|

Re: Hangprinter version 3 November 22, 2017 01:11PM |

Registered: 6 years ago Posts: 48 |

|

Re: Hangprinter version 3 November 22, 2017 02:31PM |

Registered: 10 years ago Posts: 401 |

@imrcly

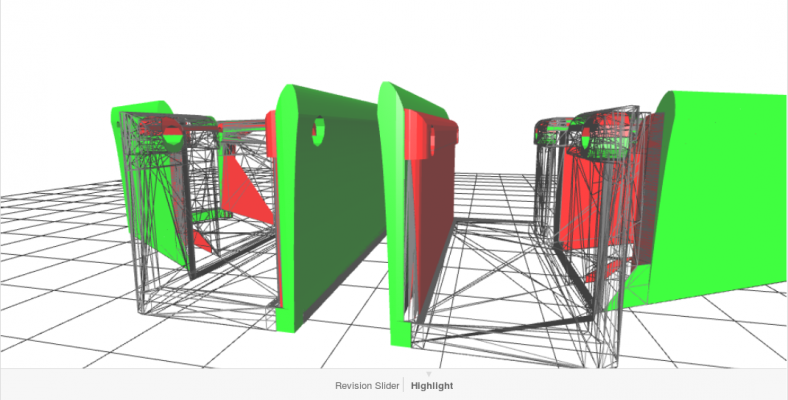

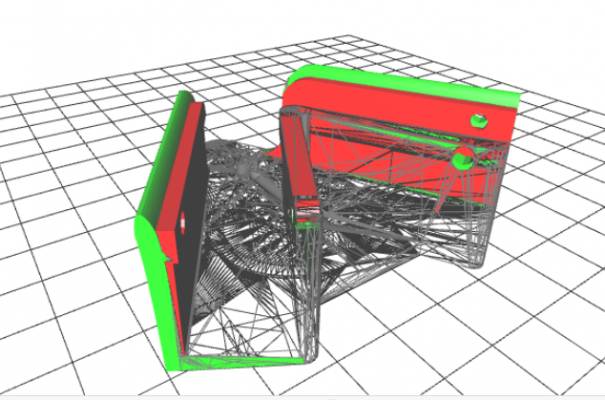

Got around to make beam insertion more practical today. This one was fun to code =)

Green faces were added, red faces were removed

torbjornludvigsen.com

Got around to make beam insertion more practical today. This one was fun to code =)

Green faces were added, red faces were removed

torbjornludvigsen.com

|

Re: Hangprinter version 3 November 22, 2017 03:12PM |

Registered: 6 years ago Posts: 48 |

|

Re: Hangprinter version 3 November 22, 2017 03:53PM |

Registered: 10 years ago Posts: 401 |

Change parameters in parameters.scad. Change

Edited 1 time(s). Last edit at 11/22/2017 03:54PM by tobben.

torbjornludvigsen.com

Beam_width to match the width your us wooden beams. Then open a terminal cd to your hangprinter directory and domake openscad_stl/beam_clamp.stl openscad_stl/corner_clamp.stl openscad_stl/beam_slider.stlThis should create three new stls that matches your parameters.

Edited 1 time(s). Last edit at 11/22/2017 03:54PM by tobben.

torbjornludvigsen.com

|

Re: Hangprinter version 3 November 22, 2017 06:46PM |

Registered: 6 years ago Posts: 48 |

|

Re: Hangprinter version 3 November 22, 2017 11:47PM |

Registered: 6 years ago Posts: 48 |

|

Re: Hangprinter version 3 November 23, 2017 07:16PM |

Registered: 6 years ago Posts: 48 |

|

Re: Hangprinter version 3 November 24, 2017 04:04AM |

Registered: 10 years ago Posts: 401 |

|

Re: Hangprinter version 3 November 24, 2017 11:23PM |

Registered: 6 years ago Posts: 48 |

So we have ordered all the parts! The build will start next week we are using an e3d vacano also using Mechaduinos.

This is the part list are we missing anything?

