*solved* A Blender made 125 tooth pulley won't be sliced correctly  December 03, 2012 05:03PM |

Registered: 14 years ago Posts: 65 |

time is pressing.. and i won't get my big pulley-mould printed.

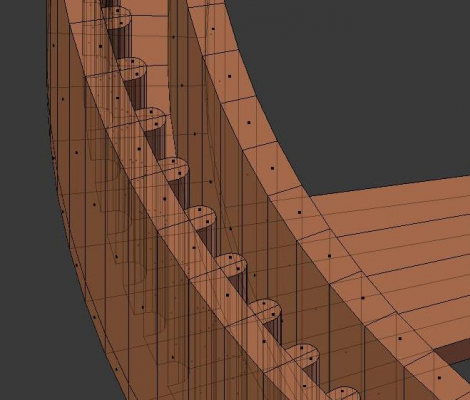

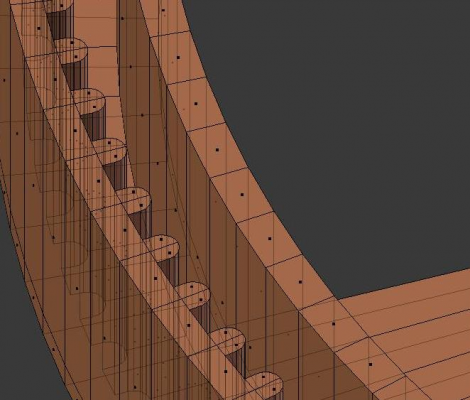

with some try and error it worked with a 112 pulley:

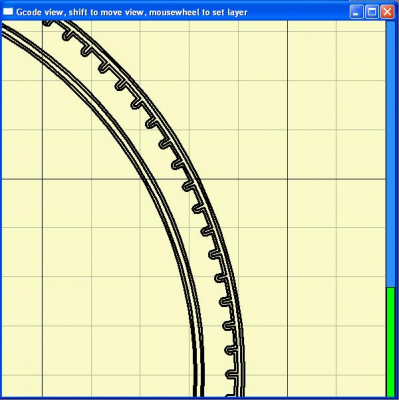

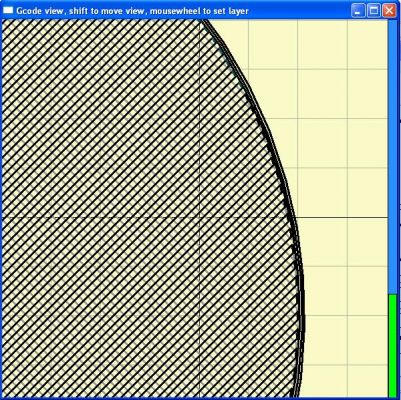

but the 125 pulley that i made exactly like the smaler one is only sliced into big "black" discs:

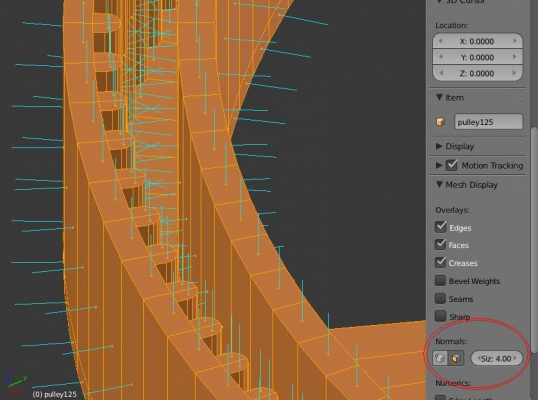

It is a perfect manifold (strg+shift+alt+M no longer yields any verts)

and i simply don't know what else i can try :'(

my blend file: pulley125b.rar

the stl export of the 125 tooth pulley mould: pulley125b.stl

the gcode file: pulley125b_export.zip

i don't know why slic3r says "The model has overlapping or self-intersecting facets."

dasRoland.de

Ideas welcome :-/

Edited 1 time(s). Last edit at 12/03/2012 06:58PM by roland.

with some try and error it worked with a 112 pulley:

but the 125 pulley that i made exactly like the smaler one is only sliced into big "black" discs:

