Home

>

Reprappers

>

Topic

Volcano 1.2mm nozzle extrusion fail

Posted by sungod3k

|

Volcano 1.2mm nozzle extrusion fail June 20, 2016 11:47AM |

Registered: 11 years ago Posts: 805 |

Hi,

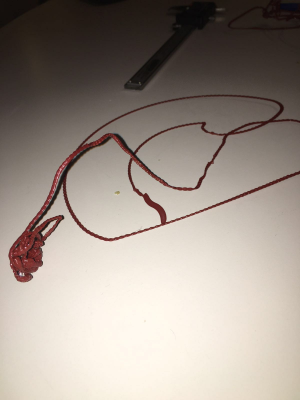

I recently strapped my e3d Volcano nozzle on my printer again and tested the 0.6 and 1.2mm nozzle. and while the 0,6 worked very well, the 1.2 is showing some interesting extrusion.

As you can see the first 20mm (middle of the picture) are a nice thick bead, perfectly squeezed out, but after that it almost starts blobbing. The filament feed stays constant and the same pattern emerges in Cura and Simplyfy3D. The nozzle is not obstructed, not are there any other weird sounds. I would understand that there is something wrong if it starts coming out blobby but the first 20mms looking right really puzzles me.

Any ideas where this could come from?

Cheers

I recently strapped my e3d Volcano nozzle on my printer again and tested the 0.6 and 1.2mm nozzle. and while the 0,6 worked very well, the 1.2 is showing some interesting extrusion.

As you can see the first 20mm (middle of the picture) are a nice thick bead, perfectly squeezed out, but after that it almost starts blobbing. The filament feed stays constant and the same pattern emerges in Cura and Simplyfy3D. The nozzle is not obstructed, not are there any other weird sounds. I would understand that there is something wrong if it starts coming out blobby but the first 20mms looking right really puzzles me.

Any ideas where this could come from?

Cheers

|

Re: Volcano 1.2mm nozzle extrusion fail June 20, 2016 01:39PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Volcano 1.2mm nozzle extrusion fail June 20, 2016 07:46PM |

Registered: 11 years ago Posts: 805 |

|

Re: Volcano 1.2mm nozzle extrusion fail June 21, 2016 07:04AM |

Registered: 11 years ago Posts: 805 |

|

Re: Volcano 1.2mm nozzle extrusion fail June 21, 2016 12:38PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Volcano 1.2mm nozzle extrusion fail June 21, 2016 12:58PM |

Registered: 12 years ago Posts: 548 |

Quote

sungod3k

I still dont understand what could cause a pulsating pattern like that and it doesnt look like underextrusion /too high extrusion speed.

No matter what the micro-stepping is set to, a stepper motor always moves in steps. The extruder & hotend can act like they have a piston pump style of output under some conditions.

|

Re: Volcano 1.2mm nozzle extrusion fail June 22, 2016 06:35AM |

Registered: 11 years ago Posts: 805 |

|

Re: Volcano 1.2mm nozzle extrusion fail June 22, 2016 02:44PM |

Registered: 12 years ago Posts: 548 |

For every step a stepper motor moves, it starts at 0, accelerates to some speed, then slows to a stop. When it's rotating fast enough it never slows to zero, but the slow down is there. It's one thing that makes a stepper motor noisy.

A piston pump only pumps on each stroke, pressure is at zero, goes up, then back to zero.

So, the extrusion can occur like the output of a piston pump. The filament coming out of the nozzle will vary in diameter due to the pressure changes and if the back pressure is reduced enough, it's easier for the size to vary.

If you put a "pressure gauge" in the hotend right before the nozzle, you would see the pressure vary during each step the stepper motor takes. You'd probably need a very sensitive gauge to see them.

When you feel the filament going into an extruder with your fingers, you'll feel what seems to be a slight vibration in it's movement.

A piston pump only pumps on each stroke, pressure is at zero, goes up, then back to zero.

So, the extrusion can occur like the output of a piston pump. The filament coming out of the nozzle will vary in diameter due to the pressure changes and if the back pressure is reduced enough, it's easier for the size to vary.