Extruder

E3D V6 Hot End Kit 3mm 12v

E3D Nozzle Spanner

E3D Volcano Eruption Pack 3mm 12v

E3D Titan Extruder

E3D Volcano Silicone Socks

E3D 30mm Fan (heatsink fan)12V

E3D V6 Fan Shroud (Heatsink Mount)

build plate

42x42in glass build plate

Silicone Heater Pad 240V 1000W 450x450MM

parts

5 x Nema17 steppers

60 m FireLine 0.5 mm

ca 47x47 cm MDF or plywood sheet

1 x Arduino Mega

1 x RAMPS

L7805 Positive Voltage Regulator Output 5v TO-220 x 20

TB6612 1.2A DC/Stepper Motor Driver Breakout Board x2

A4988 Stepstick Stepper Motor Driver Module + Heat Sink x 5

Jumpers

1 x USB cable, type B plug

15x15 mm wooden beams lengths 3x40 cm + 1x20 cm

1 x Power supply (12 V, 10 A recommended)

13 x M3 screws, length 25 mm

16 x M3 screws, length 5 mm

2 x M3 screws, length 10 mm

4 x M8 screws, length > 50 mm, head countersunk

8 x 608 bearing

12 x 623 V-groove bearing

More than 20 self tapping wooden screws, length 10 - 20 mm, width ca 4 mm

5 m of 20-lead ribbon wire

washers for all screws

4 x Mechaduino PCB

More than 20 jumper wires

5V->3V3 level converter for i2c usage

Raspberry Pi

raspberry pi camera wide angle

All the printed parts will be printed in Polymaker Polymax PLA how much fiament dose it take to build all the parts?

Thanks for your great project

Alex

Edited 1 time(s). Last edit at 11/24/2017 11:26PM by delloman.

This is the part list are we missing anything?

Extruder

E3D V6 Hot End Kit 3mm 12v

E3D Nozzle Spanner

E3D Volcano Eruption Pack 3mm 12v

E3D Titan Extruder

E3D Volcano Silicone Socks

E3D 30mm Fan (heatsink fan)12V

E3D V6 Fan Shroud (Heatsink Mount)

build plate

42x42in glass build plate

Silicone Heater Pad 240V 1000W 450x450MM

parts

5 x Nema17 steppers

60 m FireLine 0.5 mm

ca 47x47 cm MDF or plywood sheet

1 x Arduino Mega

1 x RAMPS

L7805 Positive Voltage Regulator Output 5v TO-220 x 20

TB6612 1.2A DC/Stepper Motor Driver Breakout Board x2

A4988 Stepstick Stepper Motor Driver Module + Heat Sink x 5

Jumpers

1 x USB cable, type B plug

15x15 mm wooden beams lengths 3x40 cm + 1x20 cm

1 x Power supply (12 V, 10 A recommended)

13 x M3 screws, length 25 mm

16 x M3 screws, length 5 mm

2 x M3 screws, length 10 mm

4 x M8 screws, length > 50 mm, head countersunk

8 x 608 bearing

12 x 623 V-groove bearing

More than 20 self tapping wooden screws, length 10 - 20 mm, width ca 4 mm

5 m of 20-lead ribbon wire

washers for all screws

4 x Mechaduino PCB

More than 20 jumper wires

5V->3V3 level converter for i2c usage

Raspberry Pi

raspberry pi camera wide angle

All the printed parts will be printed in Polymaker Polymax PLA how much fiament dose it take to build all the parts?

Thanks for your great project

Alex

Edited 1 time(s). Last edit at 11/24/2017 11:26PM by delloman.

|

Re: Hangprinter version 3 November 25, 2017 05:12AM |

Registered: 10 years ago Posts: 14,672 |

Quote

tobben

@delloman

Cool! I'm excited to hear that. Mechaduinos give you closed-loop control. Details are on my blog.

@dc42

Forward kinematicsanchor_ABCD_xyzare calibration constants.carthesian[XYZ_AXIS]are absolute positions from G0/G1-command. Motor names are mapped like [X, Y, Z, E0, E1] <-> [A, B, C, D, E].

The motors A, B, C, and D should be constantly enabled.

Homing for HP3 with Mechaduino: Put all motors in torque/constant force-mode and drag mover to origo by hand. Then send G28.

Homing for HP3 without Mechaduino: Get mover to origo by manually stepping individual motors using G6 (I know it makes more sense to call this command G1 S2). Then send G28.

Suggestions for more repeatable, less time consuming homing are welcome

Thanks! I've implemented the basic kinematics and I am finishing off the auto calibration. Documentation is at [duet3d.com]. Release will be in the next 1.20 beta or release candidate firmware.

Notes on the implementation:

- Line buildup compensation isn't implemented yet

- For now I am using segmentation-based kinematics. The basic Hangprinter kinematics is fairly simple (i.e. quadratic), so it should be easy enough to implement the same segmentation-free kinematics that we use on deltas. However, I want to see whether I can integrate line buildup compensation into segmentation-free kinematics before I go that route.

