Folger Tech 2020 i3 Printer Kit (Official Thread)

Posted by Dan_FolgerTech

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 08, 2015 03:10PM |

Registered: 8 years ago Posts: 80 |

Ok, I've got a problem now, and need help! I've had 2 days of consistently excellent printing, with probably 32 hours of continuous use. But that was then...

About half-way through printing a really nice horse in ABS, the flow rate became restricted to about half, with ugly results. I removed and reinserted the filiment, with the flow rate going back to normal, but after about 15 minutes it was restricted again.

My first thought was that the nozzle was partially clogged. I removed the nozzle, soaked it in acetone for 30 minutes, and then hit it with a blowtorch for a minute. The nozzle was as clean as if it had never been used. Tried it again and... same thing. A few minutes of normal flow, and then restricted. I repeated the cleaning procedure just in case I missed something (I know I didn't!) but the repeated cleaning didn't help.

The stepper motor is calibrated correctly. If I remove the hotend and ask the machine to extrude 10 cm, it extrudes 10 cm. But if I put the hotend on, it only extrudes 5-6 cm. I have taken off the fan and heatsink to watch the motor as it extrudes. It looks like it is struggling to turn, and missing steps. It looks like the drive gear is getting a good grip on the filament, so it appears there is just not enough torque. Aha, I thought! I'll just increase the motor driver voltage reference to increase the motor current. I increased it from 0.7 V to 1.0 V (or 1.25 Amp current limit). It didn't help. I also thought that perhaps something was wrong with the motor driver itself so switch it out with the spare, but no luck.

I also thought that perhaps adding a little more heat would help. I've been printing ABS at 230, so increased it to 240 without success. One other thought I had is that perhaps the thermistor in the heatblock wasn't measuring the right temperature. I attached my multimeter's thermistor to the heatblock and it measured exactly the same temperature (240), so that's not it.

I'm about out of things to try. As far as I can tell, the hotend is in pristine condition. No clogs in the nozzle, completely clean and possible to see daylight through the hole. The PTFE tube looks fine, and allows the filiment to pass smoothly to the nozzle. If something physically changed, I can't tell. Still, I'm willing to replace it if anyone thinks that might still be the problem. The only other possibility I can think of is that the motor torque has degraded somehow (I've already concluded the driver is fine). It's rated at 2.6 kg/cm, but maybe it isn't putting out as much torque anymore. Possible? I suppose I can try switching that motor out.

Has anyone had to troubleshoot a similar issue? If so, any ideas on how I can get out of my rut here?

Edited 1 time(s). Last edit at 11/08/2015 03:29PM by elkayem.

About half-way through printing a really nice horse in ABS, the flow rate became restricted to about half, with ugly results. I removed and reinserted the filiment, with the flow rate going back to normal, but after about 15 minutes it was restricted again.

My first thought was that the nozzle was partially clogged. I removed the nozzle, soaked it in acetone for 30 minutes, and then hit it with a blowtorch for a minute. The nozzle was as clean as if it had never been used. Tried it again and... same thing. A few minutes of normal flow, and then restricted. I repeated the cleaning procedure just in case I missed something (I know I didn't!) but the repeated cleaning didn't help.

The stepper motor is calibrated correctly. If I remove the hotend and ask the machine to extrude 10 cm, it extrudes 10 cm. But if I put the hotend on, it only extrudes 5-6 cm. I have taken off the fan and heatsink to watch the motor as it extrudes. It looks like it is struggling to turn, and missing steps. It looks like the drive gear is getting a good grip on the filament, so it appears there is just not enough torque. Aha, I thought! I'll just increase the motor driver voltage reference to increase the motor current. I increased it from 0.7 V to 1.0 V (or 1.25 Amp current limit). It didn't help. I also thought that perhaps something was wrong with the motor driver itself so switch it out with the spare, but no luck.

I also thought that perhaps adding a little more heat would help. I've been printing ABS at 230, so increased it to 240 without success. One other thought I had is that perhaps the thermistor in the heatblock wasn't measuring the right temperature. I attached my multimeter's thermistor to the heatblock and it measured exactly the same temperature (240), so that's not it.

I'm about out of things to try. As far as I can tell, the hotend is in pristine condition. No clogs in the nozzle, completely clean and possible to see daylight through the hole. The PTFE tube looks fine, and allows the filiment to pass smoothly to the nozzle. If something physically changed, I can't tell. Still, I'm willing to replace it if anyone thinks that might still be the problem. The only other possibility I can think of is that the motor torque has degraded somehow (I've already concluded the driver is fine). It's rated at 2.6 kg/cm, but maybe it isn't putting out as much torque anymore. Possible? I suppose I can try switching that motor out.

Has anyone had to troubleshoot a similar issue? If so, any ideas on how I can get out of my rut here?

Edited 1 time(s). Last edit at 11/08/2015 03:29PM by elkayem.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 08, 2015 04:40PM |

Registered: 8 years ago Posts: 80 |

Solved it! Sometimes it is worthwhile to go back and remeasure what you thought you already measured. When I was watching the gear drive struggling to turn, I thought I saw a problem with the motor struggling to overcome the torque required to push the filiment through the nozzle. Not the case! I went back and stuck a piece of tape to the motor shaft, and then saw the shaft was turning just fine, while the drive gear wasn't turning as fast. You guessed it... the set screws attaching the drive gear to the motor had come a little loose.

After tightening the set screws, I'm now back in business!

One other side effect... I ordered an E3D Lite6 hotend, and a 5.5 kg/cm Kysan stepper motor, just in case the hotend or motor turned out to be the culprit. Looks like I'll be getting an upgraded hotend and motor out of this!

After tightening the set screws, I'm now back in business!

