Bowden extruder is missing a brass union... what can I do?

Posted by 0x0000

|

Bowden extruder is missing a brass union... what can I do? January 03, 2016 10:55PM |

Registered: 8 years ago Posts: 164 |

Hey all,

In my adventures of assembling my scratch Ormerod, I'm now at the point where I need to print my orthoganal axes. I'm having problems extruding filament with my generic V6 hotend. It's working great, melting away PLA strands on to my heated bed, except for one detail... when I extrude filament, the PTFE tube gets pushed off of the tongue and out the top of the extruder. It's not held in at all... and it's because the PTFE tube I purchased doesn't have a brass union at one end(shown here: [reprappro.com]). The tube catches on the filament and gets lifted out of the extruder. Some filament will accumulate in the hotend, but there's simply not enough force to push it through.

I'd like to improvise something in the short term so that I can continue calibrating my printer. Any ideas while I hunt around for a proper union? Is there an alternate non-Bowden extruder I can use?

Thanks for all of your help so far!

Cheers,

~0

In my adventures of assembling my scratch Ormerod, I'm now at the point where I need to print my orthoganal axes. I'm having problems extruding filament with my generic V6 hotend. It's working great, melting away PLA strands on to my heated bed, except for one detail... when I extrude filament, the PTFE tube gets pushed off of the tongue and out the top of the extruder. It's not held in at all... and it's because the PTFE tube I purchased doesn't have a brass union at one end(shown here: [reprappro.com]). The tube catches on the filament and gets lifted out of the extruder. Some filament will accumulate in the hotend, but there's simply not enough force to push it through.

I'd like to improvise something in the short term so that I can continue calibrating my printer. Any ideas while I hunt around for a proper union? Is there an alternate non-Bowden extruder I can use?

Thanks for all of your help so far!

Cheers,

~0

|

Re: Bowden extruder is missing a brass union... what can I do? January 04, 2016 02:28AM |

Registered: 9 years ago Posts: 191 |

|

Re: Bowden extruder is missing a brass union... what can I do? January 04, 2016 10:15PM |

Registered: 8 years ago Posts: 164 |

In light of the recent shutdown news, I can't order from RRP so I thought about the problem a bit and I did some reading. Few things grip PTFE very well, and ti turns out that a simple M4 nut can be threaded pretty tightly onto a 4mm PTFE tube, which also leaves "permanent" threads on it. This means you can print a part that captures a nut, and secure the part down to something sturdy (like the extruder itself). They don't need to take much force, just enough to overcome the force of the filament coming out of the extruder. This is pretty much what the brass unions are doing anyway, so in theory, I could thread an M4 onto it with a wide washer, and clamp the washer down with binder clips or something. Perhaps I can put the little M3 sized hole within the tongue to good use, or we could print a plastic union of the same shape?

There's a Bowden extruder already on Thingiverse somewhere that's been modified to do something like this. I've lost the link, but I may be able to dig it out of my history later. It'd be sweet to create one that accepted "straight push" fittings like my hotend does.

Edited 1 time(s). Last edit at 01/04/2016 10:18PM by 0x0000.

There's a Bowden extruder already on Thingiverse somewhere that's been modified to do something like this. I've lost the link, but I may be able to dig it out of my history later. It'd be sweet to create one that accepted "straight push" fittings like my hotend does.

Edited 1 time(s). Last edit at 01/04/2016 10:18PM by 0x0000.

|

Re: Bowden extruder is missing a brass union... what can I do? January 04, 2016 10:28PM |

Registered: 8 years ago Posts: 164 |

@fotomas, no results found for pneumatic  Do you mean one of these?

Do you mean one of these?

I have one on my hotend, it works great. It came with my hotend kit but it's too big to be used on the stock extruder. The thread looks to be about 6mm for a 4mm PTFE tube, so the extruder could probably be modified to capture an M6 nut within the plastic body (kind of like the X-carriage does)

Do you mean one of these?

Do you mean one of these? I have one on my hotend, it works great. It came with my hotend kit but it's too big to be used on the stock extruder. The thread looks to be about 6mm for a 4mm PTFE tube, so the extruder could probably be modified to capture an M6 nut within the plastic body (kind of like the X-carriage does)

|

Re: Bowden extruder is missing a brass union... what can I do? January 05, 2016 12:27AM |

Registered: 9 years ago Posts: 1,699 |

Many users here (including me) use pneumatic fittings at the extruder like your one.

