Gen7 Endstop 1.3.1

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Release status: working

| Description | General purpose optical endstop.

|

| License | GPL v2

|

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | |

| CAD Models | |

| External Link |

This is an optical endstop compatible with RAMPS, Sanguinololu, Generation 7 Electronics and any other controller running on 5 V or 3.3 V. Simple, affordable and easy to build.

| |

Gen7 Endstop has moved This page shows Gen7 Endstop up to year 2015. Documentation has moved since then to RepRap DIY. |

Contents

How to get it

PCBs

Get Gen7 Endstop PCBs from RepRap DIY (Traumflug's outlet).

If you want to make them yourself you can find production files in the release documents folder of the Github repository and manufacturing instructions on the Gen7 main page.

Electronic components

Get Gen7 Endstop Parts Kits from RepRap DIY (Traumflug's outlet).

Assembled Boards

Parts List

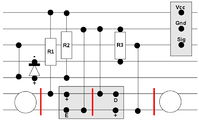

| Name | Count | Designations | Remarks |

|---|---|---|---|

| Resistor 180 Ohms | 1 | R1 | |

| Resistor 1 kOhms | 1 | R2 | |

| Resistor 2.2 kOhms | 1 | R3 | |

| LED 3 mm Red | 1 | LED1 | |

| Photointerrupter TCST1103 | 1 | U1 | This one is without mounting flange. |

| Alternative Photointerrupter TCST2103 | 1 | U1 | This one has a mounting flange which might help mounting. |

| Molex KK100 3 Pin Header | 1 | CONN1 | Reichelt are tested to be fully compatible with Molex |

| Cable Connector for the above | 1 | ||

| Crimp Contact for the above | 3 |

Assembly Instructions

- You'll need a soldering toolkit to do most of this.

- Read our Electronics Fabrication Guide if you're new.

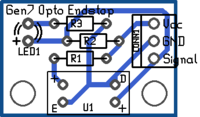

- To find out which components to put where, have the layout on your PC screen available.

- PCBs fabricated with Voronoi paths need more heat, so raise your soldering iron's temperature by about 20 deg Celsius.

- Start with the flattest parts, usually wire bridges or resistors. This way, components won't fall out when you lay the PCB on it's front for soldering. Then continue with parts of raising height, connectors are usually among the last ones.

- To ease soldering jumper headers and similar components, put a small drop of cyanacrylate glue onto the component side before inserting them. As the PCB is single-sided, this won't hurt the solder point.

- Take care to not overheat the photo sensor. Solder one pin on each side then pause for a minute before continuing.

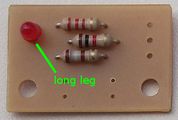

- As LEDs have to be inserted the right way they have legs of different length to indicate polarity. The longer leg (+) goes into the hole closer to the photo sensor and the shorter one (-) into the hole closer to the border.

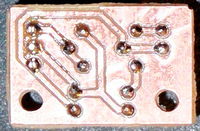

Assembly in Pictures

Click on the pictures to view them bigger.

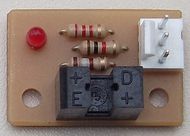

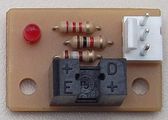

Now we're done, these pictures show the work of StevBrennan:

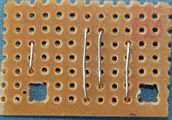

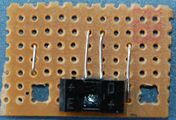

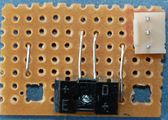

Assembly on Veroboard in Pictures

If you don't want to etch or buy an endstop board, here is a veroboard version.

Click on the pictures to view them bigger.

Setup

TBD

Testing

A first test would be to connect Vcc and GND, only.

- With the light barrier open, LED should stay dark, putting (opaque) cardboard into it should light the LED up.

- Low signal (light barrier open) on the signal pin should be around 0.3 V, well below 1.0 V, when operated on 3.3 V.

- High signal (light barrier interrupted) should be around 2.8 V, well above 2.3 V, when connected to 3.3 V.

With everything wired correctly, it should run through the general endstop test just fine.