Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 11:31AM |

Registered: 8 years ago Posts: 35 |

Howdy y'all!

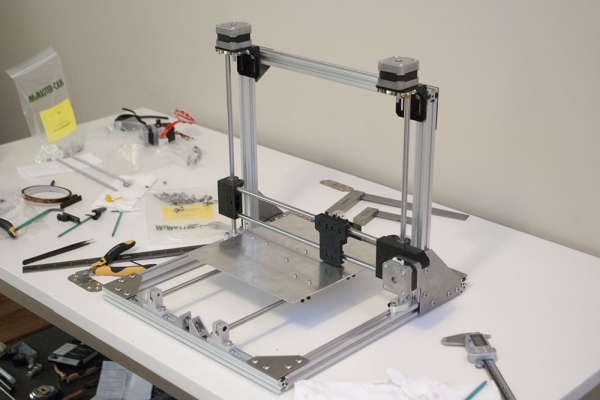

I got this printer last week and got it assembled and finally got some printing started over the weekend. I've read through this whole thread and haven't experienced (yet anyway) most of these issues. My first print was a 20x20mm cube that came out pretty good.

The real only issue I had was the most prevalent one in this thread and that is the X axis not being correct, at least as far as it is mentioned in the build guide. I put the end stop on the left side and that remedied that issue. My LCD worked fine. Heaters all work. Extruder works fine. I had all the screws and nuts required and some extra.

I've built tons of R/C cars, helicopters, airplanes, robots, etc and have a very high mechanical aptitude so the mechanical part of this kit was not overly challenging. I had to clean up and file some things but I don't really consider that a negative given the price of the kit and what it costs to pay someone else to do those tedius tasks.

One of my A4988 modules was DOA but they give you one extra and it worked fine so I'm good there.

The longer M3 bolts that hold the extruder assembly together were too long. These are the bottom two that go through the fan, heatsink, and extruder and into the motor. The fan and everything was loose. No big deal though, just took about .7mm off the tips of the threaded ends and bolted it all back up.

The holders for the end stop switches needed to be sanded down. When you bolt the switch to it the switch arm did not extend out far enough to clear the plastic for it to actually work. Sanding down the holder gave the arm extra room so they work properly now.

I also epoxied the M5 nuts into the Z/X brackets and while I was doing that I dabbed a little epoxy on each end of the bearing holder sections because they were a bit loose and seemed like they slide right out. Just a little dab on each end to act as a stop.

The calibration that I've done so far is setting up the extruder. The default is 90 and I put mine to 81, based off my calculations. That did help the print quality quite a bit. Haven't really needed to change anything else thus far. Mostly working on hot end temps and slicer settings.

I lubed up the moving parts with a light silicone oil. Its all smooth like butter.

A small challenge I've had is finding out where to actually change settings. I found lots of theory on changing the steps for the extruder but a bit of conflicting information about where to actually set it in the software. Eventually I found a thread somewhere that mentioned the string I needed and I was able to figure out the rest.

All in all I have had a good experience with this printer so far. I've only been using PLA for now figuring I'd master one medium before switching to another.

Edited 1 time(s). Last edit at 07/15/2015 11:48AM by RedneckGeek.

I got this printer last week and got it assembled and finally got some printing started over the weekend. I've read through this whole thread and haven't experienced (yet anyway) most of these issues. My first print was a 20x20mm cube that came out pretty good.

The real only issue I had was the most prevalent one in this thread and that is the X axis not being correct, at least as far as it is mentioned in the build guide. I put the end stop on the left side and that remedied that issue. My LCD worked fine. Heaters all work. Extruder works fine. I had all the screws and nuts required and some extra.

I've built tons of R/C cars, helicopters, airplanes, robots, etc and have a very high mechanical aptitude so the mechanical part of this kit was not overly challenging. I had to clean up and file some things but I don't really consider that a negative given the price of the kit and what it costs to pay someone else to do those tedius tasks.

One of my A4988 modules was DOA but they give you one extra and it worked fine so I'm good there.

The longer M3 bolts that hold the extruder assembly together were too long. These are the bottom two that go through the fan, heatsink, and extruder and into the motor. The fan and everything was loose. No big deal though, just took about .7mm off the tips of the threaded ends and bolted it all back up.

The holders for the end stop switches needed to be sanded down. When you bolt the switch to it the switch arm did not extend out far enough to clear the plastic for it to actually work. Sanding down the holder gave the arm extra room so they work properly now.

I also epoxied the M5 nuts into the Z/X brackets and while I was doing that I dabbed a little epoxy on each end of the bearing holder sections because they were a bit loose and seemed like they slide right out. Just a little dab on each end to act as a stop.

The calibration that I've done so far is setting up the extruder. The default is 90 and I put mine to 81, based off my calculations. That did help the print quality quite a bit. Haven't really needed to change anything else thus far. Mostly working on hot end temps and slicer settings.

I lubed up the moving parts with a light silicone oil. Its all smooth like butter.

A small challenge I've had is finding out where to actually change settings. I found lots of theory on changing the steps for the extruder but a bit of conflicting information about where to actually set it in the software. Eventually I found a thread somewhere that mentioned the string I needed and I was able to figure out the rest.

All in all I have had a good experience with this printer so far. I've only been using PLA for now figuring I'd master one medium before switching to another.

Edited 1 time(s). Last edit at 07/15/2015 11:48AM by RedneckGeek.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 12:23PM |

Registered: 8 years ago Posts: 135 |

Quote

RedneckGeek

The longer M3 bolts that hold the extruder assembly together were too long. These are the bottom two that go through the fan, heatsink, and extruder and into the motor. The fan and everything was loose. No big deal though, just took about .7mm off the tips of the threaded ends and bolted it all back up.

I also epoxied the M5 nuts into the Z/X brackets and while I was doing that I dabbed a little epoxy on each end of the bearing holder sections because they were a bit loose and seemed like they slide right out. Just a little dab on each end to act as a stop.

A small challenge I've had is finding out where to actually change settings. I found lots of theory on changing the steps for the extruder but a bit of conflicting information about where to actually set it in the software. Eventually I found a thread somewhere that mentioned the string I needed and I was able to figure out the rest.

