User:Chuckdeev/Class Blog

Main | About Me | Class Blog

Enjoy my weekly blogs pertaining to the world of Additive Manufacturing.

Contents

- 1 Blog 1: Exploring Thingiverse

- 2 Blog 2: Marcin's Open Source Ecology

- 3 Blog 3: RoboHand

- 4 Blog 4: Reviewing Blog 2

- 5 Blog 5: RepRap Media Timeline

- 6 Blog 6: Our Next Step to Improve

- 7 Blog 7: Two 3D Printing Articles

- 8 Blog 8: Intellectual Property Rights

- 9 Blog 9: Exploring Filament Types

- 10 Blog 10: Exploring Extruder Types

- 11 Blog 11: Reviewing Show & Tell Presentations

- 12 Personal Blog (Bonus Blog) Osteoid Cast

- 13 Blog 12: Review of Blog 5

- 14 Blog 13: Review of Blog 7

- 15 Blog 14: Review of Blog 8

- 16 Tony Armlin=

Blog 1: Exploring Thingiverse

Exploring the wide world of Thingiverse and the projected uses of printed items”

A) Something Amazing This gear sphere is incredible on so many levels that it confuses me. How each gear is printed perfectly inside one another while being created on the surface of a sphere is truly fascinating. I would love to see this actually work.

B) Something Funny”"

This Pipe extender is hilarious. When was the last time you were smoking a pipe and said “I wish the bowl was an extra foot farther from my face”? It’s a funny idea and makes you look like a boss when you’re kickin’ back on your porch smoking plants.

C) Something Useless This miniature model is a great representation of how much time people have on their hands and how incredible additive manufacturing really is. The attention to detail for such a useless object is flawless. There is absolutely no use for this in life, anywhere, at any time…

D) Something Useful Stumbling across this GoPro Mount made me realize how useful a personal 3D printer would be. I currently have a GoPro, but lost the mount a year ago and was too lazy to get a new one. Having a printer at your disposal would really change how you go about acquiring any of those small, customizable objects, especially when they are lost.

D) Something Surprising This Rollercoaster car surprised me for different reasons. I understand the capability of these printers and was surprised to see a design for something that would need to have the capability to withstand tons of pressure & weight. I would like to see a full scale print of this that had enough strength to actually work.

Blog 2: Marcin's Open Source Ecology

Exploring the ideas of Marcin Jakubowski.Check out this video to get a general understanding of this man's goal.

Impression and External Information

The world needs more people like Jakubowski. His idea, if completed correctly, could revolutionize the development of our planet's society. Technology is constantly advancing, yet most of it is not available to a majority of people. This is a great way to allow developing or underdeveloped nations to "leapfrog" older, inefficient technologies and skip ahead to better, cleaner, less intensive ways of altering and utilizing their local environments and resources. We run into advanced development issues due to the fact that areas are already developed. Creating this Open Source Ecology manual promotes the cleaner, more advanced technologies that go along with the process we have made as a society. Aside from this project helping undeveloped regions of our world, I can see it being the main focus for building a society on other planets/moons in the future. With all of our technologies these days, we can really make a flawless plan of expanding development if we could start from the beginning.

New Yorker and Marcin Response Articles

Emily Eakin of New Yorker Magazine wrote an article (source) about Marcin's plan of actions, but in reality she bashed and made fun of his way of living and personal tendencies. In a pathetic excuse for journalism, Eakin managed to show us why more people don't have ideas capable of producing major society impacts. She spent four paragraphs explaining what kinds of blue jeans he wears and how his obsessive temperament gets in the way instead of diving into the possibilities this guide book could have on tons of people in the future. Jakubowski wrote up a response (source) in a well mannered way, stating all of the discrepancies between Eakin's analysis and his actual project.

Capabilities at PSU

This type of project could easily spark interest as a think-tank club at Penn State University. There may not be any purpose for completion of designs following the full process that Marcin is carrying out, but what would be interesting and useful is a club that focuses on creating their own basic machines through ideas computer program projections. "Rough draft" versions could be created with the help of our rep rap printers as well. This project could be incorporated into a ton of other clubs, especially those who have service trips to third world countries or work in metal shop. That way we could test out designs on the people who would benefit the most out of this.