One other side effect... I ordered an E3D Lite6 hotend, and a 5.5 kg/cm Kysan stepper motor, just in case the hotend or motor turned out to be the culprit. Looks like I'll be getting an upgraded hotend and motor out of this!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 08, 2015 04:56PM |

Registered: 8 years ago Posts: 2 |

If anyone is interested in a super-easy way to decrease rolling friction for the spool and thereby ease filament tension issues, please check out this simple addition to the printer at http://www.thingiverse.com/thing:1119390. Print two of these, use the extra bearings that you should have maybe got with the kit and you'll be good to go in no time. I was finding before this change that I had some filament slipping on parts as the x axis was moving away from the spool quickly, which caused some gapping.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 08, 2015 05:09PM |

Registered: 8 years ago Posts: 4 |

My first forray into 3d printers, but I'm technical, i'm familiar with arduino stuff (i said) and it'll be fun (i said), and the product has been out for months so the manual should be pretty solid by now (i said)... and being somewhat naive, I asked around and decided to go with the FolgerTech 2020 (2 reasons: 1):recommended by a coworker that does 3d printing stuff, 2: Folgertech is based in NH, only an hour drive from my house, support local economy+1).

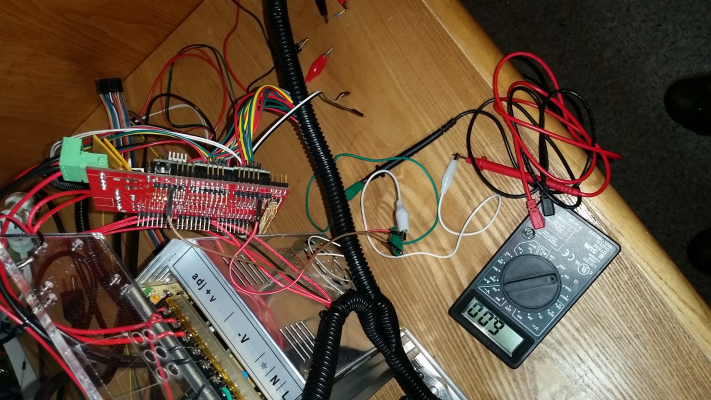

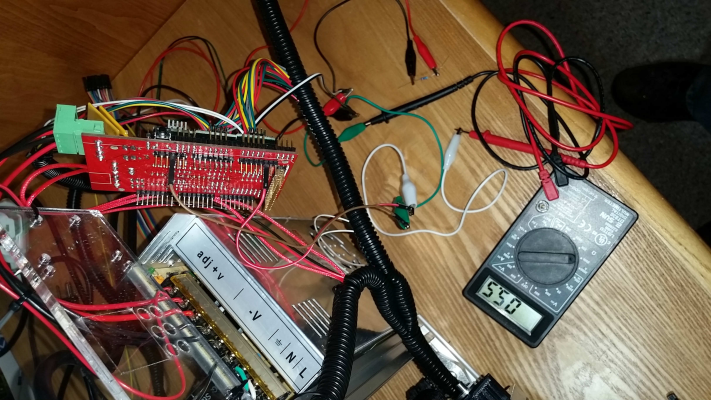

Off and on working on this for a few weeks and I'm almost done putting this kit together; the motors work (home and endstop properly), the device doesnt burst into flame or short out.. and now i'm debugging what could be a hardware problem with my RAMPS board..

It looks like the thermistor inputs from the hotend and the hotbed are Not being read in by the Arduino (looks like either a serious Marlin issue or a problem with the RAMPS board).

Per the configuration manual, no values were changes in the Marlin settings from the GoogleDrive location.

When connected with Repetier-Host (and on the Serial monitor in Arduino software) the system is returning the following error:

Troubleshooting steps so far:

1) I've validated that the thermistors (100k EPOS NTC) in both the hotend and the bed are both returning valid values (multimeter) properly with varying resistance on temp change (temp up = lower resistance, 120k->110K with a finger on the sensor).

2) I've validated the Marlin arduino code is pointing at the proper pins (pins.h) on the RAMPS1.4 board for T0/Extruder (a13) and T1/Hotbed (a14). And that the MinTemp for both is 5C (configuration.h).

3) I've applied a 100k resistor to the sensor pins so the software (if it were getting any signal from the pins at all) would get the equiv resistance of 25C on the 3 Thermistor sensor pinsets (T0, T1, T2); still throwing the MinTemp error after reset. Same (neg) result when I shorted the Thermistor pins with jumpers.

* The RAMPS board seems to be working for everything else though; X,Y,Z motors all move and Home properly (albeit the bed and hotend arent getting power, but that's an expected software safety with the thermistor issue).

* From what I've read online, this could mean the Ramps board or the Arduino is broken. So, I flashed the Marlin code on my own MEGA2560 (mine is branded for SunFounder and it looks like your Arduino is mfg'd by the same company as the PCB logo/backing is exactly the same - yours without the brand markings) and got the same problem

All this leads me to believe this is either some convoluted software/configuration issue or a bad RAMPS1.4 board.

Any suggestions for what to try next?

Edited 2 time(s). Last edit at 11/08/2015 06:51PM by thejonnyg.

Off and on working on this for a few weeks and I'm almost done putting this kit together; the motors work (home and endstop properly), the device doesnt burst into flame or short out.. and now i'm debugging what could be a hardware problem with my RAMPS board..

It looks like the thermistor inputs from the hotend and the hotbed are Not being read in by the Arduino (looks like either a serious Marlin issue or a problem with the RAMPS board).

Per the configuration manual, no values were changes in the Marlin settings from the GoogleDrive location.

When connected with Repetier-Host (and on the Serial monitor in Arduino software) the system is returning the following error:

start echo:Marlin 1.0.0 echo: Last Updated: Nov 8 2015 5-20-15 14:47:22 | Author: (FOLGER TECH, 8 i3 Prusa Config) Compiled: Nov 8 2015 echo: Free Memory: 5512 PlannerBufferBytes: 1232 Error:0 : Extruder switched off. MINTEMP triggered ! Error: Printer stopped due to errors. Fix the error and use M999 to restart. (Temperature is reset. Set it after restarting)

Troubleshooting steps so far:

1) I've validated that the thermistors (100k EPOS NTC) in both the hotend and the bed are both returning valid values (multimeter) properly with varying resistance on temp change (temp up = lower resistance, 120k->110K with a finger on the sensor).

2) I've validated the Marlin arduino code is pointing at the proper pins (pins.h) on the RAMPS1.4 board for T0/Extruder (a13) and T1/Hotbed (a14). And that the MinTemp for both is 5C (configuration.h).

3) I've applied a 100k resistor to the sensor pins so the software (if it were getting any signal from the pins at all) would get the equiv resistance of 25C on the 3 Thermistor sensor pinsets (T0, T1, T2); still throwing the MinTemp error after reset. Same (neg) result when I shorted the Thermistor pins with jumpers.