- Auto calibration using a Z probe supports 3, 6 or 9 factors. The first 3 factors are the spool motor zero positions; the next 3 are the anchor XY coordinates, and the final 3 are the anchor Z coordinates. I have a feeling that calibrating the anchor Z coordinates may not work very well, at least until line buildup compensation is implemented.

- For homing, I suggest starting with the effector in a position that is known at least approximately (e.g. just above the floor at X0 Y0, but any measurable position will do), sending G92 Xxx Yyy Zzz to tell the firmware where that position is, then running 3-factor calibration to establish it more accurately.

Edited 1 time(s). Last edit at 11/25/2017 05:17AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Hangprinter version 3 November 25, 2017 06:32AM |

Registered: 6 years ago Posts: 48 |

@dc43 we where talking about the duet for our build the guys liked the idea. we like your hardware I was going to get a little moster and replce all the junk with a duet and real e3d parts but found the hang printer and it's really a cool idea for a club. project

Edited 2 time(s). Last edit at 11/25/2017 06:34AM by delloman.

Edited 2 time(s). Last edit at 11/25/2017 06:34AM by delloman.

|

Re: Hangprinter version 3 November 25, 2017 06:52AM |

Registered: 10 years ago Posts: 401 |

@delloman

Nice! Some sheet material for the anchors can be practical. I've not included any official way of building ABC anchors in the design, but here is one solution: [twitter.com]

@dc42

Thanks, this is great! Looking forward to test it! I will try to find the time to look into the code and do physical testing in January. (In the meantime I'll happily support Hangprinter+Duetwifi builders here )

)

I'm reading through the wiki page and commenting what I see there:

The D motor carry a spool from which three lines are connected to the effector.

Earlier in the text it says that D-motor is connected to E0 and extruder motor is connected to E1.

The auto calibration section looks very interesting!

I have two questions about the procedure you describe.

Does it assume an even bed to find anchor locations, or does it assume correct anchor positions to compensate an uneven bed?

The procedure uses a bed probe, which is not part of a standard Hangprinter, but it can be easily added.

torbjornludvigsen.com

Nice! Some sheet material for the anchors can be practical. I've not included any official way of building ABC anchors in the design, but here is one solution: [twitter.com]

@dc42

Thanks, this is great! Looking forward to test it! I will try to find the time to look into the code and do physical testing in January. (In the meantime I'll happily support Hangprinter+Duetwifi builders here

)

)I'm reading through the wiki page and commenting what I see there:

A Hangprinter has four positioning motors, three suspended from the floor (ABC), and one suspended from the ceiling (D).Quote

A Hangprinter has three positioning motors suspended from the ceiling.

Each of the ABC motors carry a spool, from which a pair of lines is connected to the effector.Quote

Each motor carries a spool, from which a pair of lines is connected to the effector.

The D motor carry a spool from which three lines are connected to the effector.

Is this correct?Quote

M569 P3 S1 ; drive 3 (D) goes forwards

M569 P4 S1 ; drive 4 (E0) goes forwards

Earlier in the text it says that D-motor is connected to E0 and extruder motor is connected to E1.

The auto calibration section looks very interesting!

I have two questions about the procedure you describe.

Does it assume an even bed to find anchor locations, or does it assume correct anchor positions to compensate an uneven bed?

Does this procedure use stallGuard2 data to tighten lines, or does it assume tight lines in order to find current cartesian position of the effector?Quote

3-factor: adjusts the spool zero positions.

The procedure uses a bed probe, which is not part of a standard Hangprinter, but it can be easily added.

torbjornludvigsen.com

|

Re: Hangprinter version 3 November 25, 2017 12:36PM |

Registered: 10 years ago Posts: 14,672 |

I'm sorry, I misunderstood. I thought the effector was suspended from 3 spools on the ceiling and the D anchor was used to keep the extruder drive within reach of the extruder. I've now found your documentation, and I will modify the wiki page.

The auto calibration assumes that the bed is even. If it isn't, you can choose points to probe to avoid the least even spots, and you could use the H parameter to adjust for known unevenness. After auto calibration, you can use mesh bed compensation to handle unevenness.

I think we could use stall detection to tighten the lines, by selecting stall detection endstops in the M574 command, temporarily reducing the current on the ABC motors (M913), and then using a G1 S1 command to tighten ABC simultaneously - rather like homing a delta printer. See [duet3d.com].