If you put a "pressure gauge" in the hotend right before the nozzle, you would see the pressure vary during each step the stepper motor takes. You'd probably need a very sensitive gauge to see them.

When you feel the filament going into an extruder with your fingers, you'll feel what seems to be a slight vibration in it's movement.

|

Re: Volcano 1.2mm nozzle extrusion fail June 22, 2016 05:02PM |

Registered: 11 years ago Posts: 471 |

|

Re: Volcano 1.2mm nozzle extrusion fail June 23, 2016 12:33AM |

Registered: 11 years ago Posts: 805 |

I see, although it seems to me that the the blobbing that comes out is way more extreme than any stepping issues that could come from the motor. and it would mean that it should start right away not delayed like it does. Also the feed feels fine, if there are some steeping issues I would feel them on the motor and definitely on the filament feed, which is smooth.

|

Re: Volcano 1.2mm nozzle extrusion fail June 23, 2016 11:00AM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Volcano 1.2mm nozzle extrusion fail June 23, 2016 12:49PM |

Registered: 11 years ago Posts: 805 |

|

Re: Volcano 1.2mm nozzle extrusion fail June 24, 2016 03:29AM |

Registered: 11 years ago Posts: 805 |

|

Re: Volcano 1.2mm nozzle extrusion fail June 24, 2016 08:43AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Volcano 1.2mm nozzle extrusion fail June 24, 2016 04:41PM |

Registered: 11 years ago Posts: 805 |

|

Re: Volcano 1.2mm nozzle extrusion fail June 25, 2016 12:20PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Volcano 1.2mm nozzle extrusion fail June 25, 2016 01:40PM |

Registered: 11 years ago Posts: 805 |

|

Re: Volcano 1.2mm nozzle extrusion fail June 25, 2016 05:09PM |

Registered: 8 years ago Posts: 622 |

One way to check if it's heater related might be this:

The 1.2mm nozzle has an area of 1.44mm^2. At 15mm/sec the volume flow of melted filament is 15 * 1.44 = 21.6 mm^3/sec. Maybe that's the limit that your heater block can do for whatever reason? To check this, put the 0.6mm nozzle back in. This has an area of 0.36 mm^2. So if we take the flow rate of 21.6 mm^3/sec and divide it by the area (0.36) we get a speed of 60mm/sec. So try printing with the 0.6mm nozzle at a speed higher than 60 mm/sec and see if you get the same problem. If you do, then it's because your hot end won't melt more than 21.6mm^3/sec. These are only rough calculations, I haven't taken account of layer heights etc but you get the idea. You haven't said (or at least I didn't see it anywhere) if it's 3mm or 1.75 mm filament. It' takes a lot more energy to melt 3mm filament - something to do with surface area but the full explanation escapes me at the moment.

The 1.2mm nozzle has an area of 1.44mm^2. At 15mm/sec the volume flow of melted filament is 15 * 1.44 = 21.6 mm^3/sec. Maybe that's the limit that your heater block can do for whatever reason? To check this, put the 0.6mm nozzle back in. This has an area of 0.36 mm^2. So if we take the flow rate of 21.6 mm^3/sec and divide it by the area (0.36) we get a speed of 60mm/sec. So try printing with the 0.6mm nozzle at a speed higher than 60 mm/sec and see if you get the same problem. If you do, then it's because your hot end won't melt more than 21.6mm^3/sec. These are only rough calculations, I haven't taken account of layer heights etc but you get the idea. You haven't said (or at least I didn't see it anywhere) if it's 3mm or 1.75 mm filament. It' takes a lot more energy to melt 3mm filament - something to do with surface area but the full explanation escapes me at the moment.

|

Re: Volcano 1.2mm nozzle extrusion fail July 21, 2016 09:00AM |

Registered: 7 years ago Posts: 1 |

I think the bobbling at higher speeds is caused by the effect that you try to push too much filament, it is breaked by beeing too cold, then as it heats (in fractions of seconds) it is "allowed" to pass, then it cools down the nozzle a little, and the effect repeats itself.

Edited 1 time(s). Last edit at 07/21/2016 09:02AM by Swordriff.

Edited 1 time(s). Last edit at 07/21/2016 09:02AM by Swordriff.

Sorry, only registered users may post in this forum.