm in France.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

If you don't find a solution nearest to you, contact me back, I'm willing to print your Prism parts at cost price to help a fellow "Prismer", but I'm in France.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

|

Re: Introducing the Prism Mendel July 25, 2012 12:12PM |

Registered: 12 years ago Posts: 40 |

|

Re: Introducing the Prism Mendel July 29, 2012 02:32PM |

Registered: 12 years ago Posts: 809 |

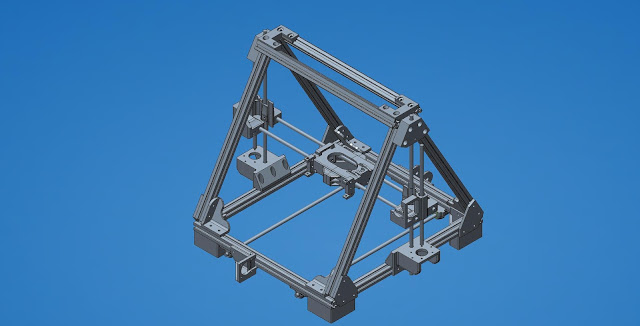

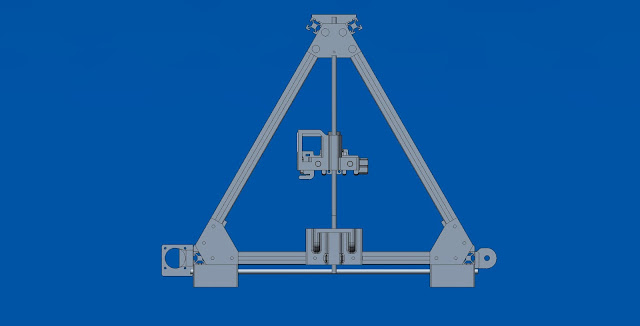

Prism Mendel 1.5

Total re-design of all parts. New X-ends and a new open top.

I'll be putting the files up on my github later this week, I just want to get the first one done to the point that I'm satisfied that the actual machine fits together as well as the virtual one does.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

Total re-design of all parts. New X-ends and a new open top.

I'll be putting the files up on my github later this week, I just want to get the first one done to the point that I'm satisfied that the actual machine fits together as well as the virtual one does.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Introducing the Prism Mendel July 30, 2012 09:01AM |

Registered: 11 years ago Posts: 64 |

That looks really nice, very sturdy. Something about all the threaded rods in the standard Prusa Mendel makes it look like an erector set even though it's very functional and sturdy. The aluminum frame on this one just makes it look more 'finished'.

Any idea about the difference in weight and availability of these aluminum pieces? Threaded rod and nuts are available pretty much everywhere, I'm not sure about these frame pieces, I've never looked for them.

Any idea about the difference in weight and availability of these aluminum pieces? Threaded rod and nuts are available pretty much everywhere, I'm not sure about these frame pieces, I've never looked for them.

|

Re: Introducing the Prism Mendel July 30, 2012 06:35PM |

Admin Registered: 15 years ago Posts: 1,470 |

a_shorething Wrote:

-------------------------------------------------------

> I'm not sure about these frame pieces, I've never

> looked for them.

They can be had almost anywhere. Check eBay for 2020 extrusions, or Misumi. Misumi is probably the best priced stuff out there, and cuts to length for free too.

-------------------------------------------------------

> I'm not sure about these frame pieces, I've never

> looked for them.

They can be had almost anywhere. Check eBay for 2020 extrusions, or Misumi. Misumi is probably the best priced stuff out there, and cuts to length for free too.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Introducing the Prism Mendel July 31, 2012 11:51AM |

Registered: 12 years ago Posts: 809 |

Misumi is where I order the extrusions from. As far as the weight I'm not certain of the comparison to a Prusa. I'll have to look into that. But I'm sure that a full set of extrusions are cheaper than the quantity of stainless M8 allthread used in a Prusa. Cheaper in the US anyway.

@misumi (10) HFS5-2020-400 = $23

@mcmaster (6) 99055A125 = $26 (which have to be then be cut)

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

@misumi (10) HFS5-2020-400 = $23

@mcmaster (6) 99055A125 = $26 (which have to be then be cut)

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Introducing the Prism Mendel July 31, 2012 01:21PM |

Registered: 11 years ago Posts: 64 |

Very cool.

Thanks to both of you. I love the look of this design.

As I think about it more than half of the parts need to be sourced online anyway, so it makes sense to order the rails too, especially if you can get them cut to length.

I can't wait to get my current printer going so I can start on my next one.

Thanks to both of you. I love the look of this design.

As I think about it more than half of the parts need to be sourced online anyway, so it makes sense to order the rails too, especially if you can get them cut to length.