What type of print bed do you normally use with Hangprinter?

Edited 1 time(s). Last edit at 11/25/2017 12:39PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The auto calibration assumes that the bed is even. If it isn't, you can choose points to probe to avoid the least even spots, and you could use the H parameter to adjust for known unevenness. After auto calibration, you can use mesh bed compensation to handle unevenness.

I think we could use stall detection to tighten the lines, by selecting stall detection endstops in the M574 command, temporarily reducing the current on the ABC motors (M913), and then using a G1 S1 command to tighten ABC simultaneously - rather like homing a delta printer. See [duet3d.com].

What type of print bed do you normally use with Hangprinter?

Edited 1 time(s). Last edit at 11/25/2017 12:39PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Hangprinter version 3 November 25, 2017 06:13PM |

Registered: 10 years ago Posts: 401 |

Cool. Automatically and reliably tightening lines with stallGuard2 would be a big UX improvement for non-Mechaduino users

I normally use a piece of plywood covered in white glue as a print bed.

(Suggestions for other suitable big, cheap and flat things that could be printed on welcome. )

)

torbjornludvigsen.com

I normally use a piece of plywood covered in white glue as a print bed.

(Suggestions for other suitable big, cheap and flat things that could be printed on welcome.

)

)torbjornludvigsen.com

|

Re: Hangprinter version 3 November 25, 2017 09:57PM |

Registered: 6 years ago Posts: 48 |

We are going to use a 1066mm2 glass table top with possibly a heated bed using 4 of these [m.aliexpress.com]

Possibly PEI sheets but i can't find bigger then 12 x 12 in.

Possibly PEI sheets but i can't find bigger then 12 x 12 in.

|

Re: Hangprinter version 3 November 26, 2017 09:43PM |

Registered: 6 years ago Posts: 14 |

I can't find Fireline in .5mm diameter in the US.

I found this :

[www.berkley-fishing.com]

.48mm and 80lbs break test?

Will that work?

Thank you

I found this :

[www.berkley-fishing.com]

.48mm and 80lbs break test?

Will that work?

Thank you

|

Re: Hangprinter version 3 November 27, 2017 01:43AM |

Registered: 6 years ago Posts: 48 |

|

Re: Hangprinter version 3 November 27, 2017 01:50AM |

Registered: 6 years ago Posts: 48 |

About to order some 100lb [www.amazon.com]

|

Re: Hangprinter version 3 November 27, 2017 03:56AM |

Registered: 10 years ago Posts: 401 |

This was a brain fart. I've used 8 mm and 12 mm plywood, as well as 12 mm MDF.Quote

tobben

I've used 4mm and 5mm plywood, as well as 5 mm MDF

I've also made a spreadsheet with weight data of my mover parts: here.

In short:

Pinewood beams weigh 171 g.

Square carbon fibre tubes weigh 91 g.

torbjornludvigsen.com

|

Re: Hangprinter version 3 November 27, 2017 04:11AM |

Registered: 10 years ago Posts: 401 |

@delloman

0.48 mm Fireline will work well, particularly if your mover is light. If you enable line buildup compensation feature, remember to adjust your spool buildup factor accordingly.

I'm not sure if the 100 ib fishing line is what you want. You want as stiff and thin as possible. I think that line is a bit flexible and very thick.

My opinion on DuetWifi is already in this thread. Smoothieboard and Replicape are also very good RepRap controllers, but they currently have no Hangprinter support in their firmwares as far as I know.

torbjornludvigsen.com

0.48 mm Fireline will work well, particularly if your mover is light. If you enable line buildup compensation feature, remember to adjust your spool buildup factor accordingly.

I'm not sure if the 100 ib fishing line is what you want. You want as stiff and thin as possible. I think that line is a bit flexible and very thick.

My opinion on DuetWifi is already in this thread. Smoothieboard and Replicape are also very good RepRap controllers, but they currently have no Hangprinter support in their firmwares as far as I know.

torbjornludvigsen.com

|

Re: Hangprinter version 3 November 27, 2017 04:54AM |

Registered: 10 years ago Posts: 401 |

To your defense, it would be interesting to see someone testing this setup. It could be implemented by moving abc-anchors to the ceiling, attaching extruder drive to D-lines and configuring achor_abcd_xys to match reality as usual.Quote

dc42

I thought the effector was suspended from 3 spools on the ceiling and the D anchor was used to keep the extruder drive within reach of the extruder.

torbjornludvigsen.com

|

Re: Hangprinter version 3 November 27, 2017 06:19AM |

Registered: 10 years ago Posts: 14,672 |

Quote

tobben

To your defense, it would be interesting to see someone testing this setup. It could be implemented by moving abc-anchors to the ceiling, attaching extruder drive to D-lines and configuring achor_abcd_xys to match reality as usual.Quote

dc42

I thought the effector was suspended from 3 spools on the ceiling and the D anchor was used to keep the extruder drive within reach of the extruder.

