Adding Multi extruder support - howto

Posted by colsenfoto

|

Re: Adding Multi extruder support - howto July 29, 2014 05:59AM |

Registered: 13 years ago Posts: 1,611 |

|

Re: Adding Multi extruder support - howto July 29, 2014 06:51AM |

Registered: 10 years ago Posts: 14,672 |

It really annoys me when people patent the bleeding obvious.

Before anyone patents it, how about modifying the Ormerod nozzle mount so that it can rotate the hot end a few degrees about the Y axis? My dual nozzles are 22mm apart, so a total rotation of 2.5 degrees would be enough to lift the inactive nozzle by 0.5mm relative to the other one. In theory you could use a bimetallic strip to raise whichever nozzle is cooler, but it's probably easier to use either the voice coil mechanism from a hard disk drive or a pair of solenoids, and electronic control. I feel another hot end board coming on...

Unfortunately, this doesn't easily generalize to more than 2 nozzles.

That said, I am getting only a small amount of interference between the two nozzles now, to the extent that I use the dual nozzle head for single colour prints as well.

Edited 3 time(s). Last edit at 07/29/2014 06:54AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Before anyone patents it, how about modifying the Ormerod nozzle mount so that it can rotate the hot end a few degrees about the Y axis? My dual nozzles are 22mm apart, so a total rotation of 2.5 degrees would be enough to lift the inactive nozzle by 0.5mm relative to the other one. In theory you could use a bimetallic strip to raise whichever nozzle is cooler, but it's probably easier to use either the voice coil mechanism from a hard disk drive or a pair of solenoids, and electronic control. I feel another hot end board coming on...

Unfortunately, this doesn't easily generalize to more than 2 nozzles.

That said, I am getting only a small amount of interference between the two nozzles now, to the extent that I use the dual nozzle head for single colour prints as well.

Edited 3 time(s). Last edit at 07/29/2014 06:54AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto July 29, 2014 07:55AM |

Registered: 10 years ago Posts: 119 |

DC,

Good idea, someone previously made the suggestion of mimicking the lense mount on a microscope that has multiple lenses. I was trying to think of a way of lifting the nozzle, where the screw threaded barrel acted something like a smaller version of the z-axis, but then I thought it would need a stepper to do that and my thought process stalled.

If you split the hot end x-carriage in two with a bearing race on each and left the adjustment on the back slack you could use your solenoid principal to pull the head towards the X-axis arm thus lifting it. It could be triggered by your board when the temperature exceeds a particular level. Maybe spring loaded to hold the head down or in the up position.

Edited 1 time(s). Last edit at 07/29/2014 08:04AM by ezwul.

Good idea, someone previously made the suggestion of mimicking the lense mount on a microscope that has multiple lenses. I was trying to think of a way of lifting the nozzle, where the screw threaded barrel acted something like a smaller version of the z-axis, but then I thought it would need a stepper to do that and my thought process stalled.

If you split the hot end x-carriage in two with a bearing race on each and left the adjustment on the back slack you could use your solenoid principal to pull the head towards the X-axis arm thus lifting it. It could be triggered by your board when the temperature exceeds a particular level. Maybe spring loaded to hold the head down or in the up position.

Edited 1 time(s). Last edit at 07/29/2014 08:04AM by ezwul.

|

Re: Adding Multi extruder support - howto July 29, 2014 09:41AM |

Registered: 10 years ago Posts: 14,672 |

Ezwul, that's a nice idea, but unless I have misinterpreted your suggestion I would need to split the heatsink block too and duplicate the heatsink, fan and plastic parts.

I think my idea of rotating the whole hot end a few degrees could be made to work. I would screw a large bearing on to the face of the x-carriage where the nozzle mount is currently, then fit the nozzle mount around the bearing and clamp it in place. That would allow it to rotate. What I haven't yet worked out is where to put the solenoids.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I think my idea of rotating the whole hot end a few degrees could be made to work. I would screw a large bearing on to the face of the x-carriage where the nozzle mount is currently, then fit the nozzle mount around the bearing and clamp it in place. That would allow it to rotate. What I haven't yet worked out is where to put the solenoids.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto July 29, 2014 09:53AM |

Registered: 10 years ago Posts: 119 |

DC

I also thought about putting another full hot end assemply on the other side of the X-arm, thats why I wanted a heatsink with the 3 holes in it from DaveK.

A bit like the saddle bags slung over a donkey, then your solenoid could be used to level the whole assembly either on one side of the x-arm or the other.