* The RAMPS board seems to be working for everything else though; X,Y,Z motors all move and Home properly (albeit the bed and hotend arent getting power, but that's an expected software safety with the thermistor issue).

* From what I've read online, this could mean the Ramps board or the Arduino is broken. So, I flashed the Marlin code on my own MEGA2560 (mine is branded for SunFounder and it looks like your Arduino is mfg'd by the same company as the PCB logo/backing is exactly the same - yours without the brand markings) and got the same problem

All this leads me to believe this is either some convoluted software/configuration issue or a bad RAMPS1.4 board.

Any suggestions for what to try next?

Edited 2 time(s). Last edit at 11/08/2015 06:51PM by thejonnyg.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 08, 2015 05:19PM |

Registered: 8 years ago Posts: 367 |

Quote

elkayem

Solved it! Sometimes it is worthwhile to go back and remeasure what you thought you already measured. When I was watching the gear drive struggling to turn, I thought I saw a problem with the motor struggling to overcome the torque required to push the filiment through the nozzle. Not the case! I went back and stuck a piece of tape to the motor shaft, and then saw the shaft was turning just fine, while the drive gear wasn't turning as fast. You guessed it... the set screws attaching the drive gear to the motor had come a little loose.

After tightening the set screws, I'm now back in business!

One other side effect... I ordered an E3D Lite6 hotend, and a 5.5 kg/cm Kysan stepper motor, just in case the hotend or motor turned out to be the culprit. Looks like I'll be getting an upgraded hotend and motor out of this!

Awesome - good work! I have an E3D Lite6 as well. I slightly regret not getting the all-metal E3D as I get a bit nervous when the temperature is around 240-250, but you can buy just the parts for an upgrade. I have a few different versions of a mount for it, see [www.thingiverse.com]. It's a tight fit but you can do it.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 08, 2015 05:38PM |

Registered: 8 years ago Posts: 80 |

Quote

animoose

Quote

elkayem

Solved it! Sometimes it is worthwhile to go back and remeasure what you thought you already measured. When I was watching the gear drive struggling to turn, I thought I saw a problem with the motor struggling to overcome the torque required to push the filiment through the nozzle. Not the case! I went back and stuck a piece of tape to the motor shaft, and then saw the shaft was turning just fine, while the drive gear wasn't turning as fast. You guessed it... the set screws attaching the drive gear to the motor had come a little loose.

After tightening the set screws, I'm now back in business!

One other side effect... I ordered an E3D Lite6 hotend, and a 5.5 kg/cm Kysan stepper motor, just in case the hotend or motor turned out to be the culprit. Looks like I'll be getting an upgraded hotend and motor out of this!

Awesome - good work! I have an E3D Lite6 as well. I slightly regret not getting the all-metal E3D as I get a bit nervous when the temperature is around 240-250, but you can buy just the parts for an upgrade. I have a few different versions of a mount for it, see [www.thingiverse.com]. It's a tight fit but you can do it.

I just printed your mount out in ABS as my first test print post-fix, thanks for putting that together! I plan to use it once the the E3D Lite6 comes in. Looks like your MK9 extruder is the same as mine, so hopefully it is a good fit. A few questions... It looks like your mount attaches directly to the E3D heat sink, which would cause me to worry a little about the ABS getting soft and distorting. Do the temperatures stay relatively cool at the interface? Also, I see you have a fan duct that cools the heat sink and the extruded filament. Is this fan on all the time?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 08, 2015 06:04PM |

Registered: 8 years ago Posts: 367 |

Quote

elkayem

Quote

animoose

Quote

elkayem

Solved it! Sometimes it is worthwhile to go back and remeasure what you thought you already measured. When I was watching the gear drive struggling to turn, I thought I saw a problem with the motor struggling to overcome the torque required to push the filiment through the nozzle. Not the case! I went back and stuck a piece of tape to the motor shaft, and then saw the shaft was turning just fine, while the drive gear wasn't turning as fast. You guessed it... the set screws attaching the drive gear to the motor had come a little loose.

After tightening the set screws, I'm now back in business!

One other side effect... I ordered an E3D Lite6 hotend, and a 5.5 kg/cm Kysan stepper motor, just in case the hotend or motor turned out to be the culprit. Looks like I'll be getting an upgraded hotend and motor out of this!

Awesome - good work! I have an E3D Lite6 as well. I slightly regret not getting the all-metal E3D as I get a bit nervous when the temperature is around 240-250, but you can buy just the parts for an upgrade. I have a few different versions of a mount for it, see [www.thingiverse.com]. It's a tight fit but you can do it.

I just printed your mount out in ABS as my first test print post-fix, thanks for putting that together! I plan to use it once the the E3D Lite6 comes in. Looks like your MK9 extruder is the same as mine, so hopefully it is a good fit. A few questions... It looks like your mount attaches directly to the E3D heat sink, which would cause me to worry a little about the ABS getting soft and distorting. Do the temperatures stay relatively cool at the interface? Also, I see you have a fan duct that cools the heat sink and the extruded filament. Is this fan on all the time?

The top end of the E3D is quite cool - that's part of the design of the E3D which means there is a very sharp transition from the heat in the nozzle to the cool region in the heatsink. I printed my mount in PLA and have never had any problems. The E3D comes with a fan, and it works fine. I replaced it for two reasons: it is surprisingly noisy, and I wanted to direct some of the airflow to the print bed, as this (maybe) helps with printing PLA. For getting it to fit, the main thing to be careful of is cut the PTFE really flush with the collett on the E3D. There isn't much clearance, and the relative positions of the flanges on the top of the E3D and the bolt holes on the front of the motor mean you can't really add any. Also, if you find the filament is not feeding, try taking the extruder off and then reattaching it with washer between it and the motor block. The tolerance for getting the filament to go into the E3D are quite tight.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 08, 2015 06:05PM |

Registered: 8 years ago Posts: 51 |

Hey all,

Got my printer all set-up over the weekend, its been great fun and still getting the calibration right.

