Noob Questions

Posted by simonj

|

Noob Questions March 19, 2014 01:45PM |

Registered: 10 years ago Posts: 1 |

I'm a relaitvely new Mendel 90 user and have been wrestling with a couple of problems for the last few months...

1. First layer adhesion problems and getting the filament to bond with the glass.

I've tried various remedies, adjusting the heated bed temperature, cleaning the glass with white wine vinegar, lowering the Z_Home height.

I have gone through all of nopheads checks in the guide and it is really inconsistent - sometimes it's OK, other times not.

Any suggestions here?

2. Problems with layer height or alignment.

I've levelled the bed many times, checked the extruder feed rate, etc - but the calibration Android just isn't printed consistently across all axis.

I really am lost....

Any help is gratefull received.

1. First layer adhesion problems and getting the filament to bond with the glass.

I've tried various remedies, adjusting the heated bed temperature, cleaning the glass with white wine vinegar, lowering the Z_Home height.

I have gone through all of nopheads checks in the guide and it is really inconsistent - sometimes it's OK, other times not.

Any suggestions here?

2. Problems with layer height or alignment.

I've levelled the bed many times, checked the extruder feed rate, etc - but the calibration Android just isn't printed consistently across all axis.

I really am lost....

Any help is gratefull received.

|

Re: Noob Questions March 19, 2014 02:23PM |

Registered: 11 years ago Posts: 71 |

Are you printing with PLA or ABS?

If PLA, heat your bed to 70c. Mix a small amount of PVA glue (in the US - Elmore's Glue) with water. I do 1 part glue to 10 parts water. Mix and brush a thin layer on the bed surface. Let it evaporate completely. Print away. Also don't try to remove the printed part until the bed is below 30c. Or you might use too much force and mess up the bed alignment.

If ABS, do the same with an ABS slurry. Sorry, but I don't know the proper bed temp or the ABS/Acetone mix as I've only been using PLA.