The see-saw action rises one side and lowers the other, the bearing is the pivot point and the solenoid could be used to pull the x-arm adjuster bearing tight or loose.

I also thought about putting another full hot end assemply on the other side of the X-arm, thats why I wanted a heatsink with the 3 holes in it from DaveK.

A bit like the saddle bags slung over a donkey, then your solenoid could be used to level the whole assembly either on one side of the x-arm or the other.

The see-saw action rises one side and lowers the other, the bearing is the pivot point and the solenoid could be used to pull the x-arm adjuster bearing tight or loose.

|

Re: Adding Multi extruder support - howto July 29, 2014 10:15AM |

Registered: 10 years ago Posts: 14,672 |

So if we combine your idea and mine, we could switch between 4 nozzles!

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto July 29, 2014 10:52AM |

Registered: 10 years ago Posts: 119 |

|

Re: Adding Multi extruder support - howto July 29, 2014 03:21PM |

Registered: 10 years ago Posts: 119 |

DC

Instead of a Solenoid, using a RC Servo to see-saw the head backwards and forwards might be a better method, for both ideas, it would also lock the head in position without the need for continuous current as in a solenoid. Then the heads could move back and forth between some adjustable limits setup by a couple of bearings for my design, similar to the adjustable ones we use now.

Instead of a Solenoid, using a RC Servo to see-saw the head backwards and forwards might be a better method, for both ideas, it would also lock the head in position without the need for continuous current as in a solenoid. Then the heads could move back and forth between some adjustable limits setup by a couple of bearings for my design, similar to the adjustable ones we use now.

|

Re: Adding Multi extruder support - howto July 29, 2014 06:17PM |

Registered: 10 years ago Posts: 378 |

|

Re: Adding Multi extruder support - howto July 31, 2014 03:11PM |

Registered: 13 years ago Posts: 1,611 |

Interesting stuff! Unfortunately, the see-saw version is also patented by Stratasys, I believe. That doesn't stop anyone implementing it for themselves, of course. My idea is to have the hot ends mounted around a circular plate, which is set at an angle. Then you rotate the plate, to move on hot end around and up, and another can come down. If it's well-engineered, there's no need for a nozzle offset, either. You can also fit as many hot ends as you want/can on the plate.

Ian

RepRapPro tech support

Ian

RepRapPro tech support

|

Re: Adding Multi extruder support - howto July 31, 2014 03:33PM |

Registered: 9 years ago Posts: 35 |

|

Re: Adding Multi extruder support - howto July 31, 2014 06:39PM |

Registered: 10 years ago Posts: 119 |

|

Re: Adding Multi extruder support - howto August 01, 2014 02:56AM |

Registered: 10 years ago Posts: 378 |

I think you are only prohibited by the patent from selling / distributing the actual "invention", but it might be that distributing drawings / stl files / schematics are covered. Might be somewhat of a legal gray-zone. I do know that source code for LZW compression (used in for example GIF/TIFF image compression) was widely available as open source code long before the Unisys patent expired, but I used some commercial image-manipulating library that required an extra license to unlock the LZW functionality.

In any case, does anyone know which patent this is? Stratasys have quite a few and it is far from obvious which one might cover this. If they only have a US patent for it, it wouldn't matter to many of us.

In any case, does anyone know which patent this is? Stratasys have quite a few and it is far from obvious which one might cover this. If they only have a US patent for it, it wouldn't matter to many of us.

|

Re: Adding Multi extruder support - howto August 01, 2014 11:13AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Adding Multi extruder support - howto August 02, 2014 04:47PM |

Registered: 10 years ago Posts: 378 |

I guess the patent in question is US8153182 (if I decoded the patent language correctly). I can't find any non-US patent similar to it, but Stratasys have a crapload of European patents/patent applications.

|

Re: Adding Multi extruder support - howto August 03, 2014 11:20AM |

Registered: 9 years ago Posts: 138 |

Hi to all,

i now finished modding my printer to a dual-tall-merod....

a small test print with one noozle works fine.... all test without printing looks good.

so i wanted to print the traffic cone, but on the tool change- the printer doesn´t wait until the printing temperature is reached.

in my tpost1.g and tpost2.g i have added the wait command, but it dousnt wait....

; tpost1.g

; Put G/M Codes in here to run after Tool 1 is selected

M116 P1

; tpost2.g

; Put G/M Codes in here to run after Tool 1 is selected

M116 P2

i´m using dc42-078f - firmware

greetings

Edited 1 time(s). Last edit at 08/03/2014 11:52AM by muggi.

i now finished modding my printer to a dual-tall-merod....

a small test print with one noozle works fine.... all test without printing looks good.

so i wanted to print the traffic cone, but on the tool change- the printer doesn´t wait until the printing temperature is reached.

in my tpost1.g and tpost2.g i have added the wait command, but it dousnt wait....