It is a perfect manifold (strg+shift+alt+M no longer yields any verts)

and i simply don't know what else i can try :'(

my blend file: pulley125b.rar

the stl export of the 125 tooth pulley mould: pulley125b.stl

the gcode file: pulley125b_export.zip

i don't know why slic3r says "The model has overlapping or self-intersecting facets."

dasRoland.de

Ideas welcome :-/

Slicing D:\reprap\pulley\pulley125b.stl Slicing: Slic3r/slic3r.exe $s --load Slic3r/config.ini --output $o => Processing input file D:\reprap\pulley\pulley125b.stl => Processing triangulated mesh The model has overlapping or self-intersecting facets. I tried to repair it, however you might want to check the results or repair the input file and retry. => Generating perimeters => Detecting solid surfaces => Preparing infill surfaces => Cleaning up => Detect bridges => Cleaning up the perimeters => Generating horizontal shells => Combining infill => Infilling layers => Generating skirt => Exporting GCODE to D:\reprap\pulley\pulley125b_export.gcode Done. Process took 1 minutes and 51.406 seconds Filament required: 49248.1mm (348.1cm3) 49247.13568 mm of filament used in this print the print goes from 12.739000 mm to 227.379000 mm in X and is 214.640000 mm wide the print goes from 12.604000 mm to 227.384000 mm in Y and is 214.780000 mm wide the print goes from 0.400000 mm to 22.000000 mm in Z and is 21.600000 mm high Estimated duration (pessimistic): 55 layers, 09:10:15

Edited 1 time(s). Last edit at 12/03/2012 06:58PM by roland.

Re: A Blender made 125 tooth pulley won't be sliced correctly  December 03, 2012 06:30PM |

Registered: 14 years ago Posts: 65 |

okay, the 112 pulley does not have these "intersecting faces":

some more hours of frustrating blender-work tomorrow..

*good night and good luck*

Slicing D:\reprap\pulley\pulley112.stl Slicing: Slic3r/slic3r.exe $s --load Slic3r/config.ini --output $o => Processing input file D:\reprap\pulley\pulley112.stl => Processing triangulated mesh => Generating perimeters => Detecting solid surfaces => Preparing infill surfaces => Cleaning up => Detect bridges => Cleaning up the perimeters => Generating horizontal shells => Combining infill => Infilling layers => Generating skirt => Exporting GCODE to D:\reprap\pulley\pulley112_export.gcode Done. Process took 5 minutes and 21.547 seconds Filament required: 11125.1mm (78.6cm3) 11124.07823 mm of filament used in this print the print goes from 22.780000 mm to 217.210000 mm in X and is 194.430000 mm wide the print goes from 22.782000 mm to 217.212000 mm in Y and is 194.430000 mm wide the print goes from 0.400000 mm to 22.000000 mm in Z and is 21.600000 mm high Estimated duration (pessimistic): 55 layers, 03:49:08

some more hours of frustrating blender-work tomorrow..

*good night and good luck*

|

solved :-) December 03, 2012 06:57PM |

Registered: 14 years ago Posts: 65 |

Re: *solved* A Blender made 125 tooth pulley won't be sliced correctly  December 11, 2012 03:17PM |

Registered: 11 years ago Posts: 25 |

Re: *solved* A Blender made 125 tooth pulley won't be sliced correctly  January 22, 2013 05:54AM |

Registered: 12 years ago Posts: 9 |

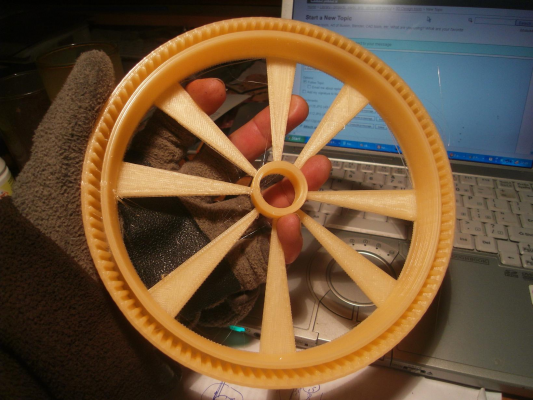

I usually use cloud.netfabb.com to check my STL exports.

It's a beautiful design btw! What technique did you use?

It's a beautiful design btw! What technique did you use?

Sorry, only registered users may post in this forum.