Ebay SINTRON Kossel Mini full kit

Posted by Miamicraft

|

Re: Ebay SINTRON Kossel Mini full kit October 01, 2015 04:49PM |

Registered: 8 years ago Posts: 319 |

Quote

Tha_Reaper

thanks for the pictures. They help a lot. I cut the belts, and i've decided to adjust the pulley and the top corners later.

I just installed the endstops with the endstop brackets from the second page of this topic. they fit, but there is a little problem that you cant get to the screw to move the endstop up and down without physicly removing the endstop first. Ive tried to measure it out so that they are in the same spot, but that will probably be off by a mm or so. do they need to be at the exact same hight?

Also i have 6 endstops in my kit... i know where to place 3 of them, but why do i need 6?! Everyone got 6?

I have build a little blog by the way about the building progress. [kosselreprap.blogspot.be]

Not much usefull info there, but for people that want to start building maybe a good place to check for what to expect.

I got 6 as well as 5 stepper drivers. I asked Sintron and they said that the 5th stepper is an extra cuz they burn out a lot? But I decided not to say anything about the extra three endstops.

Also the endstops on the machine will all be at different heights. You need to calibrate the center of the nozzle. Once that is done, you need to measure the height from the carriage to the endstop of one of them. And make it so that all 3 are at the same height from the carriage that is at x0, y0, z0.

|

Re: Ebay SINTRON Kossel Mini full kit October 01, 2015 04:55PM |

Registered: 8 years ago Posts: 89 |

|

Re: Ebay SINTRON Kossel Mini full kit October 01, 2015 05:23PM |

Registered: 8 years ago Posts: 255 |

Quote

Tha_Reaper

thanks for the pictures. They help a lot. I cut the belts, and i've decided to adjust the pulley and the top corners later.

I just installed the endstops with the endstop brackets from the second page of this topic. they fit, but there is a little problem that you cant get to the screw to move the endstop up and down without physicly removing the endstop first. Ive tried to measure it out so that they are in the same spot, but that will probably be off by a mm or so. do they need to be at the exact same hight?

The carriages should be at the exact same height when they're stopped. It's like you support carriage with the stick and slide endstop so that it is triggered at this height.

Not sure what would be the best endstop holder, but I designed (if I am allowed to use the word

) this one — http://www.thingiverse.com/thing:1047133. It's pretty much original "design", except for it doesn't have funny useless holes and is somewhat stable.

) this one — http://www.thingiverse.com/thing:1047133. It's pretty much original "design", except for it doesn't have funny useless holes and is somewhat stable.

|

Re: Ebay SINTRON Kossel Mini full kit October 01, 2015 06:11PM |

Registered: 8 years ago Posts: 319 |

I printed a knob for my LCD screen. And the hole in the knob is 2mm too wide. Is there an easy fix for this? The print took 19min. And it looks really good. Just not right size.

Also, for endstop placement I found the shortested distance between the carriage and one of the endstops once I had it at x0 yo z0. Then I cut a piece of wood that size. I then used it as a template to adjust the height of the other 2 endstops on the machine. I got the idea from someone on the web.

Edited 1 time(s). Last edit at 10/01/2015 06:15PM by DRTak.

Also, for endstop placement I found the shortested distance between the carriage and one of the endstops once I had it at x0 yo z0. Then I cut a piece of wood that size. I then used it as a template to adjust the height of the other 2 endstops on the machine. I got the idea from someone on the web.

Edited 1 time(s). Last edit at 10/01/2015 06:15PM by DRTak.

|

Re: Ebay SINTRON Kossel Mini full kit October 01, 2015 06:13PM |

Registered: 8 years ago Posts: 255 |

|

Re: Ebay SINTRON Kossel Mini full kit October 01, 2015 06:16PM |

Registered: 8 years ago Posts: 319 |

Quote

hacker

Quote

DRTak

I printed a knob for my LCD screen. And the hole that fits the knob is 2mm too wide. Is there an easy fix for this?

do you print on the blue tape? That should do, I think.

I print on aluminum sintron bed. But I use kapton tape on the bed since aluminum is not sticky enough for abs.