; tpost1.g

; Put G/M Codes in here to run after Tool 1 is selected

M116 P1

; tpost2.g

; Put G/M Codes in here to run after Tool 1 is selected

M116 P2

i´m using dc42-078f - firmware

greetings

Edited 1 time(s). Last edit at 08/03/2014 11:52AM by muggi.

|

Re: Adding Multi extruder support - howto August 03, 2014 03:27PM |

Registered: 10 years ago Posts: 14,672 |

Hi muggi,

Those files are working OK for me. Some questions:

1. What have you set the active and standby temperatures of the extruders to?

2. Are you sure you have the tpost1.g and tpost2.g files in the /sys directory of the SD card?

3. If you connect via Pronterface (as well as the web interface, if that is what you normally use), does the Pronterface message log report any messages about the tool change files not being found?

Edited 1 time(s). Last edit at 08/03/2014 03:29PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Those files are working OK for me. Some questions:

1. What have you set the active and standby temperatures of the extruders to?

2. Are you sure you have the tpost1.g and tpost2.g files in the /sys directory of the SD card?

3. If you connect via Pronterface (as well as the web interface, if that is what you normally use), does the Pronterface message log report any messages about the tool change files not being found?

Edited 1 time(s). Last edit at 08/03/2014 03:29PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto August 03, 2014 04:38PM |

Registered: 9 years ago Posts: 138 |

|

Re: Adding Multi extruder support - howto August 03, 2014 04:54PM |

Registered: 10 years ago Posts: 14,672 |

Here they are. They might not suit your machine. I am using my differential IR board for X- and Z-homing and bed compensation, and 5-point bed compensation with firmware 0.78h-dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto August 04, 2014 06:31AM |

Registered: 9 years ago Posts: 138 |

Hi David,

1. What have you set the active and standby temperatures of the extruders to?

Yes, i Have this in my custom start g-code section:

; layer_height = [layer_height]

M563 S1

G10 P1 R150

G10 P2 R150

2. Are you sure you have the tpost1.g and tpost2.g files in the /sys directory of the SD card?

Yes

3. If you connect via Pronterface (as well as the web interface, if that is what you normally use), does the Pronterface message log report any messages about the tool change files not being found?

so i compared the files, they lokks equal. but i replaced the tool change files with yours and now it waits for reaching the temperature on tool-changing.

Maybe my files were corrupt.

Now i can fine-tune by print a small sample.

greetings and many thanks....

1. What have you set the active and standby temperatures of the extruders to?

Yes, i Have this in my custom start g-code section:

; layer_height = [layer_height]

M563 S1

G10 P1 R150

G10 P2 R150

2. Are you sure you have the tpost1.g and tpost2.g files in the /sys directory of the SD card?

Yes

3. If you connect via Pronterface (as well as the web interface, if that is what you normally use), does the Pronterface message log report any messages about the tool change files not being found?

so i compared the files, they lokks equal. but i replaced the tool change files with yours and now it waits for reaching the temperature on tool-changing.

Maybe my files were corrupt.

Now i can fine-tune by print a small sample.

greetings and many thanks....

|

Re: Adding Multi extruder support - howto August 04, 2014 07:41AM |

Registered: 10 years ago Posts: 14,672 |

In version 0.78h I fixed a long-standing bug that caused the last line of a macros file to be incompletely executed if it didn't have a newline character at the end. You said you were running 0.78f, so maybe you hit that bug.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto August 04, 2014 04:08PM |

Registered: 10 years ago Posts: 14,672 |

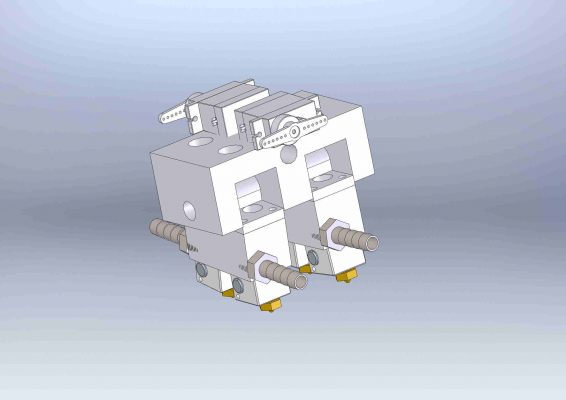

I've updated the Duet+X4 and 1/2 nozzle mount designs at [github.com]. The Duet+X4 enclosure now has stronger mounting pillars and access holes for the X4 power terminal screws. The 1-or-2 nozzle mount now has a 'long' option to make it easier to get started with ABS printing, as described by Ludo91 here [forums.reprap.org].