All in all I have had a good experience with this printer so far. I've only been using PLA for now figuring I'd master one medium before switching to another.

Welcome to the discussion! I reduced the quote to the points I am going to comment on (just to reduce scrolling on the forum).

My bolts were a tad too long as well, though I just wedged a couple small pieces of foam on both sides of the heat sink (fan/extruder) which actually turned out nice because it helps dampen vibration. All the add-ons for the mk7 expect the longer screws so everything is snug with add-ons such as the fan shroud I uploaded.

Epoxying those nuts would probably be a good idea, but I feel like there are some better, less permanent designs out there. when it comes time to disassemble your x-carriage (which you will have to do eventually for any variety of reasons) its much easier to just pop out the m5 nuts than to undo the whole threaded rod.

For changing settings, if you can, always change it in the firmware and keep a log of your changes for when you update firmware so you know what you changed and what the values were. This way, you can hook up any computer/print server/lcd to your printer and never have to mess with your calibration settings. However for best print quality you should have fine tuned your filament diameter and extrusion multiplier in your slicing software for each filament.

I also enjoyed PLA but came to the realization, that I need backup parts for my printer, and most of them just can't be PLA due to temps/durability. When I first switched to ABS I hated it. Hard to get it to stick, layer separation, its a lot more touchy about temp settings, having to use some sort of coating on the bed, the smell, etc. However after switching to ABS and discovering purple glue stick, I really don't want to go back to PLA (after switching back and forth a few times to be sure). Once you deal with your first PLA clogs, and get into longer prints, you will probably start running into the downsides of PLA. Plus there's the magic of the purple glue stick and ABS. It sticks so well you practically have to break the glass to remove it while its hot, but if you let it cool you will hear loud pops and cracks that almost sound like glass cracking and at that point the print is almost completely released from the bed and you can just pick it up without any prying. Its really amazing.

Some tips on glue stick for people curious/just starting out with it (these are just things I discovered on my own):

- Always let your heated bed cool down until the print pops off by itself, pulling off prints while hot will remove some of the glue stick and force you to clean/reapply

- You can get away with coating the bed once every 5-8 prints if you let the bed cool as described above

- You can touch up little spots that may have lost their glue to the print, but only expect to get 1 more print out of that coat, and its usually best to just redo it

- If touching up don't let your coat get too thick or it will peel from the glass when you remove your print (doesnt really matter though because you should only print 1-2 more times max on a touched up coating)

Steps for cleaning/coating with glue stick:

- raise your z axis up out of the way and home the x axis

- Hold the tip of the glue stick as flat as possible on the bed and try to make nice clean/even lines when applying

- try to put as little as possible on while still covering the whole glass surface, the thinner you get it, the better it will perform and longer it will last

- for cleaning, just saturate a paper towel in isopropyl alcohol and wipe clean, wait to dry (like a minute or 2) before reapplying glue

You can use glue stick on PLA, but just know it won't let go when it cools like ABS and is a bitch to pry off.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 12:59PM |

Registered: 8 years ago Posts: 20 |

Quote

mel0n

Quote

RedneckGeek

The longer M3 bolts that hold the extruder assembly together were too long. These are the bottom two that go through the fan, heatsink, and extruder and into the motor. The fan and everything was loose. No big deal though, just took about .7mm off the tips of the threaded ends and bolted it all back up.

I also epoxied the M5 nuts into the Z/X brackets and while I was doing that I dabbed a little epoxy on each end of the bearing holder sections because they were a bit loose and seemed like they slide right out. Just a little dab on each end to act as a stop.

A small challenge I've had is finding out where to actually change settings. I found lots of theory on changing the steps for the extruder but a bit of conflicting information about where to actually set it in the software. Eventually I found a thread somewhere that mentioned the string I needed and I was able to figure out the rest.

All in all I have had a good experience with this printer so far. I've only been using PLA for now figuring I'd master one medium before switching to another.

Welcome to the discussion! I reduced the quote to the points I am going to comment on (just to reduce scrolling on the forum).

My bolts were a tad too long as well, though I just wedged a couple small pieces of foam on both sides of the heat sink (fan/extruder) which actually turned out nice because it helps dampen vibration. All the add-ons for the mk7 expect the longer screws so everything is snug with add-ons such as the fan shroud I uploaded.

Epoxying those nuts would probably be a good idea, but I feel like there are some better, less permanent designs out there. when it comes time to disassemble your x-carriage (which you will have to do eventually for any variety of reasons) its much easier to just pop out the m5 nuts than to undo the whole threaded rod.

For changing settings, if you can, always change it in the firmware and keep a log of your changes for when you update firmware so you know what you changed and what the values were. This way, you can hook up any computer/print server/lcd to your printer and never have to mess with your calibration settings. However for best print quality you should have fine tuned your filament diameter and extrusion multiplier in your slicing software for each filament.

I also enjoyed PLA but came to the realization, that I need backup parts for my printer, and most of them just can't be PLA due to temps/durability. When I first switched to ABS I hated it. Hard to get it to stick, layer separation, its a lot more touchy about temp settings, having to use some sort of coating on the bed, the smell, etc. However after switching to ABS and discovering purple glue stick, I really don't want to go back to PLA (after switching back and forth a few times to be sure). Once you deal with your first PLA clogs, and get into longer prints, you will probably start running into the downsides of PLA. Plus there's the magic of the purple glue stick and ABS. It sticks so well you practically have to break the glass to remove it while its hot, but if you let it cool you will hear loud pops and cracks that almost sound like glass cracking and at that point the print is almost completely released from the bed and you can just pick it up without any prying. Its really amazing.

Some tips on glue stick for people curious/just starting out with it (these are just things I discovered on my own):

- Always let your heated bed cool down until the print pops off by itself, pulling off prints while hot will remove some of the glue stick and force you to clean/reapply

- You can get away with coating the bed once every 5-8 prints if you let the bed cool as described above

- You can touch up little spots that may have lost their glue to the print, but only expect to get 1 more print out of that coat, and its usually best to just redo it

- If touching up don't let your coat get too thick or it will peel from the glass when you remove your print (doesnt really matter though because you should only print 1-2 more times max on a touched up coating)

Steps for cleaning/coating with glue stick:

- raise your z axis up out of the way and home the x axis

- Hold the tip of the glue stick as flat as possible on the bed and try to make nice clean/even lines when applying

- try to put as little as possible on while still covering the whole glass surface, the thinner you get it, the better it will perform and longer it will last

- for cleaning, just saturate a paper towel in isopropyl alcohol and wipe clean, wait to dry (like a minute or 2) before reapplying glue

You can use glue stick on PLA, but just know it won't let go when it cools like ABS and is a bitch to pry off.