But the knob in general is too wide. It hits the sensor thing on the lcd screen

|

Re: Ebay SINTRON Kossel Mini full kit October 01, 2015 06:50PM |

Registered: 8 years ago Posts: 197 |

Max and min endstops.

The only ones that are really needed are the max which should be the top of each axis.

If you have the liner rails. You put the other endstop mounts on the bottom. Kinda stops the part from sliding compeltey off the rail if something was to break. But as said there not really needed.

And yes abs isnt for starters.

Pla is so easy to print. It just needs a cooling fan.

Ive printed abs before and i couldnt do it inside.

Had to print it in the garage where it stay warm and there was no brezzy. Once i did that got abs to print righr on painters tape with only a glue stick. No wraping at all

The only ones that are really needed are the max which should be the top of each axis.

If you have the liner rails. You put the other endstop mounts on the bottom. Kinda stops the part from sliding compeltey off the rail if something was to break. But as said there not really needed.

And yes abs isnt for starters.

Pla is so easy to print. It just needs a cooling fan.

Ive printed abs before and i couldnt do it inside.

Had to print it in the garage where it stay warm and there was no brezzy. Once i did that got abs to print righr on painters tape with only a glue stick. No wraping at all

|

Re: Ebay SINTRON Kossel Mini full kit October 01, 2015 07:35PM |

Registered: 8 years ago Posts: 104 |

Quote

xile6

Max and min endstops.

...

If you have the liner rails. You put the other endstop mounts on the bottom. Kinda stops the part from sliding compeltey off the rail if something was to break. But as said there not really needed.

I also got 6 endstops. But, actually, there are not enough pins to connect all of them. Because "Z-min" pins are already occupied by autolevel probe.

And even in case of linear rails you can physically limit them (to prevent them off), using large screws (or something like that) at the ends.

BTW, I think 6 endstops are used to limit axes on classic (non-delta) printers. And they just include electronics set from Prusa or Mendel.

Edited 1 time(s). Last edit at 10/01/2015 07:41PM by GrAndAG.

|

Re: Ebay SINTRON Kossel Mini full kit October 01, 2015 09:17PM |

Registered: 8 years ago Posts: 916 |

Quote

DRTak

I am in the process of filing down the rods.

But in the interim, how do you hide the wires to make this look pretty. I had friend come over and he was NOT impressed. He had this look like it looks like a rats nest.

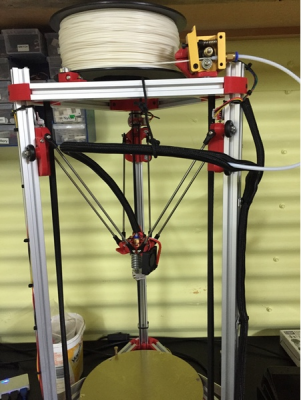

Self-closing braided wrap is really handy for this:

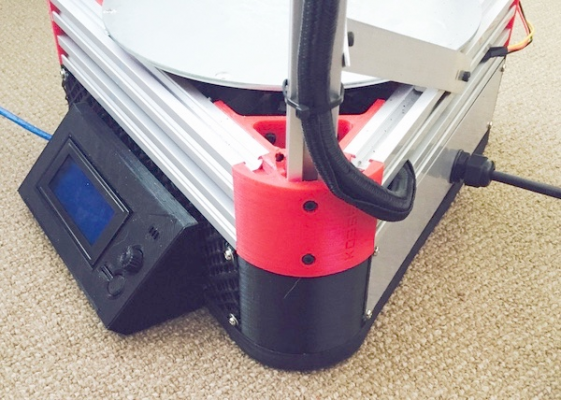

You can also build a pedestal to put your power supply and cables so that everything is all in one place without visible wires:

[www.thingiverse.com]

Edited 1 time(s). Last edit at 10/01/2015 09:19PM by nebbian.

|

Re: Ebay SINTRON Kossel Mini full kit October 01, 2015 10:13PM |

Registered: 8 years ago Posts: 319 |

Quote

nebbian

Quote

DRTak

I am in the process of filing down the rods.

But in the interim, how do you hide the wires to make this look pretty. I had friend come over and he was NOT impressed. He had this look like it looks like a rats nest.