Blog 3: RoboHand

Exploring specific uses for additive manufacturing. Check out this story”

Creation of the design

This project was a collaboration between two people across the world from each other. Richard Van As, a South Africa native, lost four of his fingers in an accident, which provided him with some motivation to create this device. After he saw a YouTube video of the mechanics behind making a prosthetic hand, he contacted Ivan Owen of the United States in order to come up with their own robotic hand design for a young boy who was born without a hand.

Where to find it

With the design being open sourced, it is extremely easy to copy the work of Richard Van As & Ivan Owen. Follow this link to the Thingiverse webpage to learn everything you need to carry out the project.

Read more on this

Blog 4: Reviewing Blog 2

I enjoyed reading this blog entry because it was so different from my own. I was so positive about what the project could do in the future that I forgot to analyze the feasibility of it all. Chai does an excellent job of brining those issues to light.

Nam seemed to share the same enthusiasm that I initially had for Marcel's project. He took it a little farther than I did by stating a counter opinion against the project saying that the completion of this could severely hurt the businesses that are known to make these machines.

Kevin did a great job in relating this project to the open source of rep rap printing. Although he brought up a valid argument pertaining to the buyout of this sort of thing, I don't think that would be possible especially because Marcel created this from the ground up and has a strong passion for its possibilities.

I enjoyed reading the paragraph that challenges the use of this project. He says that since Marcel is not proficient in the fields that these machines would be used for, he would not be able to develop them efficiently. I would counter this statement by saying that Marcel is not trying to develop perfect machines, rather simple machines that will JUST get the job done in areas that don't have any machines of these types.

Blog 5: RepRap Media Timeline

Topics receiving continued interested

Thingiverse:

2008 November; Thingiverse is launched;

2011 September 20; Article on the Make blog about a working AR-15 magazine on thingiverse.

2013 January 24; RoboHand is uploaded to Thingiverse.

2013 November 11; Smartrap [201] Summary: Brook Drumm released his design of a reprap based off of the printrbot sample on thingiverse.

Thingiverse is obviously receiving continued interest since it is the first website to ever offer open source codes for rep rap printers. The progression shown in the media timeline is a great way to understand where this has all gone since 2008.

3D printing crime and security

2006 January 12th; 'Printcrime' a short story about RepRap by Cory Doctorow.

2012 July 16; 3D printed keys used to hack high security handcuffs.

2013 April 26; 3D-Printed Guns Can't Be Stopped.

2013 November 7; World's first 3D printed metal gun

3D scanner:

2012 July 17; 3D Printers In The Library; Toward a FabLab in the Academic Library. Summary: The DeLaMare Science & Engineering Library at the University of Nevada, Reno has added two 3D printers, a 3D scanner, and supporting software available for general use to the school community.

2012 November 12; 3D-Printing Photo Booth Makes You Into an Action Figure. Summary: A photo booth in Japan will scan your body and create a figurine of you. It can be a maximum of 8 inches tall and doesn't have the precision yet to pick up on shiny jewelry, earrings, mesh items, or glasses. Customers must pose for about 15 minutes for the machine to collect their body data.

2013 April 26; 3D Scanners Reproduce Real Life.

2013 September 4;All-in-one 3D printer-and-scanners.

2013 December 8; Scientists develop new app to turn mobile phones into 3D scanners

Topics that have slowed/stopped

2012 September 21; 3D Print Wood with Laywood Filament

This is the only post pertaining to this type of printing. I can see why because this does not seem like a good idea at all. Wood isn't man made like the other substances used in printing so this "project" seems a bit useless.

2011 August 25th; Chipotle and Artem use Stratasys Dimension 3D printer for stop motion animation commercial.

This event seems pointless to the progression of 3D printing and is not again mentioned in the timeline.

An influential event

2008 February 9; The Darwin printer is able to print more than half of its own parts, thus self-replication is successful

This is a hugely influential event through the years of 3D printing. To be able to make your own parts really gives this type of printing the opportunity to expand everywhere and anywhere. Self-replication will allow printers to be made in third world countries and provide easy answers to their problems. This probably led to Thingiverse being created as well.

A not so influential event

2010 April 30 'The disruptive future of printing' an article by Bill Thompson of the BBC about RepRap and its future.

By the title of the article, it does not seem that Bill Thompson had anything good to say about the new found world of 3D printing. Obviously, bad media attention will always set back any type of movement.