I can't wait to get my current printer going so I can start on my next one.

|

Re: Introducing the Prism Mendel July 31, 2012 02:01PM |

Registered: 12 years ago Posts: 809 |

One of the design principles was to make the machine as cost efficient as possible. A single size screw for all the frame connections (M4-14mm) means less wasted hardware and an overall simpler build. It wasn't feasible to maintain the same size screw for the trapped nuts (M4 is a little large for these). But there are only 32 M3 screws in the machine (28@10mm, 4@20mm), 20 M3 washers and 12 nuts. And all the M3 hardware is for connecting/securing the X, Y and Z smooth rods to the machine. Sure you could pick up a box of each at mcmaster or go to the local hardware store and get only what you need. These count's don't include the extruder though. Still working on that.

Trying to lower the barriers to entry with this design, both economic and technical. Writing up the instructions and BOM now. Going to have a teenage girl (non-maker) assemble the frame of the machine and time her. If she can do it so can you!

Basic Frame BOM:

From Misumi:

(10) HFS5-2020-400 $22.80

(1) HNKK5-4 $19.32

Subtotal: $42.12

From McMaster:

(1) 91290A148 $5.58

(1) 93475A230 $1.86

(1) 91111A121 $2.10

Subtotal: $9.54

Frame Hardware Total $51.66

If you want to order the M3 hardware from mcmaster in bulk toss in another $20

Not too bad.

To finish the machine you'd need leadscrews or allthread, M8 smooth rod, bearings, steppers, timing pulleys and belts, etc. But the cost of the build if self-sourced should be fairly low. If you can find someone to print the parts at a decent price then I'd say you should be able to keep the machine under $700 easily, especially if you don't go crazy with high-end components.

Edited 1 time(s). Last edit at 08/01/2012 07:22AM by akhlut.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

Trying to lower the barriers to entry with this design, both economic and technical. Writing up the instructions and BOM now. Going to have a teenage girl (non-maker) assemble the frame of the machine and time her. If she can do it so can you!

Basic Frame BOM:

From Misumi:

(10) HFS5-2020-400 $22.80

(1) HNKK5-4 $19.32

Subtotal: $42.12

From McMaster:

(1) 91290A148 $5.58

(1) 93475A230 $1.86

(1) 91111A121 $2.10

Subtotal: $9.54

Frame Hardware Total $51.66

If you want to order the M3 hardware from mcmaster in bulk toss in another $20

Not too bad.

To finish the machine you'd need leadscrews or allthread, M8 smooth rod, bearings, steppers, timing pulleys and belts, etc. But the cost of the build if self-sourced should be fairly low. If you can find someone to print the parts at a decent price then I'd say you should be able to keep the machine under $700 easily, especially if you don't go crazy with high-end components.

Edited 1 time(s). Last edit at 08/01/2012 07:22AM by akhlut.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Introducing the Prism Mendel August 03, 2012 12:25AM |

Registered: 11 years ago Posts: 20 |

I've been following this thread with interest, and am now amassing parts to make my second Mendel as a prism. I've got an Azteeg X3 and a new heated bed on pre-order, and will start sourcing in the motors and endswitches in a couple weeks.

Has anybody tried, or thought of using extrusions as axis ways, instead of smooth rod?

Has anybody tried, or thought of using extrusions as axis ways, instead of smooth rod?

|

Re: Introducing the Prism Mendel August 03, 2012 06:22AM |

Registered: 12 years ago Posts: 809 |

Yes, egenoup has started a Prism using makerslide. Page 4 of the thread.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Introducing the Prism Mendel August 07, 2012 05:41AM |

Admin Registered: 12 years ago Posts: 2,569 |

Very nice job Akhlut, I'll probably partially upgrade my machine to your design.

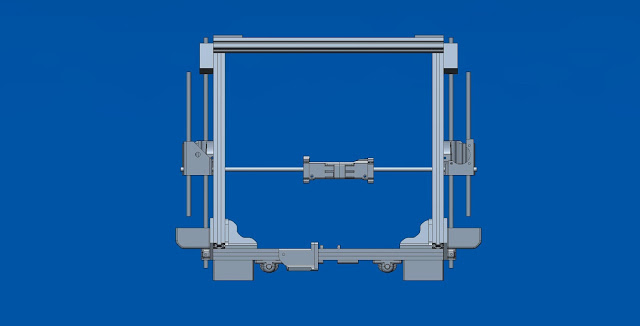

Ah, a quick extruder release X carriage; nice.

And moving the Z threaded rods outside of the frame, good - will need a custom build plate, as a PCB heated bed mk2 will be far too narrow to use all that width then

You're going for 2 motors for Z if I get it right ?

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

Ah, a quick extruder release X carriage; nice.

And moving the Z threaded rods outside of the frame, good - will need a custom build plate, as a PCB heated bed mk2 will be far too narrow to use all that width then

You're going for 2 motors for Z if I get it right ?