Self-closing braided wrap is really handy for this:

[attachment 63357 IMG_4545.jpeg]

You can also build a pedestal to put your power supply and cables so that everything is all in one place without visible wires:

[www.thingiverse.com]

[attachment 63358 IMG_4487.jpeg]

Wow that looks great. How did you attach the pedastal to the base?

|

Re: Ebay SINTRON Kossel Mini full kit October 01, 2015 10:40PM |

Registered: 8 years ago Posts: 916 |

|

Re: Ebay SINTRON Kossel Mini full kit October 02, 2015 12:02AM |

Registered: 8 years ago Posts: 319 |

So I am using this to calibrate:

[www.instructables.com]

But for some reason my Repetier doesnt show any number when I type M501. So I am going to do a mashup up of that links calibration and Sintrons calibration procedure which is altering configuration.h where it says: #define DEFAULT_AXIS_STEPS_PER_UNIT {100, 100, 100, 95}.

Edited 1 time(s). Last edit at 10/02/2015 10:08AM by DRTak.

[www.instructables.com]

But for some reason my Repetier doesnt show any number when I type M501. So I am going to do a mashup up of that links calibration and Sintrons calibration procedure which is altering configuration.h where it says: #define DEFAULT_AXIS_STEPS_PER_UNIT {100, 100, 100, 95}.

Edited 1 time(s). Last edit at 10/02/2015 10:08AM by DRTak.

|

Re: Ebay SINTRON Kossel Mini full kit October 02, 2015 12:03AM |

Registered: 8 years ago Posts: 319 |

Also, my Y and X axis on my Kossel do not match up with the picture of the X, Y axis of Repetier. My x is where the Y is and my Y is where the x is. So I moved the wires to match the picture. Now my X is X and my Y is Y. Otherwise when I was printing. The picture imaged and the print was inverted.

Now I am having an Issue. There is this link on calibration but I cannot find M503 or M501 command. When I type it into repetier nothing happens. I cant get it to work. So I have been messing with DEFAULT_AXIS_STEPS_PER_UNIT in configuration.h. I made the x, y, z axis all the same number. Now When I move x it is exactly 10mm by my calipers. But it has messed up homing etc. So I am fixing that now.

Edited 2 time(s). Last edit at 10/02/2015 12:29PM by DRTak.

Now I am having an Issue. There is this link on calibration but I cannot find M503 or M501 command. When I type it into repetier nothing happens. I cant get it to work. So I have been messing with DEFAULT_AXIS_STEPS_PER_UNIT in configuration.h. I made the x, y, z axis all the same number. Now When I move x it is exactly 10mm by my calipers. But it has messed up homing etc. So I am fixing that now.

Edited 2 time(s). Last edit at 10/02/2015 12:29PM by DRTak.

|

Re: Ebay SINTRON Kossel Mini full kit October 02, 2015 04:32AM |

Registered: 9 years ago Posts: 5,232 |

I´m using this customizable knob file. I edit it with openSCAD, but it should work with thingiverses customizer, too.

But all the customizing doesn´t work well, before your printer isn´t calibrated...

As a rule of thumb, you´d always add 0.2-0.5mm diameter for small holes, they tend to be printed smaller usually

-Olaf

But all the customizing doesn´t work well, before your printer isn´t calibrated...

As a rule of thumb, you´d always add 0.2-0.5mm diameter for small holes, they tend to be printed smaller usually

-Olaf

|

Re: Ebay SINTRON Kossel Mini full kit October 02, 2015 08:07AM |

Registered: 8 years ago Posts: 197 |

Quote

GrAndAG

Quote

xile6

Max and min endstops.

...

If you have the liner rails. You put the other endstop mounts on the bottom. Kinda stops the part from sliding compeltey off the rail if something was to break. But as said there not really needed.

I also got 6 endstops. But, actually, there are not enough pins to connect all of them. Because "Z-min" pins are already occupied by autolevel probe.

And even in case of linear rails you can physically limit them (to prevent them off), using large screws (or something like that) at the ends.

BTW, I think 6 endstops are used to limit axes on classic (non-delta) printers. And they just include electronics set from Prusa or Mendel.

Nah my prusa i3 used only 3 endstop. The travel limit is firmware.