Do you use kapton tape under the glue stick, or apply straight to the glass bed?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 01:24PM |

Registered: 8 years ago Posts: 135 |

straight on glass, Tape is too expensive/annoying as a disposable IMO. I got a triple sized glue stick for 90 cents at Walmart which is going to last a really, really long time

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 02:35PM |

Registered: 8 years ago Posts: 35 |

Quote

mel0n

I also enjoyed PLA but came to the realization, that I need backup parts for my printer, and most of them just can't be PLA due to temps/durability. When I first switched to ABS I hated it. Hard to get it to stick, layer separation, its a lot more touchy about temp settings, having to use some sort of coating on the bed, the smell, etc. However after switching to ABS and discovering purple glue stick, I really don't want to go back to PLA (after switching back and forth a few times to be sure). Once you deal with your first PLA clogs, and get into longer prints, you will probably start running into the downsides of PLA. Plus there's the magic of the purple glue stick and ABS. It sticks so well you practically have to break the glass to remove it while its hot, but if you let it cool you will hear loud pops and cracks that almost sound like glass cracking and at that point the print is almost completely released from the bed and you can just pick it up without any prying. Its really amazing.

Some tips on glue stick for people curious/just starting out with it (these are just things I discovered on my own):

- Always let your heated bed cool down until the print pops off by itself, pulling off prints while hot will remove some of the glue stick and force you to clean/reapply

- You can get away with coating the bed once every 5-8 prints if you let the bed cool as described above

- You can touch up little spots that may have lost their glue to the print, but only expect to get 1 more print out of that coat, and its usually best to just redo it

- If touching up don't let your coat get too thick or it will peel from the glass when you remove your print (doesnt really matter though because you should only print 1-2 more times max on a touched up coating)

Steps for cleaning/coating with glue stick:

- raise your z axis up out of the way and home the x axis

- Hold the tip of the glue stick as flat as possible on the bed and try to make nice clean/even lines when applying

- try to put as little as possible on while still covering the whole glass surface, the thinner you get it, the better it will perform and longer it will last

- for cleaning, just saturate a paper towel in isopropyl alcohol and wipe clean, wait to dry (like a minute or 2) before reapplying glue

You can use glue stick on PLA, but just know it won't let go when it cools like ABS and is a bitch to pry off.

Thanks for this info! I just might give ABS a try sooner than I thought. I have a full spool of it and a pile of sample spools in various colors.

I have a question... Does the filament size in the firmware have that big of an effect on the print vs the filament size set in the printer settings of Repetier? I ask because in the firmware config I noticied the filament was set to something like 2.85mm vs the 1.75mm that the printer actually uses. Its set to 1.75mm in Repetier of course. The prints look great so I'm hesiatant to change it. I printed up some LCD holders one of yall posted in this thread and they came out pretty slick and work great.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 02:42PM |

Registered: 8 years ago Posts: 135 |

leave filament settings to the slicer/host. All other calibration such as Esteps should be in Firmware. I say this because your Filament changes, your machine's parametrics don't.

Filament size makes the biggest difference imo, I usually take 10 or so measurements of the filament with my calipers and average them. I found most filaments are <1.75 and typically around 1.72mm / 1.73mm.

Your extrusion multiplier also makes a difference.

Be careful switching from PLA to ABS and back. I have had a couple nasty clogs as a result of switching which is why I am mostly sticking to ABS for now and when I switch I make sure I have everything I want in that color lined up so I don't have to switch as frequently.

Switching from ABS to PLA is obviously where the challenges occur with ABS having a higher melting temp. So I just deal with the nasty smell overheated PLA gives off and extrude ~400 - 600mm of PLA at 220C until I feel confident that most of the ABS is purged. The PLA I am using really likes high temps too so I print at 205C which helps any stray ABS bits to get through during the print. Its not flawless and I am trying to get a process nailed down for switching, but I am sick of dealing with clogs so I haven't switched back to PLA in a few days.

Just realized this is post # 666 O.o

Edited 3 time(s). Last edit at 07/15/2015 03:17PM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

Filament size makes the biggest difference imo, I usually take 10 or so measurements of the filament with my calipers and average them. I found most filaments are <1.75 and typically around 1.72mm / 1.73mm.

Your extrusion multiplier also makes a difference.

Be careful switching from PLA to ABS and back. I have had a couple nasty clogs as a result of switching which is why I am mostly sticking to ABS for now and when I switch I make sure I have everything I want in that color lined up so I don't have to switch as frequently.

Switching from ABS to PLA is obviously where the challenges occur with ABS having a higher melting temp. So I just deal with the nasty smell overheated PLA gives off and extrude ~400 - 600mm of PLA at 220C until I feel confident that most of the ABS is purged. The PLA I am using really likes high temps too so I print at 205C which helps any stray ABS bits to get through during the print. Its not flawless and I am trying to get a process nailed down for switching, but I am sick of dealing with clogs so I haven't switched back to PLA in a few days.

Just realized this is post # 666 O.o

Edited 3 time(s). Last edit at 07/15/2015 03:17PM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 04:44PM |

Registered: 8 years ago Posts: 19 |

Quote

691175002

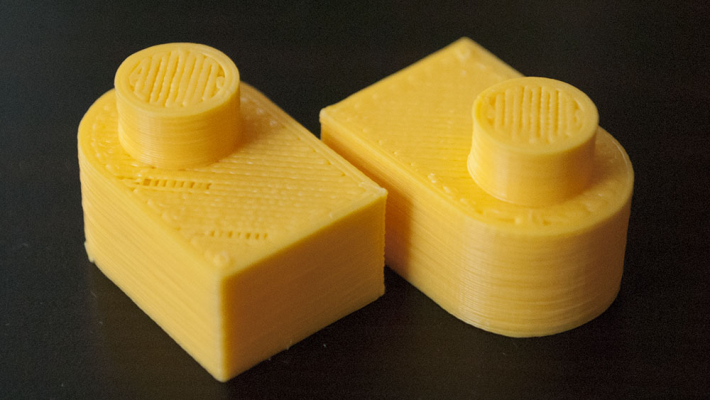

Alright, finally got some reasonable prints. I am using the enclosure again, but with some tweaks to avoid melting the printer components. My heated bed is now set to 70c for all layers (previously 105c). I I have also turned the X and E steppers down to 0.15V (previously 0.35V) and will probably go even lower. I also leave the door ajar and periodically check the temperature to avoid going higher than 40c.