Something I found interesting

"(unknown date) Artist uses solar powered 3D printer to make glass objects found here The machine focuses the sun into a dot that is so hot it sinters the sand layer by layer into objects like bowls.

Blog 6: Our Next Step to Improve

I used the final entry in my last blog "Something I found that interests me" to lead me in the right direction for our next step to improve.

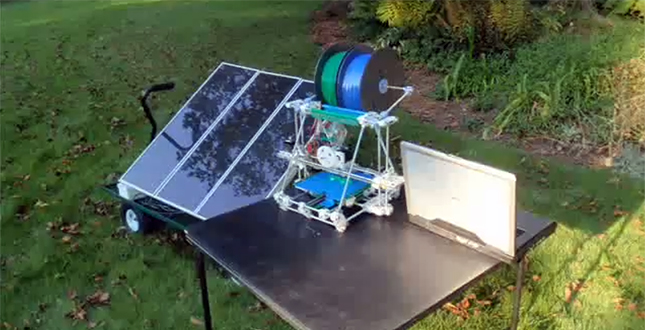

The whole purpose of 3D printing is to advance the world of manufacturing into the technology of the 21st century. The harnessing of our galaxy's most efficient energy source, which is free and available to everyone, could very well turn the tides for societies that have not had the opportunities to grow with the rest of the world. With that in mind, I decided to research what progress engineers have made in this field. Check out this VIDEO to see the latest designs and ideas for changing how things are produced in every corner of the globe.

With this in mind, I am planning on putting together a solar powered RepRap printer in our classroom. We have a solar panel that could replace the electricity we use when we plug in the printer to a wall socket. I think it would be a great change of scene for us to experiment with printing something outdoors. I do not have all of the necessary information yet, but this blog will be updated with each progression I make.

Blog 7: Two 3D Printing Articles

1. 3D printing could offer developing world savings on replica lab kit

"The Positive"

With the right development, this could revolutionize the medical world through cost and efficiency. The production of drugs and medical research dropping significantly in price would result in lower prices for said drugs. General health would be easier to attain and experiments would happen more frequently. When I think of this topic, my mind sets on the cure for cancer. Today, the price for a patient to undergo treatments that will only give them a chance to live is through the roof. If the production of these drugs significantly dropped, there would be a better chance to cure more people and use trial & error to find a more reliable process.

"The Negative"

The problem I have with all of these 'revolutionary advances' that additive manufacturing can lead to is the fact that the world that we live in is not ready for them. We are obsessed with property rights and the financial advancement of oneself instead of trying to proceed as a global whole. As long as this is the general frame of mind, 3D printing, among other things, will not allow us to develop as a society. For now, we have to rely on a few smart and generous people to create their own designs and open them to the public.

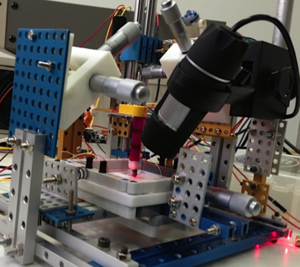

2. How to build a low-cost AFM nanoscope out of LEGO + Arduino board

First of all, the article title is misleading. There is no set of instructions on "how to build a low cost nanoscope" anywhere in the article. Besides that, I basically have the same response that I did for the first article. It is realistic to believe that this could be reproduced through a set of instructions and open source printing, but once again, it will all depend on how willing the participants would be to give up their award winning design for the sake of human advancement. The use of legos is a great idea because they are universal 'toys' found everywhere and they are more solid in creating a fundamental design than just 3D printed objects.

The original project event webpage can be found here.

Blog 8: Intellectual Property Rights

Definitions

Patents protect people's inventions from being produced commercially by company's without the consent of the inventor.

Trademarks protect the aspects of products that would be used to identify said product. They also protect names, logos, colors, smells, and other aspects of that sort.

A trade secret is a technique that is used in confidentiality by a company so that no other company can use their manufacturing process.

Copyright is basically the overall "law" that combines the previous two concepts. It is intellectual property that gives the creator of a work, rights to its use and distribution to receive compensation for their work.

Analyzation of this article

The fives I’s: Infringement Identification Impractical Impossible Irrelevant

These represent the future (and demise) of intellectual property rights. With everyone having their own 3D manufacturer at home, the possibility of holding on to the conventions of property rights seems impossible.

