Category:FoldaRap Development

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Contents

- 1 R&D

- 2 Versions

- 2.1 FoldaRap 2.2

- 2.2 FoldaRap 2

- 2.3 FoldaRap 1.1

- 2.4 FoldaRap 1.0

- 2.4.1 Use plastic tubing for Z-coupling : adopted

- 2.4.2 Replace the M6 Z-threaded rods by M5 : adopted

- 2.4.3 Replace the steel stubs by aluminium plain rods : working

- 2.4.4 Motor cooling

- 2.4.5 Print Cooling : working

- 2.4.6 Replace the 6.8 ohm resistor (=20W@12v) : working

- 2.4.7 Adding two LED stripes

- 2.4.8 Autonomous printing

R&D

Some other ideas I wanted to try, or may try some days :

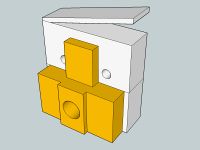

Dual hotend

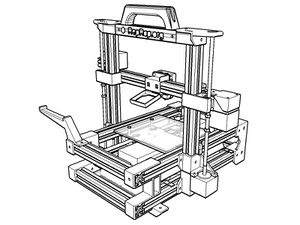

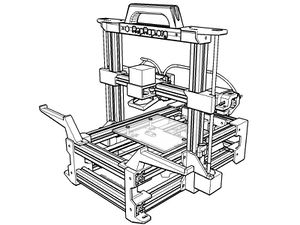

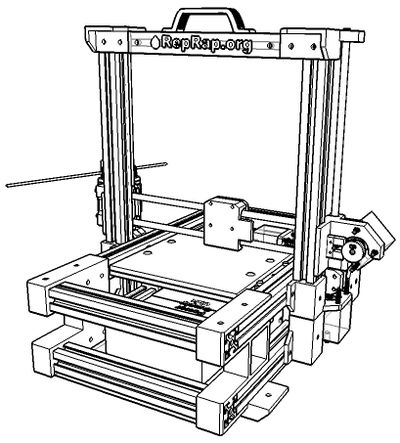

FoldaRap 4 (planned)

- belt driven Z-axis ?

- single z-motor ?

FoldaRap 3 (planned)

- Y-gliders on the base frame ! (as tried a little before)

- 2 RP parts in addition

- remove the last 2 smooth rods and 3 lm6uu

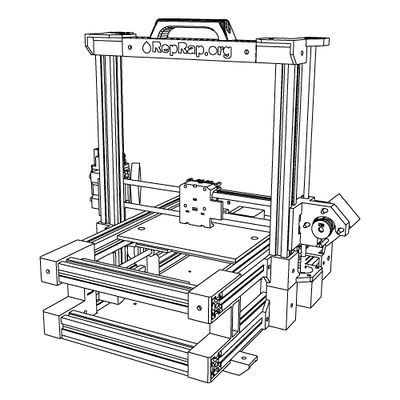

Versions

FoldaRap 2.2

- integrated endstop holder for X, Y, Z

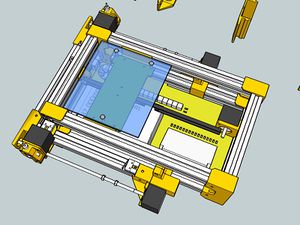

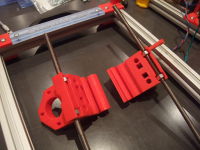

FoldaRap 2

- major changes

- X-axis use a PLA glider x-carriage (new x-carriage, x-ends, z-top, z-motor more rigid)

- remove 2 smooth rods and 3 lm6uu

- minor changes

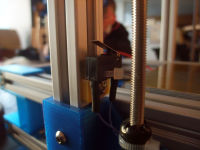

- threaded rods Z axis are now in the same plane than the Z gliders

- endstop holder for t-slot = glue gun no longer needed for the Z stop

- stronger hinges and z-motor-holder

- save few vitamins

Vitamins :

5 m4x8 / x-belt-clamp (2), z-slider (2), z-endstop-holder (1) 5 m4 Tnut / x-belt-clamp (2), z-slider (2), z-endstop-holder (1)