But I have an annoying rattle(?) from the Y axis bed. It only really does it on long and fast movements - see this video: [www.youtube.com]

I thought it was from the side with only a single bearing as it seemed to mainly come from that side. I also re adjusted the smooth rods. I also have put 3 in 1 oil into all of the bearings as has been recommended.

Any ideas would be a great help.

Cheers

Got my printer all set-up over the weekend, its been great fun and still getting the calibration right.

But I have an annoying rattle(?) from the Y axis bed. It only really does it on long and fast movements - see this video: [www.youtube.com]

I thought it was from the side with only a single bearing as it seemed to mainly come from that side. I also re adjusted the smooth rods. I also have put 3 in 1 oil into all of the bearings as has been recommended.

Any ideas would be a great help.

Cheers

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 08, 2015 06:17PM |

Registered: 8 years ago Posts: 367 |

Quote

peeejayz

Hey all,

Got my printer all set-up over the weekend, its been great fun and still getting the calibration right.

But I have an annoying rattle(?) from the Y axis bed. It only really does it on long and fast movements - see this video: [www.youtube.com]

I thought it was from the side with only a single bearing as it seemed to mainly come from that side. I also re adjusted the smooth rods. I also have put 3 in 1 oil into all of the bearings as has been recommended.

Any ideas would be a great help.

Cheers

I am very familiar with that rattle, and have never managed to make it go away! I've tried replacing and lubricating the bearing and realigning the chrome rods, and both more and less tension in the Y belt. Some days it goes away altogether, the next day it is back. I think what happens is that if there is any vibration, the aluminium plate acts like a sounding board. I think I read of someone trying putting a soft pad (like a soft plastic) between the Y mounts and the bed, but I've not tried this. I've just got to living with it.

See my blog at [moosteria.blogspot.com].

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 08, 2015 06:21PM |

Registered: 8 years ago Posts: 51 |

Quote

animoose

Quote

peeejayz

Hey all,

Got my printer all set-up over the weekend, its been great fun and still getting the calibration right.

But I have an annoying rattle(?) from the Y axis bed. It only really does it on long and fast movements - see this video: [www.youtube.com]

I thought it was from the side with only a single bearing as it seemed to mainly come from that side. I also re adjusted the smooth rods. I also have put 3 in 1 oil into all of the bearings as has been recommended.

Any ideas would be a great help.

Cheers

I am very familiar with that rattle, and have never managed to make it go away! I've tried replacing and lubricating the bearing and realigning the chrome rods, and both more and less tension in the Y belt. Some days it goes away altogether, the next day it is back. I think what happens is that if there is any vibration, the aluminium plate acts like a sounding board. I think I read of someone trying putting a soft pad (like a soft plastic) between the Y mounts and the bed, but I've not tried this. I've just got to living with it.

I have been wondering it its to do with only having 1 bearing on 1 side. Many be need to add another. I've also wondered about putting some insulation under the heated bed, I've heard about cork or head resistant foam too. Maybe that will help dampen?

The annoying part is the vibration is causes, as my desk is attached to the wall it vibrates on that. I already have the printer mounted on anti vibration plates too.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 08, 2015 06:36PM |

Registered: 8 years ago Posts: 80 |

This occurred to me as well! It looks like the only difference is the heat sink ($20) and heat break ($18), or $38 total. Since the Lite6 is $35 and the all-metal v6 is $75, with a price difference of $40, it appears $2 better to purchase the Lite6 and the upgrade parts! Unless I'm forgetting something.Quote

animoose

I slightly regret not getting the all-metal E3D as I get a bit nervous when the temperature is around 240-250, but you can buy just the parts for an upgrade.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 08, 2015 08:20PM |

Registered: 8 years ago Posts: 14 |

Quote

pjvpjv

If anyone is interested in a super-easy way to decrease rolling friction for the spool and thereby ease filament tension issues, please check out this simple addition to the printer at http://www.thingiverse.com/thing:1119390. Print two of these, use the extra bearings that you should have maybe got with the kit and you'll be good to go in no time. I was finding before this change that I had some filament slipping on parts as the x axis was moving away from the spool quickly, which caused some gapping.

I didn't make this, but saw it today during my research into getting a 2020: http://www.thingiverse.com/thing:996398. It looks like it needs to be desk-mounted, but it's the same sort of idea.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 08, 2015 08:31PM |

Registered: 8 years ago Posts: 430 |

Quote

animoose

Quote

peeejayz

Hey all,

Got my printer all set-up over the weekend, its been great fun and still getting the calibration right.

But I have an annoying rattle(?) from the Y axis bed. It only really does it on long and fast movements - see this video: [www.youtube.com]

I thought it was from the side with only a single bearing as it seemed to mainly come from that side. I also re adjusted the smooth rods. I also have put 3 in 1 oil into all of the bearings as has been recommended.

Any ideas would be a great help.

Cheers

I am very familiar with that rattle, and have never managed to make it go away! I've tried replacing and lubricating the bearing and realigning the chrome rods, and both more and less tension in the Y belt. Some days it goes away altogether, the next day it is back. I think what happens is that if there is any vibration, the aluminium plate acts like a sounding board. I think I read of someone trying putting a soft pad (like a soft plastic) between the Y mounts and the bed, but I've not tried this. I've just got to living with it.

Switching to having 4 bearings on the Y axis got rid of that for me.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 09, 2015 01:00AM |

Registered: 8 years ago Posts: 62 |

I have a question that is not related to the Hardware of our Prusa-i3 but to the host software.

I tried today to slice a complex file and Slic3r failed to generate a usable object (lower half of the item was missing)... I check it with the inspector tool of Meshmixer and only one point needed repair but even after that Slic3r returned multiple errors (unable to close this loop) and the object was mutilated... I switch to Cura and the object was sliced with out problems and looking on the preview at Repetier as I was expecting it should be, I'm going to give it a try tomorrow to see how good the printer run the G-Code generated by Cura.

What engine are you using for slicing the files and what pointers can you give me on the configuration of the settings to obtain the best performance of the Hardware that we have on the printer?

Mr.Fus

<------------------------------------------------->

Green M3D (Running v.1.3.6.3Beta)

FolgerTech Prusa i3 (2020 Frame)

<------------------------------------------------>

I tried today to slice a complex file and Slic3r failed to generate a usable object (lower half of the item was missing)... I check it with the inspector tool of Meshmixer and only one point needed repair but even after that Slic3r returned multiple errors (unable to close this loop) and the object was mutilated... I switch to Cura and the object was sliced with out problems and looking on the preview at Repetier as I was expecting it should be, I'm going to give it a try tomorrow to see how good the printer run the G-Code generated by Cura.