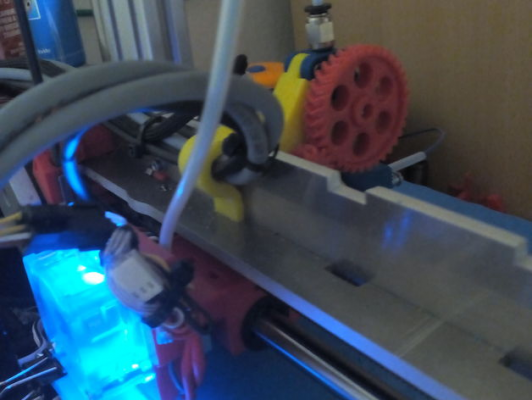

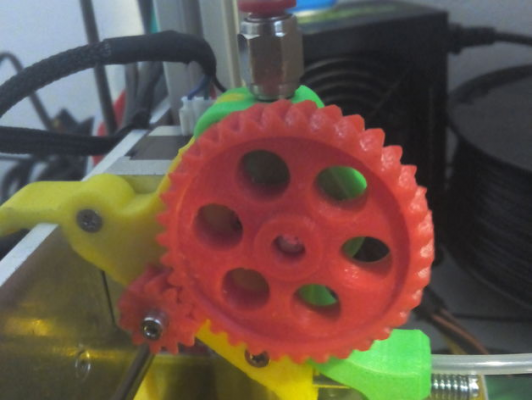

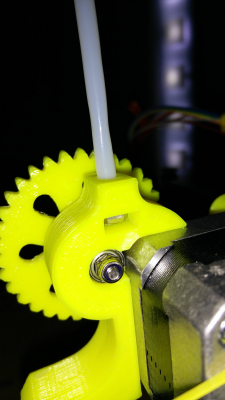

This is my remix of the spring loaded extruder including the remix of Amsterdamman:

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

This is my remix of the spring loaded extruder including the remix of Amsterdamman:

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Bowden extruder is missing a brass union... what can I do? January 05, 2016 02:33AM |

Registered: 8 years ago Posts: 164 |

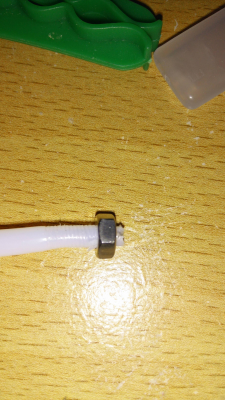

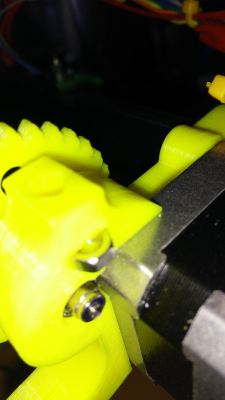

I think I've worked out a solution that only requires an extra M4 nut, no modifications, and no brass unions from an overseas supplier!

As noted above, it's possible to thread an M4 nut onto a 4mm PTFE tube and have it grip pretty well. I later noticed that an M4 fits into the tongue slot of the extruder without and drilling or force, which gave me this idea!

Before you begin, make sure your PTFE tube is disconnected from your hotend. You're going to have to rotate the entire tube a few times for this to work.

1. This bit may not be required depending on your tube (or your nut). Shave a thin layer of PTFE off the tip of the tube using an exacto knife or a pencil sharpener. Don't cut the tip, we're just thinning the tube a bit to get it into the nut.

2. Gently thread your M4 nut onto the tube. There needs to be enough thread to get to the bottom of the extruder, but it's about 3-5mm.

3. Gently unscrew the nut from the tube. You should be left with a bare threaded PTFE tube

4. Remove the tongue from the extruder, if you haven't done so already

5. Insert the M4 nut you used to thread the PTFE into the tongue slot

6. You should now be able to carefully thread the PTFE tube into the captured nut through the hole.

I used a flat screwdriver to hold the nut in place while screwing the tube into place. It took a few tries, and I had to cut the "shaved" tip off to finally get it to catch. Once it did, there's no way I can pull the tube without taking the extruder off of the X-axis.

Threaded PTFE

M4 fits into tongue slot

PTFE threaded onto captive nut

Edited 1 time(s). Last edit at 01/05/2016 02:34AM by 0x0000.

As noted above, it's possible to thread an M4 nut onto a 4mm PTFE tube and have it grip pretty well. I later noticed that an M4 fits into the tongue slot of the extruder without and drilling or force, which gave me this idea!

Before you begin, make sure your PTFE tube is disconnected from your hotend. You're going to have to rotate the entire tube a few times for this to work.

1. This bit may not be required depending on your tube (or your nut). Shave a thin layer of PTFE off the tip of the tube using an exacto knife or a pencil sharpener. Don't cut the tip, we're just thinning the tube a bit to get it into the nut.

2. Gently thread your M4 nut onto the tube. There needs to be enough thread to get to the bottom of the extruder, but it's about 3-5mm.

3. Gently unscrew the nut from the tube. You should be left with a bare threaded PTFE tube

4. Remove the tongue from the extruder, if you haven't done so already

5. Insert the M4 nut you used to thread the PTFE into the tongue slot

6. You should now be able to carefully thread the PTFE tube into the captured nut through the hole.

I used a flat screwdriver to hold the nut in place while screwing the tube into place. It took a few tries, and I had to cut the "shaved" tip off to finally get it to catch. Once it did, there's no way I can pull the tube without taking the extruder off of the X-axis.