ABS at 0.2mm

There is still a bit more tweaking I can do in the slicer but I think I've basically hit the mechanical repeatability limit of the printer. There is quite a bit of slop in the bearings and compliance in general, but for a $270 printer I can't really complain.

This looks great!... What color and brand filament is this?

Where do you guys get your filament in general? I want to give Folgertech my business but most of their filaments are always out of stock.

Their auto level kit for this printer was apparently supposed to launch on the website this week , but no sign so far. And there's no one to replace Dan on the forums. They really need to step it up a notch.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 04:53PM |

Registered: 8 years ago Posts: 135 |

I have been kinda curious as to where Dan went. His last post was 4 weeks ago, and it seemed like up until then he was pretty regular/active. We haven't really heard anything from anybody at Folger in a while now. They haven't really posted much on their facebook or blog in a long time either. I get all my filament from amazon because of price, shipping, and its easy to find reviews.

Edited 1 time(s). Last edit at 07/15/2015 04:57PM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

Edited 1 time(s). Last edit at 07/15/2015 04:57PM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 07:00PM |

Registered: 8 years ago Posts: 95 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 07:54PM |

Registered: 8 years ago Posts: 430 |

Quote

msaeger

Has anyone used PETG filament with this machine? I want to try something that will won't soften from being in the car on a hot day and I have been reading PETG doesn't smell like ABS.

Here's the thread I started about PETG if anyone is curious.

[forums.reprap.org]

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 08:01PM |

Registered: 8 years ago Posts: 135 |

Quote

691175002

Alright, finally got some reasonable prints. I am using the enclosure again, but with some tweaks to avoid melting the printer components. My heated bed is now set to 70c for all layers (previously 105c). I I have also turned the X and E steppers down to 0.15V (previously 0.35V) and will probably go even lower. I also leave the door ajar and periodically check the temperature to avoid going higher than 40c.

ABS at 0.2mm

There is still a bit more tweaking I can do in the slicer but I think I've basically hit the mechanical repeatability limit of the printer. There is quite a bit of slop in the bearings and compliance in general, but for a $270 printer I can't really complain.

My ABS at 0.2mm layer height (files too large to upload to the forum so I added them as a make for the item on thingiverse)

[www.thingiverse.com]

Keep in mind this is after many clogs, 2.5 whole rolls of filament, and non-stop printing for about 3 weeks straight at this point.

I will probably make another one once my E3D v6 gets here (tomorrow) and is installed to compare.

Edited 1 time(s). Last edit at 07/15/2015 08:02PM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 08:44PM |

Registered: 8 years ago Posts: 35 |

Quote

mike3

Hopefully they are still in business as they are still taking peoples money including mine... but havn't recieved a valid tracking on My Printer.. just label created...

They did that to me too. I just kept checking the tracking number on usps.com every day for 3 or 4 days until it actually shipped. Shipping was quick for a 2000 mile journey from up north to here in Texas. 2 days

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 09:00PM |

Registered: 8 years ago Posts: 3 |

@ Mike3,

Just an FYI, I ordered mine the 9th and it came today. My first dive into 3d printing, so it should be interesting!

I did a quick look at the contents of the box, and it looks like its all there. The 3d printed parts look good, but the RAMPS board, well.. some bent pins, solder joints don't look the best either I will propbably hit them with an iron to make sure.

I will propbably hit them with an iron to make sure.

I would usually be up all night putting this together like a kid on christmas, but I just pulled a 12 hr shift.

Wish me luck! I am sure I will be back here re-reading and looking for tips.

And a BIG thanks to all of those that are helping out here!!

Just an FYI, I ordered mine the 9th and it came today. My first dive into 3d printing, so it should be interesting!

I did a quick look at the contents of the box, and it looks like its all there. The 3d printed parts look good, but the RAMPS board, well.. some bent pins, solder joints don't look the best either

I will propbably hit them with an iron to make sure.

I will propbably hit them with an iron to make sure. I would usually be up all night putting this together like a kid on christmas, but I just pulled a 12 hr shift.

Wish me luck! I am sure I will be back here re-reading and looking for tips.

And a BIG thanks to all of those that are helping out here!!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 09:39PM |

Registered: 11 years ago Posts: 335 |

Quote

go_gn

This looks great!... What color and brand filament is this?

Its Botfeeder yellow ABS. I just chose them at random, it seems like there are several filament suppliers that get consistantly good reviews.

Quote

mel0n

That looks great, but I found you only see artifacts on mostly flat vertical sections, so I think thats why I am not seeing any artifacting in that print.

Artifacts are definitely more noticeable on flat sections. You can spot some if you look closely enough but at arms length they look pretty smooth.

The left print had some missed extruder steps since I was tweaking the motor (0.12V, now at 0.16V). I've been blessed by a non-leaking extruder (at least so far). I'm mostly using this guy to print components for a second printer so it won't have to last long.

I found that if there was even a hint of misalignment the provided bearings would immediately become very rough which leads to a wavy surface finish.

I installed the belts and threaded rods as the final step so that I could slide every axis by hand and ensure they were as smooth as possible. There aren't many options if your X axis is rough, but there is room to adjust Y and Z. My Y axis required a lot of work ( [forums.reprap.org] ).

I'll be honest here, I am genuinely surprised at how finicky the linear motion components are. I've used my fair share of chinese bearings in the past ( [www.cnczone.com] ) and they are generally quite robust.