What engine are you using for slicing the files and what pointers can you give me on the configuration of the settings to obtain the best performance of the Hardware that we have on the printer?

Mr.Fus

<------------------------------------------------->

Green M3D (Running v.1.3.6.3Beta)

FolgerTech Prusa i3 (2020 Frame)

<------------------------------------------------>

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 09, 2015 02:42AM |

Registered: 8 years ago Posts: 45 |

Quote

peeejayz

Hey all,

Got my printer all set-up over the weekend, its been great fun and still getting the calibration right.

But I have an annoying rattle(?) from the Y axis bed. It only really does it on long and fast movements - see this video: [www.youtube.com]

I thought it was from the side with only a single bearing as it seemed to mainly come from that side. I also re adjusted the smooth rods. I also have put 3 in 1 oil into all of the bearings as has been recommended.

Any ideas would be a great help.

Cheers

What is the 3D printed part surrounding your fan for? Does it help prevent cooling the bed? Can you share the design?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 09, 2015 04:00AM |

Registered: 8 years ago Posts: 51 |

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 09, 2015 04:02AM |

Registered: 8 years ago Posts: 51 |

Quote

msaeger

Quote

animoose

Quote

peeejayz

Hey all,

Got my printer all set-up over the weekend, its been great fun and still getting the calibration right.

But I have an annoying rattle(?) from the Y axis bed. It only really does it on long and fast movements - see this video: [www.youtube.com]

I thought it was from the side with only a single bearing as it seemed to mainly come from that side. I also re adjusted the smooth rods. I also have put 3 in 1 oil into all of the bearings as has been recommended.

Any ideas would be a great help.

Cheers

I am very familiar with that rattle, and have never managed to make it go away! I've tried replacing and lubricating the bearing and realigning the chrome rods, and both more and less tension in the Y belt. Some days it goes away altogether, the next day it is back. I think what happens is that if there is any vibration, the aluminium plate acts like a sounding board. I think I read of someone trying putting a soft pad (like a soft plastic) between the Y mounts and the bed, but I've not tried this. I've just got to living with it.

Switching to having 4 bearings on the Y axis got rid of that for me.

I'm thinking the same. Did you just drill your bed or buy a new one?

Maybe something like [www.ebay.co.uk] or [www.ebay.co.uk]

Edited 2 time(s). Last edit at 11/09/2015 05:19AM by peeejayz.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 09, 2015 08:45AM |

Registered: 8 years ago Posts: 51 |

Had a little play around with the current single bearing mount.

What about doubling it. I mocked up a quick one using the current mount as the starting point and duplicated and moved the mounting: [www.tinkercad.com]

Only possible problem is still getting clearance for the motor so you still get full Y movement.

Would I be able to get away with printing this part in PLA or due to the bed it needs to be ABS?

Edited 1 time(s). Last edit at 11/09/2015 08:48AM by peeejayz.

What about doubling it. I mocked up a quick one using the current mount as the starting point and duplicated and moved the mounting: [www.tinkercad.com]

Only possible problem is still getting clearance for the motor so you still get full Y movement.

Would I be able to get away with printing this part in PLA or due to the bed it needs to be ABS?

Edited 1 time(s). Last edit at 11/09/2015 08:48AM by peeejayz.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 09, 2015 09:33AM |

Registered: 8 years ago Posts: 268 |

Quote

tjnamtiw

I'm happier than a pig in poop! I just finished three of these babies! It took a loooooooooong time but well worth it! They are beautiful. I also added the Z axis extension. I did note that the extensions' holes are too small for the boss on the bottom of the Z motors so I've changed the .stl file and will be printing new ones.

Oh, 190 C on first layer and 185 on the rest. 70 C on the bed with just hair spray on the tempered borosilicate glass from Amazon. Sticks like heck!

[attachment 65428 tn_WP_20151105_001.jpg]

[attachment 65429 tn_WP_20151105_003.jpg]

[attachment 65430 tn_WP_20151105_007.jpg]

[attachment 65431 tn_WP_20151106_002.jpg]

First: Beautiful work!!!

Second: Not sure if anyone has mentioned this, but I think you have your Z extensions upside down, the end with the rounded inner portion is for a 608 bearing the open end goes towards the top (connects to the motor). Or at least that's how the ones I used worked!?!?

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 09, 2015 10:55AM |

Registered: 8 years ago Posts: 541 |

Quote

sonnylowe

Quote

tjnamtiw

I'm happier than a pig in poop! I just finished three of these babies! It took a loooooooooong time but well worth it! They are beautiful. I also added the Z axis extension. I did note that the extensions' holes are too small for the boss on the bottom of the Z motors so I've changed the .stl file and will be printing new ones.

Oh, 190 C on first layer and 185 on the rest. 70 C on the bed with just hair spray on the tempered borosilicate glass from Amazon. Sticks like heck!

[attachment 65428 tn_WP_20151105_001.jpg]

[attachment 65429 tn_WP_20151105_003.jpg]

[attachment 65430 tn_WP_20151105_007.jpg]

[attachment 65431 tn_WP_20151106_002.jpg]

First: Beautiful work!!!

Second: Not sure if anyone has mentioned this, but I think you have your Z extensions upside down, the end with the rounded inner portion is for a 608 bearing the open end goes towards the top (connects to the motor). Or at least that's how the ones I used worked!?!?

yup, hahahaha. That was a Crown Royal installation!!!! hic...

I wondered if anyone would notice. Since been corrected. It's heck to get old.

I wondered if anyone would notice. Since been corrected. It's heck to get old. Thanks and happy printing!!!

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 09, 2015 07:17PM |

Registered: 8 years ago Posts: 4 |

Quote

thejonnyg

My first forray into 3d printers, but I'm technical, i'm familiar with arduino stuff (i said) and it'll be fun (i said), and the product has been out for months so the manual should be pretty solid by now (i said)... and being somewhat naive, I asked around and decided to go with the FolgerTech 2020 (2 reasons: 1):recommended by a coworker that does 3d printing stuff, 2: Folgertech is based in NH, only an hour drive from my house, support local economy+1).

