Ormerod2 - Slic3r optimizing

Posted by Alex74

|

Ormerod2 - Slic3r optimizing November 20, 2014 04:37PM |

Registered: 9 years ago Posts: 22 |

Hello,

the Results with de default settings in Slic3R for the Ormerod2 are very good on bigger objects and on reproducing/reprinting the individual Parts of the Ormerod2.

The Printing of the Demo-Whistle was very good.

Today I tried to print a little 'Marvin' with 2.4 x 1.9 x 2.5 cm.

The results are not as good as other Objects. I thing, it is too hot because the Layers are printed to fast and so the PLA is to 'soft or weak' if the next level ist printed?

Are there some optimizations for Slic3r ?

I've seen the Layer height is set to 0.24mm.

Is this the Minimum for the Ormerod2 or can I print thinner Layers ?

Can I print with lower speed an thinner Layers ?

Has anyone already experience with this ?

Thank's for your Idea's, hints and help,

Greetings,

Alex

the Results with de default settings in Slic3R for the Ormerod2 are very good on bigger objects and on reproducing/reprinting the individual Parts of the Ormerod2.

The Printing of the Demo-Whistle was very good.

Today I tried to print a little 'Marvin' with 2.4 x 1.9 x 2.5 cm.

The results are not as good as other Objects. I thing, it is too hot because the Layers are printed to fast and so the PLA is to 'soft or weak' if the next level ist printed?

Are there some optimizations for Slic3r ?

I've seen the Layer height is set to 0.24mm.

Is this the Minimum for the Ormerod2 or can I print thinner Layers ?

Can I print with lower speed an thinner Layers ?

Has anyone already experience with this ?

Thank's for your Idea's, hints and help,

Greetings,

Alex

|

Re: Ormerod2 - Slic3r optimizing November 20, 2014 06:18PM |

Registered: 9 years ago Posts: 102 |

Hi Alex

I have optimized my O2 now and have made prints with a layer hight down to 0.1mm. I don't think less makes much sense with a 0.5mm nozzle.

There is also a half step option in the web interface. This should increase the theoretical resolution of the layer thickness but i think the z-rod solution of the

O2 has already a pretty good z-axis resolution...

But before you start with thin layers make sure that you have your filament feeding calibrated exactly have your board leveled really good, especially if you start with a 0.1mm layer.

Best regards

Tim

I have optimized my O2 now and have made prints with a layer hight down to 0.1mm. I don't think less makes much sense with a 0.5mm nozzle.

There is also a half step option in the web interface. This should increase the theoretical resolution of the layer thickness but i think the z-rod solution of the

O2 has already a pretty good z-axis resolution...

But before you start with thin layers make sure that you have your filament feeding calibrated exactly have your board leveled really good, especially if you start with a 0.1mm layer.

Best regards

Tim

|

Re: Ormerod2 - Slic3r optimizing November 21, 2014 04:10AM |

Registered: 10 years ago Posts: 275 |

Quote

Alex74

Hello,

Today I tried to print a little 'Marvin' with 2.4 x 1.9 x 2.5 cm.

Greetings,

Alex

Hi Alex,

I printed Marvin as the first order for 3D HUBS....

Temp. bed 53.4 (on the web interface 65)... printing on glass directly.

Extruder 205 first layer and then 185

speed 50% (web interface control) layer 0.24

I'm not interested in more accurate definition... printers 400mm high it takes too long.

So medium quality for me it's ok.

With a good filament you can do better.

Regards

Dario

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

|

Re: Ormerod2 - Slic3r optimizing November 21, 2014 05:20AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Alex74

,,Today I tried to print a little 'Marvin' with 2.4 x 1.9 x 2.5 cm.

The results are not as good as other Objects. I thing, it is too hot because the Layers are printed to fast and so the PLA is to 'soft or weak' if the next level ist printed? ...