I had to make one change to the firmware to switch from that setup to the actual Hangprinter setup. In the forward kinematics calculation, Hangprinter needs the positive root of the quadratic equation, because the effector is above the ABC anchors. The alternative setup has the effector below the anchors, so the negative root would be used instead.

Edited 1 time(s). Last edit at 11/27/2017 06:27AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Hangprinter version 3 November 27, 2017 08:12AM |

Registered: 10 years ago Posts: 401 |

Yes, the positive root is the right one.

In HangprinterMarlin, I've left it up to the user to use the right signs when configuring anchor positions. In the usual setup, with abc anchor at the floor, users have the freedom to rotate their cartesian coordinate systems around Z. By convention, I use

torbjornludvigsen.com

I think you might be mixing up the fourQuote

dc42

Hangprinter needs the positive root of the quadratic equation, because the effector is above the ABC anchors. The alternative setup has the effector below the anchors, so the negative root would be used instead.

anchor_abcd_z parameters and the line_length[abcd] parameters. The square root is part of an euclidean distance (between anchor and effector) calculation, which is positive by definition. However, the anchor_abc_z parameters do indeed change sign when switching between the two setups for the reason you mention.In HangprinterMarlin, I've left it up to the user to use the right signs when configuring anchor positions. In the usual setup, with abc anchor at the floor, users have the freedom to rotate their cartesian coordinate systems around Z. By convention, I use

anchor_a_x=0.0 to determine this rotational freedom. I haven't informed users about signs before, so posting signs of anchor positions in conventional Hangprinter setup here:ANCHOR_A_X 0.0 ANCHOR_A_Y [negative number] ANCHOR_B_X [positive number] ANCHOR_B_Y [positive number] ANCHOR_C_X [negative number] ANCHOR_C_Y [positive number] ANCHOR_D_Z [positive number] ANCHOR_A_Z [negative number] ANCHOR_B_Z [negative number] ANCHOR_C_Z [negative number]@dc42 In your suggested setup, the three last ones would be positive.

torbjornludvigsen.com

|

Re: Hangprinter version 3 November 27, 2017 08:23AM |

Registered: 10 years ago Posts: 14,672 |

Tobben, I think you are referring to the inverse kinematics, used to calculate the line lengths for a given head position in space. I was referring to the forward kinematics, which are used to calculate the XYZ position given the line lengths. The terminology is a little confusing, because it's the inverse kinematics that are used most of the time in the calculations. I'm not sure that Marlin uses forward kinematics at all.

For the forward kinematics calculation, the problem is over-constrained, so only the distances to 3 anchors are used. I use the ABC distances. If these anchors are at more or less the same height, there will be 2 solutions: one above the anchors, and one below.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

For the forward kinematics calculation, the problem is over-constrained, so only the distances to 3 anchors are used. I use the ABC distances. If these anchors are at more or less the same height, there will be 2 solutions: one above the anchors, and one below.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Hangprinter version 3 November 27, 2017 08:43AM |

Registered: 10 years ago Posts: 14,672 |

I've given some more thought to how to auto calibrate a Hangprinter using just a Z probe. We can define X0 Y0 to be the coordinates of the D anchor, and as heights are not sensitive to rotation of the axes we can also assume that anchor A lines on X=0 as you suggest. Then we need to establish 5 anchor XY coordinates, 3 line length starting positions and 3 Z coordinates. Total 11 calibration factors. So 11 or more probe points will be needed.

The risk is that because the head position is mathematically over-constrained (because there are 4 lines instead of 3), unless the calibration is good to start with, as the head moves one of the lines may become slack. Or the lines may become excessively taut, leading to stretching so that the line length is not what the firmware thinks it is - or worse, a motor skipping steps.

So I am wondering whether the following is a practical solution:

1. Only probe at points at which exactly one of the lines doesn't need to carry any tension. So don't probe close to the centre, and don't probe along a line between the centre and an anchor.