Off and on working on this for a few weeks and I'm almost done putting this kit together; the motors work (home and endstop properly), the device doesnt burst into flame or short out.. and now i'm debugging what could be a hardware problem with my RAMPS board..

It looks like the thermistor inputs from the hotend and the hotbed are Not being read in by the Arduino (looks like either a serious Marlin issue or a problem with the RAMPS board).

Per the configuration manual, no values were changes in the Marlin settings from the GoogleDrive location.

When connected with Repetier-Host (and on the Serial monitor in Arduino software) the system is returning the following error:

start echo:Marlin 1.0.0 echo: Last Updated: Nov 8 2015 5-20-15 14:47:22 | Author: (FOLGER TECH, 8 i3 Prusa Config) Compiled: Nov 8 2015 echo: Free Memory: 5512 PlannerBufferBytes: 1232 Error:0 : Extruder switched off. MINTEMP triggered ! Error: Printer stopped due to errors. Fix the error and use M999 to restart. (Temperature is reset. Set it after restarting)

Troubleshooting steps so far:

1) I've validated that the thermistors (100k EPOS NTC) in both the hotend and the bed are both returning valid values (multimeter) properly with varying resistance on temp change (temp up = lower resistance, 120k->110K with a finger on the sensor).

2) I've validated the Marlin arduino code is pointing at the proper pins (pins.h) on the RAMPS1.4 board for T0/Extruder (a13) and T1/Hotbed (a14). And that the MinTemp for both is 5C (configuration.h).

3) I've applied a 100k resistor to the sensor pins so the software (if it were getting any signal from the pins at all) would get the equiv resistance of 25C on the 3 Thermistor sensor pinsets (T0, T1, T2); still throwing the MinTemp error after reset. Same (neg) result when I shorted the Thermistor pins with jumpers.

* The RAMPS board seems to be working for everything else though; X,Y,Z motors all move and Home properly (albeit the bed and hotend arent getting power, but that's an expected software safety with the thermistor issue).

* From what I've read online, this could mean the Ramps board or the Arduino is broken. So, I flashed the Marlin code on my own MEGA2560 (mine is branded for SunFounder and it looks like your Arduino is mfg'd by the same company as the PCB logo/backing is exactly the same - yours without the brand markings) and got the same problem

All this leads me to believe this is either some convoluted software/configuration issue or a bad RAMPS1.4 board.

Any suggestions for what to try next?

Update::

Friend suggested finding out what/if the pin that goes into A13 (I should also note that the A14 and A15 pins on the back of the RAMPS also acted similarly as below) on the Arduino from the RAMPS is providing signal in various scenarios (Not connected, Connected to 100k resistor to simulate 25C hotend temp, Connected to jumper to simulate maxtemp):

1) Not Connected: checking reistance between pins on the back of the RAMPS: the A13 pin and the pin that goes to ground: there's a 6.0k resistance (wTF?) I read that there's supposed to be a 4.7k resistor, but its returning as 6k; is this the problem?

Black and white cables go to T0 (black to the ground pin, white to the A13 pin)

2) Connected to a 100k Reistor: value of 5.5K resistance (this could be reasonable, but it seems fishy)

3) Connected to jumper: Value of 0.0K (actual: 5.3 ohms on my multimeter, close enough to 0 resistance to reasonably account for cable length)

4) I connected to the actual HotEnd thermistor; and it seems to be acting appropriately (temp goes up, resistance goes down); but its acting in the range of 5.73k and then goes lower to 5.70k as I apply my finger to the thermistor on the HotEnd. Is there anyone out there that knows if this is the expected range in the Arduino software? I cant find anything in the .h files that would indicate a value caluclation/conversion from the sub 6k ohms range to a centigrade temperature value.

Can anyone tell if these are expected values for a RAMPS1.4? (i couldnt find anything related to this with about 15min of google searching)

If so, i can focus on why the Arduino code isnt recognizing these values as valid..

Edited 3 time(s). Last edit at 11/09/2015 11:41PM by thejonnyg.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 09, 2015 08:18PM |

Registered: 8 years ago Posts: 430 |

Quote

peeejayz

Quote

msaeger

Quote

animoose

Quote

peeejayz

Hey all,

Got my printer all set-up over the weekend, its been great fun and still getting the calibration right.

But I have an annoying rattle(?) from the Y axis bed. It only really does it on long and fast movements - see this video: [www.youtube.com]

I thought it was from the side with only a single bearing as it seemed to mainly come from that side. I also re adjusted the smooth rods. I also have put 3 in 1 oil into all of the bearings as has been recommended.

Any ideas would be a great help.

Cheers

I am very familiar with that rattle, and have never managed to make it go away! I've tried replacing and lubricating the bearing and realigning the chrome rods, and both more and less tension in the Y belt. Some days it goes away altogether, the next day it is back. I think what happens is that if there is any vibration, the aluminium plate acts like a sounding board. I think I read of someone trying putting a soft pad (like a soft plastic) between the Y mounts and the bed, but I've not tried this. I've just got to living with it.

Switching to having 4 bearings on the Y axis got rid of that for me.

I'm thinking the same. Did you just drill your bed or buy a new one?

Maybe something like [www.ebay.co.uk] or [www.ebay.co.uk]

Here are some pictures. [goo.gl]

I originally just printed another stock bearing holder but then discovered that it hit the Y motor and the bed wouldn't go all the way to the rear. I flipped the Y motor to fix that. I ended up using different bearing holders because I wanted some that had elongated holes to help compensate for not getting the new holes drilled perfectly in the plate. Then I had to use the different Y end stop holder because I couldn't mount the stock one in a way that would let the bed go all the way back.

Here's the bearing holders and end stops I used. [www.thingiverse.com] and [www.thingiverse.com]

Also here is the Z end stop switch holder that I modified to fit the 2020 i3 this makes it so much easier to set the bed height.

[www.thingiverse.com]

Edited 1 time(s). Last edit at 11/09/2015 08:36PM by msaeger.

Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 09, 2015 10:20PM |

Registered: 8 years ago Posts: 4 |

HI. I just finished assembling my printer 2 days ago and have had fun printing a few things.