I'm complaining a lot but realistically this kit is amazing for its price. If you can assemble it you will learn a lot.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 09:45PM |

Registered: 8 years ago Posts: 171 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 09:52PM |

Registered: 8 years ago Posts: 135 |

Quote

691175002

I found that if there was even a hint of misalignment the provided bearings would immediately become very rough which leads to a wavy surface finish.

I installed the belts and threaded rods as the final step so that I could slide every axis by hand and ensure they were as smooth as possible. There aren't many options if your X axis is rough, but there is room to adjust Y and Z. My Y axis required a lot of work ( [forums.reprap.org] ).

I'll be honest here, I am genuinely surprised at how finicky the linear motion components are. I've used my fair share of chinese bearings in the past ( [www.cnczone.com] ) and they are generally quite robust.

I'm complaining a lot but realistically this kit is amazing for its price. If you can assemble it you will learn a lot.

Wow your cnczone link is insanely cool. Thats the type of stuff I am hoping to work up to (started out with the 3d printer). Thats interesting what you said about the bearings and I am really curious about bushings as well. I can tell my artifacting comes from vibrations but there's just so many sources and I am still figuring out vibration dampening and possibly replacing my bearings with bushings or better bearings.

I also saw your Y post a few days ago and was really surprised at how off your mounts were.

What are you printing parts to build? I am curious what somebody with your technical skills has plannedQuote

691175002

I'm mostly using this guy to print components for a second printer so it won't have to last long.

Me either >.<Quote

markts

I hate to admit this, but I haven't touched the voltages to the motors. How is that affecting my prints?

I am not missing any steps, and my prints are coming out pretty well for the most part and I have had lots of successful long (7+hour) prints at this point and I just don't wanna mess with it. I have touched litterally everything several times with the exception of those pots haha

Edited 1 time(s). Last edit at 07/15/2015 09:56PM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 10:10PM |

Registered: 8 years ago Posts: 81 |

Quote

mel0n

Quote

RedneckGeek

The longer M3 bolts that hold the extruder assembly together were too long. These are the bottom two that go through the fan, heatsink, and extruder and into the motor. The fan and everything was loose. No big deal though, just took about .7mm off the tips of the threaded ends and bolted it all back up.

I also epoxied the M5 nuts into the Z/X brackets and while I was doing that I dabbed a little epoxy on each end of the bearing holder sections because they were a bit loose and seemed like they slide right out. Just a little dab on each end to act as a stop.

A small challenge I've had is finding out where to actually change settings. I found lots of theory on changing the steps for the extruder but a bit of conflicting information about where to actually set it in the software. Eventually I found a thread somewhere that mentioned the string I needed and I was able to figure out the rest.

All in all I have had a good experience with this printer so far. I've only been using PLA for now figuring I'd master one medium before switching to another.

Welcome to the discussion! I reduced the quote to the points I am going to comment on (just to reduce scrolling on the forum).

My bolts were a tad too long as well, though I just wedged a couple small pieces of foam on both sides of the heat sink (fan/extruder) which actually turned out nice because it helps dampen vibration. All the add-ons for the mk7 expect the longer screws so everything is snug with add-ons such as the fan shroud I uploaded.

Epoxying those nuts would probably be a good idea, but I feel like there are some better, less permanent designs out there. when it comes time to disassemble your x-carriage (which you will have to do eventually for any variety of reasons) its much easier to just pop out the m5 nuts than to undo the whole threaded rod.

For changing settings, if you can, always change it in the firmware and keep a log of your changes for when you update firmware so you know what you changed and what the values were. This way, you can hook up any computer/print server/lcd to your printer and never have to mess with your calibration settings. However for best print quality you should have fine tuned your filament diameter and extrusion multiplier in your slicing software for each filament.

I also enjoyed PLA but came to the realization, that I need backup parts for my printer, and most of them just can't be PLA due to temps/durability. When I first switched to ABS I hated it. Hard to get it to stick, layer separation, its a lot more touchy about temp settings, having to use some sort of coating on the bed, the smell, etc. However after switching to ABS and discovering purple glue stick, I really don't want to go back to PLA (after switching back and forth a few times to be sure). Once you deal with your first PLA clogs, and get into longer prints, you will probably start running into the downsides of PLA. Plus there's the magic of the purple glue stick and ABS. It sticks so well you practically have to break the glass to remove it while its hot, but if you let it cool you will hear loud pops and cracks that almost sound like glass cracking and at that point the print is almost completely released from the bed and you can just pick it up without any prying. Its really amazing.

Some tips on glue stick for people curious/just starting out with it (these are just things I discovered on my own):

- Always let your heated bed cool down until the print pops off by itself, pulling off prints while hot will remove some of the glue stick and force you to clean/reapply

- You can get away with coating the bed once every 5-8 prints if you let the bed cool as described above

- You can touch up little spots that may have lost their glue to the print, but only expect to get 1 more print out of that coat, and its usually best to just redo it

- If touching up don't let your coat get too thick or it will peel from the glass when you remove your print (doesnt really matter though because you should only print 1-2 more times max on a touched up coating)

Steps for cleaning/coating with glue stick:

- raise your z axis up out of the way and home the x axis

- Hold the tip of the glue stick as flat as possible on the bed and try to make nice clean/even lines when applying

- try to put as little as possible on while still covering the whole glass surface, the thinner you get it, the better it will perform and longer it will last

- for cleaning, just saturate a paper towel in isopropyl alcohol and wipe clean, wait to dry (like a minute or 2) before reapplying glue

You can use glue stick on PLA, but just know it won't let go when it cools like ABS and is a bitch to pry off.

@mel0n

How hot do you set your bed when using glue stick? Right now im printing on bare glass with temp at 95'C.

Thanks to animoose for pointing out the 30% speed and 200% extrusion width on first layer, i've got better adhesion. Though i still got some corner lifts but it's very minimal.

I wanted to remove them altogether so i might try out using glue stick too.

@all

Anyone experienced that after leaving a long print running, you find that a layer of your print is offset on x-axis and it stayed that way till the top?

This happened to me and it was due to the print head getting stucked on an over extruded portion of the print.

It turns out, when these over-extruded areas cooled (usually my infills), it is sturdy enough to stop the head from going where its supposed to go. The print gets offset from there on.