Edited 1 time(s). Last edit at 08/04/2014 04:10PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 08/04/2014 04:10PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto August 05, 2014 12:25PM |

Registered: 9 years ago Posts: 138 |

Quote

dc42

I've updated the Duet+X4 and 1/2 nozzle mount designs at [github.com]. The Duet+X4 enclosure now has stronger mounting pillars and access holes for the X4 power terminal screws. The 1-or-2 nozzle mount now has a 'long' option to make it easier to get started with ABS printing, as described by Ludo91 here [forums.reprap.org].

Hi David,

for the long noozle mount i think we need a lower "sensorpad-diff-led.stl". Can you modify your sensorpad-diff-led.stl for the long noozle mount?

|

Re: Adding Multi extruder support - howto August 06, 2014 05:12AM |

Registered: 10 years ago Posts: 94 |

Hi David would it be hard to have 2 micro servo to move on nozzle change?

|

Re: Adding Multi extruder support - howto August 06, 2014 09:49AM |

Registered: 9 years ago Posts: 138 |

Hi to all,

thanks for the first class support and special thanks to david and his big blog post for the dual noozle upgrade.....

my test pieces looking real good.

Edited 1 time(s). Last edit at 08/06/2014 09:49AM by muggi.

thanks for the first class support and special thanks to david and his big blog post for the dual noozle upgrade.....

my test pieces looking real good.

Edited 1 time(s). Last edit at 08/06/2014 09:49AM by muggi.

|

Re: Adding Multi extruder support - howto August 06, 2014 11:28AM |

Registered: 10 years ago Posts: 14,672 |

Quote

muggi

for the long noozle mount i think we need a lower "sensorpad-diff-led.stl". Can you modify your sensorpad-diff-led.stl for the long noozle mount?

I've just done that - see [github.com] - but I've not tried printing it yet.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto August 08, 2014 01:46PM |

Registered: 10 years ago Posts: 14,672 |

Muggi, congratulatons on getting a dual-colour print to work on the Ormerod! I think you are either #3 or #4 to do so, not counting RepRapPro themselves and perhaps TPT3.

Edited 1 time(s). Last edit at 08/08/2014 01:47PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Edited 1 time(s). Last edit at 08/08/2014 01:47PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto August 08, 2014 02:01PM |

Registered: 10 years ago Posts: 14,672 |

Today I finished hacking one of my differential IR hot end boards and modifying the firmware to monitor 2 thermistors for the fan control. It now turns the fan on if either thermistor is disconnected or above about 42C, and off again if both thermistors are connected and below about 39C.

If there is enough interest, I'll order 10 PCBs and do a limited-edition batch of dual-nozzle-capable boards, along with a separate connector board for connecting the additional heater and thermistor cables and with another amber LED to indicate the heater is on. If not, I'll publish a blog entry showing how I modified a standard board, along with the new firmware.

Please note that although I have included some smoothing to try to reduce the problem of noise on the second thermistor from the ground line of the DueX4, I can't guarantee that this will be sufficient, in particular to keep the fan off when both thermistors are cold. I modified my Duet and DueX4 to avoid this problem as described at [miscsolutions.wordpress.com], and I don't really want to reverse the modifications just to do some tests.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

If there is enough interest, I'll order 10 PCBs and do a limited-edition batch of dual-nozzle-capable boards, along with a separate connector board for connecting the additional heater and thermistor cables and with another amber LED to indicate the heater is on. If not, I'll publish a blog entry showing how I modified a standard board, along with the new firmware.

Please note that although I have included some smoothing to try to reduce the problem of noise on the second thermistor from the ground line of the DueX4, I can't guarantee that this will be sufficient, in particular to keep the fan off when both thermistors are cold. I modified my Duet and DueX4 to avoid this problem as described at [miscsolutions.wordpress.com], and I don't really want to reverse the modifications just to do some tests.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Adding Multi extruder support - howto August 08, 2014 04:02PM |

Registered: 9 years ago Posts: 138 |

|

Re: Adding Multi extruder support - howto August 12, 2014 07:03AM |

Registered: 10 years ago Posts: 94 |

Sorry, only registered users may post in this forum.