So once home it wont travel pass X amount of mm.

|

Re: Ebay SINTRON Kossel Mini full kit October 02, 2015 04:05PM |

Registered: 8 years ago Posts: 104 |

AFAIR, in our config should be specified 80 steps per mm for XYZ due to 20 teeth pulleys we have. 100 is for 16 teeth pulleys. You can check it in calculator.Quote

DRTak

#define DEFAULT_AXIS_STEPS_PER_UNIT {100, 100, 100, 95}

Meanwhile I have a question - what the correct voltage reference should be set on drivers for out steppers?

Edited 2 time(s). Last edit at 10/02/2015 04:22PM by GrAndAG.

|

Re: Ebay SINTRON Kossel Mini full kit October 02, 2015 04:16PM |

Registered: 8 years ago Posts: 104 |

BTW, Here is the correct LCD wiring. Because there are 2 identical cables and therefore you can connect them in 2 ways. On adapter board the sockets are labeled, but I could not found any labels on LCD board.

|

Re: Ebay SINTRON Kossel Mini full kit October 02, 2015 05:52PM |

Registered: 8 years ago Posts: 319 |

Man I wished I would have seen this earlier. All day I have been guessing numbers from 100. I finally hit 80 and tested a print. It was 10.5mm instead of what I had before which is 11.6mm.Quote

GrAndAG

AFAIR, in our config should be specified 80 steps per mm for XYZ due to 20 teeth pulleys we have. 100 is for 16 teeth pulleys. You can check it in calculator.Quote

DRTak

#define DEFAULT_AXIS_STEPS_PER_UNIT {100, 100, 100, 95}

Meanwhile I have a question - what the correct voltage reference should be set on drivers for out steppers?

So now I am testing out #define DEFAULT_AXIS_STEPS_PER_UNIT 75, 75, 75, 95 to see if that is even closer to 10mm cube.

I didnt test the stepper driver voltage. I just plugged it in and went with it

|

Re: Ebay SINTRON Kossel Mini full kit October 02, 2015 05:57PM |

Registered: 8 years ago Posts: 255 |

Quote

DRTak

Man I wished I would have seen this earlier. All day I have been guessing numbers from 100. I finally hit 80 and tested a print. It was 10.5mm instead of what I had before which is 11.6mm.Quote

GrAndAG

AFAIR, in our config should be specified 80 steps per mm for XYZ due to 20 teeth pulleys we have. 100 is for 16 teeth pulleys. You can check it in calculator.Quote

DRTak

#define DEFAULT_AXIS_STEPS_PER_UNIT {100, 100, 100, 95}

Meanwhile I have a question - what the correct voltage reference should be set on drivers for out steppers?

So now I am testing out #define DEFAULT_AXIS_STEPS_PER_UNIT 75, 75, 75, 95 to see if that is even closer to 10mm cube.

I didnt test the stepper driver voltage. I just plugged it in and went with it

The firmware they provide has 79 steps per unit. Which seems to be a spot on despite meaningful calculations.

|

Re: Ebay SINTRON Kossel Mini full kit October 02, 2015 06:24PM |

Registered: 9 years ago Posts: 445 |

Quote

hacker

Quote

DRTak

Man I wished I would have seen this earlier. All day I have been guessing numbers from 100. I finally hit 80 and tested a print. It was 10.5mm instead of what I had before which is 11.6mm.Quote

GrAndAG

AFAIR, in our config should be specified 80 steps per mm for XYZ due to 20 teeth pulleys we have. 100 is for 16 teeth pulleys. You can check it in calculator.Quote

DRTak

#define DEFAULT_AXIS_STEPS_PER_UNIT {100, 100, 100, 95}

Meanwhile I have a question - what the correct voltage reference should be set on drivers for out steppers?

So now I am testing out #define DEFAULT_AXIS_STEPS_PER_UNIT 75, 75, 75, 95 to see if that is even closer to 10mm cube.

I didnt test the stepper driver voltage. I just plugged it in and went with it

The firmware they provide has 79 steps per unit. Which seems to be a spot on despite meaningful calculations.

The only real measurement on a delta that you can do that directly relates to steps/mm is measuring the height of an object (Z-axis), the X/Y-plane is is also depending on the length of your rods.