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

|

Re: Introducing the Prism Mendel August 07, 2012 07:17AM |

Registered: 12 years ago Posts: 809 |

Yes, two Z motors on the bottom.

And yes, pushing the Z-axis to outside the frame provides a ridiculous amount of room. For example 500mm extrusions provide enough room for 350-375mm in X, 300-320mm in Y and around 250mm in Z (depending on hotend and Y-carriage construction).

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

And yes, pushing the Z-axis to outside the frame provides a ridiculous amount of room. For example 500mm extrusions provide enough room for 350-375mm in X, 300-320mm in Y and around 250mm in Z (depending on hotend and Y-carriage construction).

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Introducing the Prism Mendel August 07, 2012 02:27PM |

Registered: 12 years ago Posts: 1,236 |

|

Re: Introducing the Prism Mendel August 15, 2012 03:00PM |

Registered: 12 years ago Posts: 809 |

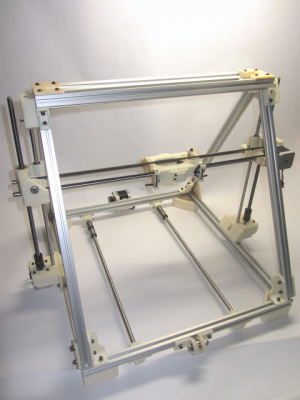

The basic frame is together.

Visual instruction manual due out this weekend.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

Visual instruction manual due out this weekend.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Introducing the Prism Mendel August 15, 2012 04:58PM |

Admin Registered: 15 years ago Posts: 1,470 |

That looks so nice! Good work!

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Introducing the Prism Mendel August 15, 2012 05:53PM |

Registered: 12 years ago Posts: 809 |

Thanks! Hoping to have it complete soon, then put it through its paces.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Introducing the Prism Mendel August 15, 2012 07:36PM |

Registered: 14 years ago Posts: 93 |

Just joining in to the conversation, currently I have a mostly functional mendel prusa, (some nozzle issues haning on) that I share with 2 other guys. we agreed we would get one up and running, then build 2 more so we each had one. interested in the Prism. Where in USA have people found the extruded aluminum? I just set up an account with Misumi, got the quote for 22.80 for the 10 frame pieces, don't know how much shipping will be, it looks like they won't tell me till I place the order. Not sure why. any other suppliers in the USA people have found?

Thanks

Thanks

|

Re: Introducing the Prism Mendel August 15, 2012 08:26PM |

Registered: 12 years ago Posts: 809 |

Misumi is pretty good - just get a quote and they'll give you a price for shipping in the quote.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Introducing the Prism Mendel August 15, 2012 08:42PM |

Registered: 12 years ago Posts: 40 |

|

Re: Introducing the Prism Mendel August 15, 2012 08:46PM |

Registered: 12 years ago Posts: 40 |

|

Re: Introducing the Prism Mendel August 15, 2012 11:24PM |

Registered: 14 years ago Posts: 93 |

akhlut Wrote:

-------------------------------------------------------

> Misumi is pretty good - just get a quote and

> they'll give you a price for shipping in the

> quote.

My quote said shipping to be calculated when order is placed. We have a metals recycler that quite often gets extruded metal as scrap, I am checking with them this week if they have any the right size. The prism design looks very promising.

-------------------------------------------------------

> Misumi is pretty good - just get a quote and

> they'll give you a price for shipping in the

> quote.

My quote said shipping to be calculated when order is placed. We have a metals recycler that quite often gets extruded metal as scrap, I am checking with them this week if they have any the right size. The prism design looks very promising.

|

Re: Introducing the Prism Mendel August 15, 2012 11:33PM |

Registered: 12 years ago Posts: 809 |

Thanks!

Don't worry - I have an X-end version for 8mm smooth rods and M8/ACME 1/4" drive nuts. Standard hardware will work with the design.

Placing the rods under the the frame should provide additional Z - about 55mm compared to placing them on top, and about 22mm if they are placed in the center of the extrusion. iven the current configuration, Zmin provides 60mm of clearance between the top of the rod and the tip of the hotend. Less 10mm for the LM10UU's, holders and Dibond drive plate leaves 50mm of space for the leveling screws, build stage and heated bed. That should be plenty of room to accommodate those components. Maybe not enough room.

For a Prism made of 500mm extrusions you have approximately 275mm of Z for build space, and the X and Y axes can fit a 350mm square build plate.

