|

Poor Finished (Solved) September 12, 2014 10:26AM |

Registered: 10 years ago Posts: 859 |

For just over a week I've been experiancing a poor finish in parts of my prints.

The rest of the print was first class, but just after a cut out in the side of the print... Yuck!

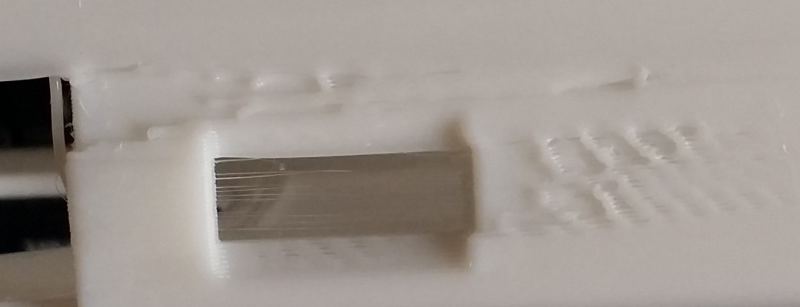

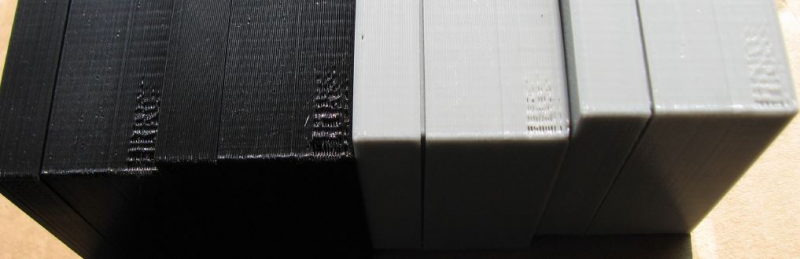

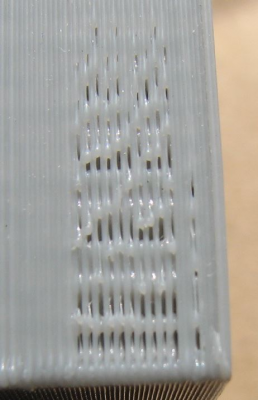

Here's a picture of what was happening... Sometimes it was so bad I'd have to just throw the print away.

I tweeked settings in Slic3r, but nope.... It was Still there... Not just on one design, but all of them, and it seemed

to be getting worse... I realised it had something to do with the acceleration of the feeder, so started to tweek the settings.

It was just as the first print with the new settings was just starting that the Penny dropped.

I'd been thinking about this allot, and luckily got distracted, and then came back to it, when I thought, 'I wonder if the Hobbed nut's come loose'.

I stripped down the feeder, and sure enough that was the problem.... It wasn't even finger tight any more.

So a dab of super glue, then tightend up with the pliers quickly, and all is well.

Perfect prints again.... Ok I know I may well have to replace the hobbed nut at a later date, as I suspect I won't be able to remove it now.

But the replacement cost is far less than the down time this problem was causing....

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

The rest of the print was first class, but just after a cut out in the side of the print... Yuck!

Here's a picture of what was happening... Sometimes it was so bad I'd have to just throw the print away.

I tweeked settings in Slic3r, but nope.... It was Still there... Not just on one design, but all of them, and it seemed

to be getting worse... I realised it had something to do with the acceleration of the feeder, so started to tweek the settings.

It was just as the first print with the new settings was just starting that the Penny dropped.

I'd been thinking about this allot, and luckily got distracted, and then came back to it, when I thought, 'I wonder if the Hobbed nut's come loose'.

I stripped down the feeder, and sure enough that was the problem.... It wasn't even finger tight any more.

So a dab of super glue, then tightend up with the pliers quickly, and all is well.

Perfect prints again.... Ok I know I may well have to replace the hobbed nut at a later date, as I suspect I won't be able to remove it now.

But the replacement cost is far less than the down time this problem was causing....

Kim

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Poor Finished (Solved) September 12, 2014 11:00AM |

Registered: 10 years ago Posts: 859 |

Hmmmm seems I spoke to soon. The problem still exists..

Any one got a suggestion please...

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Any one got a suggestion please...