79 vs 80 steps/mm is a difference of 0.15µm/step, in reality this means you would actually have to print something at least 50mm high to be able to measure any real difference + your printer have to really have to have a superbly calibrated Z-axis, irregularities in top/bottom layer are probably going to be bigger.

To be real sure you'd have to print something at least 100mm high to rule out other stuff than steps/mm.

Here's a good calibration guide that covers both scaling errors as well as dimensional errors.

EDIT: Easier way to measure the Z: Make a mark on the tower extrusion where the top of the roller/carriage is then send it down to Z0 and measure the distance from your mark to the top of the carriage it, should be spot on with your Z height in that you put in the firmware.

Edited 1 time(s). Last edit at 10/02/2015 06:36PM by Koenig.

|

Re: Ebay SINTRON Kossel Mini full kit October 02, 2015 06:33PM |

Registered: 8 years ago Posts: 255 |

Quote

Koenig

Quote

hacker

Quote

DRTak

Man I wished I would have seen this earlier. All day I have been guessing numbers from 100. I finally hit 80 and tested a print. It was 10.5mm instead of what I had before which is 11.6mm.Quote

GrAndAG

AFAIR, in our config should be specified 80 steps per mm for XYZ due to 20 teeth pulleys we have. 100 is for 16 teeth pulleys. You can check it in calculator.Quote

DRTak

#define DEFAULT_AXIS_STEPS_PER_UNIT {100, 100, 100, 95}

Meanwhile I have a question - what the correct voltage reference should be set on drivers for out steppers?

So now I am testing out #define DEFAULT_AXIS_STEPS_PER_UNIT 75, 75, 75, 95 to see if that is even closer to 10mm cube.

I didnt test the stepper driver voltage. I just plugged it in and went with it

The firmware they provide has 79 steps per unit. Which seems to be a spot on despite meaningful calculations.

The only real measurement on a delta that you can do that directly relates to steps/mm is measuring the height of an object (Z-axis), the X/Y-plane is is also depending on the length of your rods.

79 vs 80 steps/mm is a difference of 0.15µm/step, in reality this means you would actually have to print something at least 50mm high to be able to measure any real difference + your printer have to really have to have a superbly calibrated Z-axis, irregularities in top/bottom layer are probably going to be bigger.

To be real sure you'd have to print something at least 100mm high to rule out other stuff than steps/mm.

Here's a good calibration guide that covers both scaling errors as well as dimensional errors.

Thank you for the link. I think steps per mm affect xy plane as well, I think in delta everything affects everything. I don't remember what oddity went away when I changed 80 to 79, but it was definitely not the height of 100mm object. It could be of course that there were other reasons for it.

|

Re: Ebay SINTRON Kossel Mini full kit October 02, 2015 06:39PM |

Registered: 9 years ago Posts: 445 |

Quote

hacker

Quote

Koenig

Quote

hacker

Quote

DRTak

Man I wished I would have seen this earlier. All day I have been guessing numbers from 100. I finally hit 80 and tested a print. It was 10.5mm instead of what I had before which is 11.6mm.Quote

GrAndAG

AFAIR, in our config should be specified 80 steps per mm for XYZ due to 20 teeth pulleys we have. 100 is for 16 teeth pulleys. You can check it in calculator.Quote

DRTak

#define DEFAULT_AXIS_STEPS_PER_UNIT {100, 100, 100, 95}

Meanwhile I have a question - what the correct voltage reference should be set on drivers for out steppers?

So now I am testing out #define DEFAULT_AXIS_STEPS_PER_UNIT 75, 75, 75, 95 to see if that is even closer to 10mm cube.

I didnt test the stepper driver voltage. I just plugged it in and went with it

The firmware they provide has 79 steps per unit. Which seems to be a spot on despite meaningful calculations.

The only real measurement on a delta that you can do that directly relates to steps/mm is measuring the height of an object (Z-axis), the X/Y-plane is is also depending on the length of your rods.

79 vs 80 steps/mm is a difference of 0.15µm/step, in reality this means you would actually have to print something at least 50mm high to be able to measure any real difference + your printer have to really have to have a superbly calibrated Z-axis, irregularities in top/bottom layer are probably going to be bigger.