2. When moving to a probe point and probing, slacken the line that doesn't need to carry any tension by a few mm, so that we can be sure that the other lines are not being stretched.

3. In the least squares computation, for that probe point set the derivative of height against that line length and its anchor coordinates to zero.

Does that sound viable? Or will the slack line cause problems, either with constraining the effector sufficiently or when it rewound back onto the spool?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

The risk is that because the head position is mathematically over-constrained (because there are 4 lines instead of 3), unless the calibration is good to start with, as the head moves one of the lines may become slack. Or the lines may become excessively taut, leading to stretching so that the line length is not what the firmware thinks it is - or worse, a motor skipping steps.

So I am wondering whether the following is a practical solution:

1. Only probe at points at which exactly one of the lines doesn't need to carry any tension. So don't probe close to the centre, and don't probe along a line between the centre and an anchor.

2. When moving to a probe point and probing, slacken the line that doesn't need to carry any tension by a few mm, so that we can be sure that the other lines are not being stretched.

3. In the least squares computation, for that probe point set the derivative of height against that line length and its anchor coordinates to zero.

Does that sound viable? Or will the slack line cause problems, either with constraining the effector sufficiently or when it rewound back onto the spool?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Hangprinter version 3 November 27, 2017 11:01AM |

Registered: 6 years ago Posts: 48 |

So what size are you recommending?

Material Line Length strength Line Diameter

PE 1000M 10LB 0.14MM

PE 1000M 20LB 0.20MM

PE 1000M 30LB 0.26MM

PE 1000M 40LB 0.32MM

PE 1000M 50LB 0.36MM

PE 1000M 60LB 0.40MM

PE 1000M 70LB 0.44MM

PE 1000M 80LB 0.48MM

PE 1000M 90LB 0.50MM

PE 1000M 100LB 0.55MM

Edited 1 time(s). Last edit at 11/27/2017 11:05AM by delloman.

Material Line Length strength Line Diameter

PE 1000M 10LB 0.14MM

PE 1000M 20LB 0.20MM

PE 1000M 30LB 0.26MM

PE 1000M 40LB 0.32MM

PE 1000M 50LB 0.36MM

PE 1000M 60LB 0.40MM

PE 1000M 70LB 0.44MM

PE 1000M 80LB 0.48MM

PE 1000M 90LB 0.50MM

PE 1000M 100LB 0.55MM

Edited 1 time(s). Last edit at 11/27/2017 11:05AM by delloman.

|

Re: Hangprinter version 3 November 27, 2017 05:52PM |

Registered: 10 years ago Posts: 401 |

Ah, thanks for the clarification.Quote

dc42

Tobben, I think you are referring to the inverse kinematics

Yes, I think it might be viable. The two problems to overcome would be making spools that can handle lots of slack line (like a very wide brim), and making line wind in line in a way such that slack is not "trapped" on the spool (all line is fairly tightly wound onto the spool).Quote

dc42

Does that sound viable? Or will the slack line cause problems, either with constraining the effector sufficiently or when it rewound back onto the spool?

Those two problems could maybe be solved by temporarily attaching a 0.5l bottle of water in the slack line, in between the winch and the anchor.

I'm recommending as thick FireLine as you can find.Quote

delloman

So what size are you recommending?

I think the 0.34 mm one, which is more widely available than the 0.5 mm one, can work well.

The line you linked to earlier is braided in such a way that it flexes, and it is made out of Polyethylene, which is not very stiff.

It will not give good results regardless of its diameter.

What we really want is thick long chains of Ultra-high-molecular-weight polyethylene.

Such fibres are most often called Dyneema or Spectra.

However, I've seen a line from ebay marked "Dyneema" that flexed badly.

Maybe it flexed because of the way it was braided, or maybe it wasn't really dyneema.

I recommend Berkley FireLine because it's the only dyneema line that I've tried.

There are other brands out there that would work equally well, I think.

Berkley also makes the "NanoFil" line, which is stiff for it's small diameter, but they don't produce it in thick diameters, which is why I recommend FireLine.

For more, see this post.

Best regards!

torbjornludvigsen.com

|

Re: Hangprinter version 3 November 27, 2017 10:04PM |

Registered: 6 years ago Posts: 48 |

|

Re: Hangprinter version 3 November 28, 2017 03:36AM |

Registered: 10 years ago Posts: 401 |

|

Re: Hangprinter version 3 November 28, 2017 06:57PM |

Registered: 6 years ago Posts: 14 |

Sorry, only registered users may post in this forum.