Home

>

Reprappers

>

Topic

Request Sample

Posted by deideo

|

Request Sample January 16, 2011 02:50PM |

Registered: 13 years ago Posts: 5 |

Hello everyone,

Actually, I am really interested to buy a new 3D printer such as Mendel one.

However, I am really doubt about its quality.

You know, AFAIK, there are architectural and engineering project that demand a high resolution, good quality and finishing.

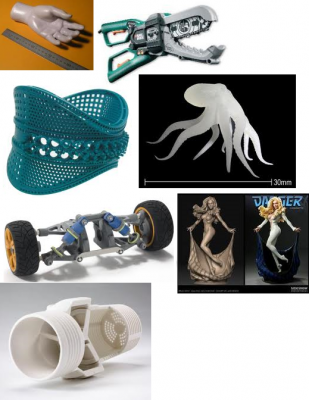

Please take a look at below image for an example of high resolution 3D printer work:

And if anyone here don't mind, I have a 3D part as a request to be printed by Mendel 3D printer itself, to see whether Mendel 3D printer is suitable for me or not.

Please see the attached of the 3D .stl file and a screenshot of it:

3D.stl

Deideo

Actually, I am really interested to buy a new 3D printer such as Mendel one.

However, I am really doubt about its quality.

You know, AFAIK, there are architectural and engineering project that demand a high resolution, good quality and finishing.

Please take a look at below image for an example of high resolution 3D printer work:

And if anyone here don't mind, I have a 3D part as a request to be printed by Mendel 3D printer itself, to see whether Mendel 3D printer is suitable for me or not.

Please see the attached of the 3D .stl file and a screenshot of it:

3D.stl

Deideo

|

Re: Request Sample January 16, 2011 04:07PM |

Admin Registered: 15 years ago Posts: 1,470 |

Unfortunately the RepRap is a rather low-end printer. While the output is amazing for the price, it is not capable of producing anything quite like you've pictured, at least not without a lot of post-print finishing.

Edit: I would look through Thingiverse to see examples of what can be done.

Edited 1 time(s). Last edit at 01/16/2011 04:10PM by NewPerfection.

Edit: I would look through Thingiverse to see examples of what can be done.

Edited 1 time(s). Last edit at 01/16/2011 04:10PM by NewPerfection.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Request Sample January 16, 2011 11:41PM |

Registered: 14 years ago Posts: 458 |

|

Re: Request Sample January 17, 2011 05:02PM |

Admin Registered: 15 years ago Posts: 1,470 |

Grogyan Wrote:

-------------------------------------------------------

> A lot of those pics are from the ZCORP machine

> which uses powder.

>

> You can if you want to, use a small nozzle, in the

> region of 0.25mm dia as opposed to 0.5mm dia

> standard.

Makes sense. I though those looked way too high resolution to be FDM produced.

-------------------------------------------------------

> A lot of those pics are from the ZCORP machine

> which uses powder.

>

> You can if you want to, use a small nozzle, in the

> region of 0.25mm dia as opposed to 0.5mm dia

> standard.

Makes sense. I though those looked way too high resolution to be FDM produced.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Request Sample January 18, 2011 11:45PM |

Registered: 13 years ago Posts: 65 |

|

Re: Request Sample January 20, 2011 09:34PM |

Registered: 13 years ago Posts: 79 |

Please read the following before judging the print

I have only been at this for a few months and I am not very well versed in Skeinforge settings yet.

This is the first time I've printed a part using support and I seem to have overdone it bit. The mesh is probably double what it needs to be..... made it rather hard to remove and leaving it looking a little ragged. Given a little time it could be cleaned up to look much better.

Although hard to see in the picture the slotted collar printed quite well.

The machine itself had no problem printing the spines however the extruder was not appropriate for that application. It has a large melt chamber designed for printing at high volume (not so good for starts and stops) and the nozzle at roughly .37 mm was a bit too big for the job. Together they left the spines looking pretty blurby. Just to say: The poor quality of the spines was the result of poor choice of hot end and not a limitation of the machine. A slightly smaller nozzle on a smaller more articulate hot end would have produced a much nicer print.

I just bought some .2 mm drill bits, maybe I'll give it another go

Edited 1 time(s). Last edit at 12/19/2011 09:37PM by Bruce.

I have only been at this for a few months and I am not very well versed in Skeinforge settings yet.

This is the first time I've printed a part using support and I seem to have overdone it bit. The mesh is probably double what it needs to be..... made it rather hard to remove and leaving it looking a little ragged. Given a little time it could be cleaned up to look much better.

Although hard to see in the picture the slotted collar printed quite well.

The machine itself had no problem printing the spines however the extruder was not appropriate for that application. It has a large melt chamber designed for printing at high volume (not so good for starts and stops) and the nozzle at roughly .37 mm was a bit too big for the job. Together they left the spines looking pretty blurby. Just to say: The poor quality of the spines was the result of poor choice of hot end and not a limitation of the machine. A slightly smaller nozzle on a smaller more articulate hot end would have produced a much nicer print.

I just bought some .2 mm drill bits, maybe I'll give it another go

Edited 1 time(s). Last edit at 12/19/2011 09:37PM by Bruce.

|

Re: Request Sample January 21, 2011 12:05AM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Request Sample January 21, 2011 01:09AM |

Registered: 14 years ago Posts: 3,742 |

The print result turned out very well IMHO.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Request Sample January 21, 2011 05:53AM |

Registered: 13 years ago Posts: 818 |

|

Re: Request Sample January 21, 2011 01:55PM |

Admin Registered: 15 years ago Posts: 1,470 |

That actually looks very nice! I think you're right that with a .25 mm or so nozzle and a small melt chamber you could probably print the spines very nicely.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

Sorry, only registered users may post in this forum.