Threaded PTFE

M4 fits into tongue slot

PTFE threaded onto captive nut

Edited 1 time(s). Last edit at 01/05/2016 02:34AM by 0x0000.

|

Re: Bowden extruder is missing a brass union... what can I do? January 05, 2016 02:38AM |

Registered: 8 years ago Posts: 164 |

|

Re: Bowden extruder is missing a brass union... what can I do? January 05, 2016 03:01AM |

Registered: 10 years ago Posts: 1,230 |

|

Re: Bowden extruder is missing a brass union... what can I do? January 05, 2016 03:42AM |

Registered: 9 years ago Posts: 1,699 |

It is a remixed version of a spring loaded Extruder. It consists of two parts instead of one. It has some advantages: You have always the same grip at the filament independent from the real diameter. Therefore you have the spring and nut. It is easy to clean and the herringbone gears are easy to attach.

[www.thingiverse.com]

That design is for the Ormerod 1 so I used the Remix from Amsterdamman to have a secure fit. As I wanted to add a tube at the entrance (it is not PTFE it is a cheaper one with OD 4mm and ID 2.5mm) and the existing designs did not fit I decided to make my own remix.

Attaching the nut and spring is very easy. If needed I may provide some more pictures.

Besides there was a big discussion on how to secure the PTFE tube to the Extruder and nobody had your easy and simple idea. The only disadvantage is that you cannot remove the tube quickly if the filament got stuck, but very well done.

BTW this type of LED fan is not available anymore (in Germany), but there is still a 10mm version. This one I use at my Ormerod 2 and I consider to exchange the fan of my Ormerod 1 so the head can easily pass the controller board case.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

[www.thingiverse.com]

That design is for the Ormerod 1 so I used the Remix from Amsterdamman to have a secure fit. As I wanted to add a tube at the entrance (it is not PTFE it is a cheaper one with OD 4mm and ID 2.5mm) and the existing designs did not fit I decided to make my own remix.

Attaching the nut and spring is very easy. If needed I may provide some more pictures.

Besides there was a big discussion on how to secure the PTFE tube to the Extruder and nobody had your easy and simple idea. The only disadvantage is that you cannot remove the tube quickly if the filament got stuck, but very well done.

BTW this type of LED fan is not available anymore (in Germany), but there is still a 10mm version. This one I use at my Ormerod 2 and I consider to exchange the fan of my Ormerod 1 so the head can easily pass the controller board case.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Bowden extruder is missing a brass union... what can I do? January 05, 2016 04:29AM |

Registered: 9 years ago Posts: 191 |

|

Re: Bowden extruder is missing a brass union... what can I do? January 05, 2016 07:37AM |

Registered: 10 years ago Posts: 2,472 |

|

Re: Bowden extruder is missing a brass union... what can I do? January 30, 2016 03:07AM |

Registered: 8 years ago Posts: 164 |

Now that my Duet is back in business, I'm having filament issues. Turns out I have to push my filament into the extruder really hard to get it to start feeding. I thought this was normal while setting it up and just went with it, but now it doesn't seem to feed in at all on its own. If I'm not standing there forcing it in, it doesn't extrude. What is the cause of this?

The documentation mentions that the large gear is supposed to come out "easily" to make cleaning the hobbed insert. How do I go about doing this? Just pull the large gear really hard?

The documentation mentions that the large gear is supposed to come out "easily" to make cleaning the hobbed insert. How do I go about doing this? Just pull the large gear really hard?

|

Re: Bowden extruder is missing a brass union... what can I do? January 30, 2016 03:17AM |

Registered: 9 years ago Posts: 1,699 |

Maybe the temperature is too low? You can try to remove the bowden tube, heat up the nozzle and feed the filament slowly by hand. How is that?

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

Slicer: Simplify3D 4.0; sometimes CraftWare 1.14 or Cura 2.7

Delta with Duet-WiFi, FW: 1.20.1RC2; mini-sensor board by dc42 for auto-leveling

Ormerod common modifications: Mini-sensor board by dc42, aluminum X-arm, 0.4 mm nozzle E3D like, 2nd fan, Z stepper nut M5 x 15, Herringbone gears, Z-axis bearing at top, spring loaded extruder with pneumatic fitting, Y belt axis tensioner

Ormerod 2: FW: 1.19-dc42 on Duet-WiFi. own build, modifications: GT2-belts, silicone heat-bed, different motors and so on. Printed parts: bed support, (PSU holder) and Y-feet.

Ormerod 1: FW: 1.15c-dc42 on 1k Duet-Board. Modifications: Aluminium bed-support, (nearly) all parts reprinted in PLA/ ABS, and so on.

|

Re: Bowden extruder is missing a brass union... what can I do? January 30, 2016 04:55AM |

Registered: 8 years ago Posts: 164 |

Sorry, only registered users may post in this forum.