I did calibrate the axis, but have done no other tuning. All of the settings are the default set in the config guide and presets from Folger Tech. (The guide is here [drive.google.com])

A few questions:

It looks like in it's current configuration I only have ~150 mm available on the Z axis. Is that normal? I see there are adapters available to move the motors above the brackets to give you more room. I'll probably print them soon.

One of the first prints I did was a 10X10X10 mm cube. I kept all the default settings in slic3r. It printed well, but the top of the cube sagged in. I tried increasing the infill from 10% to 20% and lowering the temperature from 219 to 205 (I'm using hatchbox brand pla filament), but it still sagged on a later print. How do I fix that?

I tried printing a little figuring that I knew would need support so I ticked the box to add pillars and kept all the default settings. It made a LOT more support pillars than I thought would be neccicary. I printed it anyway but I ended up ripping off the figure's head and arms trying to get the pillars off it. Any suggestions there?

Whenever the hot end is hot, it seems to constantly leak a little bit of filament. Is that normal?

Maybe related, when moving from place to place during a print, it leave little hair fine strands of filament behind. Is that normal?

Thanks in advance for the help.

I did calibrate the axis, but have done no other tuning. All of the settings are the default set in the config guide and presets from Folger Tech. (The guide is here [drive.google.com])

A few questions:

It looks like in it's current configuration I only have ~150 mm available on the Z axis. Is that normal? I see there are adapters available to move the motors above the brackets to give you more room. I'll probably print them soon.

One of the first prints I did was a 10X10X10 mm cube. I kept all the default settings in slic3r. It printed well, but the top of the cube sagged in. I tried increasing the infill from 10% to 20% and lowering the temperature from 219 to 205 (I'm using hatchbox brand pla filament), but it still sagged on a later print. How do I fix that?

I tried printing a little figuring that I knew would need support so I ticked the box to add pillars and kept all the default settings. It made a LOT more support pillars than I thought would be neccicary. I printed it anyway but I ended up ripping off the figure's head and arms trying to get the pillars off it. Any suggestions there?

Whenever the hot end is hot, it seems to constantly leak a little bit of filament. Is that normal?

Maybe related, when moving from place to place during a print, it leave little hair fine strands of filament behind. Is that normal?

Thanks in advance for the help.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 09, 2015 11:16PM |

Registered: 8 years ago Posts: 285 |

Quote

TollBoothWilly

HI. I just finished assembling my printer 2 days ago and have had fun printing a few things.

I did calibrate the axis, but have done no other tuning. All of the settings are the default set in the config guide and presets from Folger Tech. (The guide is here [drive.google.com])

A few questions:

It looks like in it's current configuration I only have ~150 mm available on the Z axis. Is that normal? I see there are adapters available to move the motors above the brackets to give you more room. I'll probably print them soon.

One of the first prints I did was a 10X10X10 mm cube. I kept all the default settings in slic3r. It printed well, but the top of the cube sagged in. I tried increasing the infill from 10% to 20% and lowering the temperature from 219 to 205 (I'm using hatchbox brand pla filament), but it still sagged on a later print. How do I fix that?

I tried printing a little figuring that I knew would need support so I ticked the box to add pillars and kept all the default settings. It made a LOT more support pillars than I thought would be neccicary. I printed it anyway but I ended up ripping off the figure's head and arms trying to get the pillars off it. Any suggestions there?

Whenever the hot end is hot, it seems to constantly leak a little bit of filament. Is that normal?

Maybe related, when moving from place to place during a print, it leave little hair fine strands of filament behind. Is that normal?

Thanks in advance for the help.

The issue with the Z axis only giving 150mm is indeed normal. Interestingly enough though is that I get less on my printer. It is also normal for the hotend to leak a bit. The hotends that FT gives I would say are on the lower end of the quality spectrum when it comes to hotends, but even higher quality hotends do still leak. Yes the small hairs that are left during travel moves are normal, but these can be reduced by increasing the retraction. I have disabled retraction with my printer because it seems to cause me more problems that it solves, but having retraction on is fine too. As far as the problem with the supports, I would suggest maybe not even bothering too much with slic3r (personal opinion). I have not actually used slic3r myself (I use cura) but from what I have heard, it seems that cura is better at everything from slicing to overall print quality. If you are just getting used to a using slic3r, I would suggest switching over to cura before getting to accustomed with slic3r (again personal opinion)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 09, 2015 11:25PM |

Registered: 8 years ago Posts: 62 |

Quote

TollBoothWilly

HI. I just finished assembling my printer 2 days ago and have had fun printing a few things.

I did calibrate the axis, but have done no other tuning. All of the settings are the default set in the config guide and presets from Folger Tech. (The guide is here [drive.google.com])

A few questions:

It looks like in it's current configuration I only have ~150 mm available on the Z axis. Is that normal? I see there are adapters available to move the motors above the brackets to give you more room. I'll probably print them soon.

One of the first prints I did was a 10X10X10 mm cube. I kept all the default settings in slic3r. It printed well, but the top of the cube sagged in. I tried increasing the infill from 10% to 20% and lowering the temperature from 219 to 205 (I'm using hatchbox brand pla filament), but it still sagged on a later print. How do I fix that?

I tried printing a little figuring that I knew would need support so I ticked the box to add pillars and kept all the default settings. It made a LOT more support pillars than I thought would be neccicary. I printed it anyway but I ended up ripping off the figure's head and arms trying to get the pillars off it. Any suggestions there?

Whenever the hot end is hot, it seems to constantly leak a little bit of filament. Is that normal?

Maybe related, when moving from place to place during a print, it leave little hair fine strands of filament behind. Is that normal?

Thanks in advance for the help.

I have my temperature set on 190 for first layers and 185 for the rest of the print... +200 it's too hot for Hatchbox and will string like crazy!!

I tried Slic3r at the start and worked fine for a couple of parts but I was having problems with the support material part, I almost destroyed the parts while removing the supports! So switched to Cura and I was able to print a really complex part that needed support material for overhanging sections and removed the supports without problems, and I will say that I got very good results on resolution and quality...

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 09, 2015 11:39PM |

Registered: 8 years ago Posts: 430 |

Quote

Mach

Quote

TollBoothWilly

HI. I just finished assembling my printer 2 days ago and have had fun printing a few things.