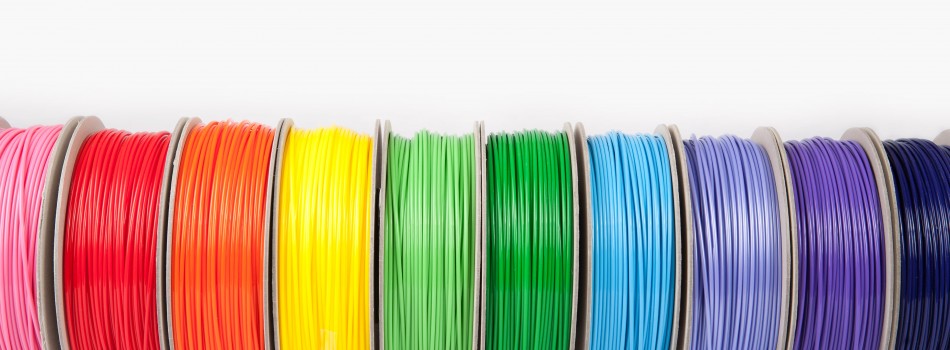

Blog 9: Exploring Filament Types

Buyer's Guide

-Follow to this page for a list of printer companies matched with the diameter of the filament, material characteristics, color differences, prices, and other aspects

ABS vs. PLA -Use this link to understand the importance of a high quality filament and a more in depth look at the differences between ABS and PLA

Filament Suppliers -Here is a link to another RepRap Wiki page, which has a complete list of companies that sell 3D printer filament, the average cost each company offers, country of origin, and a few reviews of the product

Going through these web pages it is clear that there is not one almighty company or type of filament. Each filament has their own chemical characteristics, colors, and prices that would work for different situations. More importantly than choosing "the best" filament, you need to recognize what type of item you are printing and under what conditions. For example, when using a dual extrusion printer it would be beneficial to use polyvinyl alcohol (PVA) as the filament for the support structure because it dissolves away when placed in water.

Blog 10: Exploring Extruder Types

The first interesting thing that I came about when researching the functionality of different extruders is a new project developed by Luminar Products where the new extruder would be able to print filament ranging in diameter between 1.75mm to 4.75mm and use different filament materials. Read more about it here

There are five main types of extruders:

- Makerbot StepStruder - the part that pushes the filament into the feed gear wears easily

- best for 1.75mm filament - interchangeable nozzles

- Makergear Stepper Plastruder - additional torque to feed in filament

- needs a larger frame - complicated nichrome replacement

- Modified Wades Extruder with Arcol Hot End - great for high-melting-point plastics (aluminum)

-nozzle is not interchangeable

- Reifsnyder Precision Works J Head - long lasting (solid metal head)

- nozzle is not interchangeable

- Lulzbot Budaschnozzle 1.3 - interchangable nozzle

- solid metal head - great for high-melting-point plastics (including wood infused)

Blog 11: Reviewing Show & Tell Presentations

I did not know much about additive manufacturing before I enrolled in this class so everything that I know about these machines has came from researching for these blogs and show & tell presentations. What I found the most interesting came from the presentations about printing from a picture application on your phone and the possibilities of 3D printing in the medical field.

One of my classmates gave a presentation about a phone application called 123D Catch that allows you to print a 3D model of anything you take multiple pictures of. You are supposed to take as many pictures as possible in as many angles/positions as possible of the object you want to print. The app does not work perfectly yet but you can only imagine the future of that software.

Another one of my classmates gave a presentation about the potential of 3D printing in the world of biomedics. He talked about the possibility of machines "building" tissues, muscles, and more. I couldn't find his presentation but here are a few links to relevant pages.

Personal Blog (Bonus Blog) Osteoid Cast

Re-Imagining the Cast

A recent development in the use of low intensity impulsed ultrasound to heal broken or fractured bones has sparked the interest of the additive manufacturing world. According to Deniz Karahasin, pressing small ultrasound probes to the area of the break on the skin will significantly reduce the time it takes to heal, in some cases up to 40%. This is a giant break through in the medical world, although there are limitations that present ways of healing a broken bone create. The bulky plaster cast design has been around for 200 YEARS! How have we, as a constantly developing society, never changed the way we heal bones? Well now there is a chance for our generation to make that happen. The ultrasound probe discovery interested New Zealand native, Jake Evill. He developed a design and code to print two halves of a cast that would snap together. The cast (seen to the right) has holes in it to allow the ultrasound probes to reach the skin. In addition to that, Evill's design offers a lighter, breathable, and more environmentally friendly alternative to the plaster cast design we have used for hundreds of years. How long will it take for doctors across the globe to adopt this method?