Yes it will get too hot nomatter how low you go in layer hight or printing speed (will get worse actually) - the cure (besides extra cooling) could be to print more Marvin's with some distance between

The lowest nozzle and bed temp. you can get away with will also be of help

Erik

|

Re: Ormerod2 - Slic3r optimizing November 21, 2014 06:02AM |

Registered: 10 years ago Posts: 275 |

Quote

Yes it will get too hot nomatter how low you go in layer hight or printing speed (will get worse actually)

Erik

really? I can increase speed and improve the quality?

This interests me very much can you give me more details?... firmware?......

I also tried on some print 200% speed but the quality has been lower....

Obviously I can not print 10 Marvin if I have one on order ....my interest is the single piece.

Yes an additional fan helps but with more speed it's not enough with this little Marvin.. (I only tried it once sorry)

Dario

|

Re: Ormerod2 - Slic3r optimizing November 21, 2014 07:15AM |

Registered: 10 years ago Posts: 2,472 |

Items that have layers with a very small cross section cannot be printed normally because as you have seen, the whole column gets too hot and you end up with a shapeless blob. The easiest solution is to print more than one at a time as has been suggested. If spaced apart it will force the head to move between the objects, giving each time to cool. Another solution is to create a tall thin sacrificial column the same height as the object and print that some distance away to achieve the same thing. Another solution is to set the skirt to print full height.

There is one other solution that does not involve wasting plastic. If the slicing software has the facility to insert custom code at each layer change, you can insert code that moves the head away from the print and then back again at a speed that wastes enough time to allow the part to cool. If the slicer does not have such a facility, you can still achieve the same thing by loading the G-code into a text editor, searching for each layer change (easy because they are just about the only lines containing the letter "Z"), and pasting your custom code in by hand just before or after each Z move. This has the advantage that you can paste the code only at the layers that have a small cross section so the rest of the print is not slowed down. If you have a text editor that allows you to record macros you can modify a G-code file very quickly.

Dave

There is one other solution that does not involve wasting plastic. If the slicing software has the facility to insert custom code at each layer change, you can insert code that moves the head away from the print and then back again at a speed that wastes enough time to allow the part to cool. If the slicer does not have such a facility, you can still achieve the same thing by loading the G-code into a text editor, searching for each layer change (easy because they are just about the only lines containing the letter "Z"), and pasting your custom code in by hand just before or after each Z move. This has the advantage that you can paste the code only at the layers that have a small cross section so the rest of the print is not slowed down. If you have a text editor that allows you to record macros you can modify a G-code file very quickly.

Dave

|

Re: Ormerod2 - Slic3r optimizing November 22, 2014 05:31AM |

Registered: 10 years ago Posts: 1,230 |

Quote

Ormerod187

Quote

Yes it will get too hot nomatter how low you go in layer hight or printing speed (will get worse actually)

Erik

really? I can increase speed and improve the quality?

No not in the general sense, only if the lower speed decreased the quality in the first place, e.g. made the perimeters sag from heat buildup in the printed part (heat radiated from nozzle)

My normal settings are 60mm/sec, 40 for best quality

Quote

... firmware?......

dc42 all the way :-)

Quote

I also tried on some print 200% speed but the quality has been lower....

I guess my setup with standard z-hight is more solid and stable than you z-axis to the moon setup, on my system its mostly the nozzle-jumps that degrades the quality

Quote

Obviously I can not print 10 Marvin if I have one on order ....my interest is the single piece.

Queue orders :-) - don't have to be Marvin's, only just as high models or higher :-)

Quote

Yes an additional fan helps but with more speed it's not enough with this little Marvin.. (I only tried it once sorry)