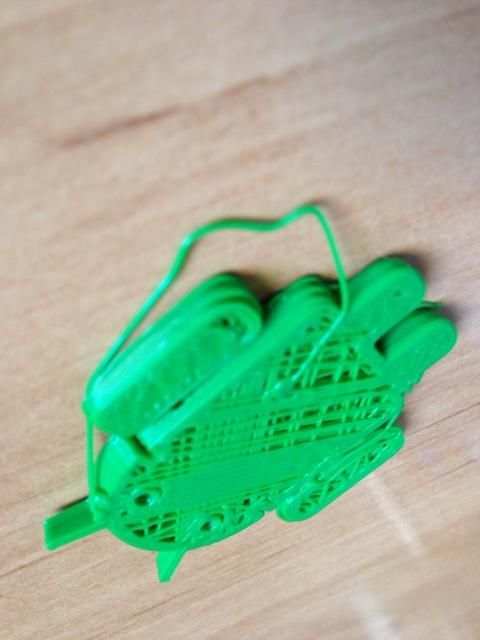

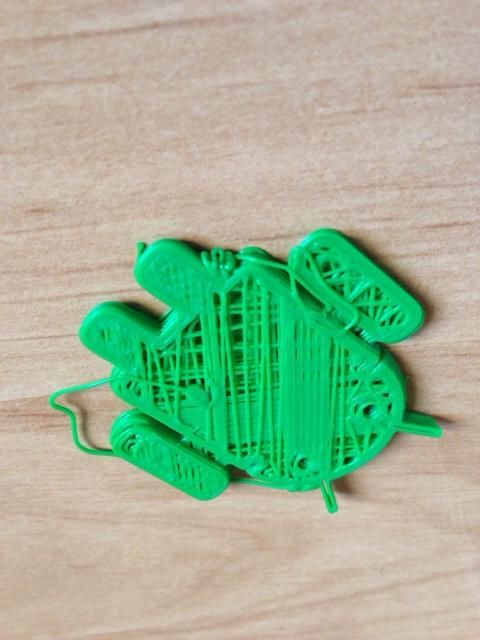

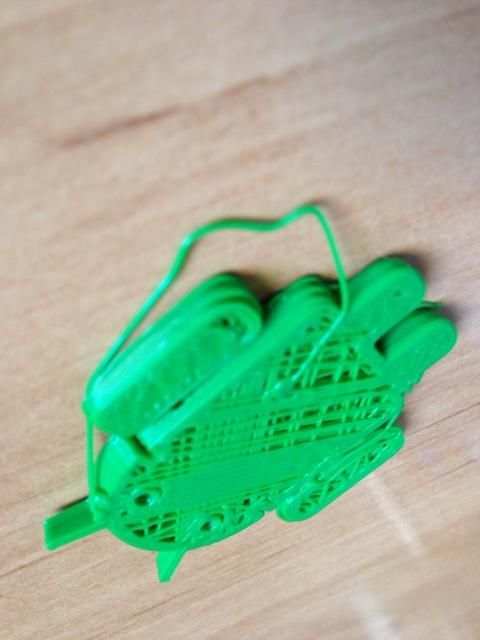

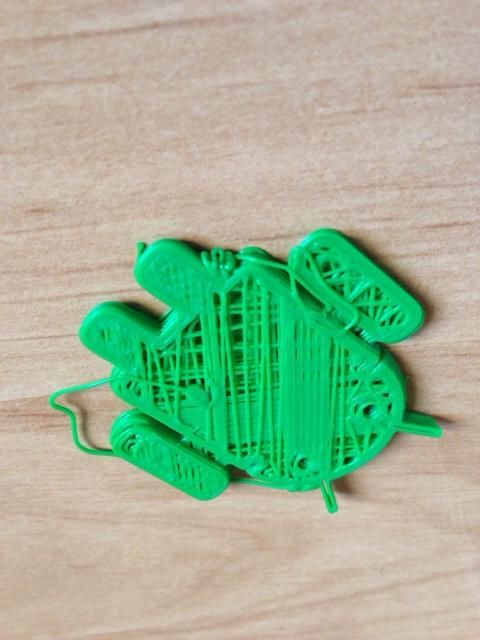

Now for alignment, it's hard to tell from your pic but it seems the left side of the android print is lower than the right. So check the bed level and also the brass nut for the each threaded rod. Something is off. Could also be a loose clamp on one of the threaded rods and it's slipping (maybe). BUT be careful. I don't want to cause you to break it from over tightening.

If PLA, heat your bed to 70c. Mix a small amount of PVA glue (in the US - Elmore's Glue) with water. I do 1 part glue to 10 parts water. Mix and brush a thin layer on the bed surface. Let it evaporate completely. Print away. Also don't try to remove the printed part until the bed is below 30c. Or you might use too much force and mess up the bed alignment.

If ABS, do the same with an ABS slurry. Sorry, but I don't know the proper bed temp or the ABS/Acetone mix as I've only been using PLA.

Now for alignment, it's hard to tell from your pic but it seems the left side of the android print is lower than the right. So check the bed level and also the brass nut for the each threaded rod. Something is off. Could also be a loose clamp on one of the threaded rods and it's slipping (maybe). BUT be careful. I don't want to cause you to break it from over tightening.

|

Re: Noob Questions March 19, 2014 03:29PM |

Registered: 10 years ago Posts: 439 |

|

Re: Noob Questions March 21, 2014 01:56PM |

Registered: 10 years ago Posts: 22 |

I'm relatively new too but what I see is inconsistent material flow: look at the infill, it's dense and then suddenly not dense at all. On the bottom layer this can mean your nozzle is too close to the bed (ie z height too low) causing the flow to jam and then suddenly break loose as pressure builds up. However, this pattern seems to continue on the second layer so something else may be causing a flow problem.

Try extruding 40 or 50mm of plastic into air and see if it comes out nice and smooth, or not.

Also try adding a skirt to your print and see how it looks. If your z height is correct, the skirt height, as measured with calipers, should match the (first) layer height you have set in the slicer.

What are your print speeds?

Nozzle temperature?

Are you priming the nozzle before starting your print?

Edited 3 time(s). Last edit at 03/22/2014 03:03AM by ashleywebster.

Try extruding 40 or 50mm of plastic into air and see if it comes out nice and smooth, or not.

Also try adding a skirt to your print and see how it looks. If your z height is correct, the skirt height, as measured with calipers, should match the (first) layer height you have set in the slicer.

What are your print speeds?

Nozzle temperature?

Are you priming the nozzle before starting your print?

Edited 3 time(s). Last edit at 03/22/2014 03:03AM by ashleywebster.

Sorry, only registered users may post in this forum.