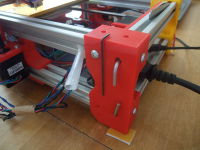

Endstop holder

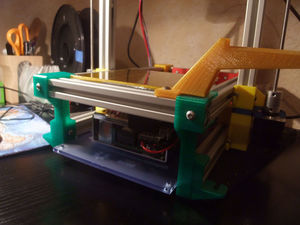

FoldaRap 1.1

- major changes

- y-carriage is now lasercutted instead of printed (stop loosing the linear bearing, perfect distance, but no more nut trap)

- extruder motor is now fixed to nema14 while a PG35L was used before

- minor change

- printed parts have been simplified (removed the arrow shape that was hard to print with good tolerance to fit the extrusion channel, also more universal now), and reduced in volume (3mm general thickness, was 4mm)

- and a lot of little things [1]

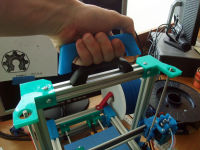

Printed Handle

Something I was reluctant to adopt since many handles for Ultimaker led to bad things, but after several request here is one ! Larger than the KJN injected handle (more comfort) and seems quite sturdy. It is derived from the FreeDeePee handle.

Store basic tools in the frame

Would be convenient

FoldaRap 1.0

Little things tried along the way :

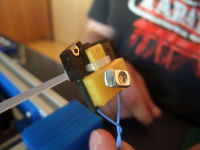

Use plastic tubing for Z-coupling : adopted

http://forums.reprap.org/read.php?283,151801,151837

Pro : cheap, 2 printed part in less, also 8 m3x20, 8 m3 washer and 8 m3 nut in less... interesting !

Cons : 2 more non-printed-part (you are still free to choose what you prefer)

Replace the M6 Z-threaded rods by M5 : adopted

With the above flexible coupling you can choose M5 or M6 with the same coupling.

Pros : use the same M5 nuts as on the pneumatic fittings (less different parts), finer z-step-mm, also easier to put in the tubing (-> maybe less grip on it).

Cons : M6 = faster z-speed (maybe less blobs at layer change ?)

Replace the steel stubs by aluminium plain rods : working

Cons : more prone to bend (but at 300mm and with our light loads...), need bushings

Pros : cheaper, lighter, easier to source, easier to cut, bushings makes less noise than lm6uu

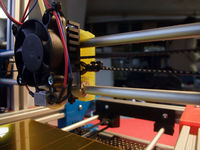

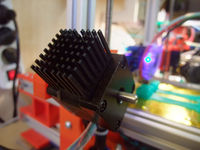

Motor cooling

Add 30mm heatsinks :)

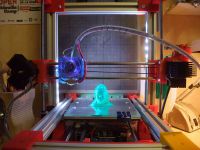

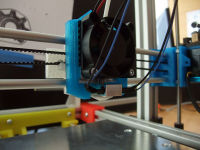

Print Cooling : working

Active cooling with a bowden tube pointing on the x-carriage and the print (e.g.: CDrom-motor-pump + cooling nozzle

Active cooling with a bowden tube pointing on the x-carriage and the print (e.g.: CDrom-motor-pump + cooling nozzle

- Pros : very compact and very precise cooling, just another tube using the second head slot in a modified reprappro hotend

- Cons : maybe easier to put a fan on the x-carriage

- Have a look at this solution by Okatake : thing47573

I finally implemented a passive cooling : thing52240

I finally implemented a passive cooling : thing52240 maybe a simpler solution for an active cooling thing84345

maybe a simpler solution for an active cooling thing84345

Replace the 6.8 ohm resistor (=20W@12v) : working

By one with a lower ohm (e.g 3 ohm) or even a cartridge heater (12v-40w)

Pro: faster heat-up, allow higher temp (for abs)

Cons: more power consumption

(video using a 03mm nozzle)

(video using a 03mm nozzle)

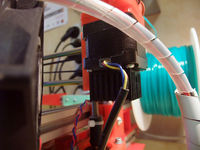

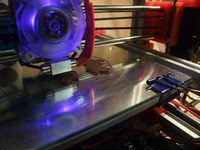

Adding two LED stripes

Good for taking pictures or to print at a party

Autonomous printing

- Battery powered

Pages in category "FoldaRap Development"

The following 7 pages are in this category, out of 7 total.