I have already calibrated my extruder steps but it still wont get rid of those over extrusions.

As for increasing motor torque, i tried it but either the motor runs too hot or my print will get knocked off from the bed.

So, what remedied it for me is to use z-lift on retract on slic3r settings.

Setting it around your layer height (i use 0.25mm) provides plenty of clearance when the head moves to a different location yet it doesn't add that much overhead on your printing time.

Currently printing a z motor stand-off to recover lost z due to motor shaft and coupler:

Z stand-off

Edited 1 time(s). Last edit at 07/15/2015 10:18PM by wderoxas.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 10:29PM |

Registered: 11 years ago Posts: 335 |

Quote

markts

I hate to admit this, but I haven't touched the voltages to the motors. How is that affecting my prints?

It really doesn't change much. The higher your current, the more heat the motors will generate. If you go too low they will stop working but going too high has no consequences (except excess heat). Adjusting them for a heated enclosure is a balancing act because if the current is too high the motors will melt their mounts but if the current is too low they wont turn.

Quote

mel0n

What are you printing parts to build? I am curious what somebody with your technical skills has planned

I breifly started a blog but got busy and haven't updated it for a few months. I am going to direct drive an E3D Chimera and bolt it to the following linear stages: [www.everythingbends.com]

Its not a practical design, but it will be extremely high performance. The linear servos have 0.00001mm resolution (closed loop) and can reach roughly 30x the speed and acceleration of a typical 3d printer. I've made some progress and have pictures so eventually the blog will get updated.

The structural components will be aluminium but I need some printed odds and ends for cable management and such.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 15, 2015 10:33PM |

Registered: 8 years ago Posts: 135 |

I use 100C bed temp for ABS. Just works and I see no reason to lower it. Same for PLA at 55C.

Those standoffs look/sound interesting, let us know how it works out! I am already going to gain all that lost Z space and then some with the new E3D and direct extruder design, but I wouldn't mind a little more

"Anyone experienced that after leaving a long print running, you find that a layer of your print is offset on x-axis and it stayed that way till the top?"

Sounds like your X motor could have missed a few steps in 1 direction? I haven't had anything like that happen so I can't be sure of my assumption.

On the stepper tuning topic, I just checked mine which haven't been changed since I got them and they all read at 600-650 mV DC I turned one of them down to 420 to see what would happen ("plus thats what some guy on youtube said as a number, but I have heard varying things on what to set them at.)

I am not sure how to test for skipped steps, and have been trying to research it but I cant find much information on tuning these things other than a wiki. There's a guide for literally everything, and I had noticed even before I bought my kit that most of the major guides/review guys avoid doing a video or thorough guide on adjusting the drivers.

Just saw you posted right as I was typing mine:

What you told him about motors makes sense with what I could find but I wasn't really 100% sure. That is a really cool looking project and it looks like it would deff beat the crap out of any reprap, or even most commercial consumer printers!

Edited 1 time(s). Last edit at 07/15/2015 10:36PM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

Those standoffs look/sound interesting, let us know how it works out! I am already going to gain all that lost Z space and then some with the new E3D and direct extruder design, but I wouldn't mind a little more

"Anyone experienced that after leaving a long print running, you find that a layer of your print is offset on x-axis and it stayed that way till the top?"

Sounds like your X motor could have missed a few steps in 1 direction? I haven't had anything like that happen so I can't be sure of my assumption.

On the stepper tuning topic, I just checked mine which haven't been changed since I got them and they all read at 600-650 mV DC I turned one of them down to 420 to see what would happen ("plus thats what some guy on youtube said as a number, but I have heard varying things on what to set them at.)

I am not sure how to test for skipped steps, and have been trying to research it but I cant find much information on tuning these things other than a wiki. There's a guide for literally everything, and I had noticed even before I bought my kit that most of the major guides/review guys avoid doing a video or thorough guide on adjusting the drivers.

Just saw you posted right as I was typing mine:

Quote

691175002

Quote

markts

I hate to admit this, but I haven't touched the voltages to the motors. How is that affecting my prints?

It really doesn't change much. The higher your current, the more heat the motors will generate. If you go too low they will stop working but going too high has no consequences (except excess heat). Adjusting them for a heated enclosure is a balancing act because if the current is too high the motors will melt their mounts but if the current is too low they wont turn.

Quote

mel0n

What are you printing parts to build? I am curious what somebody with your technical skills has planned

I breifly started a blog but got busy and haven't updated it for a few months. I am going to direct drive an E3D Chimera and bolt it to the following linear stages: [www.everythingbends.com]

Its not a practical design, but it will be extremely high performance. The linear servos have 0.00001mm resolution (closed loop) and can reach roughly 30x the speed and acceleration of a typical 3d printer. I've made some progress and have pictures so eventually the blog will get updated.

The structural components will be aluminium but I need some printed odds and ends for cable management and such.

What you told him about motors makes sense with what I could find but I wasn't really 100% sure. That is a really cool looking project and it looks like it would deff beat the crap out of any reprap, or even most commercial consumer printers!

Edited 1 time(s). Last edit at 07/15/2015 10:36PM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 16, 2015 12:03AM |

Registered: 8 years ago Posts: 81 |

The standoff could potentially free up another 40 mm in z. The supplied threaded rod has plenty of extra length to accomodate for this so it should be ok. However, in my case im switching them out for lead screw so the initial design has a provision for a 608 bearing to constrain the top end. I know constraining the rod/lead screw could induce z banding but then, i really dont like the feeling of my x axis hangging to the springgy motor coupler. So gotta have to try out. Im just constraining 1 end anyway so i think it should be ok. Plus, hopefully, the 8mm leadscrew i bought from FT is straighter than the regular threaded rods.

One issue i might have on the initial design is that, i might need to use an m3 screw longer than 60mm.

If i cant find a screw with this length, then i might move the constraint at the bottom end of the screw

One issue i might have on the initial design is that, i might need to use an m3 screw longer than 60mm.