Links to a few articles

Blog 12: Review of Blog 5

Tony Armlin

Tony felt like the most important moment in the timeline was when student's were granted the ability to use 3D printers for their classes. He references a time when he built a vacuum made from 3D parts for a class. I believe that he took this as more of a promising important moment than an important developmental moment (like I did). I enjoyed reading what he found interesting as well. He explained the possibilities with printers being able to make circuit boards.

Todd Troutman

Todd points out that the most influential moment was the launching of Thingiverse. I wrote about this as well when I was summarizing the most talked about topics on the timeline. I felt that this event was just as important as the one I posted (printers being able to print half of their own parts). I loved how Todd pointed out the complete uselessness of one article that tried to persuade people to print hermit crab shells. He also seemed interested in 3D printers making instruments. I have to disagree with this one mainly because making instruments in an art form, and although machines make them now, I still feel we should stay close to the original development.

Yuan Chai

Chai had the same kind of idea that I did when I was thinking about the most influential event in the timeline of additive manufacturing when he wrote about the Mendel printer "self replicating" itself. He also shared the same opinion with me about 3D printing wood. It doesn't seem like a good idea to print with a "filament" that isn't originally man made.

Lee Schwartz

Lee took the easy influential event and said that Chuck Hull's invention of the 3D printer in the 80's was the most important. This is pretty obviously the most influential event since everything else follows this, but I took the whole "influential event" thing differently. Lee put a twist on a non influential event and found something that could hinder people's understanding of the whole additive manufacturing concept. A CNN article had the title "The Machine that can Print Anything" and Lee (as well as myself) believed that it would be giving people false hope.

Dongao Yang

Dongao had the same idea that I did when it came to the most influential event in the 3D printing timeline. He stated that Adrian Bowyer's publication of the idea for a self replicating 3D printer was the real beginning of the 3D printing we know today. I didn't like how pessimistic he was about an article pertaining to titanium printing. Yes, metal printing has a long way to go, but that doesn't mean that small steps along the way are not important.

Jessica Mewkalo

Jessica took a different route than most people's blogs that I've read. She found something interesting, something important, and something not so important all in the same field of 3D printing (Medical). Like Todd, she found the article about printing hermit crab shells pretty useless. Jess also wrote highly on the ideas of printing cartilage and bio-engineering human ears.

Eva Vivu

Eva shared the same thoughts that I did on printers being able to self replicate. We both found this to be the most influential event that has lead us to where we are today. Eva also shared another particular interest of mine, printing food. Although I did not mention this in my Blog 5, but I really see this as being the distant future of food processing.

Brian Prentice

Brian's assessment of the timeline resembled Todd's in that they both believed launching Thingiverse was the most influential event in the world of 3D printing today. He also mentioned something about how uninteresting the article about being able to 3D print your unborn child from scanning. I didn't see that when I initially went through the Rep Rap Timeline, but I think this could quite possibly the creepiest thing I have ever seen. Who would ever want a 3D print of an unborn child?

Drew Golterman

Drew took the same stance that Lee did, in that he believed that the most influential moment in the history of 3D printing was the origination by Chuck Hull. He also mentioned that the most influential public event in the timeline had to be the ability to access open source codes for Rep Rap printers (just as Todd had pointed out). Drew thought that any events that had to do with printers manufacturing food (chocolate) was irrelevant, which is in opposition to the ideas that Eva and myself shared. As I said before, I believe even the smallest step in the right direction can prove important.

Blog 13: Review of Blog 7

Yuan Chai

Chai shared the same concerns that I did, as many other people probably did as well. It was good to read that someone who is from a country halfway across the globe still has the same pessimistic views of intellectual property rights hindering the development of 3D printing and technology as a whole. Chai also agreed that using legos as an alternate form of building a printer would be a good idea, but he didn't mention (as I did) how universally used these are and how easily they would be acquired.