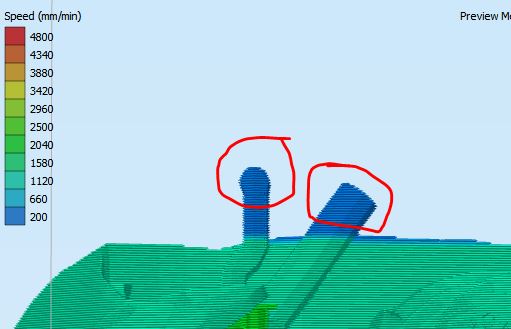

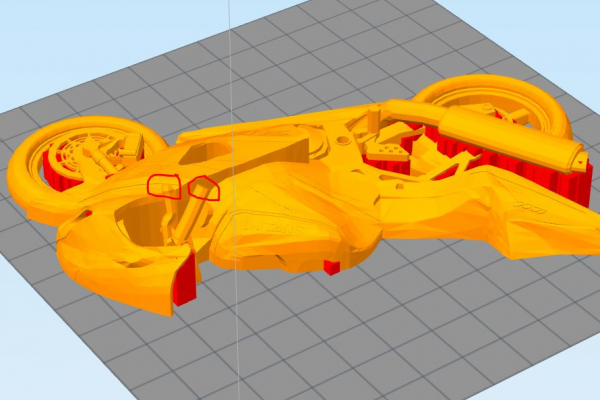

A fan may not always be enough, on this print I use a high pressure air hose to cool the last printed pointy bits down (red circle)

Erik

|

Re: Ormerod2 - Slic3r optimizing November 22, 2014 06:37AM |

Registered: 10 years ago Posts: 275 |

Thanks Erik

nice track....

beautiful prints!

As well as the printers of the moon I'm still using Ormerod Bamboo and Ormerod187 (I changed as little as possible)

With Ormerod187, dc42 firmware, reduced speed in the last step (is a tiny ring on top) the little Marvin_KeyChain it's easy.

Dario

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

nice track....

beautiful prints!

As well as the printers of the moon I'm still using Ormerod Bamboo and Ormerod187 (I changed as little as possible)

With Ormerod187, dc42 firmware, reduced speed in the last step (is a tiny ring on top) the little Marvin_KeyChain it's easy.

Dario

Ormerod 187

Firmware Electronics: Duet 0.6

Firmware Version:1.18.1 (2017-04-07)

Web Interface Version:1.15a

Slic3r 1.2.9a and Simplify3D 4.0.0

[www.dropbox.com]

|

Re: Ormerod2 - Slic3r optimizing November 24, 2014 05:10AM |

Registered: 9 years ago Posts: 22 |

Thanks a lot for all the hints.

I'll try to test ist again.

Some Question again:

- If I say to Slic3r that I want layer thickness 0.12mm (instead of 0.24mm), do I have to tell this my Ormerod too in the Webinterface ?

- If I choose the "half steps", the resolution of the Steppers will increase. On the GCode I have to change nothing, or

- If I want to slow down the last Layers, do I have to do this manually by using the Webinterface (from DC42) ?

Alex

I'll try to test ist again.

Some Question again:

- If I say to Slic3r that I want layer thickness 0.12mm (instead of 0.24mm), do I have to tell this my Ormerod too in the Webinterface ?

- If I choose the "half steps", the resolution of the Steppers will increase. On the GCode I have to change nothing, or

- If I want to slow down the last Layers, do I have to do this manually by using the Webinterface (from DC42) ?

Alex

|

Re: Ormerod2 - Slic3r optimizing November 24, 2014 06:13AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Alex74

- If I say to Slic3r that I want layer thickness 0.12mm (instead of 0.24mm), do I have to tell this my Ormerod too in the Webinterface ?

If you are using my or zpl's firmware, or you are using RRP's firmware and web interface and are printing direct over Ethernet, then the firmware or web interface will normally pick up the layer height automatically from the gcode file. So you don't need to set it in the web interface.

Quote

Alex74

- If I choose the "half steps", the resolution of the Steppers will increase. On the GCode I have to change nothing, or

That option in the web interface merely changes the Z movement buttons from 100/10/1/0.1mm to 50/5/0.5/0.05mm. The purpose is to allow you to set a more accurate Z=0 position.

Quote

Alex74

- If I want to slow down the last Layers, do I have to do this manually by using the Webinterface (from DC42) ?

Either that, or edit the gcode file, for example by inserting a suitable M220 command at the point at which you want the print slowed down.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Ormerod2 - Slic3r optimizing November 25, 2014 08:54AM |

Registered: 9 years ago Posts: 22 |

Sorry, only registered users may post in this forum.