If i cant find a screw with this length, then i might move the constraint at the bottom end of the screw

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 16, 2015 12:35AM |

Registered: 8 years ago Posts: 2 |

I got the acrylic kit last Thursday (July 10) after ordering it the Thursday before. Shipping was to Canada and was therefore insanely expensive and came with a surprise $66.60 customs fee on delivery. The category was "steel" so I think they were being merciful -- the customs fee for 20 lbs of "electronics" would probably have bee more than I paid for the kit. (There's only one Canadian reprap supplier, and individuals, small businesses, and even researchers don't get to benefit much from our free trade agreements.)

The mechanical part of the assembly went well. The guide wasn't entirely perfect, but I could figure things out. I was constantly grateful that I had digital calipers. Eventually I found a Torx T10 screwdriver bit that would fit the M3 bolts -- not all of them do -- and that made things easier too.

When I finished the wiring and plugged it in, nothing happened. Eventually I figured out that one of the stepper motor drivers was broken, and I've been able to drive the motors, but so far I can't run anything off the D8/D9/D10 12 V lines. Either the FETs overheat or nothing happens. I've resoldered the RAMPS board several times, replaced the D1 diode and the thermistor caps... even with external power, the power to the Arduino seems to fluctuate, and it freezes or resets often. I think all the problem is with the RAMPS board.

My RAMPS, as shipped, had the polyfuses and the FETs bent down, and there were visible signs of solder sputter on both sides, as well as incomplete joints (ones with a gap). The solder work was dark dull gray on most of the board.

Has anyone gotten similar problems? I've emailed Folgertech, no response yet.

The mechanical part of the assembly went well. The guide wasn't entirely perfect, but I could figure things out. I was constantly grateful that I had digital calipers. Eventually I found a Torx T10 screwdriver bit that would fit the M3 bolts -- not all of them do -- and that made things easier too.

When I finished the wiring and plugged it in, nothing happened. Eventually I figured out that one of the stepper motor drivers was broken, and I've been able to drive the motors, but so far I can't run anything off the D8/D9/D10 12 V lines. Either the FETs overheat or nothing happens. I've resoldered the RAMPS board several times, replaced the D1 diode and the thermistor caps... even with external power, the power to the Arduino seems to fluctuate, and it freezes or resets often. I think all the problem is with the RAMPS board.

My RAMPS, as shipped, had the polyfuses and the FETs bent down, and there were visible signs of solder sputter on both sides, as well as incomplete joints (ones with a gap). The solder work was dark dull gray on most of the board.

Has anyone gotten similar problems? I've emailed Folgertech, no response yet.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 16, 2015 12:55AM |

Registered: 8 years ago Posts: 81 |

Quote

Roches

I got the acrylic kit last Thursday (July 10) after ordering it the Thursday before. Shipping was to Canada and was therefore insanely expensive and came with a surprise $66.60 customs fee on delivery. The category was "steel" so I think they were being merciful -- the customs fee for 20 lbs of "electronics" would probably have bee more than I paid for the kit. (There's only one Canadian reprap supplier, and individuals, small businesses, and even researchers don't get to benefit much from our free trade agreements.)

The mechanical part of the assembly went well. The guide wasn't entirely perfect, but I could figure things out. I was constantly grateful that I had digital calipers. Eventually I found a Torx T10 screwdriver bit that would fit the M3 bolts -- not all of them do -- and that made things easier too.

When I finished the wiring and plugged it in, nothing happened. Eventually I figured out that one of the stepper motor drivers was broken, and I've been able to drive the motors, but so far I can't run anything off the D8/D9/D10 12 V lines. Either the FETs overheat or nothing happens. I've resoldered the RAMPS board several times, replaced the D1 diode and the thermistor caps... even with external power, the power to the Arduino seems to fluctuate, and it freezes or resets often. I think all the problem is with the RAMPS board.

My RAMPS, as shipped, had the polyfuses and the FETs bent down, and there were visible signs of solder sputter on both sides, as well as incomplete joints (ones with a gap). The solder work was dark dull gray on most of the board.

Has anyone gotten similar problems? I've emailed Folgertech, no response yet.

From your description, especially the power to arduino fluctuating, sounds like your psu goes to overcurrent then resets (not sure if the kit's psu has that feature, but switching supplies usually have it) or the polyfuses does. If you had made sure that all solders on ramps are clean of shorts, then you can do the following:

1) Without anything wired to D8, D9, D10, do you see the same problem? If it does, then the heater FETs are a likely suspect. If not, then you can inspect your heated bed or hotend cartridge for shorts.

2) Check if the FETs drain and source pins are shorted. You might need to check out its data sheet for the pin-outs. Usually the metal tab is the drain.

Edit: I just realized that the drain is likely floating on this board which the one end of the heater should connect to. So if it was indeed shorted then your problem is gonna be that the heater will heat-up even without activating it from software. Unless the drain got somehow shorted to the 12v input line then it will trigger a reset on the polyfuses or psu

Just wondrin though, why did you opt for the acrylic? The 2020 aluminum looks more rigid.

Edited 1 time(s). Last edit at 07/16/2015 01:06AM by wderoxas.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 16, 2015 03:27AM |

Registered: 8 years ago Posts: 276 |

Ok, so here's a weird problem, and I'm wondering if anyone else knows the solution before I take apart the entire Y-axis to troubleshoot...

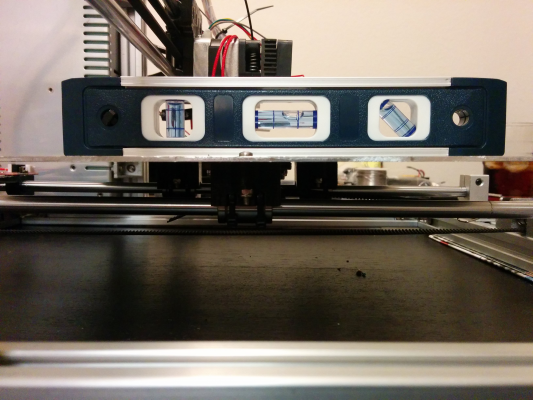

I haven't been able to use my printer for a little over week (was waiting on some 4-pin servo leads and pins so I could shorten wires). I cleaned up all the wires tonight, installed an aluminum plate/PEI plastic on top of the heated pdb (shouldn't matter for this, it's not even attached in the photos), and went to calibrate the Z-axis so I could try to print the extruder/autolevel/fan attachment for my soon to be installed e3d.