As for the placement of the Y-axis drive-train outside the frame I did this keep the build as simple as possible while maintaining component strength. The component I was worried about was the drive plate. In order to keep as much rigidity as possible I wanted it to be uniform - no cut-outs for the motor or idler. That meant placing the idler and motor outside the frame. This led to the necessity of centering the motor and idler on the vertical face of the extrusion so that the belt would clear it. So the 608ZZ bearing is fine - the diameter is 22mm. And a 36 tooth GT2 pulley has a tooth diameter of 23mm. So now the tolerances for the belting are very tight ~ 1mm to the top and bottom of the extrusion. As a happy accident this means the belts must be parallel for the entire distance of Y to maintain clearance. This is a very good thing as steps/mm will not change over the distance of the Y-Axis due to changes in the angle of approach of the belt to the bed.

As far as size is concerned I think you are right. Modifying the drive plate one could place the motor/idler inside the frame. I wouldn't do it for a dibond bed, but MDF or plywood - why not?

Now that I look at it it may make sense to change the Y-axis rod holders, making them low-profile (not sticking into the frame at all). And I suppose I could alter the Z-motor mounts to provide additional Z.

Thanks rglory! You have helped me to think 'outside the prism'!

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

Don't worry - I have an X-end version for 8mm smooth rods and M8/ACME 1/4" drive nuts. Standard hardware will work with the design.

Placing the rods under the the frame should provide additional Z - about 55mm compared to placing them on top, and about 22mm if they are placed in the center of the extrusion. iven the current configuration, Zmin provides 60mm of clearance between the top of the rod and the tip of the hotend. Less 10mm for the LM10UU's, holders and Dibond drive plate leaves 50mm of space for the leveling screws, build stage and heated bed. That should be plenty of room to accommodate those components. Maybe not enough room.

For a Prism made of 500mm extrusions you have approximately 275mm of Z for build space, and the X and Y axes can fit a 350mm square build plate.

As for the placement of the Y-axis drive-train outside the frame I did this keep the build as simple as possible while maintaining component strength. The component I was worried about was the drive plate. In order to keep as much rigidity as possible I wanted it to be uniform - no cut-outs for the motor or idler. That meant placing the idler and motor outside the frame. This led to the necessity of centering the motor and idler on the vertical face of the extrusion so that the belt would clear it. So the 608ZZ bearing is fine - the diameter is 22mm. And a 36 tooth GT2 pulley has a tooth diameter of 23mm. So now the tolerances for the belting are very tight ~ 1mm to the top and bottom of the extrusion. As a happy accident this means the belts must be parallel for the entire distance of Y to maintain clearance. This is a very good thing as steps/mm will not change over the distance of the Y-Axis due to changes in the angle of approach of the belt to the bed.

As far as size is concerned I think you are right. Modifying the drive plate one could place the motor/idler inside the frame. I wouldn't do it for a dibond bed, but MDF or plywood - why not?

Now that I look at it it may make sense to change the Y-axis rod holders, making them low-profile (not sticking into the frame at all). And I suppose I could alter the Z-motor mounts to provide additional Z.

Thanks rglory! You have helped me to think 'outside the prism'!

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Introducing the Prism Mendel August 15, 2012 11:36PM |

Registered: 12 years ago Posts: 809 |

That's strange. Did you open an account with them? They always provide shipping costs in my quote.

But if you can get scrap extrusions that would be great. Just make sure you cut them all to the same length.

Idaholion Wrote:

> My quote said shipping to be calculated when order

> is placed. We have a metals recycler that quite

> often gets extruded metal as scrap, I am checking

> with them this week if they have any the right

> size. The prism design looks very promising.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

But if you can get scrap extrusions that would be great. Just make sure you cut them all to the same length.

Idaholion Wrote:

> My quote said shipping to be calculated when order

> is placed. We have a metals recycler that quite

> often gets extruded metal as scrap, I am checking

> with them this week if they have any the right

> size. The prism design looks very promising.

- akhlut

Just remember - Iterate, Iterate, Iterate!

[myhomelessmind.blogspot.com]

|

Re: Introducing the Prism Mendel August 16, 2012 03:35AM |

Registered: 12 years ago Posts: 40 |

>Placing the rods under the the frame should provide additional Z - about 55mm compared to placing them on top

I understand that. But if you would not let build stage and bed move over the extrusion then maximum work area for Y will be 250mm for 500mm extrusion (btw I missed moment when extrusions became 500mm instead of 400mm) or 200mm for 400mm extrusions maximum. But that in case if build stage exactly the same size as bed, usually it is bigger, that makes work area even smaller.

Edited 1 time(s). Last edit at 08/16/2012 03:55AM by rGlory.

I understand that. But if you would not let build stage and bed move over the extrusion then maximum work area for Y will be 250mm for 500mm extrusion (btw I missed moment when extrusions became 500mm instead of 400mm) or 200mm for 400mm extrusions maximum. But that in case if build stage exactly the same size as bed, usually it is bigger, that makes work area even smaller.

Edited 1 time(s). Last edit at 08/16/2012 03:55AM by rGlory.

Sorry, only registered users may post in this forum.