I did calibrate the axis, but have done no other tuning. All of the settings are the default set in the config guide and presets from Folger Tech. (The guide is here [drive.google.com])

A few questions:

It looks like in it's current configuration I only have ~150 mm available on the Z axis. Is that normal? I see there are adapters available to move the motors above the brackets to give you more room. I'll probably print them soon.

One of the first prints I did was a 10X10X10 mm cube. I kept all the default settings in slic3r. It printed well, but the top of the cube sagged in. I tried increasing the infill from 10% to 20% and lowering the temperature from 219 to 205 (I'm using hatchbox brand pla filament), but it still sagged on a later print. How do I fix that?

I tried printing a little figuring that I knew would need support so I ticked the box to add pillars and kept all the default settings. It made a LOT more support pillars than I thought would be neccicary. I printed it anyway but I ended up ripping off the figure's head and arms trying to get the pillars off it. Any suggestions there?

Whenever the hot end is hot, it seems to constantly leak a little bit of filament. Is that normal?

Maybe related, when moving from place to place during a print, it leave little hair fine strands of filament behind. Is that normal?

Thanks in advance for the help.

The issue with the Z axis only giving 150mm is indeed normal. Interestingly enough though is that I get less on my printer. It is also normal for the hotend to leak a bit. The hotends that FT gives I would say are on the lower end of the quality spectrum when it comes to hotends, but even higher quality hotends do still leak. Yes the small hairs that are left during travel moves are normal, but these can be reduced by increasing the retraction. I have disabled retraction with my printer because it seems to cause me more problems that it solves, but having retraction on is fine too. As far as the problem with the supports, I would suggest maybe not even bothering too much with slic3r (personal opinion). I have not actually used slic3r myself (I use cura) but from what I have heard, it seems that cura is better at everything from slicing to overall print quality. If you are just getting used to a using slic3r, I would suggest switching over to cura before getting to accustomed with slic3r (again personal opinion)

The E3D Lite6 I upgraded to does not leak at all not yet anyway

It actually will start putting down material right when the print starts because it all didn't leak out while heating up like the Folger one would. Defiantly was a good upgrade.

It actually will start putting down material right when the print starts because it all didn't leak out while heating up like the Folger one would. Defiantly was a good upgrade.Newbie with Folgertech 2020 i3.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 10, 2015 04:48AM |

Registered: 8 years ago Posts: 51 |

Tested out the dual bearing holder last night, seems to work well added a lot more structure and made the bed feel more secure, noticed one of my other bearings is bad so will replace that when my order of bearings comes in. I've added some pictures to the thingiverse page for it: [www.thingiverse.com]

Also did my first print of benchy last night, pretty happy with the results, still needs a little work - slightly less temps to remove the stringing? [imgur.com]

Also did my first print of benchy last night, pretty happy with the results, still needs a little work - slightly less temps to remove the stringing? [imgur.com]

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 10, 2015 06:20AM |

Registered: 8 years ago Posts: 19 |

Is there a stl file for the folgertech prusa i3 2020 bearing holders for the y axis rods? I sorted stripped the screw holes of mine from running my printer head down onto the build plate and luckily the screws gave way and made a pop noise that alerted me that the the end stop didn't trigger (mightv got moved when messing with something earlier) and now I can still print but it vibrates from the bed not being securely fastened. I would've noticed sooner but I had my noise cancelling headphones on and the pop is what came through.

(If i have to I can probably do measurements and draw up my own to print but I figured I ask first for ones that are exact)

(If i have to I can probably do measurements and draw up my own to print but I figured I ask first for ones that are exact)

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 10, 2015 06:46AM |

Registered: 8 years ago Posts: 51 |

Quote

Slaghton

Is there a stl file for the folgertech prusa i3 2020 bearing holders for the y axis rods? I sorted stripped the screw holes of mine from running my printer head down onto the build plate and luckily the screws gave way and made a pop noise that alerted me that the the end stop didn't trigger (mightv got moved when messing with something earlier) and now I can still print but it vibrates from the bed not being securely fastened. I would've noticed sooner but I had my noise cancelling headphones on and the pop is what came through.

(If i have to I can probably do measurements and draw up my own to print but I figured I ask first for ones that are exact)

[drive.google.com]

In the 2020i3 STLs folder. You want the '3x metali3standoff2.stl'.

See my above post about one I custom made to add an extra bearing on the single bearing side, so it uses 4 bearings for the plate.

|

Re: Folger Tech 2020 i3 Printer Kit (Official Thread) November 10, 2015 07:02AM |

Registered: 8 years ago Posts: 19 |

Ah thanks, not sure how I missed those stl's. I downloaded some other batch. I saw your modification  . I might have to look into it if it reduces vibration/increases print quality =).

. I might have to look into it if it reduces vibration/increases print quality =).

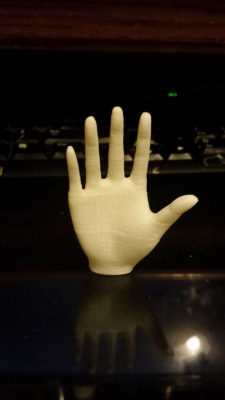

Here's my most recent print even with my heavy vibration for my bearing holders being loose.

(the band artifact was caused by me pressing my finger lightly against a rattling bearing)

P.S. For people talking about Y axis vibration sound. My plastic bearing holders having their screw holes getting stripped so the bed isn't fastened securely is causing a loud vibration sound. Printing 3 new ones since I can still print pretty good.

Edited 6 time(s). Last edit at 11/10/2015 10:51AM by Slaghton.

. I might have to look into it if it reduces vibration/increases print quality =).

. I might have to look into it if it reduces vibration/increases print quality =).Here's my most recent print even with my heavy vibration for my bearing holders being loose.

(the band artifact was caused by me pressing my finger lightly against a rattling bearing)

P.S. For people talking about Y axis vibration sound. My plastic bearing holders having their screw holes getting stripped so the bed isn't fastened securely is causing a loud vibration sound. Printing 3 new ones since I can still print pretty good.

Edited 6 time(s). Last edit at 11/10/2015 10:51AM by Slaghton.

Sorry, only registered users may post in this forum.