Lee Schwartz

Lee shared the same enthusiasm as myself when it came to the possibilities that this could bring to the developing world. His review was extremely positive, even when addressing how big businesses would react to this sort of thing. Besides mentioning that a little competition could be a good thing, Lee also pounded on the possibilities of price drops in the industrial world, as well as in an educational setting.

Tony Armlin

One unique thing about Tony's blog that I didn't see in many other people's was his statement on the quality of the product vs. the price value. We all know that we subconsciously choose more expensive products because we think that the extra money will result in a higher quality product. How will 3D printer projects be looked at when the price is a 1/4 of what each of their competitors are offering? Tony also had a skeptical view of the whole LEGO printer that I did not share

Todd Troutman

Todd related what was being stated in the article to what we are doing in EDSGN 497J in that we are producing parts for our printers that are significantly less in price than what they would be if we simply bought them from a supplier. He did not offer much else along the lines of a personal analysis of both articles other than saying that both articles were related since they were talking about reducing the price of products.

Tom Vasa

I liked Tom's assessment of the LEGO article. He brought up the point that the significant drop in prices of high end scientific devices would not only benefit developing countries, but would also benefit students at a younger age, say high school. Could you imagine the possibilities of high school education that had access to "tools" that only scientists could use before? Tom also shared the same enthusiasm that I did for the ideas put forth in the first article.

Hao Yuan

Hao had a more pessimistic view of the scientific tool kit. He said that it is illogical for us to develop this any further since the precision needed to create scientific devices would not be met by the 3D printers that are on the "market" today. While I agree with this statement for the time being, I don't understand why one would be so negative. We need things like this to push our creativity and force us to build more accurate and precise machines. The future may unpredictable, but I don't think that it is too much to say that home-based printers will soon have the dynamics to make this possible.

Jarred Glickstein

Jarred agreed with basically what I wrote in the last few sentences of my assessment of Hao's blog. He thinks that it is a worthwhile venture, even though the technology existing at this time will not permit it. He also disagrees with myself and plenty other students that the LEGO nanoscope is actually printable. He shared Hao's pessimism about the precision of 3D printers creating highly detailed scientific devices.

Yuchao Yuan

Yuan's blog forcuses on the possible errors in the medical devices due to imperfections made by the printers such as Hao had said. He did not seem too concerned with this fact though because he knows that the operators of the these printers would know the limitations of them and would print anything that would be considered out of its comfort zone.

Carson Geib

I liked the fact that Carson brought up the possibilities of these 3D printed medical devices helping those who need assistance faster than it would take them to get to the closest hospital. This process could help those people print things from the comfort of their own home. He also mentioned another point that I did not think of, the job market. Although this may seem like it would take away jobs, it could also produce jobs that we didn't even know could exist.

Blog 14: Review of Blog 8

Tony Armlin=

Tony has not yet done Blog 8

Todd Troutman

In Todd's Blog 8, he states, "I think there is still a place for Copyrights, Trademarks, Patents and Trade secrets but the items that fall under their protection will change. Some ideas will now be too common to be patentable." I completely agree.

Yuan Chai

Chai explains that he thinks that 3D printing will probably not effect patent laws in that significant of a matter because he doesn't feel like it would be possible to print a branded product. He explains that branded products are in most cases full of experimental parts and have a factor of safety built into their construction. 3D printing the same parts may not hold the same safety factor and could be dangerous in some circumstances. Looking at product development from an engineering stand point, I agree with Chai. 3D printed objects are in essence made by amateurs and there could be an inherent risk involved depending on what is printed and for what application the object will be used.

Jessica Mewkalo

Jessica states in her Blog 8 that, in the future, patent laws will become obsolete due to 3D printing. She does also state however that with the ability to 3D print any objects without patent laws being enforced, counterfeiting will become a more rampant problem and this could effect efficiency and safety of parts.

Nate Myer

Nate brings up an interesting point about companies restricting their employees use of open source. I definitely agree that some companies may be irritated if their workers are contributing to this. Especially because most companies have employees sign agreements saying anything they invent during their employment is property of the company. This would defeat the no IP on open source.

Zac Cameron

Zac says that it will take a lot for the government to get rid of IP rights. Once companies' ideas or products start getting reproduced, there will be a big blowout and big companies have the money to get their way. I see where he is coming from but he is not looking at this from a future prospective. There's no way these rights will survive once printing becomes second nature.