When I went to calibrate the Z-axis, things were waaaay off. Here is a picture of the 2020 rail with a level on it...

and here is a picture of the level on the aluminum Y chassis (no heated pdb or aluminum hot plate attached)...

Like I said, a little over a week ago everything was fine, and I didn't rest anything on the aluminum bed except for the heated pdb/glass combo while it sat there. Any ideas?

Edit: part of the problem turned out to be a Y-axis bearing that popped out of its holder a little bit. Popped it back in place, but its still pretty uneven. I'm thinking about getting longer screws for the calibration.

Edited 2 time(s). Last edit at 07/16/2015 03:59AM by therippa.

I haven't been able to use my printer for a little over week (was waiting on some 4-pin servo leads and pins so I could shorten wires). I cleaned up all the wires tonight, installed an aluminum plate/PEI plastic on top of the heated pdb (shouldn't matter for this, it's not even attached in the photos), and went to calibrate the Z-axis so I could try to print the extruder/autolevel/fan attachment for my soon to be installed e3d.

When I went to calibrate the Z-axis, things were waaaay off. Here is a picture of the 2020 rail with a level on it...

and here is a picture of the level on the aluminum Y chassis (no heated pdb or aluminum hot plate attached)...

Like I said, a little over a week ago everything was fine, and I didn't rest anything on the aluminum bed except for the heated pdb/glass combo while it sat there. Any ideas?

Edit: part of the problem turned out to be a Y-axis bearing that popped out of its holder a little bit. Popped it back in place, but its still pretty uneven. I'm thinking about getting longer screws for the calibration.

Edited 2 time(s). Last edit at 07/16/2015 03:59AM by therippa.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 16, 2015 08:50AM |

Registered: 8 years ago Posts: 135 |

Quote

therippa

Edit: part of the problem turned out to be a Y-axis bearing that popped out of its holder a little bit. Popped it back in place, but its still pretty uneven. I'm thinking about getting longer screws for the calibration.

Longer screws isn't a bad idea, but you might need longer springs? I pretty frequently make fine adjustments to my bed. Especially after prying off a hard print or doing any work to the printer as I tend to bump things I didn't want to.

Also, as has been posted and linked to many times, theres this. [forums.reprap.org]

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 16, 2015 09:10AM |

Registered: 8 years ago Posts: 35 |

Well, had my first extruder jam. Thankfully its easy to disassemle and using a heat gun and small metal rod (control rod for R/C) it was quick to clean out. When most of the stuff was out I waited for it to cool and harden then grabbed a drill bit that was slightly smaller than the feed tube and have it just enough twist to lock it in to the residual plastic and gave it a tug and it slid right out. Maybe 10 minutes start to finish and that includes trying to figure out what the heck happened.

Question about that feed tube though... I noticed the PTFE insert was only about 10mm. Not sure if that even matters but after cleaning out the tube I put it back up as high as it goes figuring it will push back down when the filament feeds through. Seems like the PTFE should be the whole length of the tube.

Question about that feed tube though... I noticed the PTFE insert was only about 10mm. Not sure if that even matters but after cleaning out the tube I put it back up as high as it goes figuring it will push back down when the filament feeds through. Seems like the PTFE should be the whole length of the tube.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 16, 2015 11:28AM |

Registered: 8 years ago Posts: 135 |

Just a friendly reminder for every1 to be conscious of the fire hazards associated with 3D printing : [forums.reprap.org]

Especially with the reported quality of the Ramps boards, I am concerned about failed FETs. Since we have a set screw for the thermistor which you should double check to make sure is sufficiently tight. The fire risk was another major reason for my decision to upgrade to an E3D with the thermistor screwed into the hot end which seems much more secure than just a set screw. That and the large heatsink/fan that would hopefully prevent heat from a runaway making its way up to the extruder parts as quickly.

Though a better hot end design doesn't protect against a failed FET. I don't think we have seen any fire incidents with any FTech printer yet, but there doesnt appear to be any safety considerations in place either. I know Marlin has some protection against this, but if the FET shorts, I don't know what the software can do to stop the flow of current.

Edited 2 time(s). Last edit at 07/16/2015 11:47AM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

Especially with the reported quality of the Ramps boards, I am concerned about failed FETs. Since we have a set screw for the thermistor which you should double check to make sure is sufficiently tight. The fire risk was another major reason for my decision to upgrade to an E3D with the thermistor screwed into the hot end which seems much more secure than just a set screw. That and the large heatsink/fan that would hopefully prevent heat from a runaway making its way up to the extruder parts as quickly.

Though a better hot end design doesn't protect against a failed FET. I don't think we have seen any fire incidents with any FTech printer yet, but there doesnt appear to be any safety considerations in place either. I know Marlin has some protection against this, but if the FET shorts, I don't know what the software can do to stop the flow of current.

Edited 2 time(s). Last edit at 07/16/2015 11:47AM by mel0n.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 16, 2015 01:07PM |

Registered: 8 years ago Posts: 95 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 16, 2015 01:35PM |

Registered: 8 years ago Posts: 171 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 16, 2015 01:55PM |

Registered: 8 years ago Posts: 1 |

I received my printer kit yesterday. Looks like everything is there except the threaded rod. I'm sure they'll ship me the missing rod. I have already sent them a message. My question is does the type or size of the threaded rod matter for this printer. I have some threaded rod around the shop that I could probably cut down if needed. What is the recommended size rod and length?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) July 16, 2015 02:12PM |

Registered: 8 years ago Posts: 135 |

Quote

jfitch

I received my printer kit yesterday. Looks like everything is there except the threaded rod. I'm sure they'll ship me the missing rod. I have already sent them a message. My question is does the type or size of the threaded rod matter for this printer. I have some threaded rod around the shop that I could probably cut down if needed. What is the recommended size rod and length?

its M5 threaded rod, and I would just match the length to the Z smooth rods. Read through the instructions to figure out the length of the Z rod. You can make it a little shorter even because the bed will sit higher than the bottom of the Z rod.

My creations/2020 aluminum parts/FolgerTech i3 upgrades [www.thingiverse.com]

Sorry, only registered users may post in this forum.