To be real sure you'd have to print something at least 100mm high to rule out other stuff than steps/mm.

Here's a good calibration guide that covers both scaling errors as well as dimensional errors.

Thank you for the link. I think steps per mm affect xy plane as well, I think in delta everything affects everything. I don't remember what oddity went away when I changed 80 to 79, but it was definitely not the height of 100mm object. It could be of course that there were other reasons for it.

They do, but the only way to verify that you have the correct steps/mm is to measure the Z-axis.

Look at my edit for an easier way to take a measurement that tells you if you have the correct steps/mm on a delta.

As the steps/mm affects everything in delta-geometry it is vital to have that correct before attempting to do any other sort of calibration/corrections.

Edited 1 time(s). Last edit at 10/02/2015 06:42PM by Koenig.

|

Re: Ebay SINTRON Kossel Mini full kit October 02, 2015 06:44PM |

Registered: 8 years ago Posts: 255 |

Quote

Koenig

They do, but the only way to verify that you have the correct steps/mm is to measure the Z-axis.

Look at my edit for an easier way to take a measurement that tells you if you have the correct steps/mm on a delta.

As the steps/mm affects everything in delta-geometry it is vital to have that correct before attempting to do any other sort of calibration/corrections.

Indeed makes sense (the easier way), thanks. And yes, maybe I hastily assumed they're spot on, it's just that it's fixed something for me and I don't even remember what

|

Re: Ebay SINTRON Kossel Mini full kit October 03, 2015 08:27AM |

Registered: 8 years ago Posts: 89 |

|

Re: Ebay SINTRON Kossel Mini full kit October 03, 2015 09:17AM |

Registered: 8 years ago Posts: 916 |

Heya Reaper,

I put a 3mm screw through the heatbed, then onto that I put:

A spring

A small washer

A larger washer

Loctite

A T nut

Repeat for a total of 3 of these adjustment stacks.

This allows you to level the bed by adjusting the screws. The loctite allows you to turn the screw a quarter turn anticlockwise, and the T nut will pop out of the extrusion. So you can remove and replace the bed without losing your calibration.

It works well.

I put a 3mm screw through the heatbed, then onto that I put:

A spring

A small washer

A larger washer

Loctite

A T nut

Repeat for a total of 3 of these adjustment stacks.

This allows you to level the bed by adjusting the screws. The loctite allows you to turn the screw a quarter turn anticlockwise, and the T nut will pop out of the extrusion. So you can remove and replace the bed without losing your calibration.

It works well.

|

Re: Ebay SINTRON Kossel Mini full kit October 03, 2015 09:19AM |

Registered: 8 years ago Posts: 916 |

|

Re: Ebay SINTRON Kossel Mini full kit October 03, 2015 09:59AM |

Registered: 8 years ago Posts: 89 |

found that picture, but mine looks like this: [www.dropbox.com]Quote

nebbian

The hotend just slides into the effector... but you do need to remove some material with a dremel. I think I posted a picture on page 3 or thereabouts.

Its kind of snug without the dremel work. would this also work, or does it needs to sit below that ridge?

And after that? i just use 6 screws to scre it to the effector, attach the fan, and the z-probe?

your bed leveling system sounds nice, but i have trouble picturing where the loctite comes into place... do you have pictures or a schematic?

Edited 1 time(s). Last edit at 10/03/2015 10:00AM by Tha_Reaper.

|

Re: Ebay SINTRON Kossel Mini full kit October 03, 2015 10:17AM |

Registered: 8 years ago Posts: 319 |

Quote

Koenig

Quote

hacker

Quote

Koenig

Quote

hacker

Quote

DRTak

Man I wished I would have seen this earlier. All day I have been guessing numbers from 100. I finally hit 80 and tested a print. It was 10.5mm instead of what I had before which is 11.6mm.Quote

GrAndAG

AFAIR, in our config should be specified 80 steps per mm for XYZ due to 20 teeth pulleys we have. 100 is for 16 teeth pulleys. You can check it in calculator.Quote

DRTak

#define DEFAULT_AXIS_STEPS_PER_UNIT {100, 100, 100, 95}

Meanwhile I have a question - what the correct voltage reference should be set on drivers for out steppers?