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Poor Finished (Solved) September 12, 2014 12:34PM |

Registered: 10 years ago Posts: 14,672 |

Which version of slic3r are you using?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Poor Finished (Solved) September 12, 2014 12:35PM |

Registered: 10 years ago Posts: 112 |

|

Re: Poor Finished (Solved) September 12, 2014 01:52PM |

Registered: 10 years ago Posts: 859 |

Yes,yes & yes

At least sorting out the Hobbed Nut has stopped the Splatter, so that's an improvement.

Edited 1 time(s). Last edit at 09/12/2014 01:54PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

At least sorting out the Hobbed Nut has stopped the Splatter, so that's an improvement.

Edited 1 time(s). Last edit at 09/12/2014 01:54PM by KimBrown.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Poor Finished (Solved) September 13, 2014 06:49AM |

Registered: 10 years ago Posts: 859 |

Hi DC 1.1.1 but I don't think it's that as it's something that has appeared over the last week. It's in line with the X axis, so I think I'll remove the x carriage today and see what the bearings like inside, and have a good look at the x axis 12mm rod to see if there's a rough patch or something. The rest of the finish is perfect, so it's annoying that this has appeared. I did have tiny pips on the walls that could be removed with your finger nail, but they've cleared up since I gave the feeder a looking at. I really thought I'd cracked it when I found the hobbed nut loose, but nope, it's still the same.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Poor Finished (Solved) September 13, 2014 08:09AM |

Registered: 10 years ago Posts: 1,230 |

Hi Kim

I ran into something similar, but it followed the infill pattern, yours don't (unless you are using some strange form of vector adding stacked infill pattern) - I do not know what caused it, heat, acceleration speed or global bloody warming, but fixed it with an extra perimeter and reduced speed, 80 to 60mm/sec

have you measured the distance between those blobs? - and if so, do that correlate with anything mechanical ormerod or your local environment?

Erik

I ran into something similar, but it followed the infill pattern, yours don't (unless you are using some strange form of vector adding stacked infill pattern) - I do not know what caused it, heat, acceleration speed or global bloody warming, but fixed it with an extra perimeter and reduced speed, 80 to 60mm/sec

have you measured the distance between those blobs? - and if so, do that correlate with anything mechanical ormerod or your local environment?

Erik

|

Re: Poor Finished (Solved) September 13, 2014 09:24AM |

Registered: 10 years ago Posts: 859 |

Hi Erik, yes that does look similar. I think it might be the Extruder Carriage Bearing, I have a spare one some where in that safe place where only the Pope can find it....

Anyway I intend to give it a looking at. I'm wondering if maybe it's a little tight, and then frees up once it's moving. I have some chores to do first then I can sit down and go over the machine with a fine toothed comb. It's the only problem I have with the finish really, so it would be good to nail in down to something. The printer has been busy for the last month or two, and it's had it's moments. But since replacing the extruder cartridge heater, and sorting out the feeder things have really improved a lot.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

Anyway I intend to give it a looking at. I'm wondering if maybe it's a little tight, and then frees up once it's moving. I have some chores to do first then I can sit down and go over the machine with a fine toothed comb. It's the only problem I have with the finish really, so it would be good to nail in down to something. The printer has been busy for the last month or two, and it's had it's moments. But since replacing the extruder cartridge heater, and sorting out the feeder things have really improved a lot.

Please send me a PM if you have suggestions, or problems with Big Blue 360.

I won't see comments in threads, as I move around to much.

Working Link to Big Blue 360 Complete

|

Re: Poor Finished (Solved) September 13, 2014 11:05AM |

Registered: 13 years ago Posts: 1,611 |

It looks like it's not advancing the filament after retracting, which is leading to weak extrusion just afterwards. We've seen this in some prints in-house too, and we're tracking down the issue - it's possibly a firmware bug related to extruder movement (actually, any motor acceleration when one axis only is moved). We've got a couple of logic analysers (only a couple of £!) to have a good look at exactly what the motor steps are doing. Why it's showing up now, and hasn't previously, is a bit of a mystery. Apart from playing around with the retraction speed (either in config.g or in your Slic3r settings), I don't have any further insight into what's going wrong at the moment, but we're working on it.

Ian

RepRapPro tech support

Ian

RepRapPro tech support

|

Re: Poor Finished (Solved) September 13, 2014 11:09AM |

Registered: 9 years ago Posts: 138 |

Sorry, only registered users may post in this forum.