So now I am testing out #define DEFAULT_AXIS_STEPS_PER_UNIT 75, 75, 75, 95 to see if that is even closer to 10mm cube.

I didnt test the stepper driver voltage. I just plugged it in and went with it

The firmware they provide has 79 steps per unit. Which seems to be a spot on despite meaningful calculations.

The only real measurement on a delta that you can do that directly relates to steps/mm is measuring the height of an object (Z-axis), the X/Y-plane is is also depending on the length of your rods.

79 vs 80 steps/mm is a difference of 0.15µm/step, in reality this means you would actually have to print something at least 50mm high to be able to measure any real difference + your printer have to really have to have a superbly calibrated Z-axis, irregularities in top/bottom layer are probably going to be bigger.

To be real sure you'd have to print something at least 100mm high to rule out other stuff than steps/mm.

Here's a good calibration guide that covers both scaling errors as well as dimensional errors.

Thank you for the link. I think steps per mm affect xy plane as well, I think in delta everything affects everything. I don't remember what oddity went away when I changed 80 to 79, but it was definitely not the height of 100mm object. It could be of course that there were other reasons for it.

They do, but the only way to verify that you have the correct steps/mm is to measure the Z-axis.

Look at my edit for an easier way to take a measurement that tells you if you have the correct steps/mm on a delta.

As the steps/mm affects everything in delta-geometry it is vital to have that correct before attempting to do any other sort of calibration/corrections.

Ok yes adjusting one item makes the rest of the calibration off. This is getting tiresome. But thanks to that calibration link, you guys are correct. I am going to reset the steps back to 80mm. Then according to the calibration site I will "At this point, you should be able to print objects that are dimensionally accurate, but the scale might be slightly off. This can be corrected by adjusting the DELTA_DIAGONAL_ROD_LENGTH value, using this formula:" So Im just going to adjust the diag rod length to get my scale correct. I was changing the DEFAULT_AXIS_STEPS_PER_UNIT per Sintrons pdf.

|

Re: Ebay SINTRON Kossel Mini full kit October 03, 2015 10:26AM |

Registered: 8 years ago Posts: 319 |

Quote

Tha_Reaper

How did everyone fix/clip/screw his printbed to the structure?

EDIT: And i'm a little confused by the printhead assembly and how its supposed to fit onto the effector. the manual just seems to skip that whole part.

Well I learned a lesson on this topic. I emailed Sintron and they sent me a pic and it is not what everyone else is showing.

[www.dropbox.com]

[www.dropbox.com]

[www.dropbox.com]

I first listened to what they said and I put it in as pictured. And the z probe works. Well I noticed that if you did it the way they said the plate that holds the hotend does not sit flush with the effector plate. So I did what everyone else did and dremel ou the U shaped part. BAD idea. Now the z probe when retracted does not go up high enough and still hits the heat bed. So I reversed the work I did and put it on as the pictures show above even though the surfaces DO not mate very well.

Edited 1 time(s). Last edit at 10/03/2015 10:27AM by DRTak.

|

Re: Ebay SINTRON Kossel Mini full kit October 03, 2015 10:31AM |

Registered: 8 years ago Posts: 319 |

Quote

nebbian

Heya Reaper,

I put a 3mm screw through the heatbed, then onto that I put:

A spring

A small washer

A larger washer

Loctite

A T nut

Repeat for a total of 3 of these adjustment stacks.

This allows you to level the bed by adjusting the screws. The loctite allows you to turn the screw a quarter turn anticlockwise, and the T nut will pop out of the extrusion. So you can remove and replace the bed without losing your calibration.

It works well.

Thats exactly what I did. I was wondering why Sintron gave us 3 springs. So I made a bed which you can level and it has helped me a lot. I actually had to go to hardware store and buy bigger bolts and bigger springs. Now I can adjust the bed angle to match my hotend. Yes it is a bit tilted and its not related to concave or convex surface. For some reason my hotend likes to slide up the X axis at a 2deg angle evenly? SO I just adjusted my bed to NOT be level to the earth but level to the hotend.

Sorry, only registered users may post in this forum.